Evaluation of the toxic effects of ammonia dispersion:consequence analysis of ammonia leakage in an industrial slaughterhouse

2021-03-03MohsenSadeghiYarandiMohsenMahdiniaJavadBarazandehAhmadSoltanzadeh

Mohsen Sadeghi Yarandi,Mohsen Mahdinia,Javad Barazandeh,Ahmad Soltanzadeh,

1 Department of Occupational Health Engineering,School of Public Health,Tehran University of Medical Sciences,Tehran,Iran

2 Department of Occupational Safety & Health Engineering,Faculty of Health,Research Center for Environmental Pollutants,Qom University of Medical Sciences,Qom,Iran

Abstract Ammonia is a toxic compound and has many toxic effects on humans and the environment.This study was designed to model the consequences of ammonia leakage in an industrial slaughterhouse.Given the potential hazard of ammonia,only the toxic dimension of this gas was evaluated.The scenarios were evaluated in the worst possible condition and in the case of the complete rupture.Findings showed that in case of a catastrophic rupture scenario in reservoir 1 in the first and second 6 months of the year,the distances of 920.37 and 569.38 m from the reservoir in the wind direction were at Emergency Response Planning Guidelines,level 3 (ERPG3),respectively.In reservoir 2,in the first and second 6 months of the year,the distances of 699.58 and 384.86 m from the reservoir were at the ERPG3 level,respectively.In reservoir 3,in the first and second 6 months of the year,the distances of 203.48 and 748.28 m from the reservoir were at the ERPG3 level,respectively.Examination of the probit values showed that in reservoirs 1 and 2,the probit values were more than 4.28 up to 100 m from the reservoirs,and in the reservoir 3,the mortality rates were lower.The findings revealed that the catastrophic rupture of ammonia reservoirs in the studied slaughterhouse and the release of ammonia could lead to the fatality of large numbers of people in ERPG2 and ERPG3 areas.Therefore,it is necessary to take control measures to reduce the vulnerability against such accidents.

Key words:ammonia; consequence modeling; gas dispersion; health effect; industrial slaughterhouse; PHAST software; probit; toxic

INTRODUCTION

Ammonia is the most important nitrogen hydrogen compound in nature and is obtained from the decomposition of nitrogenous organic matter.Ammonia is a colorless gas,with an extremely pungent taste that is tearful and suffocating.Ammonia gas is lighter than air and easily liquefied.Ammonia is highly soluble in water and freezes at -77.7°C and boils at-33.3°C.Ammonia gas is highly ignitable with an ignition limit of about 15.4-33.6 of volume percent of ammonia gas in the air.Ammonia gas decomposes at temperatures above 400°C to produce hydrogen.Ammonia irritates the respiratory tract,skin,and eyes,and can cause death by damaging the lungs due to exposure to large volumes of the gas.1-3Ammonia is used in ice factories,in making fertilizers such as nitrate,sulfate and ammonium phosphate,nitric acid,drugs and explosives.4Ammonia is used as a refrigerant due to its special thermodynamic properties (due to its ability to transfer heat to other compounds).This material is especially effective in the range of 0 to 30°C and is therefore widely used for food preservation.5The American Conference of Governmental Industrial Hygienists announced that the allowable timeweight average and short-term exposure limit for ammonia are 25 and 35 ppm,respectively.Furthermore,there is not any 50% lethal dose (LD50) for ammonia exposure for humans.Only,the LD50 and 50% lethal concentration (LC50) value that calculated for rat are 350 mg/kg and 2000 ppm (4 hours).6

Ammonia gas is toxic and flammable and can be exacerbated if other flammable agents,such as petroleum-based gases or oxidizing substances such as oxygen gas or high-reactivity compounds such as chlorine gas,bromine and iodine,are present.Ammonia gas is dangerous even at low concentrations,inhaling ammonia or contaminating the skin surface can cause burning and even death.7,8

The development and implementation of ammonia reservoirs in various projects and various industrial organizations with different industrial goals will have serious risks in the field of safety,health and the environment.Therefore,today,a prevention-based approach has been welcomed through risk identification and evaluation.The results of past events have shown that accidents in these reservoirs and related industries are generally catastrophic and cause irreparable human,environmental and economic damage.A careful study of major accidents shows that a large proportion of the likelihood of occurrence and the resulting damage was only predictable and preventable,provided that at least engineering analyzes such as consequential modeling and quantitative risk assessment were performed on time.9Evaluation of quantitative risk and consequential modeling is one of the most important ways to investigate the extent of the effect and estimate the toxic effects of releasing toxic substances into the environment.10

One of the areas where ammonia gas is widely used is industrial slaughterhouses.In these slaughterhouses,fixed ammonia refrigerators are used to preserve perishable materials(mainly meat).Ammonia refrigerators are a collection of buildings and equipment that can meet the special storage conditions of food and perishables,mainly in terms of temperature,relative humidity,and other necessary conditions using ammonia.According to the above-mentioned,the use of ammonia gas,due to its toxic nature,can lead to many losses and damages.Therefore,to reduce the risk of such chemical accidents,it is necessary to assess the likelihood of their occurrence and severity.In this regard,and due to the lack of similar studies in this field,this study has been designed and conducted to analyze the consequences of leakage from ammonia reservoirs,determining the main scenarios of their release,determining the probability of occurrence and modeling its consequences in an industrial slaughterhouse.

MATERIALS AND METHODS

Design

The present study was conducted to evaluate the human vulnerability caused by chemical accidents in 2019 in a large industrial slaughterhouse.In this study,after examining the process,records of previous accidents,and using the opinions of experts and specialists,the existing risk centers were identified.In the next step,estimation and modeling of the possible consequences of the selected scenarios were performed using Process Hazard Analysis Software Tool (PHAST) 7.2 software.In the present study,different stages of outcome assessment were implemented.The first step was to identify the site and evaluate the main systems,safety systems,review the history of accidents and near-miss,as well as gather the opinion of experts.After collecting the required information,the risk centers were identified in terms of process risks,which took the second stage of this project.The identified risk hotspots paved the way for the extraction of scenarios for further investigation,as well as the assessment and modeling of the consequences of the associated risks with these scenarios.Then,in the third stage of the study,the causes of dangerous material leaks from risk centers were determined and evaluated in terms of quantity and quality.In the fourth step,process risks were modeled using PHAST 7.2 software and its consequences were evaluated.In this study,the outcome was the level of human vulnerability and the share of human casualties was determined by the occurrence of selected scenarios.

Identifying and collecting information on studied industrial units

Due to the potential hazard of ammonia gas and the widespread use of this gas in the studied slaughterhouse,the reservoirs containing ammonia gas were selected as the center of danger.Given the potential damage of this material,only the toxic dimension of this gas was evaluated in this study.After getting acquainted with the process and operations in the industrial slaughterhouse,examining the history of accidents,interviewing employees and especially safety officials and reviewing documents,the risk centers in the site were identified in terms of the risk of toxic leaks (ammonia reservoirs).

Choosing the worst case scenarios

Scenarios are often considered to be leaks or possible ruptures in equipment.In this study,due to the importance of human vulnerability,scenarios were evaluated in the worst possible condition.For this purpose,complete rupture of the reservoir and complete leakage of materials out of the building (if there is a reservoir inside the building) were evaluated.In each case,the ammonia concentration was determined based on the Emergency Response Planning Guidelines (ERPG)criterion and plotted.11It was found that the levels of ERPG1,ERPG2,and ERPG3 for ammonia were 25,150,and 750 ppm,respectively.11

Determining the climatic conditions of the environment

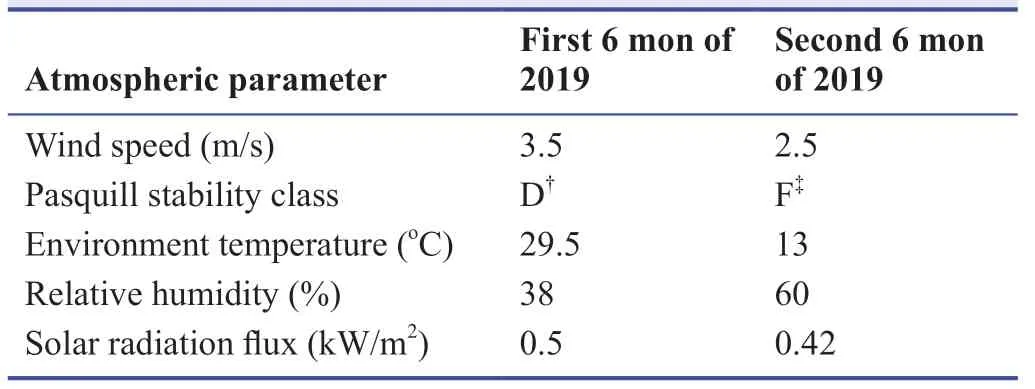

At this stage,all the physical conditions affecting the possible consequences were identified.For each scenario,factors that affect how the scenario was formed and developed were identified separately.These factors play a key role in choosing the right model and analyzing the consequences.The required climatic parameters for dispersion modeling include average ambient temperature,wind speed and direction,atmospheric stability class,ground unevenness,and relative humidity.Climatic conditions were chosen to indicate the average conditions in a one-year time period or a period of operational equipment.Climatic parameters belong to Qom Province in Iran,which was collected in December 9,2019.12The required information in this section was extracted from the nearest station of the meteorological organization of the region.Based on the identified hazards,the modeling for the industrial slaughterhouse consisted of 3 reservoirs containing ammonia in two summer weather conditions (representing the average weather conditions of the first 6 months of the year) and winter (representing the average of the second 6 months of the year).Due to the noticeable change in climatic parameters (such as wind speed and air temperature) in the first and last 6 months of the year,as well as the significant effect of wind speed on the concentration profile created by ammonia,two weather conditions were studied.The results of the present study also revealed that climatic conditions are a very important factor in the danger zone created by the catastrophic rupture of reservoirs (Table 1).

Modeling the toxic chemicals’ effects

Models of the effects of toxic substances calculate the effect of these substances on humans or affected areas.In other words,the purpose of modeling toxic effects is to assess the health effects of toxic compounds on people who are exposed to a particular concentration of toxic gas over a period of time and,if possible,to estimate the extent of the damage or mortality.Outputs of toxic effects analysis are usually the identification of populations at risk and the percentage of individuals who may be affected by exposure to a certain concentration of toxic gas.13

Modeling the consequence using PHAST software

The models provided by PHAST 7.2 software are one ofthe best models for modeling the release of materials in the environment.This model covers a wide range of lighter and heavier materials than air and also can model a mixture of materials.This software was developed by Det Norske Veritas Company (Akershus,Norway) and is known as one of the decision-making tools in the analysis of industrial hazards.This software complies with many international regulations and is widely used.14,15Features of this software include a powerful database of simulation materials and models,the ability to define a mixture of materials,the ability to adapt to a map,and the ability to draw time-varying graphs.16The software is capable of modeling a variety of scenarios,including rupture of storage reservoirs,rupture of pipelines,rupture of torn plates,leakage,failure of reservoir roofs,modeling of long pipelines,the opening of safety valves,etc.10All modeling steps in the present study were performed using PHAST 7.2 software.Gaussian models have been used to model gas emissions in PHAST software.In this model,it is assumed that the concentration profile of the diffused material in the direction perpendicular to the wind direction is in the form of a normal Gaussian function.These models are used to analyze the consequences of accidents due to their simplicity and high accuracy in predicting the concentration profile of released materials.17

Table1:Average of atmospheric parameters in Qom Province,Iran

Investigating the effects of toxicity and determining the mortality rate due to ammonia emissions

The effects of toxic gas depend on the concentration and duration of exposure.One way to predict the probability or percentage of mortality from exposure to toxic gases is to use the probit equation.The numerical value of the probit is between 0 and 8,and the larger the number,the more likely it is that people will die.To calculate the probit values through the present study,the following equation was used18:

Where,Cis the concentration,tis the time of exposure per minute,K1,K2and n are the constant coefficients for each chemical.The values of K1,K2and n for ammonia are -9.82,0.71 and 2 respectively.18

RESULTS

The results of the process conditions of the three ammonia reservoirs of the studied industrial slaughterhouse are presented in Table2.

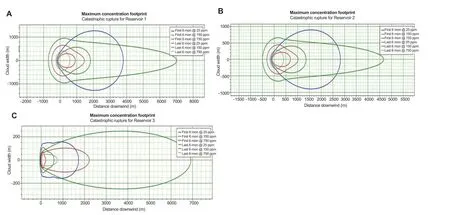

The area affected by the ammonia leak due to the catastrophic rupture of the reservoir is presented in Figure1.In each figure,three areas are identified by 750 ppm (ERPG-3 is the maximum airborne concentration below which nearly all individuals could be exposed for up to one hour without experiencing or developing life-threatening health effects),150 ppm (ERPG-2 is the maximum airborne concentration below which nearly all individuals could be exposed for up to one hour without experiencing or developing irreversible or other serious health effects or symptoms which could impair an individual’s ability to take protective action),and 25 ppm (ERPG-1 is the maximum airborne concentration below which nearly all individuals could be exposed for up to one hour without experiencing more than mild,transient adverse health effects or without perceiving a clearly defined objectionable odor).8,11

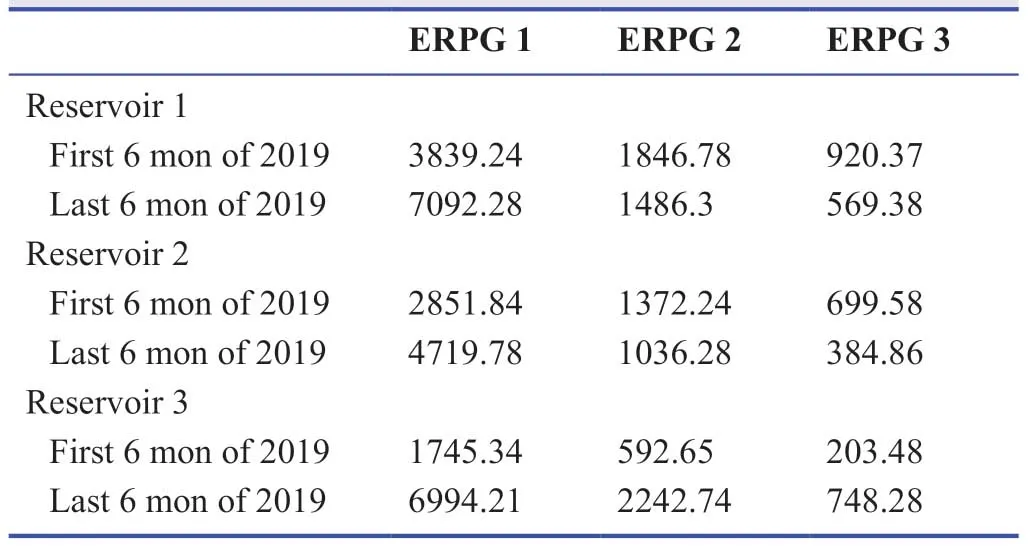

The distances affected around the reservoirs in case of a catastrophic rupture and ammonia dispersion according to ERPGlevels for two climatic conditions are presented in Table3.

Table2:Process conditions of ammonia reservoirs in the studied industrial slaughterhouse

Figure1:The area affected by ammonia leak in case of a catastrophic rupture in the reservoir (both in summer and winter climatic).

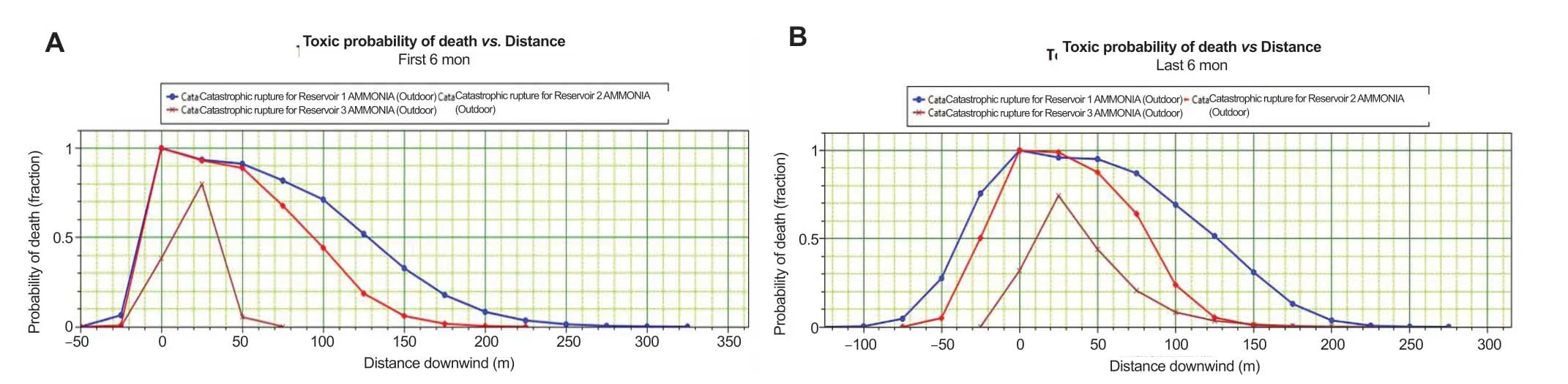

Evaluating the toxic probability of death (ratios) in the case of reservoirs rupture and ammonia leak showed that the highest mortality rate was for reservoir 1 rupture.So that,in case of an ammonia leak in reservoir 1 during the first 6 months of the year at distances 0,190,260 and 300 m from the reservoir,the probability of death (fraction) would be 0.99,0.1,0.01 and 0.001 respectively,and during the second 6 months of the year at distances 0,183,261,and 319 m from the reservoir,the probability of death (fraction) would be 0.99,0.1,0.01,and 0.001 respectively.Other mortality rates for ammonia leakage are given in terms of distance from reservoirs in both climatic conditions in Figure2.

The findings of concentration values over time showed that in reservoir 1,immediately after rupture,the concentration was 896,783 ppm.In seconds 186,the concentration reaches 750 ppm.At seconds 386 it reaches 150 ppm,and finally at seconds 2886 after rupture of reservoir,the concentration reaches zero.In reservoir 2,immediately after rupture,the concentration was 560,364 ppm.In seconds 145,the concentration reaches 750 ppm.At seconds 296 it reaches 150 ppm,and finally at seconds 2316 after the rupture of reservoir,the concentration reaches zero.Finally,in reservoir 3,immediately after rupture,the concentration was 636,241 ppm.In seconds 50,theconcentration reaches 750 ppm.At seconds 65 it reaches 150 ppm,and finally at seconds 481 after the rupture of reservoir,the concentration reaches zero.

Table3:The distances affected around the reservoirs in the direction of the wind (m) in case of a catastrophic rupture and ammonia leak according to ERPG levels

The results of investigating the probit values in case of reservoirs catastrophic rupture and ammonia leak based on the distance from the reservoirs are presented in Table4.

Investigating the calculated probit values showed that in reservoirs 1 and 2,the number of probit up to 100 m from the reservoirs was more than 4.28 and in the case of reservoir 3,due to the less volume of ammonia,death rates were lower.According to the findings,the highest death rate was for reservoirs 1 and 2.It was also found that in case of the occurrence of the studied scenario,vast areas around the slaughterhouse,including highways and nearby industries,could be affected by the concentration range of 750 ppm or ERPG3 levels (Figure3).

DISCUSSION

Small and medium-sized industries for various reasons,such as the lack of an efficient safety and health management system,poor quantitative and qualitative monitoring of regulatory bodies,and insufficient information from managers and workers about the health risks and threats of each chemical compound are at high risk of various health and safety consequences.19,20Due to the very serious effects of ammonia toxicity on human health,the framework of the present study was designed to investigate and model the toxic effects of ammonia leakage in the worst-case scenario (catastrophic rupture) in two climatic conditions (first 6 months and second 6 months of the year).The results of a study by Orozco et al.11also showed that the main risk of ammonia leakage is related to the formation of toxic vapor cloud of this compound and the risk of consequences such as fire and explosion is much lower.

Findings from the study of the created concentration profile in case of reservoir rupture according to the ERPG levels showed that in reservoir 1,during the first and last 6 months of the year,respectively,up to the distances of 920.37 and 569.38 m from the reservoir in the direction of the wind,it was in ERPG level or 750 ppm,which is a lethal range for concentration.The findings show that in the first 6 months of the year,more distances can be within the ERPG3 range,and that the studied scenario in this time period could be far more dangerous than the last 6 months of the year.Among the reasons for this are different climatic conditions and higherwind speeds,resulting in more displacement of air layers.The findings of Tan et al.’s study on the simulation of ammonia emissions in the environment showed that wind speed is the most important parameter in determining the amount and range of ammonia dispersion.5It was also found that in the first 6 months of the year,the distances of 1846.78 and 3839.24 m from the reservoir were at the levels of ERPG2 and ERPG1,respectively,and in the last 6 months of the year,the distances of 1486.30 and 7092.28 m from the reservoir were in the range of ERPG2 and ERPG1 levels,respectively.

Table4:Average probit values in case of catastrophic rupture of reservoirs 1-3 according to the distance from the reservoirs (in the wind direction)

Figure2:Probability of death based on the distance from the reservoir due to ammonia leakage from reservoirs 1-3 in case of a catastrophic rupture.

Figure3:Areas affected by the ERPG3 concentration range if ammonia is released at the study site.

Findings from the study of the concentration profile created in case of rupture of reservoir 2 revealed in the first and last 6 months of the year,the distances of 699.58 and 384.86 m from the reservoir in the direction of wind at the ERPG3 level or the concentration range of 750 ppm,respectively.That is similar to reservoir 2,but with less effect range.

The results of the dispersion modeling of ammonia in reservoir 3 also showed that in the first and last 6 months of the year,up to the distances of 203.48 and 748.28 m from the reservoir,respectively,in the wind direction it is at ERPG3 level.All of the above indicates that in case of a catastrophic rupture of the reservoirs,large areas around the reservoirs are affected by ERPG3 and ERPG2 levels,and the presence of individuals in these areas can lead to death or severe toxicity.It was found that the affected areas in reservoir 1 are wider due to the higher capacity of the reservoir and the effects of the ammonia release from this reservoir are much more severe.The results of previous studies have also shown that the release of ammonia from reservoirs can contaminate large areas and lead to the death of many people in the ERPG3 region,8,9,11which is consistent with the results of the present study.Findings in Figure3 show that in the event of a studied scenario (especially in the case of reservoir 1),even highways and industries around the study site will be in the concentration range of 750 ppm and ERPG3 levels.Due to the high volume of traffic on the highway,as well as a large number of employees in the surrounding industries,the release of ammonia can lead to irreparable damage.

Investigating the probability of death of people in case of reservoirs rupture and ammonia leakage showed that in case of ammonia leakage from reservoir 1 in the first 6 months of the year at distances of 0,190,260 and 300 m from the reservoir,the probability of death was 0.99,0.1,0.01 and 0.001,and in the second 6 months of the year at distances of 0,183,261 and 319 m from the reservoir,the probability of death was 0.99,0.1,0.01 and 0.001,respectively.In case of leakage from reservoir 2 in the first 6 months of the year at distances of 0,142,188 and 224 m from the reservoir,the probability of death was 0.99,0.1,0.01 and 0.001,respectively,and in the second 6 months of the year in the distances of 0,118,148 and 175 m from the reservoir,the probability of death was 0.99,0.1,0.01 and 0.001 respectively.Finally,the obtained results showed that in case of ammonia leakage from reservoir 3 in the first 6 months of the year at 0,25,50 and 75 m from the reservoir,the mortality rate was 0.38,0.79,0.05 and 0.00076,respectively and in the second 6 months of the year at distances of 0,25,50 and 223 m from the reservoir,the mortality rate was 0.39,0.74,0.44 and 0.001,respectively.Investigating the calculated probit values showed that in reservoirs 1 and 2,the number of probit up to 100 m from the reservoirs was more than 4.28 and in the case of reservoir 3,due to the less volume of ammonia,death rates were lower.According to the findings,the highest death rate was for reservoirs 1 and 2.

According to the findings,the highest mortality rate was in reservoirs 1 and 2.Among the reasons for this is the larger volume of ammonia as well as the greater pressure inside the reservoir.The release of ammonia gas into the environment,due to its toxic nature,can have many negative effects on individuals and the environment.Previous studies have shown that there have been many incidents of ammonia leaks around the world in recent decades.In 2010,for example,a leak of ammonia gas from tanks in an ice factory poisoned 120 employees.In 2013,an ammonia leak at a food factory in China killed 120 people and poisoned more than 60 employees.5 Many studies on the modeling of the consequences of the ammonia dispersion in the environment and its toxicity have shown the importance of this issue.5,11

Today,the expansion of the human population leads to the expansion of urban borders.On the other hand,leads to the growing human need for energy resources,as well as the expansion of various industries.This issue leads to the proximity of urban and industrial borders over time.One of the most important consequences of this proximity is the location of residential areas in the danger zone,as well as the increase in casualties in the event of an accident.

Given the high potential of ammonia gas in accidents,as well as the high intensity of the consequences of possible accidents,one of the most important strategies to reduce the human consequences of such catastrophic accidents is to predict risk limits and determine the maximum progress of urban borders to industries.The results of the present study also showed that industrial slaughterhouses,due to the high production of raw meat per day and the need to keep meat under low temperatures,are one of the most dangerous sources of ammonia gas emissions to neighboring areas in case of catastrophic accidents.Such incidents can lead to high toxicity to humans and the environment,as well as high mortality rates.The findings of the study could provide a novel inside on the scope of losses and damages caused by the release of ammonia gas in industries with cooling chambers,such as industrial slaughterhouses.One of the limitations of the present study is the inability of PHAST software to model domino events.In this study,the simultaneous rupture of three studied reservoirs can cause a significant amount of ammonia to be released.Therefore,it is recommended that researchers review and model the release of ammonia gas with other software in the future.

The findings of the present study revealed that the catastrophic rupture of ammonia reservoirs in the studied slaughterhouse and the release of ammonia could lead to the fatality of large numbers of people in ERPG2 and ERPG3 areas.Therefore,the following control measures can be an effective step to reduce the vulnerability against such accidents:

Installing detectors at regular intervals to detect leaks in a timely manner,developing preventive measures and risk-based control according to the results of consequence modeling,developing a crisis management program,developing a program dedicated training to reduce the risk of unsafe behaviors of people and personnel involved in related industries,conducting experimental maneuvers to increase employee awareness,relocating staff to safer areas,monitoring and continuous technical inspection of equipment and determining the maximum expansion of urban boundaries.

Acknowledgements

The authors would like to express their special thanks to Qom University of Medical Sciences for management and personnel of studied industrial slaughterhouse for their contribution to the present study.

Author contributions

MSY collected the data,drafted and edited the manuscript.AS designed the study and performed critical reversion of manuscript for important intellectual content,administrative and technical support.MM and JB performed consequence modeling and interpretation of data.All authors read and approved the final version of the manuscript.

Conflicts of interest

The authors declare that they have no conflict of interest.

Financial support

This work was supported by Qom University of Medical Sciences,No.772,2019.

Institutional review board statement

This study was the result of a research project with ethics code of IR.MUQ.REC.1398.108 which was sponsored by Qom University of Medical Sciences.

Copyright transfer agreement

The Copyright License Agreement has been signed by all authors before publication.

Data sharing statement

Datasets analyzed during the current study are available from the corresponding author on reasonable request.

Plagiarism check

Checked twice by iThenticate.

Peer review

Externally peer reviewed.

Open access statement

This is an open access journal,and articles are distributed under the terms of the Creative Commons Attribution-NonCommercial-ShareAlike 4.0 License,which allows others to remix,tweak,and build upon the work non-commercially,as long as appropriate credit is given and the new creations are licensed under the identical terms.

杂志排行

Medical Gas Research的其它文章

- High-flow hydrogen inhalation might suppresses the immune function of middle-aged participants:a selfcontrolled study

- The effect of dexmedetomidine on decrease of cough,hemodynamic parameters and Ramsay score versus lidocaine during general anesthesia:a randomized clinical trial

- Evaluation of audible leak versus pressure volume loop closure for polyvinyl chloride cuff and polyurethane microcuff in endotracheal tube inflated with air:a prospective randomized study

- The role of nitric oxide in peptic ulcer:a narrative review

- Therapeutic effects of hyperbaric oxygen:integrated review

- A new mechanistic approach for the treatment of chronic neuropathic pain with nitrous oxide integrated from a systems biology narrative review