Mechanical Properties of Glass Fiber/Unsaturated Polyester Resin Composite Water Collector

2021-04-08XIONGYanping熊艳平QIULiNANYanmin南延民LONGTianyu龙天瑜

XIONG Yanping(熊艳平), QIU Li(邱 莉), NAN Yanmin(南延民), LONG Tianyu(龙天瑜)

College of Textile and Light Industry, Inner Mongolia University of Technology, Hohhot 010080, China

Abstract: The water collector is operated in the humid and hot environment of the cooling tower all the year round. It also needs to carry part of the weight of water and silt. Therefore, it is particularly critical to optimize the material of the water collector and improve its mechanical properties. Polyester, a general term of polymer obtained from polyols and polyacids, is a kind of engineering plastics with excellent properties and wide applications. Glass fiber is a reinforced plastic reinforcement material, and the biggest characteristic of it is the high tensile strength and good heat resistance. In this paper, glass fiber reinforced polyester resin composite material is prepared, its tensile properties and bending properties are tested, and the performance of the imported material JK2020B is compared and analyzed. The results show that the elastic modulus along the fiber direction is relatively high, but the interlayer force in the direction of thickness and width is very small. This review provides a guidance for production process.

Key words: glass fiber; unsaturated polyester resin; composite material; water collector; mechanical property

Introduction

In recent years, water resources have been one of the focuses of social concern, but its recycling is worth studying. In China, 60% of the urban water is industrial water, and cooling water accounts for four-fifths of it[1]. In the thermal power industry, all the water consumed by factories is basically cooling water[2]. Data show that the current recycling rate of water resources in China is lower than 60% of that in developed countries. Therefore, the reuse of circulating cooling water is the key to industrial water-saving. As an important water-saving device in the cooling tower, the material properties of the water collector directly determine the water collecting effect[3].

Glass fiber has been recognized as the most common reinforcing material in industrial production due to its excellent properties such as high specific strength, high specific modulus, and strong design ability after strengthening composite materials[4]. Polyester belongs to the polymer compound, which is made up of terephthalic acid and ethylene glycol through polycondensation produce polyethylene terephthalate (PET). Part of the PET again eventually generated by underwater pelletizing is a kind of crystallization speed is quick, good electric insulation and weather resistance, excellent mechanical properties of engineering plastics, but because of its poor stability, sensitive gap size, lead to some of its applications are limited[5-11].

The factors affecting the mechanical properties of glass fiber reinforced unsaturated polyester resin composites include the type and amount of matrix and glass fiber, the interface between the matrix and glass fiber and the molding method[12-14]. Lietal.[15]used the modified polyvinyl chloride resin (PVC) material and applied it to the special water collector for seawater cooling towers. By designing the material of the water collector, the floating rate was significantly reduced.

In this paper, the glass fiber reinforced unsaturated polyester resin was used to prepare composite materials, the mechanical properties of the composite materials were tested, and the bending properties of imported materials JK2020B were compared and analyzed.

1 Experiments

1.1 Material selection

In this study, glass fiber unsaturated polyester resin composite material was selected, in which unsaturated resin system was used as the matrix, glass cloth was used as the reinforcing material, and the control group was used as the imported material JK2020B.

1.2 Sample preparation

1.2.1Preparationoftensilesamples

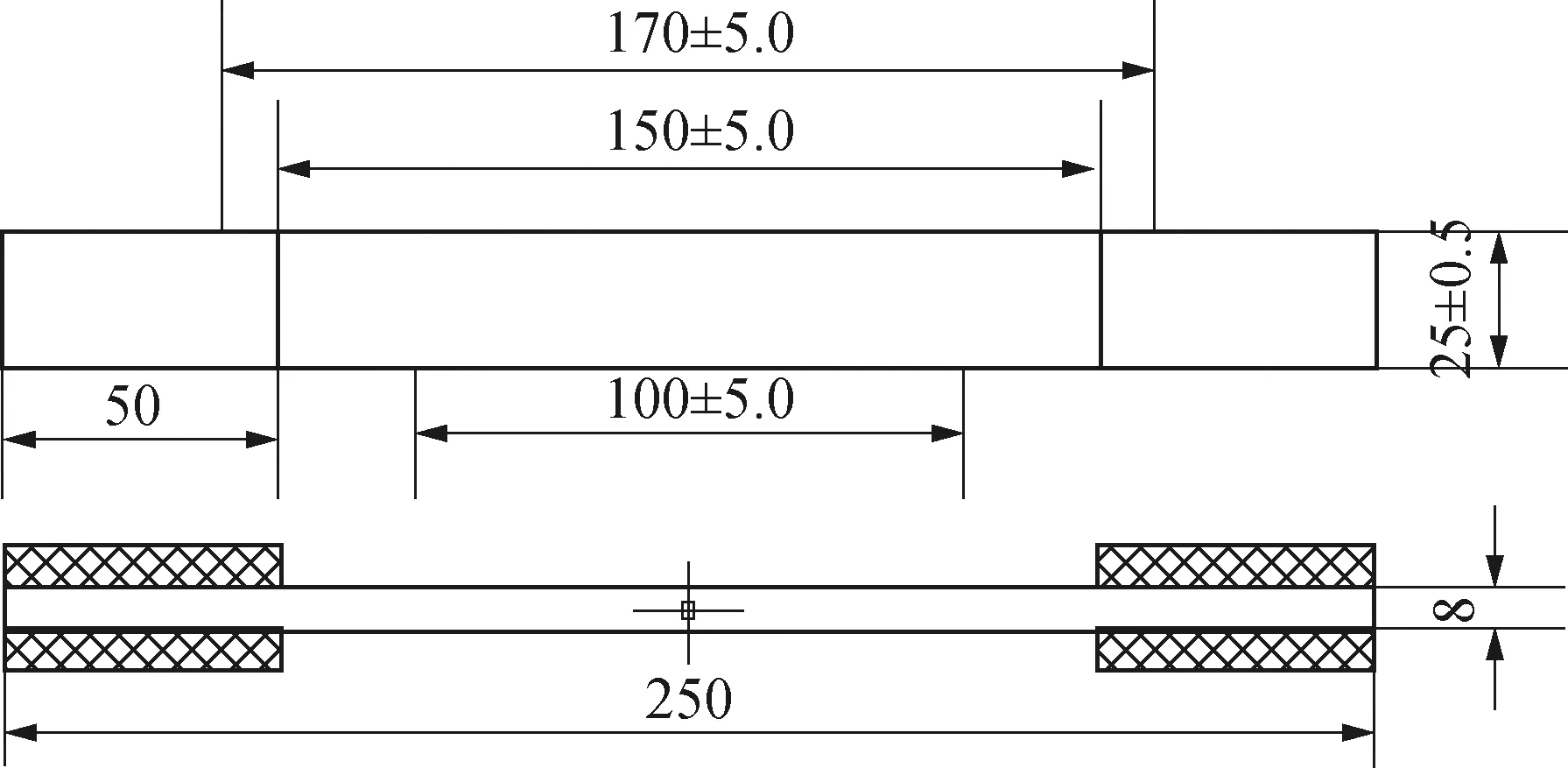

Tensile samples prepared to use the injection molding machine, specimen type and dimensions as shown in Fig. 1. The sample length is 250 mm, the width is (25±0.5) mm, and the thickness is 8 mm; the reinforcing sheet length is 50 mm, width is (25±0.5) mm, and the thickness is 8 mm. The tensile stress, tensile modulus, elongation at break and stress-strain are measured.

1.2.2Preparationofbendingsamples

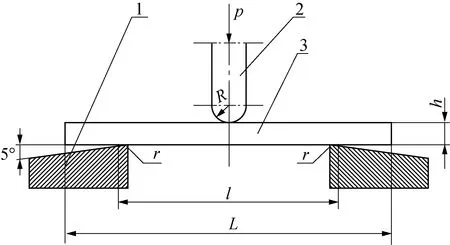

The bending samples are also prepared by injection molding machine. The sample type and size are shown in Fig. 2, the sample length 80 mm, width of (15±0.5) mm, a thickness of (4±0.2) mm, measured tensile stress, tensile modulus, elongation at break and stress-strain curve.

Fig. 1 Specimen of tensile specimen

Fig. 2 Sample of bending sample (unit: mm)

1.3 Test method

1.3.1Stretchtest

The preparation of tensile test specimens was based on GB/T1447—2005 “Test Methods for Tensile Properties of Fiber-Reinforced Plastics”. The testing equipment was electro-hydraulic servo universal testing machine (50T), and the loading speed was 5 mm/min. The static tensile load is applied uniformly along the axial direction of the sample until the sample breaks or reaches a predetermined elongation. Throughout the process, the load applied to the sample and the elongation of the sample are measured to determine the tensile stress (tensile yield stress, tensile fracture stress or tensile strength), tensile elastic modulus, elongation at break,etc.) Before the test, the samples were placed in the laboratory under standard environmental conditions for 24 h. The temperature was (23±2)℃ and the relative humidity was (50±10)%.

1.3.2Bendingtest

The bending samples were prepared according to GB/T1449—2005 “Test Methods for Bending Properties of Fiber-Reinforced Plastics” standard. The testing equipment was a bending performance testing machine with a loading speed of 5 mm/min. Through unconstrained support and three-point bending, the sample is destroyed, or it reaches the predetermined deflection value at a constant loading rate. In the whole process, the load applied on the sample and the deflection of the sample are measured to determine the bending strength, elastic modulus of bending and the relationship between bending stress and strain. The temperature was (23±2)℃ and the relative humidity was (50±10)%. Before the test, the samples were placed in the laboratory under the standard environmental conditions for 24 h. The working diagram of the equipment is shown in Fig. 3.

1-sample support; 2-loading upper head; 3-sample; l-span; R-bearing fillet radius; h-sample thickness; P-load; L-sample length; r-support fillet radius.Fig. 3 Working diagram

2 Results and Analysis

2.1 Tensile performance analysis

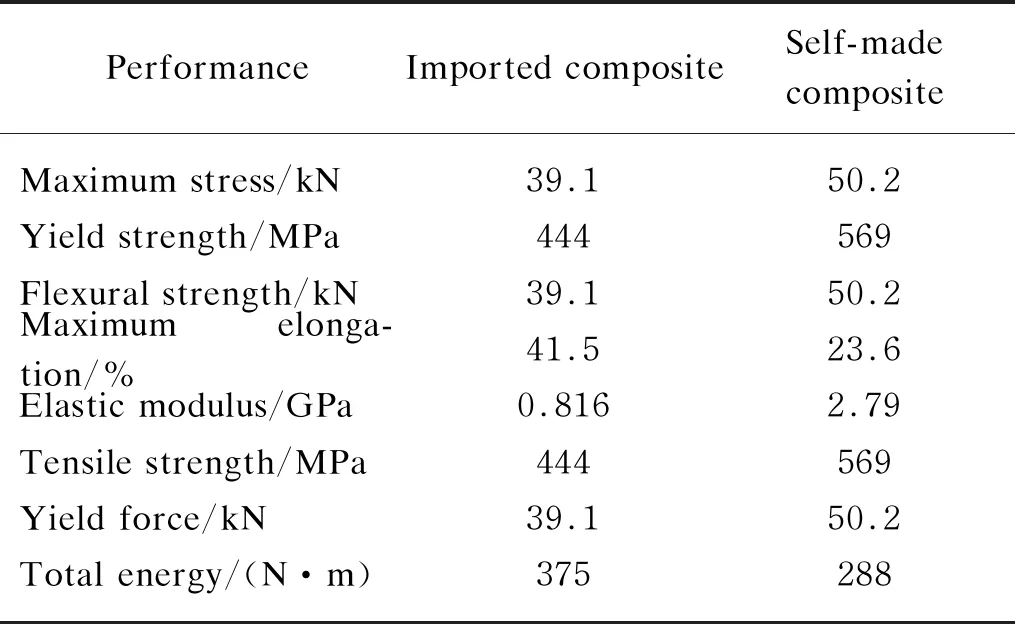

According to the standard of GB/T1447—2005 “Test Method for tensile Properties of Fiber-reinforced plastics”, imported material samples and self-made material samples were prepared respectively, and tensile tests were conducted respectively. The comparative test results of different material properties were analyzed. Table 1 shows the comparative data of maximum stress and yield strength of imported material and self-made material samples.

Table 1 Comparison test results of different composite properties

It can be seen from Table 1 that the maximum stress, flexural strength, maximum elongation, tensile strength and other parameters of the self-made composite material are significantly higher than those of the imported blade. It shows that the tensile performance of self-made glass fiber unsaturated polyester resin composite material is far greater than that of imported composite material in a tensile environment.

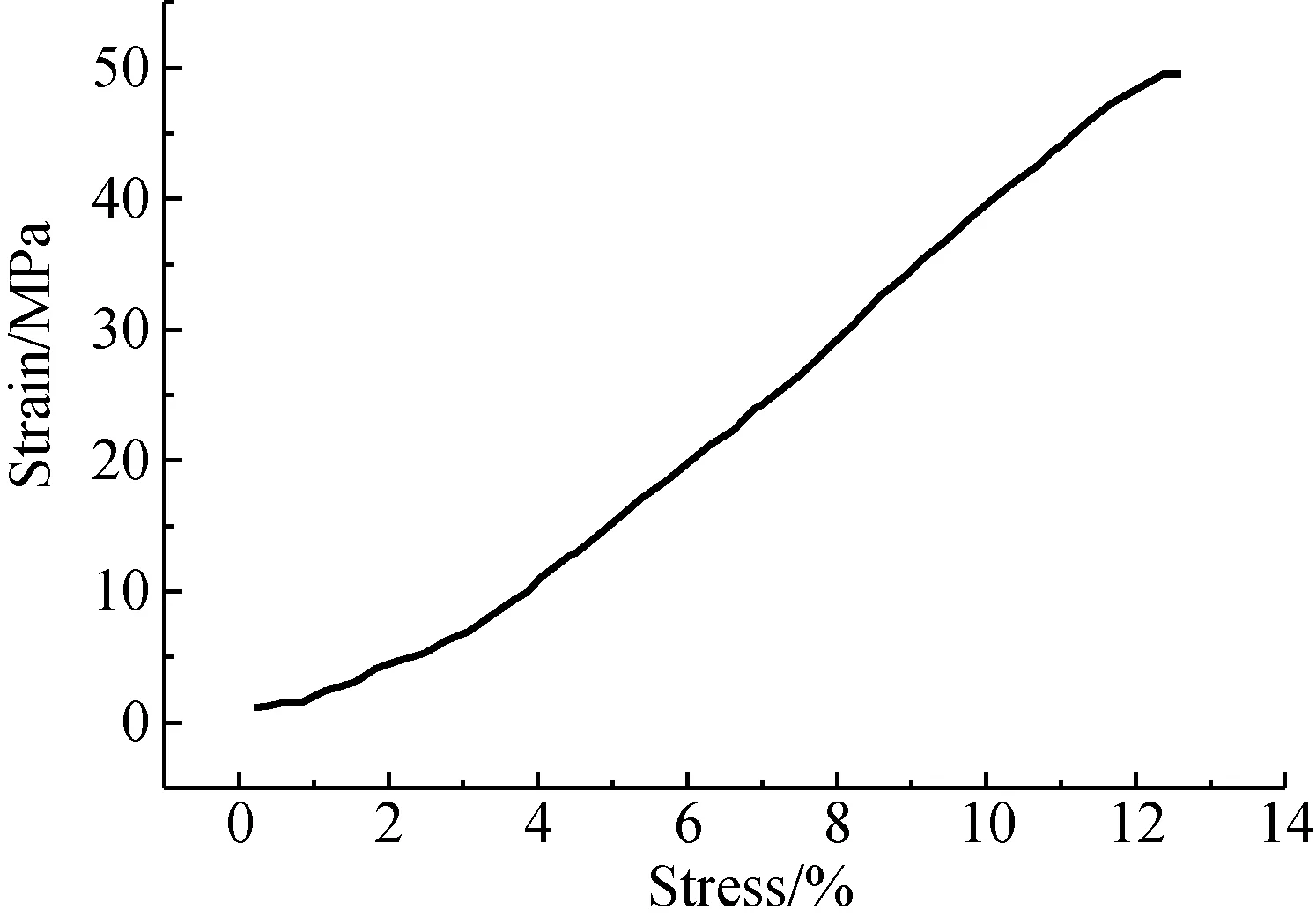

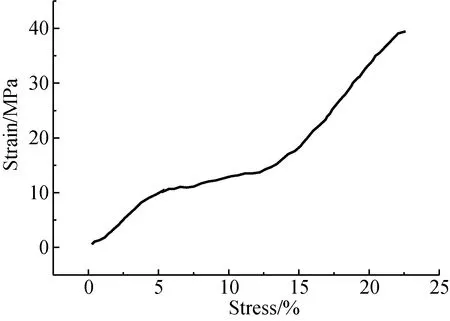

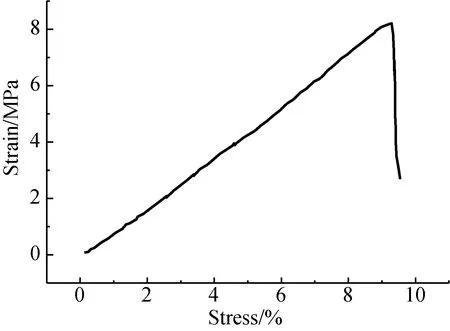

Figures 4 and 5 show the stress-strain curves of the tensile properties of imported composite material and self-made composite material, respectively.

Fig. 4 Stress-strain curve of imported materials

Fig. 5 Stress-strain curve of self-made materials

It can be seen from the stress-strain curve that the deformation amount of the self-made composite material is 7 mm, and the yield obviously appears at the moment, and then enters the plastic deformation stage. At last, the composite was broken, but the rate of change was almost the same. At the same time, the elongation of self-made composite material is twice as much as that of imported composite material, which fully indicates that the imported composite materials show the characteristics of brittle materials.

2.2 Bending performance analysis

According to the standard of GB/T 1449—2005 “Test Methods for bending Properties of Fiber-reinforced plastics”, samples of imported materials and self-made materials were prepared respectively, and bending tests were conducted respectively. The comparative test results of different material properties were analyzed. Table 2 shows the comparative data of maximum stress and yield strength of imported materials and self-made materials.

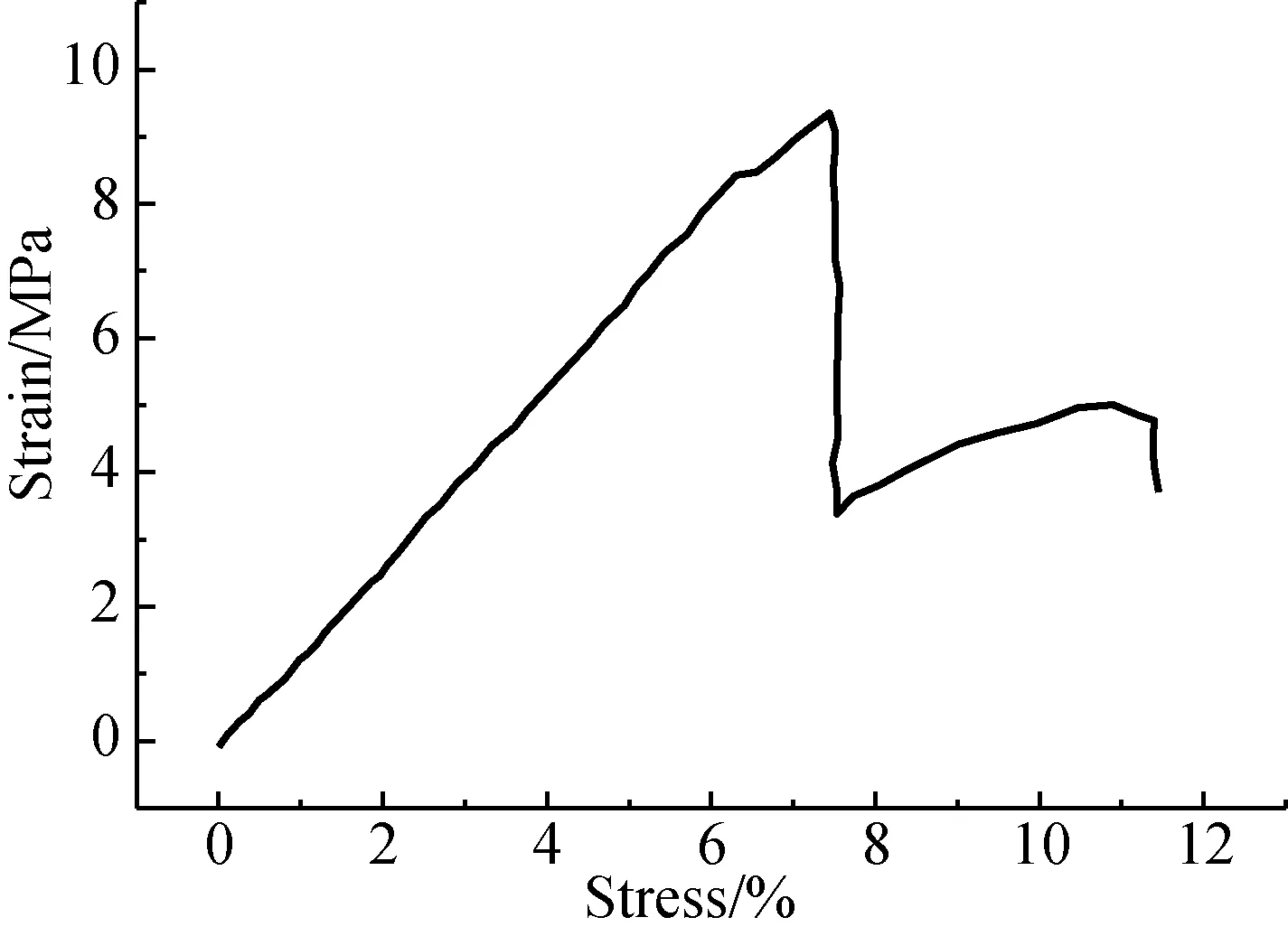

As shown in Table 2, the flexural modulus and bending strength of imported materials are higher than those of self-made composite materials, indicating that in theZdirection (thickness) of the materials, the performance of imported materials is greater than that of self-made composite materials. The total bending and fracture energy, fracture deflection and maximum bending force of the self-made composite materials are obviously greater than those of the imported materials. However, from the failure point, it can be seen that the self-made composite materials have obvious longitudinal stratification, which is divided into two parts. The very neat fracture of the imported composite materials fully indicates that the interlayer force of the self-made composite materials is obviously insufficient, but due to the fiber factor, the fracture deflection becomes larger.

Table 2 Performance comparison test results of different composite materials

As shown in Figs. 6 and 7, the stress-strain curves of the bending properties of imported composite materials and self-made composite materials are shown respectively. It can be seen from Figs 6 and 7 that the curve of the imported composite materials is relatively gentle, while the curve of the homemade composite materials appears quadratic slip, indicating that the inter-layer force of the self-made composite materials is extremely unstable and inter-layer failure will occur under the action of certain bending stress.

Fig. 6 Stress-strain curve of imported materials

Fig. 7 Stress-strain curve of self-made materials

3 Conclusions

In this paper, the tensile and flexural properties of glass fiber/unsaturated polyester resin composites were studied, And compared them with imported material JK2020B, the following conclusions were drawn.

(1) It can be seen from the tensile test and bending test that both materials have the commonness of composite materials: the elastic modulus along the fiber direction is relatively high, while the interlayer force in the direction of thickness and width is very small, which obviously shows the characteristic of orthogonal anisotropy.

(2) From the fracture process of tensile test, it is proved that the composite material has obvious stratification characteristics, which indicates that this material can be solved by the laminated plate theory. Imported longitudinal tensile strength of composite material specimen is much lower than self-made composite sample, but the performance of the thickness direction and the width direction is much better than self-made composite samples, that imports composite samples of overall performance is good, because of the special structure, with the fiber and matrix caused by infiltration of good performance. However, the self-made composite samples showed weak interlayer force, indicating that further process corrections are needed in the development process. It was observed from the stress-strain curve that the failure of self-made composite samples occurred after a very short elastic deformation stage and the material performance was unstable.

(3) By comparing the mechanical properties of imported and self-made composite samples, the commonness of composite materials is verified, and the performance difference between self-made and imported composite materials is also obtained, which will guide the future production process.

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Polyacrylonitrile/Graphene-Based Coaxial Fiber-Shaped Supercapacitors

- Highly Stretchable and Transparent Hydrogel as a Strain Sensor

- Effect of Processing Parameters on Morphology and Mechanical Properties of Hollow Gel-Spun Lignin/Graphene Oxide/Poly (Vinyl Alcohol) Fibers

- Characteristic Analysis and Harmonic Feature Identification of Micro-Vibration on Flywheels

- Defect Detection Algorithm of Patterned Fabrics Based on Convolutional Neural Network

- Tufting Carpet Machine Information Model Based on Object Linking and Embedding for Process Control Unified Architecture