多源低活性混凝土废浆再生利用的研究进展

2021-09-10高英力段开瑞何倍曾维徐艺珅卜涛龙国鑫

高英力 段开瑞 何倍 曾维 徐艺珅 卜涛 龙国鑫

摘 要:混凝土废浆(Concrete Slurry Waste, CSW)是混凝土搅拌站中特有的富含硅酸盐类矿物的未硬化废弃物,因成分复杂、高含水、毒害性、腐蚀性等特点,其再生利用一直受到极大的限制。综述当前对CSW的大宗再生利用的研究成果,包括:再生为水泥混凝土制品用粗、细骨料、填料、胶材(湿法研磨技术)和外掺剂,作为水泥熟料生产用原料,基于碳化技术和冷粘结造粒技术制备新型砼制品和轻型骨料以及与单、双组分碱激发胶材的复合再生应用。指出CSW未来高效再生利用的主要研究方向:CSW低能耗预处理技术与活性激发技术,碳化技术,重金属的长期浸出行为和耐久性研究。

关键词:混凝土废浆;硅酸盐;再生利用;废弃物

Abstract: Concrete slurry waste, CSW is a unique unhardened construction waste which is rich in silicate minerals generated from concrete ready-mixing plant. However, its recycling has always been greatly restricted owing to its complex composition, high water to solidratio, hazardous and corrosion. The large-scale recycling methods of CSW are comprehensively reported and commented in this paper, including recycling as coarse and fine aggregates, fillers, cementitious materials (wet grinding technology), additions in concrete and raw materials for cement clinker production; preparation of new type of concrete products and lightweight aggregates by carbonation and cold bonded pelletizing technique; the development in "one or two"part alkali-activated materials (AAMs).The promising research directions of CSW in the future are pointed out as follows: 1.Pre-treatment regeneration technologyand active excitation technology with low energy consumption;2. Carbonation technology; 3. Long term leaching behavior of heavy metals and durability.

Keywords: concrete slurry waste; silicate; recycling; waste

混凝土作为全球第二大人造消耗材料,年产量超过300亿t,其生产带来的大量CO2排放与废弃物的堆积一直是世界公众所担忧的问题[1-2]。目前,混凝土废弃物再生热点集中于已硬化的“建筑与拆除废弃物(Construction and Demolition Waste,CDW)”[3-4]。研究表明,CDW非常适合作为再生骨料应用于新建建筑物中[5-7],包括道路结构中沥青混合料用骨料、碎石隔离层以及沟槽的回填等[8-10]。然而,对于混凝土搅拌站中的高含水未硬化废弃物,其再生利用进展却相对较缓慢[11-12]。

在实际生产中,混凝土搅拌站得到的废弃物主要有4种:返厂的仍具有工作性的混凝土、再生骨料、再生水和混凝土废浆CSW(Concrete Slurry Waste)[13]。其中,部分返厂的仍具有工作性的混凝土,会被降级用于制备特殊的、具有标准尺寸的水泥混凝土板或用作回填垫层的充填材料[14];再生水可用于清洗搅拌车、堆料场以及拌和新拌混凝土[15-16];而分离得到的再生骨料则和CDW一样,可被收集并应用于新建建造物中[17-18];只有CSW在短暂的存放期后,会被集中运往公共场地进行堆埋。相关数据显示,亚洲国家的混凝土搅拌站平均每生产1 t混凝土,就会产生15~20 kg CSW,仅中国香港一地,每年的CSW产量就超过12万t[19-20]。笔者针对CSW的再生利用研究进行全面综述,并指出其未来高效再生利用的发展方向。

1 CSW的产生过程和理化特性

CSW的产生过程如图1所示,返厂混凝土经过鼓式再生设备或转筛式再生设备与压力水的冲洗,被分为再生骨料和废水与砂浆的混合物,经过标准沉淀池过滤后,得到CSW(pH=10.5~12.5)[18]。CSW主要由细骨料(少部分粗骨料)、水泥水化产物(包括碳化产物)、废水和少部分矿物掺合料(如粉煤灰)组成[21]。由表1中XRF的测试结果可以看出,CSW的化学组成和水泥十分相似,但CSW中的CaO含量明显少于水泥,而Al2O3含量高于水泥,这意味着CSW中含有较多硅铝酸盐矿物。

2 基于水泥混凝土体系的再生应用研究

2.1 取代骨料和填料

Audo[24]的研究结果表明,CSW中的砷(0.54 mg/kg)和铬(0.51~0.64 mg/kg)等重金属元素的浸出浓度时常会超过临界标准(根据欧洲官方标准,CSW中砷和铬的浸出浓度应小于0.50 mg/kg)。但将CSW应用于水泥混凝土中,可以有效固封住重金屬元素,从而防止CSW规模化处置带来的重金属污染。由于长时间在沉淀池中存储,CSW内部所含有的仍具有水化活性的颗粒较少,因此,将其用于替代水泥混凝土制品中的粗、细骨料和填料十分合适[25–28]。当CSW用于替代骨料时,首先需经过干燥、研磨、破碎和过筛等预处理,部分搅拌站还需经过压滤脱水。其中,CSW压滤脱水后形成的泥饼(含水率75%~113%)可以在几天之内迅速硬化,而后被破碎得到再生骨料[14]。目前,CSW替代骨料存在预处理能耗、人工机械成本较高,骨料品质较低等一系列问题,多被建议用于非结构性混凝土制品[21, 29-31]。

2.2 作為胶材和外掺剂

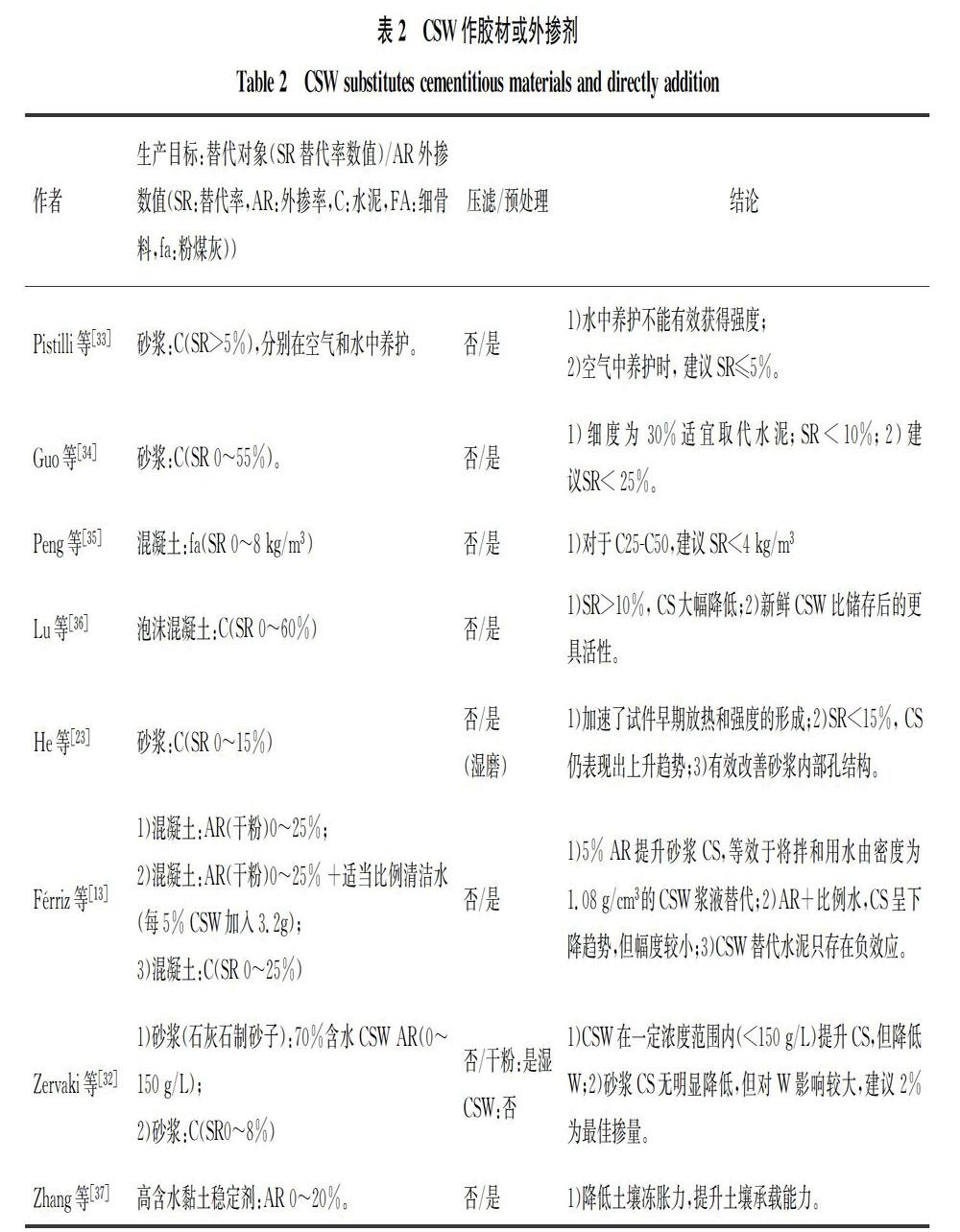

与替代骨料相比,在不过多影响流动度和试件强度的前提下,CSW作为胶凝材料的取代率仅维持在个位数水平。表2总结了CSW作为胶凝材料的部分研究成果。值得注意的是,湿法研磨技术的使用较大幅度地提升了CSW替代水泥的比例(15%),相比于传统的预处理技术,该技术对CSW的活性激发效率更高且能耗和成本更低[23]。除常规取代骨料和胶材外,部分研究人员还将CSW视为一种“外掺剂”,以干粉或原状高含水状态的形式小剂量掺入到水泥混凝土制品中,用以提升试件的抗压强度[13,32]。这种在“零预处理”前提下,将含水废浆与拌和用水混合并直接掺入制品的再生方式值得借鉴,但由于其可掺浓度较低(<150 g/L),该再生方式下CSW的利用效率是一个亟待解决的问题。

2.3 碳化与冷粘结造粒技术

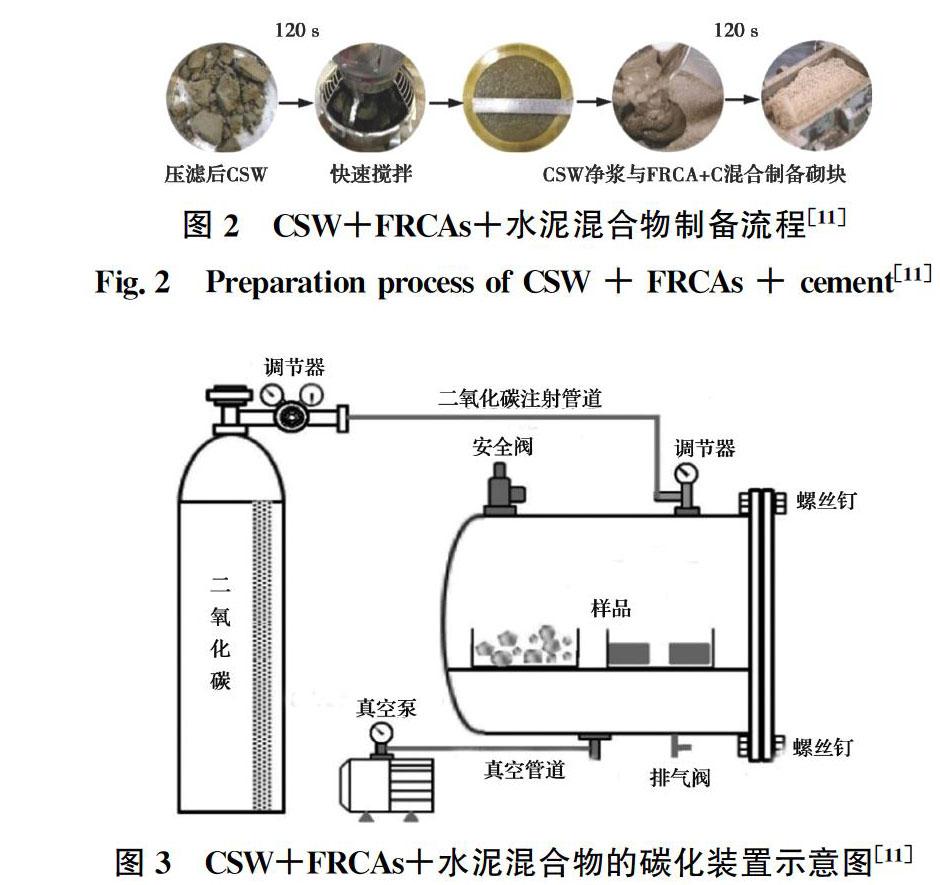

碳化技术可实现“固废”和“气废”的耦合利用,是一项区别于传统CSW再生方式的新技术[38]。Xuan等[22]研究了新鲜CSW对CO2的固存潜力,并将CSW与再生混凝土细集料(FRCAs)进行复配。结果表明,CSW、FRCAs及其混合物在矿物碳化作用下可以在数小时内快速获得强度并伴随着较低的干缩率。在此研究基础上,研究人员利用3 h加速碳化的方法制备了一种新型混凝土制品[11]:以质量比CSW∶FRCA∶水泥=1∶4∶0.15,用30 MPa

的静压力预压实,24 h后脱模,放进碳化设备加速碳化。试件制备流程如图2、图3所示。结果表明,在3 h加速碳化作用下,CSW混合物可获得28 d强度的81%,但强度受CSW的水固比影响较大。Hossain等[39]利用生命周期评价技术(LCA)评价了碳化技术对于CSW的可持续发展性。结果表明,碳化CSW生产砌块相比于普通原材料可实现能源减排59%、温室气体减排66%。此外,运用冷粘结造粒技术,将新鲜CSW与城市焚烧底灰复合,并结合CO2养护技术,可制备出轻型骨料。该技术不仅能实现CSW、

市政废弃物与气体废弃物的综合利用,还为水泥混凝土制品提供了额外的骨料来源,大大减轻了由于天然石料开采造成的资源紧缺压力[40-42]。

2.4 生产水泥熟料

Schoon等[43-44]评价了CSW是否有作为水泥熟料生产原料的可能性。结果表明,由于从不同搅拌站取出的CSW化学成分差异过大,导致了CSW并不能成为稳定可靠的水泥熟料生产原料,且CSW的细颗粒除能提升原料在烧结时的可燃性外,并不能够有效提升熟料中的有效化学成分。并指出了利用再生材料和工业副产品生产水泥原料时需要注意的要点。

3 基于单、双组分碱激发胶材(AAMs)的再生应用研究 除水泥混凝土体系外,以工业废弃物为原料的AAMs胶凝体系在CSW的再生利用中却极少受到关注。Yang等[45]曾利用CSW与偏高岭土、硅灰混合,以氢氧化钠和硅酸钠作为碱激发剂,制备了传统的“双组分”AAMs。试验结果表明,CSW作为激发原料,自身的碱激发活性较低,基体强度主要由偏高岭土等高活性硅铝质材料提供。考虑到双组分碱激发胶凝材料需预先配置具有腐蚀性和一定黏度的碱激发溶液,且CSW也具有较高的碱性,实际制备时,不论CSW以干粉或含水状态掺加,其实际可操作性、制备流程的便利性和安全性均有待考量,如图4所示[46-48]。为简化CSW与AAMs复合材料的制备流程,避免操作性和安全性问题,提出单组分AAMs与原状高含水CSW复合材料的制备思路。单组分AAMs,即,“不需提前配制碱性溶液,直接将碱颗粒与硅铝质废弃物混合,通过加水触发化学反应”[46, 49-51]。如图5所示,CSW中的废水可用于提供流动性和液体反应环境,而其内部含有的固体废弃物颗粒可被视作单组分AAMs中的骨料或填料。

4 结论与展望

1)CSW作骨料时,应注重提升骨料的品质,采取各种措施降低骨料孔隙率、移除或增强粘附在骨料上的老砂浆。

2)CSW作胶材的取代率较低,应结合包括湿法研磨等低能耗活性激发技术和分离技术(分离CSW中的惰性SiO2),从而提升CSW作为胶材的反应活性。

3)碳化技术在CSW的再生利用中极具前景,但所生产制品的环境稳定性和重金属离子的长期浸出行为还有待进一步研究。

4)应注重实现CSW与各种硅铝质废弃物的综合利用,积极开展CSW在碱激发胶凝材料体系中的再生利用研究。

参考文献:

[1] PETEK GURSEL A, MASANET E, HORVATH A, et al. Life-cycle inventory analysis of concrete production: a critical review [J]. Cement and Concrete Composites, 2014, 51: 38-48.

[2] KAZAZ A, ULUBEYLI S. Current methods for the utilization of the fresh concrete waste returned to batching plants [J]. Procedia Engineering, 2016, 161: 42-46.

[3] SHI C J, LI Y K, ZHANG J K, et al. Performance enhancement of recycled concrete aggregate - A review [J]. Journal of Cleaner Production, 2016, 112: 466-472.

[4] PARANHOS R S, CAZACLIU B G, SAMPAIO C H, et al. A sorting method to value recycled concrete [J]. Journal of Cleaner Production, 2016, 112: 2249-2258.

[5] 鮑玖文, 李树国, 张鹏, 等. 轴压重复荷载作用后再生混凝土毛细吸水性能[J]. 建筑材料学报, 2021, 24(1): 71-76.

BAO J W, LI S G, ZHANG P, et al. Water absorption of recycled aggregate concrete after repeated axialcompressive loading [J]. Journal of Building Materials, 2021, 24(1): 71-76. (in Chinese)

[6] 鲍玖文,李树国, 张鹏,等. 再生粗骨料硅烷浸渍处理对混凝土介质传输性能的影响[J]. 复合材料学报, 2020, 37(10): 2602-26.

BAO J W, LI S G, ZHANG P, et al. Effect of recycled coarse aggregate after strengthening by silane impregnation on mass transport of concrete [J]. Acta Materiae Compositae Sinica, 2020, 37(10): 2602-26. (in Chinese)

[7] 王绎景, 李珠, 秦渊, 等. 再生骨料替代率对混凝土抗压强度影响的研究[J]. 混凝土, 2018(12): 27-30, 33.

WANG Y J, LI Z, QIN Y, et al. Effect of replacement rate of recycled coarseaggretrate on compressive strength of concrete [J]. Concrete, 2018(12): 27-30, 33.(in Chinese)

[8] GMEZ-MEIJIDE B, PREZ I, PASANDN A R. Recycled construction and demolition waste in cold asphalt mixtures: Evolutionary properties [J]. Journal of Cleaner Production, 2016, 112: 588-598.

[9] DEL REY I, AYUSO J, GALVIN A P, et al. Feasibility of using unbound mixed recycled aggregates from CDW over expansive clay subgrade in unpaved rural roads [J]. Materials, 2016, 9(11): 931.

[10] OSSA A, GARCA J L, BOTERO E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry [J]. Journal of Cleaner Production, 2016, 135: 379-386.

[11] XUAN D X, ZHAN B J, POON C S, et al. Innovative reuse of concrete slurry waste from ready-mixed concrete plants in construction products [J]. Journal of Hazardous Materials, 2016, 312: 65-72.

[12] SEALEY B J, PHILLIPS P S, HILL G J. Waste management issues for the UK ready-mixed concrete industry [J]. Resources, Conservation and Recycling, 2001, 32(3/4): 321-331.

[13] FRRIZ PAP J A. Recycling of fresh concrete exceeding and wash water in concrete mixing plants [J]. Materiales De Construcción, 2014, 64(313): e004.

[14] XUAN D X, POON C S, ZHENG W. Management and sustainable utilization of processing wastes from ready-mixed concrete plants in construction: A review [J]. Resources, Conservation and Recycling, 2018, 136: 238-247.

[15] ASADOLLAHFARDI G, ASADI M, JAFARI H, et al. Experimental and statistical studies of using wash water from ready-mix concrete trucks and a batching plant in the production of fresh concrete [J]. Construction and Building Materials, 2015, 98: 305-314.

[16] SU N, MIAO B Q, LIU F S. Effect of wash water and underground water on properties of concrete [J]. Cement and Concrete Research, 2002, 32(5): 777-782.

[17] ARUNVIVEK G K, MAHESWARAN G, SENTHIL KUMAR S. Eco-friendly solution to mitigate the toxic effects of hazardous construction industry waste by reusing in concrete for pollution control [J]. Nature Environment and Pollution Technology, 2015, 14(4): 963-966.

[18] VIEIRA L D B P, FIGUEIREDO A D D. Evaluation of concrete recycling system efficiency for ready-mix concrete plants [J]. Waste Management, 2016, 56: 337-351.

[19] IIZUKA A, SAKAI Y K, YAMASAKI A, et al. Bench-scale operation of a concrete sludge recycling plant [J]. Industrial & Engineering Chemistry Research, 2012, 51(17): 6099-6104.

[20] TAM V W Y. Economic comparison of concrete recycling: A case study approach [J]. Resources, Conservation and Recycling, 2008, 52(5): 821-828.

[21] RUGHOOPUTH R, RANA J O, JOORAWON K. Possibility of using fresh concrete waste in concrete for non structural civil engineering works as a waste management strategy [J]. KSCE Journal of Civil Engineering, 2017, 21(1): 94-99.

[22] XUAN D X, ZHAN B J, POON C S, et al. Carbon dioxide sequestration of concrete slurry waste and its valorisation in construction products [J]. Construction and Building Materials, 2016, 113: 664-672.

[23] HE X Y, ZHENG Z Q, MA M Y, et al. New treatment technology: The use of wet-milling concrete slurry waste to substitute cement [J]. Journal of Cleaner Production, 2020, 242: 118347.

[24] AUDO M, MAHIEUX P Y, TURCRY P, et al. Characterization of ready-mixed concrete plants sludge and incorporation into mortars: Origin of pollutants, environmental characterization and impacts on mortars characteristics [J]. Journal of Cleaner Production, 2018, 183: 153-161.

[25] WANG R X, ZHANG Y X. Recycling fresh concrete waste: A review [J]. Structural Concrete, 2018, 19(6)1939-1955

[26] CORREIA S L, SOUZA F L, DIENSTMANN G, et al. Assessment of the recycling potential of fresh concrete waste using a factorial design of experiments [J]. Waste Management, 2009, 29(11): 2886-2891.

[27] MOON H Y, CHOI Y W, SHIN H C. A study on thepractical recycling of ready mixed concrete sludge water to concrete [J]. Geosystem Engineering, 2001, 4(3): 89-93.

[28] AUDO M, MAHIEUX P Y, TURCRY P. Utilization of sludge from ready-mixed concrete plants as a substitute for limestone fillers [J]. Construction and Building Materials, 2016, 112: 790-799.

[29] KOU S C, ZHAN B J, POON C S. Properties of partition wall blocks prepared with fresh concrete wastes [J]. Construction and Building Materials, 2012, 36: 566-571.

[30] KOU S C, ZHAN B J, POON C S. Feasibility study of using recycled fresh concrete waste as coarse aggregates in concrete [J]. Construction and Building Materials, 2012, 28(1): 549-556.

[31] KUSUI T, AMANO N N Y. Study on recycle of concrete sludge produced at concrete mills in Toyama Prefecture [J].Journal of Ecotechnology Research, 2014, 17: 39-43.

[32] ZERVAKI M, LEPTOKARIDIS C, TSIMAS S. Reuse of by-products from ready-mixed concrete plants for the production of cement mortars [J]. Journal of Sustainable Development of Energy, Water and Environment Systems, 2013, 1(2): 152-162.

[33] PISTILLI M F, PETERSON C F, SHAH S P. Properties and possible recycling of solid waste from ready-mix concrete [J]. Cement and Concrete Research, 1975, 5(3): 249-259.

[34] 郭元強, 张兴富, 陈展华, 等. 初探混凝土废浆粉对水泥胶砂性能的影响[J]. 商品混凝土, 2019(4): 34-38.

GUO Y Q, ZHANG X F, CHEN Z H, et al. The effect of concrete waste slurry powder on the performance of cement mortar [J]. Ready-Mixed Concrete, 2019(4): 34-38.(in Chinese)

[35] 彭孟啟, 张桥, 孙国彬. 废浆固渣引入量对混凝土性能的影响[J]. 中国建材科技, 2018, 27(4): 54-57.

PENG M Q, ZHANG Q, SUN G B. Effect of solid waste introduction on concrete performance [J]. China Building Materials Science & Technology, 2018, 27(4): 54-57.(in Chinese)

[36] 卢佳林, 陈景, 甘戈金. 混凝土搅拌站废浆制备泡沫混凝土技术研究[J]. 商品混凝土, 2017(Sup1): 80-82.

LU J L, CHEN J, GAN G J.Study on foamed concrete prepared by waste slurry from concrete mixing plant [J]. Ready-Mixed Concrete, 2017(Sup1): 80-82.(in Chinese)

[37] ZHANG J X, FUJIWARA T. Concrete sludge powder for soil stabilization [J]. Transportation Research Record, 2007, 2026: 54-59.

[38] 黄浩, 王涛, 方梦祥. 二氧化碳矿化养护混凝土技术及新型材料研究进展[J]. 化工进展, 2019, 38(10): 4363-4373.

HUANG H, WANG T, FANG M X. Review on carbon dioxide mineral carbonation curing technology of concrete and novel material development [J]. Chemical Industry and Engineering Progress, 2019, 38(10): 4363-4373.(in Chinese)

[39] HOSSAIN M U, XUAN D X, POON C S. Sustainable management and utilisation of concrete slurry waste: A case study in Hong Kong [J]. Waste Management, 2017, 61: 397-404.

[40] TANG P, XUAN D X, POON C S, et al. Valorization of concrete slurry waste (CSW) and fine incineration bottom ash (IBA) into cold bonded lightweight aggregates (CBLAs): Feasibility and influence of binder types [J]. Journal of Hazardous Materials, 2019, 368: 689-697.

[41] TANG P, XUAN D X, CHENG H W, et al. Use of CO2 curing to enhance the properties of cold bonded lightweight aggregates (CBLAs) produced with concrete slurry waste (CSW) and fine incineration bottom ash (IBA) [J]. Journal of Hazardous Materials, 2020, 381: 120951.

[42] TANG P, BROUWERS H J H. Integral recycling of municipal solid waste incineration (MSWI) bottom ash fines (0-2 mm) and industrial powder wastes by cold-bonding pelletization [J]. Waste Management, 2017, 62: 125-138.

[43] SCHOON J, DE BUYSSER K, VAN DRIESSCHE I, et al. Feasibility study of the use of concrete sludge as alternative raw material for Portland clinker production [J]. Journal of Materials in Civil Engineering, 2015, 27(10): 04014272.

[44] SCHOON J, VAN DER HEYDEN L, ELOY P, et al. Waste fibrecement: An interesting alternative raw material for asustainable Portland clinker production [J]. Construction and Building Materials, 2012, 36: 391-403.

[45] YANG Z X, HA N R, HWANG K H, et al. A Study of the performance of a concrete sludge-based geopolymer [J]. Journal of Ceramic Processing Research, 2009, 10: S72-S74.

[46] LUUKKONEN T, ABDOLLAHNEJAD Z, YLINIEMI J, et al. One-part alkali-activated materials: A review [J]. Cement and Concrete Research, 2018, 103: 21-34.

[47] ELYAMANY H E, ABD ELMOATY A E M, ELSHABOURY A M. Setting time and 7-day strength of geopolymer mortar with various binders [J]. Construction and Building Materials, 2018, 187: 974-983.

[48] YOUSEFI ODERJI S, CHEN B, AHMAD M R, et al. Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: Effect of slag and alkali activators [J]. Journal of Cleaner Production, 2019, 225: 1-10.

[49] JEONG Y, KANG S H, DU Y H, et al. Local Ca-structure variation and microstructural characteristics on one-part activated slag system with various activators [J]. Cement and Concrete Composites, 2019, 102: 1-13.

[50] ASKARIAN M, TAO Z, SAMALI B, et al. Mix composition and characterisation of one-part geopolymers with different activators [J]. Construction and Building Materials, 2019, 225: 526-537.

[51] LUUKKONEN T, ABDOLLAHNEJAD Z, YLINIEMI J, et al. Comparison of alkali and silica sources in one-part alkali-activated blast furnace slag mortar [J]. Journal of Cleaner Production, 2018, 187: 171-179.

(編辑 胡玲)