肉类低温保鲜技术研究进展

2021-07-11吴明黄晓红杨勇高梦祥

吴明 黄晓红 杨勇 高梦祥

摘 要:低温保鲜是肉类食品重要的保藏方式,肉类经低温保鲜能够在一定时间内维持其原有品质,但在低温条件下保鲜也不能完全避免品质劣变甚至腐败变质。肉类在低温保鲜中出现的品质变化是多种因素共同作用的结果,因此,在低温贮藏的基础上结合其他技术对肉类进行保鲜很有必要。本文概括肉类低温保鲜中的品质变化以及影响肉类低温保鲜性能的因素,同时对其他低温保鲜技术的研究进行综述,旨在为肉类低温保鲜提供参考。

关键词:肉类;低温保鲜;品质变化;影响因素;研究进展

A Review of Preservation Technologies for Meat Products Stored under Low-Temperature Conditions

WU Ming1, HUANG Xiaohong2, YANG Yong2, GAO Mengxiang1,*

(1. College of Life Science, Yangtze University, Jingzhou 404325, China;

2. College of Food Science, Sichuan Agricultural University, Yaan 625014, China)

Abstract: Low-temperature storage is an important way to maintain the quality of meat products for a certain period of time. However, meat quality deterioration and spoilage cannot be completely avoided even under low-temperature conditions. Meat quality changes under low-temperature conditions are the result of many factors. Therefore, it is necessary to combine low-temperature storage and preservation technologies in order to keep meat quality. This article summarizes meat quality changes and the factors affecting meat preservation during low-temperature storage. Besides, it reviews various preservation technologies. The aim is to provide a reference for the low-temperature preservation of meat products.

Keywords: meat; low-temperature preservation; quality change; influential factors; progress

DOI:10.7506/rlyj1001-8123-20210203-029

中图分类号:TS251.5 文献标志码:A 文章编号:1001-8123(2021)05-0060-10

引文格式:

吴明, 黄晓红, 杨勇, 等. 肉类低温保鲜技术研究进展[J]. 肉类研究, 2021, 35(5): 60-69. DOI:10.7506/rlyj1001-8123-20210203-029. http://www.rlyj.net.cn

WU Ming, HUANG Xiaohong, YANG Yong, et al. A review of preservation technologies for meat products stored under low-temperature

conditions[J]. Meat Research, 2021, 35(5): 60-69. DOI:10.7506/rlyj1001-8123-20210203-029. http://www.rlyj.net.cn

肉是人类必需的动物性食品,能为人类提供优质蛋白質。近年来,肉类因其风味、营养等方面的优势,其消费市场迅速增长[1],但由于肉类中含有丰富的必需氨基酸、维生素和矿物质,极易发生腐败变质[2]。低温贮藏和冷冻是2 种最常用的肉类食品保存技术。微生物的生命活动和酶的催化作用都需要适当的温度条件和水分。低温条件下,微生物的生长繁殖减慢;酶的活性减弱,其催化的生化反应变慢,食品的贮藏期得以延长[3]。

低温贮藏肉在一定时间内可以保持其原有品质,但随着贮藏时间的延长,冷藏肉类中腐败微生物的生长繁殖、冷冻肉类脂肪和蛋白质的氧化造成营养损失和安全隐患,其所导致的经济损失也越来越受到人们关注。因此,探究低温贮藏肉类品质的影响因素、保鲜方法,尽可能延长保质期非常重要。

1 肉类在低温贮藏中的品质变化

低温贮藏是保持肉类品质和控制微生物生长的常用方法。经过长期低温贮藏,肉的色泽会变差,同时出现蛋白质氧化、脂肪氧化和保水能力下降等现象,使得肉类营养价值降低,品质发生劣变。

肉类是优质蛋白质的重要来源。当活性氧(reactive oxygen species,ROS)超过内源性抗氧化能力的防御时,ROS会导致蛋白质氧化。与此同时,一些氨基酸在氧化过程中可能会获得或失去质子,使蛋白质分子的净电荷发生变化,导致肌原纤维膨胀,影响持水能力[4]。肌肉蛋白质的氧化损伤包括蛋白质结构的改变、氨基酸衍生物的形成、持水能力等功能性质的改变等。另外,在冷冻条件下,钙蛋白酶抑制剂活性丧失,蛋白质分解增加[5];肌肉组织中未冻水相的溶质浓度增加,引起蛋白质变性。

脂质包括脂肪及类脂。脂质氧化是通过自由基反应发生的,自由基反应攻击脂肪酸的不饱和键,导致食物颜色、香味和质地改变,还可能形成有毒化合物(如丙二醛和胆固醇氧化产物)以及挥发性羰基、醇类和酸类物质的积累。多不饱和脂肪酸自氧化引发的脂质氧化是冷冻肉变质的主要形式[6]。脂肪氧化是肉类工业非常关注的问题,因为其不仅会导致异味和酸败,而且还会为ROS的形成提供潜在前体或催化剂,导致肉类进一步发生有害变化[7]。此外,冷冻肉的脂质氧化还与冰晶的生长和分布相关[8]。

水分含量在肌肉组织中约占75%,肌纤维中的大部分水分位于肌原纤维内部和纤维之间[9]。保水性是重要的肉类品质特性,对肉类的感官品质和经济价值有重要影响[12]。低温贮藏会导致肉类的解冻损失、滴水损失和烹饪损失增加[10-11]。低温贮藏过程中肉类保水性降低可能由以下几种原因引起:1)巯基或二硫化物的氧化形成二硫键,引起蛋白质聚集,从而降低蛋白质的溶解度,这可能是肉保水性降低的一个重要原因[13];2)胞内离子强度增加引起蛋白质变性[14],使肌原纤维蛋白失去保水性,从而释放出渗液或游离水分;3)静电斥力影响蛋白质与肌浆的相互作用[15];4)肉在冷冻过程中,其中的水分发生冷冻和肌肉结构内形成冰晶,由此引起的机械损伤可能导致肉保水性降低。另外,保水能力的下降与蛋白质氧化有关的研究报道也较多[16]。

颜色是判断肉品新鲜与否的重要属性,也是影响消费者购买欲的主要因素。颜色通常是由鲜肉中紫红色的脱氧肌红蛋白、樱桃红色的氧合肌红蛋白和棕褐色的高铁肌红蛋白分布和相对比例决定的[17]。冷冻过程中,脂质氧化会增加自由基的数量,加快肌红蛋白氧化速率,进而影响颜色变化[18]。同时,冰晶形成所造成的物理损伤促使促氧化剂与肌红蛋白接触,进一步加速了氧化过程。此外,牛肉颜色还受到高铁肌红蛋白还原酶活性的影响[19]。可以认为,肉品的色泽变化与脂质氧化和高铁肌红蛋白还原酶系统密切相关[20]。

2 低温贮藏肉类品质变化的影响因素

低温贮藏是广泛使用的保持食品品质的方法。低温贮藏过程中影响肉品质量变化的因素有很多,如饲养与运输方式、屠宰方式、肉的种类与性质、冷冻条件、微生物及解冻方式等。

2.1 饲养方式

多不饱和脂肪酸对人类健康具有许多积极影响。许多功能性食品的开发是通过添加富含多不饱和脂肪酸的膳食油脂来实现的。多不饱和脂肪酸多来自动物性食品,对于家禽而言,多不饱和脂肪酸含量的增加会提高家禽的氧化应激反应[21],这对禽肉氧化稳定性提出了更高的要求。在食品工业中,防止或延缓食品氧化的常规处理方法是将抗氧化剂直接添加到食品或用抗氧化剂制备涂层包装。通过在动物饲料中添加抗氧化剂增加内源性抗氧化剂水平,也可作为防止肉类氧化损伤的另一策略,并且在降低氧化速率的同时也可以改善肉品品质。与人工合成抗氧化剂相比,人们越来越关注在动物饲料中使用富含抗氧化剂的天然提取物,以提高肉类氧化稳定性。氧化过程遵循多种机制,2 种及2 种以上膳食抗氧化剂的组合相比单一抗氧化剂可能具有协同或加和效果。

Leskovec等[22]发现,饲粮单独添加VC或硒(Se)对鸡肉品质指标无影响,单独使用VE和联合使用Se+VC

均能提高鸡胸肉中α-生育酚含量,进而抑制富含多不饱和脂肪酸饲粮及低温贮藏导致的鸡肉脂质过氧化。Fellenberg等[23]发现,日粮中添加VE能够抑制鸡肉的脂质氧化,但对蛋白质氧化的保护效果因鸡肉部位不同而有所区别。Carballo等[24]研究发现,在含丁基羟基甲苯的商业代乳品中添加虾青素饲喂羔羊,不仅能显著提高冷冻羔羊肉的脂质稳定性,而且能降低肉中丁基羟基甲苯的积累。Mariana等[25]在山羊日粮中加入富含鞣质的木本植物叶,发现木本植物叶的添加不仅能降低宰后肉的氧化状态,还能提高肉在冷藏或冷冻条件下的脂质抗氧化能力。Arowolo等[26]分别用标准饲料、标准饲料+餐馆回收油和标准饲料+玉米油作为猪饲料,发现用标准饲料+餐馆回收油饲养的猪制成的肉制品在低温贮藏过程中的氧化敏感性显著增加,与不良风味有关化合物的积累速率加快。

2.2 微生物

腐败是一个复杂的过程,与食品的初始带菌量和内源性酶活力有关。动物宰后与外界微生物接触,微生物产生的多种酶首先作用于肌肉的碳水化合物和蛋白质。一般来说,当微生物数量达到107~108 CFU/cm2時,肉品出现多种腐败迹象,如异味、变色和黏液形成。随着贮藏时间的延长,微生物代谢物的积累和释放导致食品商品价值降低甚至丧失。自然变质食品中通常多种细菌共存,微生物的相互作用决定了产品的最终腐败特性。对肉类来说,即使是在大型肉类工厂的规模化生产中,肉类宰后的微生物污染在实际情况下仍不可避免。有氧冷藏肉中分离出的常见微生物包括假单胞菌、环丝菌、不动杆菌和希瓦氏菌,最主要的微生物是嗜冷假单胞菌;而在冷冻条件下,弯曲菌属、大肠杆菌和沙门氏菌是常见的微生物。

乙酸、柠檬酸等有机酸被广泛应用于食品工业中,特别是肉类食品中,以减少食品中的食源性病原体和腐败微生物。Zheng Ruishen等[27]用喷涂法研究不同浓度苯乳酸对牛肉中产志贺毒素大肠杆菌和鼠伤寒沙门氏菌的杀菌效果,结果发现,在-20 ℃冷冻时,1.5%苯乳酸处理可显著减少牛肉中大肠杆菌O157:H7和沙门氏菌的数量,冷冻增强了苯乳酸对牛肉的杀菌作用。高压灭活病原体和腐败细菌已被普遍认为是高温灭菌处理的理想替代方法,可用于提高肉制品保质期。Porto-Fett等[28]研究高压处理对肉丸中产志贺毒素大肠杆菌的灭活效果,结果发现,杀菌效果与肉丸所用肉的种类和低温贮藏条件之间没有相关性,但与400 MPa(至少9 min)处理相比,在600 MPa下灭活相同数量大肠杆菌所需的时间更少,仅需1~3 min。Cap等[29]探讨高静水压处理压力水平和处理时间对冷冻鸡胸肉中沙门氏菌灭活的影响,结果表明,500 MPa处理1 min或400 MPa处理5 min能够完全灭活冷冻鸡胸肉中的沙门氏菌,但前者更能有效保持鸡胸肉的颜色。电离辐射灭菌主要通过破坏DNA、RNA和蛋白质等大分子来破坏微生物细胞。Arshad等[30]研究认为,3 kGy剂量的电子束辐照可以在不影响冷冻鸭肉感官特性的情况下,使细菌总数和大肠菌群数分别减少2 个和1 个对数级。

2.3 解冻方法

解冻过程是大多数冷冻食品在进一步加工或食用前必不可少的步骤,解冻过程与冷冻过程对冷冻肉品质同样重要。一般来讲,解冻过程比冷冻过程较为缓慢,较长的解冻时间可能导致肉品味道[31]、质地、颜色[32]改变以及蛋白质和脂质氧化等[33]。解冻肉品的质量损失程度取决于许多因素,如解冻温度、解冻时间,特别是解冻方法。静水解冻、冷却解冻和空气解冻等传统解冻方法存在解冻时间长、微生物滋生、交叉污染、可溶性营养成分流失、对环境不友好等缺点,因此,微波、超声波、射频、真空、高压和欧姆解冻等一些新型解冻方法被提出,这些新的解冻方法具有解冻时间短和解冻后肉类质量较好等优点。

Cevik等[34]发现,欧姆解冻后的冷冻肉糜与4 ℃空气解冻和4 ℃流水解冻相比,具有相似的流变特性,这说明欧姆解冻可以作为一种替代解冻方法。Qian Shuyi等[35]认为,与冰箱解冻相比,低压静电场解冻能有效降低解冻过程中牛肉的品质损失,显著缩短解冻时间;不仅如此,冷冻诱导的肌原纤维蛋白变性及其溶解度和表面疏水性均随解冻时间的延长而逐渐恢复。Jia Guoliang等[36]发现,空气解冻和高压静电场解冻肉中代谢产物谱存在差异,另一方面,高压静电场解冻没有引起脂质进一步氧化。Wang等[37]发现,在真空、超声、微波、14 ℃水浸渍及4 ℃冰箱解冻5 种解冻方法中,除真空解冻外,其他4 种解冻方法对猪背最长肌热稳定性和结构变化均有显著影响,其中微波解冻影响最为显著。Zhu Mingming等[38]将微波解冻分别与超声、35 ℃静水、4 ℃冷藏、空气对流和流水解冻方式结合,探究不同解冻方法对猪背最长肌理化性质和蛋白质变性的影响,结果显示,除单一微波解冻外,微波解冻与其他方法结合使用均避免了局部过热,其中微波与空气对流结合的解冻方式最能有效缩短解冻时间,保持肉的原有品质。

2.4 其他

养殖方式、动物年龄、宰前运输和屠宰方式会影响肉的低温贮藏性能。Yamak等[39]发现,谷仓中饲养的鹧鸪具有较高的活体质量和胴体质量,而自由放养的鹧鸪肉质更好。Fisinin等[40]证实了这一结果,同时发现不同饲养方式和不同屠宰日龄的鸡肉持水能力存在显著差异。Smiecinska等[41]报道发现,猪在宰前静养24 h能减轻屠宰时的应激反应。DAgata等[42]发现,屠宰方式对牛肉冷藏期间的滴水损失有影响,但这与Agbeniga等[43]的结论相反。

宰后较高的温度与低pH值影响肉类低温贮藏中的品质。高温与低pH值相互作用会导致肌球蛋白变性,使得肌球蛋白头部收缩和肌丝间距减小,诱导水分排出到细胞外间隙[44],同时,肌浆蛋白变性和肌节缩短可能会增加表面反射光强度,使肉品外观苍白。此外,屠宰期间电刺激、血管冲洗、开膛、热脂肪修剪和热去骨等处理也会影响肉品宰后及成熟过程中的温度和pH值[45]。

屠宰后的冷却方法也会影响肉的品质和货架期。宰后胴体冷却的传统方法是空气冷却,空气温度通常为1~2 ℃、风速为1~5 m/s。除传统冷却外,目前肉品工业中还使用喷雾冷却、急速冷却、冷冻室冷却和液体浸泡冷却等加速冷却方法。Janiszewski等[46]报道,与直接放入1 ℃常规冷却室24 h相比,宰后胴体经隧道(-26 ℃)冷却1 h再放入1 ℃常规冷却室24 h处理,质量损失和滴水损失存在显著差异,但其他品质特性和货架期差异并不显著,认为宰后胴体直接进入常规冷却室成熟更为经济。

3 低温贮藏肉类品质保鲜技术研究进展

低温贮藏中营养成分的变化、冰晶的形成和微生物的滋生等严重破坏了肉品品质,低温贮藏期间的肉类品质控制具有重要意义。

3.1 微冻保鲜

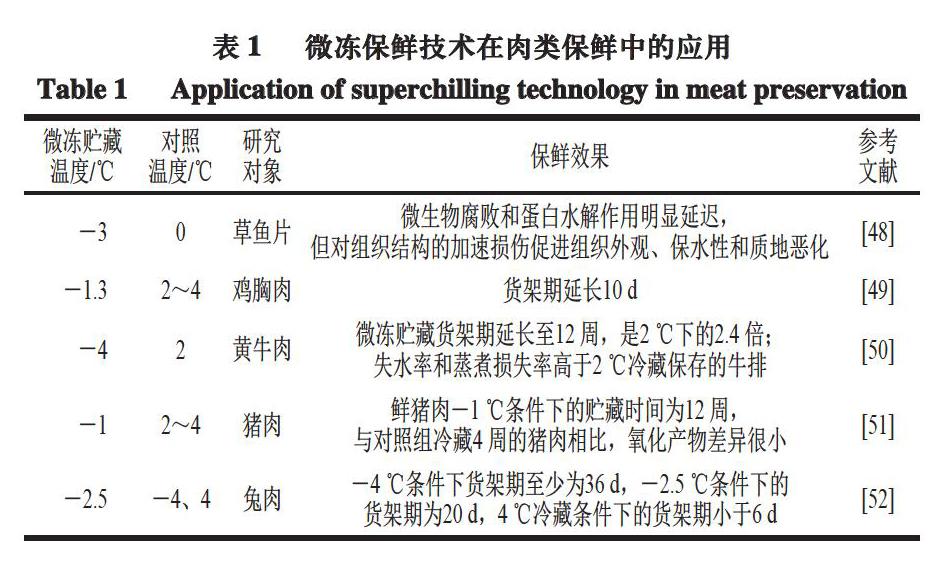

微冻是一种基于部分冰结晶的方法,可以用来延长新鲜食品的保质期[47]。在冷却过程中产品温度通常要求低于产品初始冰点1~2 ℃,使产品表面形成一层薄冰。在进一步贮存过程中,产品内部温度达到平衡,由于贮存条件的不同,冰壳可能会保留或不保留。因此,微冻也被称为“深冷”“超冷”“壳冻结”或“部分结冰”。

微冻保鲜主要是利用低温环境来抑制酶的活性和微生物的生长繁殖。在微冻贮藏条件下,细胞中部分水发生冻结,酶活动所需的自由水减少,细胞液溶质浓度增大,微生物细胞的生理生化性质发生改变,部分细菌开始死亡,未死亡细菌的活动受到严重阻碍,几乎不能繁殖,进而使产品保持较好的新鲜度。与传统冷藏相比,微冻贮藏可以将食品的保质期延长1.5~4.0 倍。微冻贮藏介于冷藏和冻藏之间,因其仅部分水分冻结,导致蛋白质的冷冻变性程度较低,对组织结构的机械损伤更小,因此微冻过程对产品品质影响也更小;此外,由于微冻处理产生了冰壳,在配送过程中可能不需要额外的冷却措施,從而降低了整体运输成本。因此,与冷冻贮藏相比,微冻贮藏可能更具吸引力。微冻保鲜已被广泛应用于海产品,并取得了很好的效果,但在肉品保鲜方面的研究相对较少(表1)。

此外,Ding Daming等[53]发现,-3 ℃的微冻贮藏在抑制猪肉微生物生长、降低脂肪和蛋白质氧化方面比-1 ℃更具有优势。微冻贮藏温度对最终食品质量有很大影响。然而,准确定义既能延长保质期又能满足生产工艺和食品质量要求的微冻贮藏温度仍是一个挑战。

3.2 高压辅助保鲜

高压加工是一种能够在保持食品新鲜度和营养特性的同时延长货架期的非热加工技术[54],高压预处理中,液态水的冰点在加压时降低,在随后的低温贮藏过程中冰核形成速率加快,利于小冰晶的形成[55]。表2列出了高压技术在肉类保鲜中的部分应用研究。

低温贮藏前的高压预处理抗菌作用研究较多,如Porto-Fett等[56]验证了加压可用于控制碎牛肉饼中产志贺毒素大肠杆菌和单核细胞增生李斯特菌。一般来说,具有抗菌作用的压力水平会导致食品中酶的分子结构和活性发生变化,但这是否会对低温贮藏过程中的氧化过程、质地和颜色产生影响还需探究。不同的压力水平和作用时间会使肌原纤维蛋白变性,并在不同程度上改变肌肉的蛋白质功能、外观和机械性能[62],这与Cartagena[57]、Pita-Calvo[58]等的发现一致,即高压预处理导致显著的蛋白质变性和盐溶性蛋白聚集,引起质构变化。另外,高压处理是否会诱导肉类中的脂质氧化说法并不统一。Bolumar等[63]认为,高压处理诱导的肉类脂质氧化与血红蛋白铁的溶出性增加、膜破裂和高压条件下自由基的形成有关。而Cartagena[57]、Mizi[59]等的研究结果显示加压对脂肪氧化具有抑制作用,这可能与压力的作用时间、肉的种类等有关。

3.3 电磁辅助保鲜

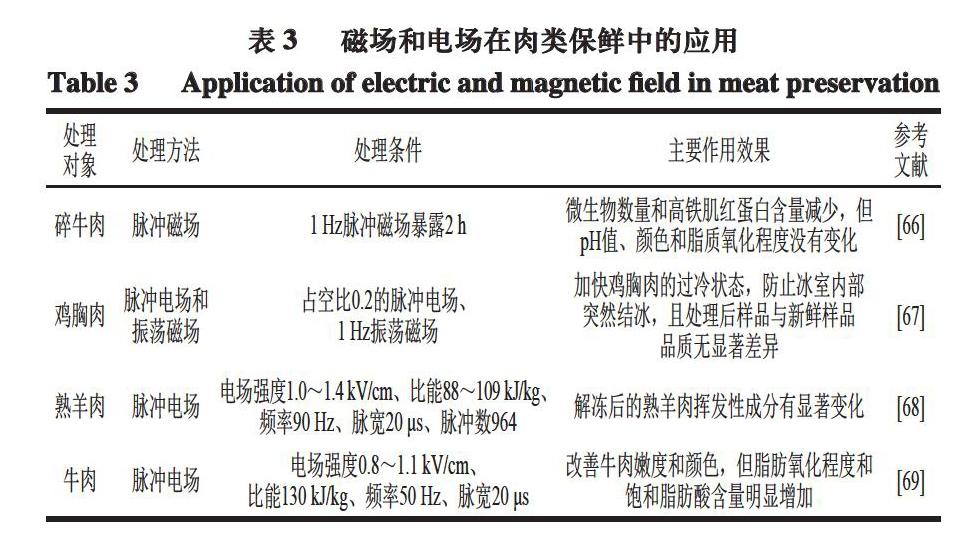

磁场和电场在食品保鲜上具有很好的应用前景。微生物对磁场具有感受效应[64],磁场对微生物的生化作用(如酶活性)有影响,会导致微生物生长受到抑制甚至死亡,从而产生抑菌效果。磁场对微生物的作用机制及生物学效应目前还没有较为全面的研究,已有研究表明,磁场对微生物的作用可能与DNA分子的变化、微生物的迁移方向、改变微生物的生长和繁殖、细胞膜变化以及ATP合成有关[64]。

脉冲电场是一种非热食品加工技术,它通过将高压短脉冲传递到置于2 个导电电极之间的食品中,使细胞膜渗透性增加[65]。脉冲电场处理可以改变肉的结构和质地,潜在改善其功能特性或有助于新产品的开发。在肌肉类食品,尤其是牛肉中使用脉冲电场,可以通过电穿孔增强细胞的通透性,从而增强蛋白质水解。表3简要总结了近几年磁场和电场在肉品保鲜中的部分研究。

此外,Wowk[70]、Mok[71]等发现,电场和磁场联合处理会影响水分子的流动性。Otero等[72]研究认为,磁场有助于在整个冷冻产品中生成微小冰晶,防止细胞被破坏,并在解冻后能够较好保持产品质量。

3.4 气调保鲜

通过包装也可对肉类进行保鲜,其中作用最为突出的是气调包装。该技术是用已知的气体(O2、CO2、N2和CO等)去除或置换产品周围空气,抑制食品的生理生化过程,实现保鲜目的。真空包装是气调包装的一种类型,通过维持产品周围真空环境,抑制需氧菌的生长。表4列出了气调包装在肉类保鲜中应用的部分研究。

70%~80% O2+20%~30% CO2的气调包装在抑制微生物生长和保持良好色泽方面成效显著,因此被广泛使用。但是,高氧气调包装可能会加速脂质氧化,导致不良味化合物的形成[79],以及诱导蛋白质分子之间的交叉连接[80],对红肉制品的嫩度和多汁性造成不利影响[81],同时降低颜色稳定性[82]。此外,微生物代谢产生的气体分压和溶解度因CO2和O2比例不同而有所差异,每种产品都有其最佳的气体成分,这是气调包装成功应用的关键因素和主要挑战。

3.5 涂膜保鲜

涂膜保鲜是将具有成膜性的物质,如海藻酸盐,经浸渍、涂布、喷洒等方法涂敷在食品表面,使其在食品表面形成一层能够抑制食品内外气体、水分和溶质交换及阻碍微生物对食品侵害等作用的薄膜,从而达到防止食品腐败变质、保持其原有新鲜度的食品保鲜技术。

烃类衍生物合成的聚合物薄膜具有不能生物降解和不能循环利用的特点,且这些塑料制品的积累会导致严重的环境污染,因此现在的研究多是基于生物来源的可食性涂膜和涂材。可食用涂膜是以蛋白质、多糖或脂类为基础应用于食品表面的薄膜,这些材料具有生物相容性、可生物降解性、广泛可得性和易处理性,使其能满足现代食品工业和消费者的需求。可食用涂膜被广泛应用于肉类、水产、水果和蔬菜的保鲜[83],其可直接在食品表面形成保护层,以抑制质量劣化,延长保质期。残留在产品上的涂膜可以在后续加工过程中分解或被食用,因此被认为是保护食品质量和安全的一种有效、环保的技术。此外,在可食用薄膜中加入天然的抗菌剂、抗氧化剂、香料和色素等添加剂来提高食品质量特性的研究备受关注。表5列出了可食性涂膜技术在肉类保鲜中的部分应用研究。

4 壳聚糖和明胶 Nisin、

葡萄籽提取物 壳聚糖-明胶-葡萄籽提取物涂膜能进一步提高肉的抗氧化活性;而壳聚糖-明胶-Nisin和壳聚糖-明胶-Nisin-葡萄籽提取物涂膜

并没有进一步提高抗菌和抗氧化效果 [89]

橄榄叶提取物和榛子皮被认为具有良好的抗氧化活性,Ozvural[90]发现冷藏21 d后,相较于使用含这2 种物质可食性涂膜处理,直接添加这2 种物质处理肉饼的硫代巴比妥酸反应物值更低;但对于冷冻样品,2 种处理方式均可有效延缓肉饼脂质氧化。Shankar等[91]将含精油和柑橘提取物的可食用涂膜分别与臭氧和辐照处理结合,探究不同保鲜方法对4 ℃贮藏鳕鱼片货架期的影响,结果发现,经涂膜和辐照处理的鱼片货架期达28 d以上,经涂膜和臭氧处理的鱼片货架期为21 d,均明显高于未经任何处理鱼片的货架期(7 d),表明通过优化组合可使有效延长鱼片保质期。Nisin是一种抗菌肽,对革兰氏阳性菌具有有效的抗菌活性[92],已在食品工业中被广泛应用。纳米技术为生物聚合物薄膜在不同方面的改性提供了新的可能性。Mohammadi等[93]评估基于羧甲基纤维素、秋葵胶和氧化锌(ZnO)钠米颗粒的纳米复合膜对4 ℃条件下贮藏12 d包装鸡胸肉货架期的影响,发现薄膜中秋葵胶的含量与鸡肉品质具有剂量依赖性,羧甲基纤维素/50%秋葵胶/ZnO薄膜包装的鸡胸肉不仅具有良好感官评分,且微生物生长和化学变化的抑制效果最佳。

3.6 糖(醇)类抗冻剂

抗冻剂是一种通过减缓冰晶生长从而保护生物组织免受冷冻损伤的物质,它可以降低肌原纤维蛋白在冷冻保存过程中的变性和(或)聚集性,从而保持蛋白质的功能特性,如凝胶形成能力、保水能力和溶解度。糖(醇)类抗冻剂是抗冻剂的一种。传统的商业抗冻剂是指质量分数4%蔗糖和质量分数4%山梨醇的共混物。蔗糖能通过稳定蛋白质周围的临界水分来达到维持蛋白質空间结构和减少冰晶形成的目的。尽管传统抗冻剂的作用效果较好,但由于甜度和热量较高不能满足特定人群需求,因此,许多研究转向寻找低甜度的冷冻保护剂。海藻糖、麦芽糖、聚葡萄糖、木糖、壳聚糖和葡甘露聚糖作为可能的替代对象,探究它们的保护作用已成为研究方向。一方面,这些糖类物质可以与蛋白质的活性基团结合,使其处于饱和状态,从而能够避免蛋白质之间的聚集变性。另一方面,糖类游离的羟基还可以促进自由水转化成结合水,从而降低“共晶点”的温度,减少冰晶体的形成,减缓蛋白质的相互聚集,防止蛋白质的聚集变性。此外,糖类分子中含有的羟基数目越多,对蛋白质冷冻变性的抑制效果也越明显。目前,糖(醇)类抗冻剂的应用研究多集中在水产品方向,在畜禽肉方面的应用有限。表6列出了几种糖类抗冻剂在水产品保鲜中的应用研究。

另外,English等[100]从消费者的角度出发,比较氯化钠、三聚磷酸钠和一种新型碳水化合物的两两组合对龙虾肉的冷冻保藏效果,结果发现,以氯化钠和新型碳水化合物为抗冻剂的冷冻保藏效果最佳。与多数研究不同的是,Zhang Bin等[101]较为系统地研究以木糖醇、山梨醇、赤藓醇、乳糖醇、甘露醇、麦芽糖醇、异麦芽糖醇溶液浸渍处理对太平洋白对虾冷藏品质的影响,发现经木糖醇和甘露醇浸渍处理的太平洋白对虾理化指标和微观结构较好,这可能是由于木糖醇和甘露醇分子可能通过与肌肉蛋白形成大的氢键取代了水分子,从而在没有水的冷冻状态下稳定其结构,并抑制组织结构的破坏;而乳糖醇、异麦芽糖醇和麦芽糖醇对虾肉低温保护没有显著作用。

3.7 抑菌剂

肉在低温贮藏中的微生物污染主要与屠宰后肉的初始微生物群有关,屠宰前健康家畜的肉是无菌的,屠宰过程中胴体会通过工人和加工环境等各种途径受到微生物污染。屠宰过程中动物皮、脚、蹄、毛、胃肠道和呼吸道中的微生物也会污染胴体肌肉,增加肉中的微生物含量。胴体表面细菌污染水平与感官变化发生的时间和肉的保质期存在相关性。根据欧洲委员会(EC)1441/2007号进一步修订的要求,猪胴体冷却前的表面总好氧菌数量不应超过4.0 (lg(CFU/cm2))。另外,尽管病原微生物,如沙门氏菌、产气荚膜梭菌、大肠埃希氏菌和空肠弯曲杆菌等在初始微生物群中数量很少,但与肉表面直接接触可能导致蛋白质降解,并在肉中产生某些有毒化合物,最终导致食物中毒,严重影响人体健康。因此,采用抑菌剂降低初始微生物群数量,对保障低温贮藏肉类安全性以及延长保质期非常必要。表7列出了抑菌剂在肉类保鲜中的部分应用研究。

天然植物,如肉豆蔻[107]、景天[108]、桉树[109]、百里香[110]和牛蒡[111]等对大肠杆菌、金黄色葡萄球菌、乳酸菌、假单胞菌、沙门氏菌的抑制作用均有报道。另外,不同处理方法的组合也适用于屠宰体的表面净化,包括用热水结合抗菌剂清洗,然后用冷水冲洗[112]以及用含抑菌剂溶液喷淋胴体[113]等。

4 结 语

肉类食品是现代饮食生活不可或缺的一部分。目前,低温贮藏仍然是保持肉类食品品质最为经济、可行的方式。因此,尽可能维持肉类原有品质仍是需要不断探索的方向。影响低温贮藏肉类品质的因素很多,现有的研究对宰前因素研究相对较少,且多是围绕对冷藏肉的肉质影响开展。國内外对于肉类保鲜方式的研究较多且在一定程度上取得了成效,因而,应进一步探究低温贮藏与其他栅栏技术的联用。同时,积极改进生产设备性能和采用新的保鲜技术也是对低温贮藏肉类品质进行有效控制的重要方向。

参考文献:

[1] ZHAO Shengming, LI Ningning, LI Zhao, et al. Shelf life of fresh chilled pork as affected by antimicrobial intervention with nisin, tea polyphenols, chitosan, and their combination[J]. International Journal of Food Properties, 2019, 22(1): 1047-1063. DOI:10.1080/10942912.2019.1625918.

[2] CHOI E J, PARK H W, CHUNG Y B, et al. Effect of tempering methods on quality changes of pork loin frozen by cryogenic immersion[J]. Meat Science, 2017, 124: 69-76. DOI:10.1016/j.meatsci.2016.11.003.

[3] LI Dongmei, ZHU Zhiwei, SUN Dawen. Effects of freezing on cell structure of fresh cellular food materials: a review[J]. Trends in Food Science and Technology, 2018, 75: 46-55. DOI:10.1016/j.tifs.2018.02.019.

[4] UTRERA M, ESTEVEZ M. Oxidation of myofibrillar proteins and impaired functionality: underlying mechanisms of the carbonylation pathway[J]. Journal of Agricultural and Food Chemistry, 2012, 60(32): 8002-8011. DOI:10.1021/jf302111j.

[5] SETYABRATA D, KIM Y H B. Impacts of aging/freezing sequence on microstructure, protein degradation and physico-chemical properties of beef muscles[J]. Meat Science, 2019, 151: 64-74. DOI:10.1016/j.meatsci.2019.01.007.

[6] FIGUEIREDO B C, TRAD I J, BARROS MARIUTTI L R, et al. Effect of annatto powder and sodium erythorbate on lipid oxidation in pork loin during frozen storage[J]. Food Research International, 2014, 65: 137-143. DOI:10.1016/j.foodres.2014.07.016.

[7] FAUSTMAN C, SUN Qun, MANCINI R, et al. Myoglobin and lipid oxidation interactions: mechanistic bases and control[J]. Meat Science, 2010, 86(1): 86-94. DOI:10.1016/j.meatsci.2010.04.025.

[8] CHEN Weiwei, SORENSEN K M, ENGELSEN S B, et al. Lipid oxidation degree of pork meat during frozen storage investigated by near-infrared hyperspectral imaging: effect of ice crystal growth and distribution[J]. Journal of Food Engineering, 2019, 263: 311-319. DOI:10.1016/j.jfoodeng.2019.07.013.

[9] HUFF-LONERGAN E, LONERGAN S M. Mechanisms of water-holding capacity of meat: the role of postmortem biochemical and structural changes[J]. Meat Science, 2005, 71(1): 194-204. DOI:10.1016/j.meatsci.2005.04.022.

[10] AROEIRA C N, TORRES FILHO R A, FONTES P R, et al. Freezing, thawing and aging effects on beef tenderness from Bos indicus and Bos taurus cattle[J]. Meat Science, 2016, 116: 118-125. DOI:10.1016/j.meatsci.2016.02.006.

[11] KIM H W, KIM J H, SEO J K, et al. Effects of aging/freezing sequence and freezing rate on meat quality and oxidative stability of pork loins[J]. Meat Science, 2018, 139: 162-170. DOI:10.1016/j.meatsci.2018.01.024.

[12] BAO Yulong, ERTBJERG P. Effects of protein oxidation on the texture and water-holding of meat: a review[J]. Critical Reviews in Food Science and Nutrition, 2019, 59(22): 3564-3578. DOI:10.1080/10408398.2018.1498444.

[13] CHEUNG I W Y, LICEAGA A M, LI-CHAN E C Y. Pacific hake (Merluccius productus) hydrolysates as cryoprotective agents in frozen pacific cod fillet mince[J]. Journal of Food Science, 2009, 74(8): C588-C594. DOI:10.1111/j.1750-3841.2009.01307.x.

[14] LEYGONIE C, BRITZ T J, HOFFMAN L C. Impact of freezing and thawing on the quality of meat: review[J]. Meat Science, 2012, 91(2): 93-98. DOI:10.1016/j.meatsci.2012.01.013.

[15] ERTBJERG P, PUOLANNE E. Muscle structure, sarcomere length and influences on meat quality: a review[J]. Meat Science, 2017, 132: 139-152. DOI:10.1016/j.meatsci.2017.04.261.

[16] CHEN Lin, ZHOU Guanghong, ZHANG Wangang. Effects of high oxygen packaging on tenderness and water holding capacity of pork through protein oxidation[J]. Food and Bioprocess Technology, 2015, 8(11): 2287-2297. DOI:10.1007/s11947-015-1566-0.

[17] LIVINGSTON D J, MCLACHLAN S J, LA MAR G N, et al. Myoglobin: cytochrome b5 interactions and the kinetic mechanism of metmyoglobin reductase[J]. The Journal of Biological Chemistry, 1985, 260(29): 15699-15707.

[18] JEONG J Y, KIM G D, YANG H S, et al. Effect of freeze-thaw cycles on physicochemical properties and color stability of beef Semimembranosus muscle[J]. Food Research International, 2011, 44(10): 3222-3228. DOI:10.1016/j.foodres.2011.08.023.

[19] SORHEIM O, WESTAD F, LARSEN H, et al. Colour of ground beef as influenced by raw materials, addition of sodium chloride and low oxygen packaging[J]. Meat Science, 2009, 81(3): 467-473. DOI:10.1016/j.meatsci.2008.09.010.

[20] NASSU R T, UTTARO B, AALHUS J L, et al. Type of packaging affects the colour stability of vitamin E enriched beef[J]. Food Chemistry, 2012, 135(3): 1868-1872. DOI:10.1016/j.foodchem.2012.06.055.

[21] JUSKIEWICZ J, JANKOWSKI J, ZIELINSKI H, et al. The fatty acid profile and oxidative stability of meat from turkeys fed diets enriched with n-3 polyunsaturated fatty acids and dried fruit pomaces as a source of polyphenols[J]. PLoS One, 2017, 12(1): e0170074. DOI:10.1371/journal.pone.0170074.

[22] LESKOVEC J, LEVART A, PERIC L, et al. Antioxidative effects of supplementing linseed oil-enriched diets with alpha-tocopherol, ascorbic acid, selenium, or their combination on carcass and meat quality in broilers[J]. Poultry Science, 2019, 98(12): 6733-6741. DOI:10.3382/ps/pez389.

[23] FELLENBERG M A, PENA I, IBANEZ R A, et al. Effect of dietary vitamin E supplementation on glutathione concentration and lipid and protein oxidation of refrigerated broiler meat[J]. European Poultry Science, 2019, 83: 283-. DOI:10.1399/eps.2019.283.

[24] CARBALLO D E, JAVIER GIRALDEZ F, ANDRES S, et al. Effects of dietary astaxanthin supplementation on the oxidative stability of meat from suckling lambs fed a commercial milk-replacer containing butylated hydroxytoluene[J]. Meat Science, 2019, 156: 68-74. DOI:10.1016/j.meatsci.2019.03.020.

[25] MARIANA GARCIA E, LOPEZ A, ZIMERMAN M, et al. Enhanced oxidative stability of meat by including tannin-rich leaves of woody plants in goat diet[J]. Asian-Australasian Journal of Animal Sciences, 2019, 32(9): 1439-1447. DOI:10.5713/ajas.18.0537.

[26] AROWOLO F K, YANG Xing, BLASER M E, et al. Presence of lipid oxidation products in swine diet lowers pork quality and stability during storage[J]. Meat Science, 2020, 160: 107946. DOI:10.1016/j.meatsci.2019.107946.

[27] ZHENG Ruisheng, ZHAO Tong, HUNG Yencon, et al. Evaluation of bactericidal effects of phenyllactic acid on Escherichia coli O157:H7 and Salmonella typhimurium on beef meat[J]. Journal of Food Protection, 2019, 82(12): 2016-2022. DOI:10.4315/0362-028x.Jfp-19-217.

[28] PORTO-FETT A C S, JACKSON-DAVIS A, KASSAMA L S, et al. Inactivation of shiga toxin-producing Escherichia coli in refrigerated and frozen meatballs using high pressure processing[J]. Microorganisms, 2020, 8(3): 360. DOI:10.3390/microorganisms8030360.

[29] CAP M, FLEITAS PAREDES P, FERNANDEZ D, et al. Effect of high hydrostatic pressure on Salmonella spp. inactivation and meat-quality of frozen chicken breast[J]. LWT-Food Science and Technology, 2020, 118: 108873. DOI:10.1016/j.lwt.2019.108873.

[30] ARSHAD M S, KWON J H, AHMAD R S, et al. Influence of E-beam irradiation on microbiological and physicochemical properties and fatty acid profile of frozen duck meat[J]. Food Science and Nutrition, 2020, 8(2): 1020-1029. DOI:10.1002/fsn3.1386.

[31] JIA Guoliang, SHA Kun, MENG Jin, et al. Effect of high voltage electrostatic field treatment on thawing characteristics and post-thawing quality of lightly salted, frozen pork tenderloin[J]. LWT-Food Science and Technology, 2019, 99: 268-275. DOI:10.1016/j.lwt.2018.09.064.

[32] ALVARENGA T I R C, HOPKINS D L, RAMOS E M, et al. Ageing-freezing/thaw process affects blooming time and myoglobin forms of lamb meat during retail display[J]. Meat Science, 2019, 153: 19-25. DOI:10.1016/j.meatsci.2019.02.016.

[33] JIA Guoliang, NIRASAWA S, JI Xiaohua, et al. Physicochemical changes in myofibrillar proteins extracted from pork tenderloin thawed by a high-voltage electrostatic field[J]. Food Chemistry, 2018, 240: 910-916. DOI:10.1016/j.foodchem.2017.07.138.

[34] CEVIK M, ICIER F. Characterization of viscoelastic properties of minced beef meat thawed by ohmic and conventional methods[J]. Food Science and Technology International, 2019, 26(4) 277-290. DOI:10.1177/1082013219888300.

[35] QIAN Shuyi, LI Xia, WANG Hang, et al. Effects of low voltage electrostatic field thawing on the changes in physicochemical properties of myofibrillar proteins of bovine Longissimus dorsi muscle[J]. Journal of Food Engineering, 2019, 261: 140-149. DOI:10.1016/j.jfoodeng.2019.06.013.

[36] JIA Guoliang, SHA Kun, FENG Xudong, et al. Post-thawing metabolite profile and amino acid oxidation of thawed pork tenderloin by HVEF: a short communication[J]. Food Chemistry, 2019, 291: 16-21. DOI:10.1016/j.foodchem.2019.03.154.

[37] WANG B, KONG B, LI F, et al. Changes in the thermal stability and structure of protein from porcine Longissimus dorsi induced by different thawing methods[J]. Food Chemistry, 2020, 316. DOI:10.1016/j.foodchem.2020.126375.

[38] ZHU Mingming, PENG Zeyu, LU Sen, et al. Physicochemical properties and protein denaturation of pork Longissimus dorsi muscle subjected to six microwave-based thawing methods[J]. Foods, 2020, 9(1): 26-42. DOI:10.3390/foods9010026.

[39] YAMAK U S, SARICA M, BOZ M A, et al. The effect of production system (barn and free-range), slaughtering age and gender on carcass traits and meat quality of partridges (Alectoris chukar)[J]. British Poultry Science, 2016, 57(2): 185-192. DOI:10.1080/00071668.2016.1144920.

[40] FISININ V I, LUKASHENKO V S, SALEYEVA I P, et al. Meat quality in broilers reared in different housing systems[J]. Voprosy Pitaniia, 2018, 87(5): 77-84. DOI:10.24411/0042-8833-2018-10056.

[41] SMIECINSKA K, DENABURSKI J, SOBOTKA W. Slaughter value, meat quality, creatine kinase activity and cortisol levels in the blood serum of growing-finishing pigs slaughtered immediately after transport and after a rest period[J]. Polish Journal of Veterinary Sciences, 2011, 14(1): 47-54. DOI:10.2478/v10181-011-0007-x.

[42] DAGATA M, RUSSO C, PREZIUSO G. Effect of Islamic ritual slaughter on beef quality[J]. Italian Journal of Animal Science, 2009, 8: 489-491. DOI:10.4081/ijas.2009.s2.489.

[43] AGBENIGA B, WEBB E C, ONEILL H A. Influence of kosher (shechita) and conventional slaughter techniques on shear force, drip and cooking loss of beef[J]. South African Journal of Animal Science, 2013, 43(5): S98-S102. DOI:10.4314/sajas.v43i5.18.

[44] OFFER G. Modelling of the formation of pale, soft and exudative meat: effects of chilling regime and rate and extent of glycolysis[J]. Meat Science, 1991, 30(2): 157-184. DOI:10.1016/0309-1740(91)90005-b.

[45] JACOB R H, HOPKINS D L. Techniques to reduce the temperature of beef muscle early in the post mortem period: a review[J]. Animal Production Science, 2014, 54(4): 482-493. DOI:10.1071/AN12338.

[46] JANISZEWSKI P, BORZUTA K, LISIAK D, et al. The quality of pork and the shelf life of the chosen carcass elements during storage depending on the method of carcass chilling[J]. Journal of Food Processing and Preservation, 2018, 42(1): e13390. DOI:10.1111/jfpp.13390.

[47] 胡玥, 吳春华, 姜晴晴, 等. 微冻技术在水产品保鲜中的研究进展[J]. 食品工业科技, 2015, 36(9): 384-390. DOI:10.13386/j.issn1002-0306.2015.09.075.

[48] LIU Dasong, LIANG Liang, XIA Wenshui, et al. Biochemical and physical changes of grass carp (Ctenopharyngodon idella) fillets stored at –3 and 0 ℃[J]. Food Chemistry, 2013, 140(1/2): 105-114. DOI:10.1016/j.foodchem.2013.02.034.

[49] KAEWTHONG P, POMPONIO L, CARRASCAL J R, et al. Changes in the quality of chicken breast meat due to superchilling and temperature fluctuations during storage[J]. Journal of Poultry Science, 2019, 56(4): 308-317. DOI:10.2141/jpsa.0180106.

[50] LU Xiao, ZHANG Yimin, ZHU Lixian, et al. Effect of superchilled storage on shelf life and quality characteristics of M. longissimus lumborum from Chinese Yellow cattle[J]. Meat Science, 2019, 149: 79-84. DOI:10.1016/j.meatsci.2018.11.014.

[51] POMPONIO L, RUIZ-CARRASCAL J. Oxidative deterioration of pork during superchilling storage[J]. Journal of the Science of Food and Agriculture, 2017, 97(15): 5211-5215. DOI:10.1002/jsfa.8403.

[52] LAN Yang, SHANG Yongbiao, SONG Ying, et al. Changes in the quality of superchilled rabbit meat stored at different temperatures[J]. Meat Science, 2016, 117: 173-181. DOI:10.1016/j.meatsci.2016.02.017.

[53] DING Daming, ZHOU Changyu, GE Xiaoyin, et al. The effect of different degrees of superchilling on shelf life and quality of pork during storage[J]. Journal of Food Processing and Preservation, 2020, 44(4): e14394. DOI:10.1111/jfpp.14394.

[54] DE OLIVEIRA F A, CABRAL NETO O, DOS SANTOS L M R, et al.

Effect of high pressure on fish meat quality: a review[J]. Trends in Food Science and Technology, 2017, 66: 1-19. DOI:10.1016/j.tifs.2017.04.014.

[55] LI Bing, SUN Dawen. Novel methods for rapid freezing and thawing of foods: a review[J]. Journal of Food Engineering, 2002, 54(3): 175-182. DOI:10.1016/S0260-8774(01)00209-6.

[56] PORTO-FETT A C S, SHANE L E, SHOYER B A, et al. Inactivation of shiga toxin-producing Escherichia coli and Listeria monocytogenes within plant versus beef burgers in response to high pressure processing[J]. Journal of Food Protection, 2020, 83(5): 865-873. DOI:10.4315/jfp-19-558.

[57] CARTAGENA L, PUERTOLAS E, DE MARANON I M. Evolution of quality parameters of high pressure processing (HPP) pretreated albacore (Thunnus alalunga) during long-term frozen storage[J]. Innovative Food Science and Emerging Technologies, 2020, 62: 102334. DOI:10.1016/j.ifset.2020.102334.

[58] PITA-CALVO C, GUERRA-RODRIGUEZ E, SARAIVA J A, et al.

Effect of high-pressure processing pretreatment on the physical properties and colour assessment of frozen European hake (Merluccius merluccius) during long term storage[J]. Food Research International, 2018, 112: 233-240. DOI:10.1016/j.foodres.2018.06.042.

[59] MIZI L, COFRADES S, BOU R, et al. Antimicrobial and antioxidant effects of combined high pressure processing and sage in beef burgers during prolonged chilled storage[J]. Innovative Food Science and Emerging Technologies, 2019, 51: 32-40. DOI:10.1016/j.ifset.2018.04.010.

[60] PEREZ-BALTAR A, SERRANO A, BRAVO D, et al. Combined effect of high pressure processing with enterocins or thymol on the inactivation of Listeria monocytogenes and the characteristics of sliced dry-cured ham[J]. Food and Bioprocess Technology, 2019, 12(2): 288-297. DOI:10.1007/s11947-018-2212-4.

[61] MONTEIRO M L G, MARSICO E T, ROSENTHAL A, et al. Synergistic effect of ultraviolet radiation and high hydrostatic pressure on texture, color, and oxidative stability of refrigerated tilapia fillets[J]. Journal of the Science of Food and Agriculture, 2019, 99(9): 4474-4481. DOI:10.1002/jsfa.9685.

[62] URESTI R M, VELAZQUEZ G, VáZQUEZ M, et al. Effect of sugars and polyols on the functional and mechanical properties of pressure-treated arrowtooth flounder (Atheresthes stomias) proteins[J]. Food Hydrocolloids, 2005, 19(6): 964-973. DOI:10.1016/j.foodhyd.2004.12.006.

[63] BOLUMAR T, LAPENA D, SKIBSTED L H, et al. Rosemary and oxygen scavenger in active packaging for prevention of high-pressure induced lipid oxidation in pork patties[J]. Food Packaging and Shelf Life, 2016, 7: 26-33. DOI:10.1016/j.fpsl.2016.01.002.

[64] FILIPIC J, KRAIGHER B, TEPUS B, et al. Effects of low-density static magnetic fields on the growth and activities of wastewater bacteria Escherichia coli and Pseudomonas putida[J]. Bioresource Technology, 2012, 120: 225-232. DOI:10.1016/j.biortech.2012.06.023.

[65] PU?RTOLAS E, LUENGO E, ?LVAREZ I, et al. Improving mass transfer to soften tissues by pulsed electric fields: fundamentals and applications[J]. Annual Review Food Science Technology, 2012, 3: 263-282. DOI:10.1146/annurev-food-022811-101208.

[66] LINS P G, SILVA A A, PICCOLI PUGINE S M, et al. Effect of exposure to pulsed magnetic field on microbiological quality, color and oxidative stability of fresh ground beef[J]. Journal of Food Process Engineering, 2017, 40(2): e12405. DOI:10.1111/jfpe.12405.

[67] MOK J H, HER J Y, KANG T, et al. Effects of pulsed electric field (PEF) and oscillating magnetic field (OMF) combination technology on the extension of supercooling for chicken breasts[J]. Journal of Food Engineering, 2017, 196: 27-35. DOI:10.1016/j.jfoodeng.2016.10.002.

[68] MA Qianli, HAMID N, OEY I, et al. Effect of chilled and freezing pre-treatments prior to pulsed electric field processing on volatile profile and sensory attributes of cooked lamb meats[J]. Innovative Food Science and Emerging Technologies, 2016, 37: 359-374. DOI:10.1016/j.ifset.2016.04.009.

[69] KANTONO K, HAMID N, OEY I, et al. Physicochemical and sensory properties of beef muscles after pulsed electric field processing[J]. Food Research International, 2019, 121: 1-11. DOI:10.1016/j.foodres.2019.03.020.

[70] WOWK B. Electric and magnetic fields in cryopreservation[J]. Cryobiology, 2012, 64(3): 301-303. DOI:10.1016/j.cryobiol.2012.02.003.

[71] MOK J H, CHOI W, PARK S H, et al. Emerging pulsed electric field (PEF) and static magnetic field (SMF) combination technology for food freezing[J]. International Journal of Refrigeration, 2015, 50: 137-145. DOI:10.1016/j.ijrefrig.2014.10.025.

[72] OTERO L, RODRIGUEZ A C, PEREZ-MATEOS M, et al. Effects of magnetic fields on freezing: application to biological products[J]. Comprehensive Reviews in Food Science and Food Safety, 2016, 15(3): 646-667. DOI:10.1111/1541-4337.12202.

[73] 韓吉娜, KOMLA S H, 杨鸿博, 等. 气调包装对冷却鸭肉的保鲜效果研究[J]. 食品与发酵工业, 2019, 45(9): 159-164. DOI:10.13995/j.cnki.11-1802/ts.018894.

[74] ORKUSZ A, MICHALCZUK M. Research note: effect of packaging atmosphere on the fatty acid profile of intramuscular, subcutaneous fat, and odor of goose meat[J]. Poultry Science, 2020, 99(1): 647-652. DOI:10.3382/ps/pez528.

[75] 亚本勤, 熊伟, 李根正, 等. 气调冷藏对牦牛肉保鲜效果的影响[J]. 食品研究与开发, 2020, 41(8): 50-54. DOI:10.12161/j.issn.1005-6521.2020.08.008

[76] RODRIGUES I, TRINDADE M A, PALU A F, et al. Modified atmosphere packaging for lamb meat: evaluation of gas composition in the extension of shelf life and consumer acceptance[J]. Journal of Food Science and Technology-Mysore, 2018, 55(9): 3547-3555. DOI:10.1007/s13197-018-3280-1.

[77] CONTE-JUNIOR C A, MONTEIRO M L G, PATRICIA R, et al. The effect of different packaging systems on the shelf life of refrigerated ground beef[J]. Foods, 2020, 9(4):495. DOI:10.3390/foods9040495.

[78] JAKOBSEN A N, SHUMILINA E, LIED H, et al. Growth and spoilage metabolites production of a mesophilic Aeromonas salmonicida strain in Atlantic salmon (Salmo salar L.) during cold storage in modified atmosphere[J]. Journal of Applied Microbiology, 2020, 129(4): 935-946. DOI:10.1111/jam.14680.

[79] LUND M N, LAMETSCH R, HVIID M S, et al. High-oxygen packaging atmosphere influences protein oxidation and tenderness of porcine Longissimus dorsi during chill storage[J]. Meat Science, 2007, 77(3): 295-303. DOI:10.1016/j.meatsci.2007.03.016.

[80] JONGBERG S, WEN Jinzhu, TORNGREN M A, et al. Effect of high-oxygen atmosphere packaging on oxidative stability and sensory quality of two chicken muscles during chill storage[J]. Food Packaging and Shelf Life, 2014, 1(1): 38-48. DOI:10.1016/j.fpsl.2013.10.004.

[81] CANTO A C V C S, COSTA-LIMA B R C, SUMAN S P, et al. Color attributes and oxidative stability of Longissimus lumborum and Psoas major muscles from Nellore bulls[J]. Meat Science, 2016, 121: 19-26. DOI:10.1016/j.meatsci.2016.05.015.

[82] VITALE M, PEREZ-JUAN M, LLORET E, et al. Effect of aging time in vacuum on tenderness, and color and lipid stability of beef from mature cows during display in high oxygen atmosphere package[J]. Meat Science, 2014, 96(1): 270-277. DOI:10.1016/j.meatsci.2013.07.027.

[83] GHIDELLI C, PEREZ-GAGO M B. Recent advances in modified atmosphere packaging and edible coatings to maintain quality of fresh-cut fruits and vegetables[J]. Critical Reviews in Food Science and Nutrition, 2018, 58(4): 662-679. DOI:10.1080/10408398.2016.1211087.

[84] WANG Fengping, ZHANG Huijun, JIN Wwengang, et al. Effects of tartary buckwheat polysaccharide combined with nisin edible coating on the storage quality of tilapia (Oreochromis niloticus) fillets[J]. Journal of the Science of Food and Agriculture, 2018, 98(8): 2880-2888. DOI:10.1002/jsfa.8781.

[85] HAGER J V, RAWLES S D, XIONGYouling, et al. Listeria monocytogenes is inhibited on fillets of cold-smoked sunshine bass, Morone chrysops × Morone saxatilis, with an edible corn zein-based coating incorporated with lemongrass essential oil or nisin[J]. Journal of the World Aquaculture Society, 2019, 50(3): 575-592. DOI:10.1111/jwas.12573.

[86] GUERRERO A, FERRERO S, BARAHONA M, et al. Effects of active edible coating based on thyme and garlic essential oils on lamb meat shelf life after long-term frozen storage[J]. Journal of the Science of Food and Agriculture, 2019, 100(2): 656-664. DOI:10.1002/jsfa.10061.

[87] RUAN Chengcheng, ZHANG Yumeng, SUN Yue, et al. Effect of sodium alginate and carboxymethyl cellulose edible coating with epigallocatechin gallate on quality and shelf life of fresh pork[J]. International Journal of Biological Macromolecules, 2019, 141: 178-184. DOI:10.1016/j.ijbiomac.2019.08.247.

[88] XIONG Yun, LI Shumin, WARNER R D, et al. Effect of oregano essential oil and resveratrol nanoemulsion loaded pectin edible coating on the preservation of pork loin in modified atmosphere packaging[J]. Food Control, 2020, 114: 107226. DOI:10.1016/j.foodcont.2020.107226.

[89] XIONG Yun, CHEN Meng, WARNER R D, et al. Incorporating nisin and grape seed extract in chitosan-gelatine edible coating and its effect on cold storage of fresh pork[J]. Food Control, 2020, 110: 10718. DOI:10.1016/j.foodcont.2019.107018.

[90] OZVURAL E B. Fabrication of olive leaf extract and hazelnut skin incorporated films to improve the quality of nuggets during refrigerated and deep freeze storage[J]. British Poultry Science, 2019, 60(6): 708-715. DOI:10.1080/00071668.2019.1656799.

[91] SHANKAR S, DANNEELS F, LACROIX M. Coating with alginate containing a mixture of essential oils and citrus extract in combination with ozonation or gamma irradiation increased the shelf life of Merluccius sp. fillets[J]. Food Packaging and Shelf Life, 2019, 22: 100434. DOI:10.1016/j.fpsl.2019.100434.

[92] SHIN J M, GWAK J W, KAMARAJAN P, et al. Biomedical applications of nisin[J]. Journal of Applied Microbiology, 2016, 120(6): 1449-1465. DOI:10.1111/jam.13033.

[93] MOHAMMADI H, KAMKAR A, MISAGHI A, et al. Nanocomposite films with CMC, okra mucilage, and ZnO nanoparticles: extending the shelf-life of chicken breast meat[J]. Food Packaging and Shelf Life, 2019, 21: 100330. DOI:10.1016/j.fpsl.2019.100330.

[94] GAO Wenhong, HUANG Yangping, ZENG Xinan, et al. Effect of soluble soybean polysaccharides on freeze-denaturation and structure of myofibrillar protein of bighead carp surimi with liquid nitrogen freezing[J]. International Journal of Biological Macromolecules, 2019, 135: 839-844. DOI:10.1016/j.ijbiomac.2019.05.186.

[95] XIONG Guangquan, CHENG Wei, YE Lixiu, et al. Effects of konjac glucomannan on physicochemical properties of myofibrillar protein and surimi gels from grass carp (Ctenopharyngodon idella)[J]. Food Chemistry, 2009, 116(2): 413-418. DOI:10.1016/j.foodchem.2009.02.056.

[96] LIU Xiaoyue, XIONG Guangquan, WANG Xiaohong, et al. Quality changes of prepared weever (Micropterus salmoides) by base trehalose solution during repeated freeze-thaw cycles[J]. Journal of Food Processing and Preservation, 2019, 43(10): e14117. DOI:10.1111/jfpp.14117.

[97] ZHANG Bin, HAO Guijuan, CAO Huijuan, et al. The cryoprotectant effect of xylooligosaccharides on denaturation of peeled shrimp (Litopenaeus vannamei) protein during frozen storage[J]. Food Hydrocolloids, 2018, 77: 228-237. DOI:10.1016/j.foodhyd.2017.09.038.

[98] MA Lukai, ZHANG Bin, DENG Shanggui, et al. Comparison of the cryoprotective effects of trehalose, alginate, and its oligosaccharides on peeled shrimp (Litopenaeus vannamei) during frozen storage[J]. Journal of Food Science, 2015, 80(3): C540-C546. DOI:10.1111/1750-3841.12793.

[99] XIE Chao, ZHANG Bin, MA Lukai, et al. Cryoprotective effects of trehalose, alginate, and its oligosaccharide on quality of cooked-shrimp (Litopenaeus vannamei) during frozen storage[J]. Journal of Food Processing and Preservation, 2017, 41(2): e12825. DOI:10.1111/jfpp.12825.

[100] ENGLISH M M, KEOUGH J M, MCSWEENEY M B, et al. Impact of a novel cryoprotectant blend on the sensory quality of frozen lobster (Homarus americanus)[J]. Journal of Food Science, 2019, 84(6): 1547-1553. DOI:10.1111/1750-3841.14642.

[101] ZHANG Bin, YAO Hui, QI He, et al. Cryoprotective characteristics of different sugar alcohols on peeled Pacific white shrimp (Litopenaeus vannamei) during frozen storage and their possible mechanisms of action[J]. International Journal of Food Properties, 2020, 23(1): 95-107. DOI:10.1080/10942912.2019.1710533.

[102] PURNELL G, JAMES C, JAMES S J, et al. Comparison of acidified sodium chlorite, chlorine dioxide, peroxyacetic acid and tri-sodium phosphate spray washes for decontamination of chicken carcasses[J]. Food and Bioprocess Technology, 2014, 7(7): 2093-2101. DOI:10.1007/s11947-013-1211-8.

[103] 江艷华, 许东勤, 姚琳, 等. 噬菌体复配抑菌剂对三文鱼中沙门氏菌的抑制与保鲜作用[J]. 农业工程学报, 2018, 34(16): 287-293. DOI:10.11975/j.issn.1002-6819.2018.16.037.

[104] 由高铭, 陈欣然, 赵前程, 等. 抑菌剂浸泡液对冷藏高白鲑鱼肉腐败菌的抑制效果[J]. 水产科学, 2018, 37(5): 584-590. DOI:10.16378/j.cnki.1003-1111.2018.05.002.

[105] MOHAMED T M, PARVEEN S, LUDWIG J B, et al. Chlorine inactivation of Salmonella kentucky isolated from chicken carcasses: evaluation of strain variation[J]. Journal of Food Protection, 2015, 78(2): 414-418. DOI:10.4315/0362-028x.Jfp-14-379.

[106] RAHMAN U U, SAHAR A, PASHA I, et al. Augmenting quality and microbial safety of broiler meat at refrigeration storage by applying chemical interventions[J]. Journal of Food Processing and Preservation, 2017, 41(4): e13030. DOI:10.1111/jfpp.13030.

[107] CUI Haiying, ZHANG Xuejing, ZHOU Hui, et al. Antibacterial properties of nutmeg oil in pork and its possible mechanism[J]. Journal of Food Safety, 2015, 35(3): 370-377. DOI:10.1111/jfs.12184.

[108] XU Feng, WANG Chunxing, WANG Hongfei, et al. Antimicrobial action of flavonoids from Sedum aizoon L. against lactic acid bacteria in vitro and in refrigerated fresh pork meat[J]. Journal of Functional Foods, 2018, 40: 744-750. DOI:10.1016/j.jff.2017.09.030.

[109] LU Hao, SHAO Xingfeng, CAO Jinxuan, et al. Antimicrobial activity of eucalyptus essential oil against Pseudomonas in vitro and potential application in refrigerated storage of pork meat[J]. International Journal of Food Science and Technology, 2016, 51(4): 994-1001. DOI:10.1111/ijfs.13052.

[110] BOSKOVIC M, DJORDJEVIC J, IVANOVIC J, et al. Inhibition of Salmonella by thyme essential oil and its effect on microbiological and sensory properties of minced pork meat packaged under vacuum and modified atmosphere[J]. International Journal of Food Microbiology, 2017, 258: 58-67. DOI:10.1016/j.ijfoodmicro.2017.07.011.

[111] LOU Zaixiang, LI Cheng, KOU Xingran, et al. Antibacterial, antibiofilm effect of burdock (Arctium lappa L.) leaf fraction and its efficiency in meatpreservation[J]. Journal of Food Protection, 2016, 79(8): 1404-1409. DOI:10.4315/0362-028x.Jfp-15-576.

[112] SOHAIB M, ANJUM F M, ARSHAD M S, et al. Postharvest intervention technologies for safety enhancement of meat and meat based products; a critical review[J]. Journal of Food Science and Technology-Mysore, 2016, 53(1): 19-30. DOI:10.1007/s13197-015-1985-y.

[113] DE SOUZA DE AZEVEDO P O, CONVERTI A, GIERUS M, et al. Application of nisin as biopreservative of pork meat by dipping and spraying methods[J]. Brazilian Journal of Microbiology, 2019, 50(2): 523-526. DOI:10.1007/s42770-019-00080-8.