Tufting Carpet Machine Information Model Based on Object Linking and Embedding for Process Control Unified Architecture

2021-04-08GUOXiangCHIXinfu郗欣甫SUNYize孙以泽

GUO Xiang(郭 祥), CHI Xinfu(郗欣甫), SUN Yize(孙以泽)

College of Mechanical Engineering, Donghua University, Shanghai 201620, China

Abstract: In view of the lack of research on the information model of tufting carpet machine in China, an information modeling method based on Object Linking and Embedding for Process Control Unified Architecture (OPC UA) framework was proposed to solve the problem of “information island” caused by the differentiated data interface between heterogeneous equipment and system in tufting carpet machine workshop. This paper established an information model of tufting carpet machine based on analyzing the system architecture, workshop equipment composition and information flow of the workshop, combined with the OPC UA information modeling specification. Subsequently, the OPC UA protocol is used to instantiate and map the information model, and the OPC UA server is developed. Finally, the practicability of tufting carpet machine information model under the OPC UA framework and the feasibility of realizing the information interconnection of heterogeneous devices in the tufting carpet machine digital workshop are verified. On this basis, the cloud and remote access to the underlying device data are realized. The application of this information model and information integration scheme in actual production explores and practices the application of OPC UA technology in the digital workshop of tufting carpet machine.

Key words: tufting carpet machine; digital workshop; information model; Object Linking and Embedding for Process Control Unified Architecture(OPC UA); interconnection

Introduction

With the introduction of concepts such as smart factories and manufacturing, countries around the world have successively formulated strategic goals suitable for the development of manufacturing industries in order to transform to smart, and strive to stand out in the new round of industrial revolution[1]. Driven by the industry 4.0 environment, accompanying the wave of intelligent industrial upgrading, the technology research and industrial development of digital workshop at home and abroad have been developing rapidly, and some open standard protocols for high-end smart textile equipment have been proposed. However, because there was no unified communication protocol and standard for each device in the workshop, the compatibility between standards was low, which severely restricted the intelligent upgrade of the textile industry.

In tufting carpet machine workshop, there was generally automation equipment and system from different manufacturers with different functions. The communication protocols of different equipment systems were relatively independent, the data information expression format was obviously different, which made it impossible to share equipment-level information. The current workshop chooses to develop data format conversion applications and communication protocol conversion interfaces to achieve information integration between heterogeneous equipment and systems, causing problems such as low information integration, high development costs, information reusability and low development efficiency. Therefore, the problem of blocking information interconnection between heterogeneous equipment and systems in tufting carpet machine workshop needs to be resolved urgently.

Information integration and interconnection is an important foundation and guarantee for eliminating information islands and realizing workshop digitization and intelligence[2], while the key is to establish a relatively unified and semantically standardized information model. European plastics and rubber manufacturers launched the EUROMAP77 standard based on Object Linking and Embedding for Process Control Unified Architecture (OPC UA), and developed a device interface for interaction between injection molding machines and manufacturing execution system (MES)[3]. Cavalierietal.[4]coordinated the OPC UA application in data modeling between client and server. After the OPC UA architecture officially became a national standard in 2017, domestic research on the OPC UA information model has flourished. Zhangetal.[5]researched the modeling method and model standardization of digital workshop. Wangetal.[6]studied the information interaction model of the digital workshop of computer numerical control (CNC) machine tool manufacturing. With the transformation and upgrading of the manufacturing industry, OPC UA technology had also begun to be applied to the textile industry. Lietal.[7]used OPC UA technology textile dyeing and finishing workshop to research the information model of dyeing and finishing workshop. However, in tufting carpet industry, there are still gaps in the research and application of tufting carpet machine information model.

The establishment of complete, standardized and effective information model is helpful for the transmission of data information in heterogeneous equipment and systems in the digital workshop of tufting carpet machine, which improves the completeness of data semantics and reducing the difficulty of data information integration in the workshop. Based on the OPC UA standard protocol, this article combs tufting carpet equipment organization structure, to abstract its physical equipment, and semantical consistent tufting carpet machine information model is established to form a unified OPC UA interface for external data transmission. The standardized integration method is adapted to provide unified interaction mode, so as to realize information integration and interconnection between heterogeneous equipment systems[8], and solve the problem that the equipment layer information cannot be shared.

1 Digital Workshop Architecture of Tufting Carpet Machine

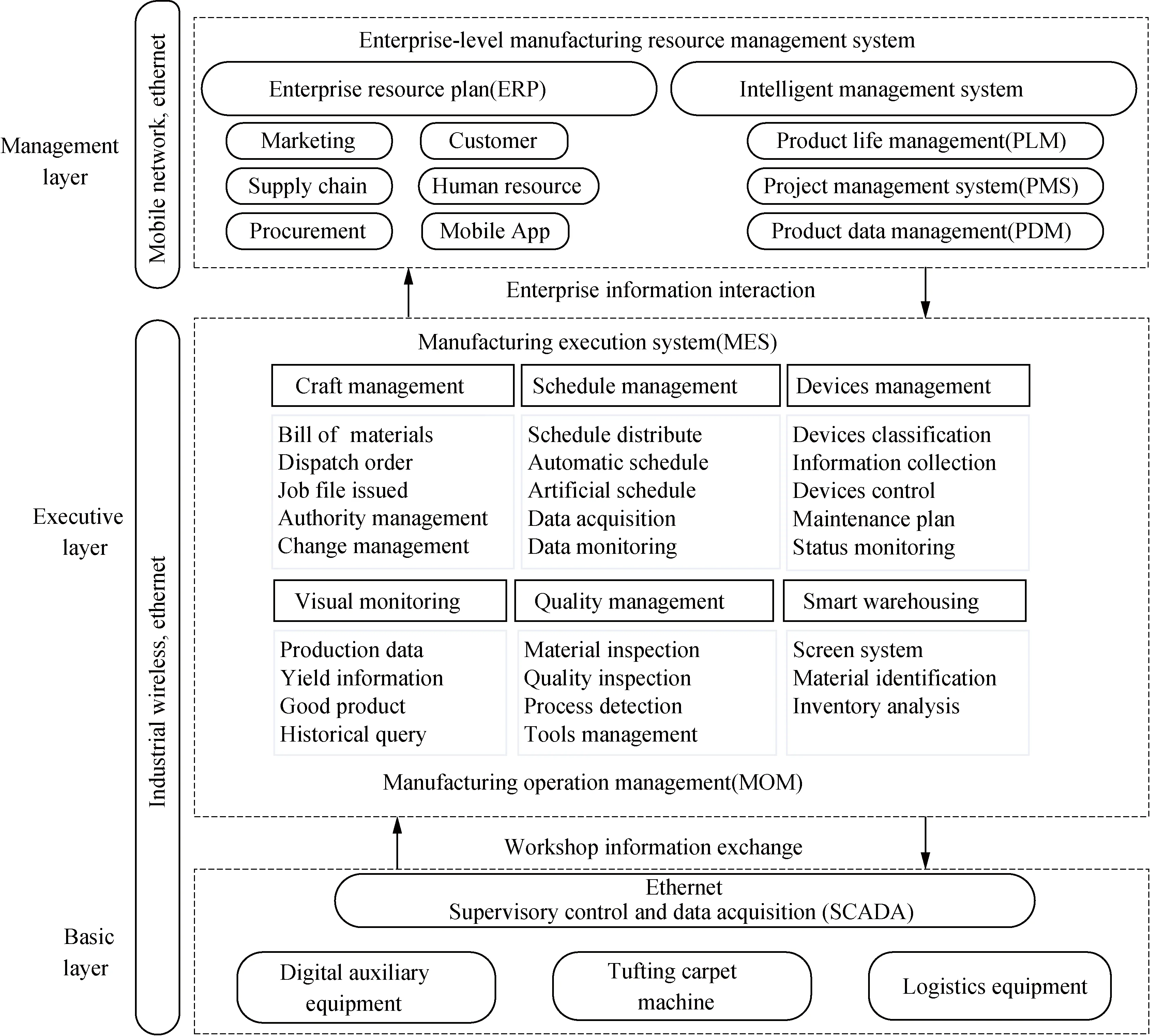

The digital workshop of tufting carpet machine covers the whole process of the production and weaving of tufting carpet. Currently, tufting carpet machine workshop does not have a unified information model, but on the basis of general technical requirements and organizational structures of the digital workshop, combined with tufting carpet machine workshop production status. Tufting carpet machine digital workshop should have a three-layer system structure, including the basic layer, executive layer and management layer, corresponding to the equipment layer, workshop layer and enterprise layer of the weaving production of tufting carpet machine workshop, respectively shown in Fig. 1.

Fig. 1 Digital workshop architecture of tufting carpet machine

The basic layer is composed of intelligent tufting carpet machine, digital auxiliary equipment and logistics equipment of the digital workshop. It is the data source of the workshop production information, responsible for the collection of production data information in the workshop and the execution of the operating instructions developed by the upper system. The function of the executive layer is mainly based on manufacturing execution system (MES) to manage various businesses in the workshop, define activities for monitoring, control the manufacturing process[9], and realize the digitization and visualization of the workshop production process. While the craft management is responsible for generating craft pattern files and distributing to the control system of tufting carpet machine; each tufting carpet machine is equipped with human machine interface (HMI) to monitor and manage equipment in real time; visual monitoring screen is provided to display the production data, status information to guide workshop production. The management layer covers all the data information of the company, which is responsible for data interaction with the MES system, realizes the overall management and control the company’s production, plans the normal operation of the entire digital workshop of tufting carpet machine[10], and allocates resources of the entire company. Management information can also be uploaded to the cloud for big data analysis.

2 Information Modeling of Tufting Carpet Machine

2.1 Abstracting tufting carpet machine

OPC UA modeling is an object-oriented approach based on metamodels[11],and it adopts the concept of integrated address space and adds object semantic recognition function to support information model[12-13]. The information model of specific domain is defined by inheritance, extension and reference relation of metamodel to meet different application scenarios. Before modeling the information of tufting carpet machine, it is necessary to clarify the relationship between equipment types, attributes, events and components, and merge the node information into the standard node category of the OPC UA architecture.

According to the information model rules and the definition of information model elements, from the analysis of mechanical structure of tufting carpet smart device, tufting carpet machine is composed of multiple components with different functions. Each component is inherited by several sub-components to form the unique physical properties or operations of the sub-components. The logical objects of tufting carpet machine are connected by references. The mapping relationship between information model elements and the physical model of tufting carpet machine is shown in Fig. 2.

Fig. 2 Tufting carpet machine and information model element mapping

2.2 Information model of tufting carpet machine

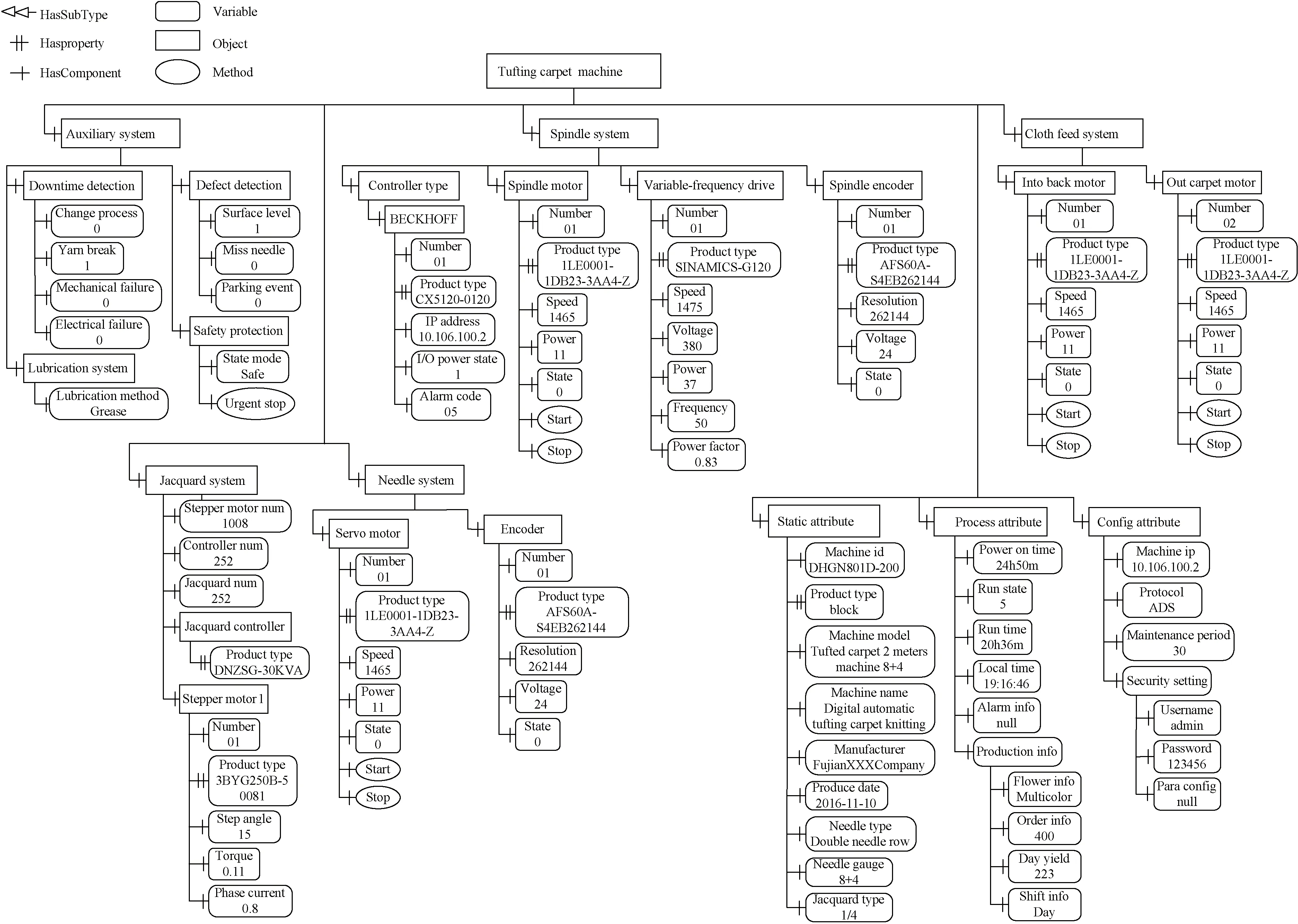

Based on OPC UA information modeling principles and specifications, tufting carpet machine metamodel is abstracted. The types of tufting carpet machine can be divided into two parts: characteristic object attribute set and component object set. The characteristic object attribute set can be further divided into static attribute set, process attribute set, and configure attribute set. Each attribute set contains its own attributes or attribute set. The component object set is divided into multiple components according to the functional elements of its physical model, and each component contains its own attribute set.

The hierarchy of the information model structure of tufting carpet machine is shown in Fig. 3. The static attribute set mainly includes the general basic information and private attribute set of the tufting carpet machine. The private attribute set includes the craft information such as the carpet width, the pattern of needle row and jacquard type. The process attribute set not only expresses equipment operating characteristics, but also includes current production process information, which mainly contain the key information of carpet production and weaving such as order information, output information, pattern information, and shift information. The configure attribute set mainly includes equipment management, communication address and protocol, and security setting information.

Tufting carpet machine component set contains the collection structure itself and can refer to the substructure or component information. It is divided into multiple components according to its physical model functional elements, and each component contains its own attribute set. The component set is divided into the jacquard system object set, the shog system object set, the spindle system object set, and the cloth feed system object set[14]. Each sub-component object set can be subdivided into several objects according to its functional structure. Besides, each object has corresponding attribute set, attribute and method information.

Fig. 3 Information model of tufting carpet machine

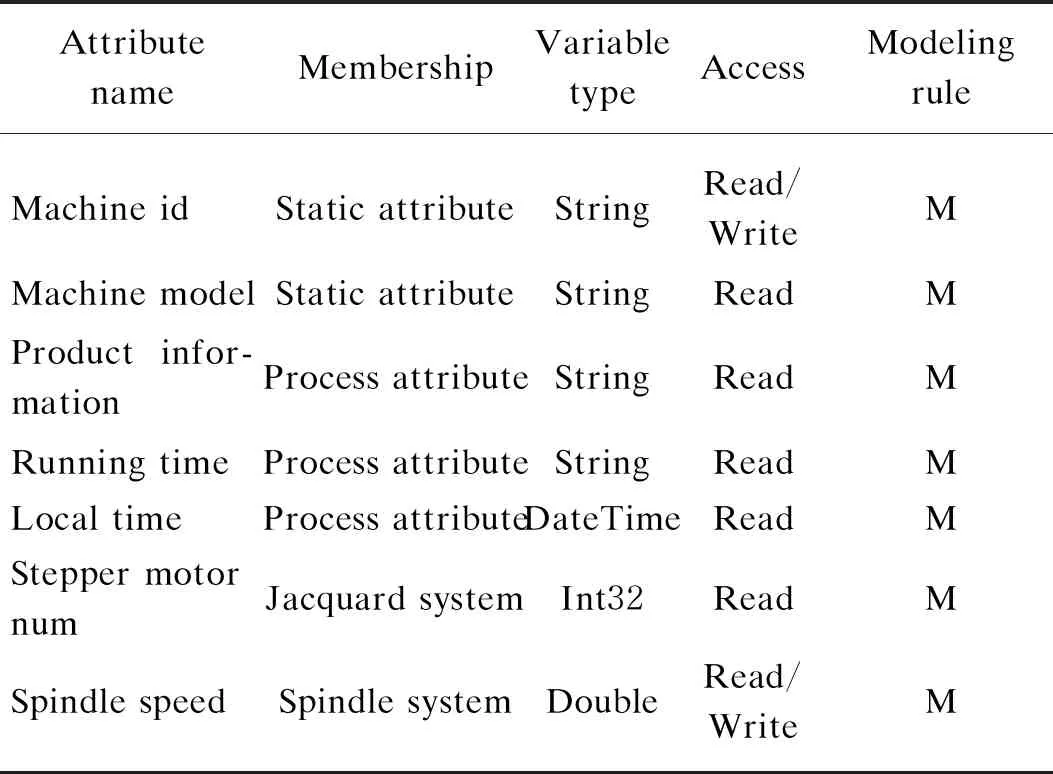

Tufting carpet machine information model specifies modeling methods for all attribute sets, component sets, attributes and subcomponents. The typical attributes of tufting carpet machine are shown in Table 1.

Table 1 Typical attributes of tufting carpet machine

According to the equipment information modeling rules and tufting carpet machine information model architecture, a modeling tool (freeOpcUa Modeler) is used to model tufting carpet machine, and the corresponding extensible markup language (XML) file is automatically generated. Tufting carpet machine object type (TuftingCarpetWeaving) inherits from the BaseObjectType under the OPC UA standard and is defined in the FolderType under the ObjectType. CarpetWeaving is associated with its attribute set and component set by HasComponent reference. The modeling result of tufting carpet machine is shown in Fig. 4.

Fig. 4 Information modeling results of tufting carpet machine

2.3 Instantiation of information model of tufting carpet machine

The information model of tufting carpet machine constructed in the previous section is only an abstract frame without actual objects and data interfaces[15]. The instantiation of the information model is to fill the physical information of the device into the frame of the information model, so that the abstract model has the instance information of the device. The instantiation of tufting carpet machine is a data conversion process. That is, the attribute set, components, sub-components and attribute information of tufting carpet machine are converted into object types such as OPC UA objects, variables, and methods according to their categories.

There are 8+4, 6+6, 1/10 and other types of tufting carpet machine in the workshop. Different types of equipment vary in width, product type, number of jacquard threads and number of stepping motors. In the process of instantiating different models of tufting carpet machine, the differences need to be considered and reflected. In the process of instantiating different models of tufting carpet machine, the differences need to be considered and reflected. A tufting carpet machine 8+4 model is selected to instantiate its various attribute sets and component system information model. The instantiation model is shown in Fig. 5.

Fig. 5 Instantiated model of tufting carpet machine

3 Application of Information Model in Tufting Carpet Machine Workshop

3.1 Information integration scheme for tufting carpet machine

The device layer in tufting carpet machine workshop has 6+6, 8+4 and 1/10 models. The equipment data collection methods include embedded system, BECKHOFF controller and Siemens programmable logic controller (PLC),etc. The equipment collection interface and data format are different, so the integration scheme is slightly different. For the 8+4 and 1/10 models, BECKHOFF controller and Siemens PLC are used as the control systems of tufting carpet machine, which support information models and have OPC UA standard interfaces. The embedded fusion method is adopted. That is, the OPC UA server is embedded in the programming equipment; while the 6+6 model uses the embedded control system, there is no interface that meets the OPC UA standard. It is necessary to develop an OPC UA data gateway on the device, provide a service interface upward, and collect field device data downward. The supervisory control and data acquisition (SCADA) of the control layer is a PC-based independent executable program, and the workshop layer MES system is regarded as an OPC UA client. The integration method is shown in Fig. 6.

For the entire digital workshop of tufting carpet machine, it is necessary to transmit the underlying equipment data to the cloud to achieve remote access and monitoring. A universal, simple and effective way is to combine the OPC UA unified architecture with the message queuing telemetry transport (MQTT) protocol to upload data to the cloud server and monitor the exhibition by publishing and subscribing[16]. The overall application framework is shown in Fig. 7. No matter what kind of communication protocols and acquisition interfaces the underlying equipment tufting carpet machine is, the integrated device protocol, or uniform interface specification, can be realized at the bottom of OPC UA server, so as to realize the integration of device data information with different types and protocols.

Fig. 6 Information integration of tufting carpet machine

Fig. 7 Internet of Things (IoT) application network architecture of tufting carpet machine

3.2 Information model experiment of tufting carpet machine

In order to verify the feasibility of realizing the information integration and interconnection in tufting carpet machine workshop based on tufting carpet machine information model established above, tufting carpet machine information model architecture, information objects and their attribute data are mapped into the address space and expressed. And an independent OPC is developed based on open 62541 software development kit (SDK) UA server to read carpet loom information model data.

Based on the model abstraction of the physical equipment of tufting carpet machine, the information model established above is created in the information model editor, and an XML document describing the data information is generated; the information model loader parses according to the mapping rules. The XML file of tufting carpet machine information model is compiled in the address space to generate the library file for the OPC UA server to call.

For universality, an OPC UA server is developed to connect to the control system of 8+4 model of tufting carpet machine instead of using BECKHOFF own UA server. Connecting the 8+4 tufting carpet machines to the OPC UA server and running the application, the client UaExpert based on OPC UA is used to access the information model on the OPC UA server. And the content of each type of node in the information model is obtained, and the result is shown in Fig. 8.

According to the server structure and attribute data obtained by the OPC UA client, it can be found that tufting carpet machine information model based on OPC UA technology has a unified interface for exposing data, and the object type of the information model can be obtained through the OPC UA client. Its attribute values indicate the feasibility of tufting carpet machine information model based on the OPC UA framework.

Tufting carpet machine at the equipment layer integrates the OPC UA server to collect production data. The OPC UA central server centrally processes the device layer data, uploads it to the data layer, and uploads it to the Aliyun server via the MQTT client. The results of the web page access are shown in Fig. 9.

Fig. 8 OPC UA client accesses attribute information of tufting carpet machine:(a) information model structure of tufting carpet machine;(b) node information of tufting carpet machine;(c) basic property information of tufting carpet machine

Fig. 9 Overview of tufting carpet machine data

Tufting carpet machine of different models and different control systems can be integrated through a unified information model and interface service, and a common IoT solution can be realized by combining MQTT protocol, so as to solve the problem of data information islands in tufting carpet machine workshop and realize the feasibility of interconnection and remote access.

4 Conclusions

The establishment of the information model is conducive to improving the intelligence and digitization level of the workshop. This article constructed an information model of tufting carpet machine based on the OPC UA technology. The conclusions are as follows.

(1) By analyzing the mechanical structure and function of tufting carpet machine, the types of tufting carpet machine are abstracted, which is more extensible than the information model in other fields. The model is accurate to the attributes of the subcomponent neutron object, and the model is more complete.

(2) The information integration scheme of tufting carpet machine workshop was proposed, and developed the OPC UA server of tufting carpet machine. The function of reading and writing attribute information of the information model is tested, and the feasibility of the information model combined with OPC UA technology in heterogeneous equipment in tufting carpet machine workshop is verified.

(3) Combining OPC UA unified architecture technology and MQTT protocol, equipment networking and data uploading to the cloud are realized, which provides remote access to workshop production data information, monitors the operating status of workshop equipment and guides workshop production.

Tufting carpet machine information model constructed in this paper based on OPC UA technology, information integration scheme and IoT solution have certain reference significance for the realization of data interconnection between heterogeneous equipment and systems in the workshop.

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Polyacrylonitrile/Graphene-Based Coaxial Fiber-Shaped Supercapacitors

- Highly Stretchable and Transparent Hydrogel as a Strain Sensor

- Effect of Processing Parameters on Morphology and Mechanical Properties of Hollow Gel-Spun Lignin/Graphene Oxide/Poly (Vinyl Alcohol) Fibers

- Characteristic Analysis and Harmonic Feature Identification of Micro-Vibration on Flywheels

- Defect Detection Algorithm of Patterned Fabrics Based on Convolutional Neural Network

- Multiple Needle Electrospinning for Fabricating Composite Nanofibers with Hierarchical Structure