Multiple Needle Electrospinning for Fabricating Composite Nanofibers with Hierarchical Structure

2021-04-08LIXiaoxia李晓霞TIANDanLIYaHEJihuan何吉欢

LI Xiaoxia(李晓霞), TIAN Dan(田 丹), LI Ya(李 雅), HE Jihuan(何吉欢), *

1 National Engineering Laboratory for Modern Silk, College of Textile and Clothing Engineering, Soochow University, Suzhou 215123, China

2 School of Science, Xi’an University of Architecture and Technology, Xi’an 710055, China

3 College of Textile Science and Engineering, Zhejiang Sci-Tech University, Hangzhou 310018, China

Abstract: Electrospinning is a powerful method for fabricating micro/nano fibers that can be applied to various fields. Composite materials with nanoscale structure can show more excellent properties than their conventional partners. Here, we reported hierarchical structured nanofibers with beads and spheres by double needle electrospinning with an auxiliary airflow. Two different spinning solutions with different concentrations were placed into different syringes. The action of airflow was able to make the two differently morphological nanofibers mixed together evenly. The results showed that the obtained nanofiber membrane has a good hierarchical structure with different morphologies.

Key words: multiple needle; electrospinning; composite nanofibers; hierarchical structure; airflow; different morphologies

Introduction

All natural materials with nanofibers with hierarchical structures always have remarkably miraculous functions, for example, the spider silk’s strength[1-2], the silkworm cocoon’s selective diffusion[3-4], the wool’s unidirectional heat conduction[5-6], and the gecko’s smart adhesion[7]. Bio-inspired hierarchical fibers have been attracting much attention, because the hierarchy can embody the artificial materials with various attractive properties from super-hydrophobicity[8], extremely high air/moisture permeability[9]to selective adsorption[10]and infrared stealth[11].

This paper aims at fabricating a composite nanofiber membrane with hierarchical structure. Such materials were widely applied to various fields, such as aerospace defense, traffic areas, sports, biological medicine, smart textile due to their excellent comprehensive performance[12-13]. Nanocomposite material is one of the most attractive part of the development strategy for new material and has an important position in the developed countries[14]. Electrospinning has been used as a simple and efficient process to manufacture nanofibers for various polymers since its development with numerous advantages over other fiber manufacturing processes, including of cost-effectiveness, simplicity, efficiency, ease of control of the fiber’s structure and diameter[15-19].

Inspired by the fantastic spider spinning, Liu and He[20]proposed the bubble electrospinning which can produce smooth nanofibers, beads, crimped fibers, nanoparticles, and others[21-28]. Inspired by many natural fibers with hierarchical structures, this paper is to fabricate a nanofiber membrane with hierarchical structure by spinning different solutions under different spinning conditions simultaneously (Fig. 1).

Fig. 1 Multiple needle electrospinning

During the electrospinning process, due to the interaction of the electric field force, the repulsive force generated between the adjacent needles in an electrospinning device with multiple needles. The repulsive force was also produced between the nanofibers generated by the adjacent needles, and the nanofibers deposited on the receptor presented multiple independent areas, which made the obtained nanofibers membrane un-uniform enough and affected the quality of the nanofibers membrane. In our work, the air flow setup was used to generate an external force to over the repulsive force between the adjacent needles, with the air flow force, the obtained nanofibers were formed a uniform nanofibers membrane. And the fibers obtained by different needles with different special morphology could be mixed uniformly. Moreover, the airflow could increase the solvent evaporation, especially for the high volatile and high dielectric constant solvent. So a hierarchical and uniform structured nanofibers membrane with special surface was obtained.

1 Experiments

1.1 Materials

Polyvinyllidene fluoride powders (PVDF, average molecular weightMw800 000-900 000) used in this experiment was obtained from Yuanye Biotechnology Co., Ltd. (Shanghai, China) with alcoholysis degree of 99.9%, PVDF was stored at room temperature and was directly used as received without any further purification. Polyacrylonitrile (PAN, average molecular weightMw150 000), alcoholysis degree was 99%. Polystyrene(PS, average molecular weightMw104.14, Aladdin, Shanghai, China), silicon dioxide particles(SiO2, about 2 μm, RHAWN,Shanghai, China), Dimethyl sulfoxide (DMSO, American Chemical Society (ACS) Reagent grade,ENOX, Suzhou, China), Chlorobenzene (CB, ACS Reagent grade, ENOX, Suzhou, China), N, N dimethylformamide (DMF, analytical reagent (AR), ENOX, Chinasun Specialty Products Co., Ltd., Suzhou, China) and acetone (AR, ENOX, Chinasun Specialty Products Co., Ltd., Suzhou, China) were used as the solvent.

1.2 Solution preparation

In this experiment, two groups solution were prepared. Firstly, 1 g PVDF was dissolved in 9 g double solvent with DMF and acetone, which were mixed in 7∶3 weight ratio. The PAN of 0.4 g was dissolved in 9 g DMF solvent.

Then, 0.4 g SiO2was dispersed in the 9.3 g DMF solvent, and 0.3 g PVDF was added in the mixed SiO2/DMF solution. Finally, the PVDF/SiO2mixed solution was magnetically stirred for 12 h at 55 ℃ for complete dissolution to form uniform spun solutions. The PS of 1 g was dissolved in the 10 mL mixed solvent (DMSO and chlorobenzene was mixed in the 4∶6 volume ratio), and magnetically stirred at 50 ℃ for 12 h to obtain homogeneous solutions before electrospinning process.

1.3 Experimental setup

The purposed setup used in this experiment was comprised of two syringes with spinnerets, an airflow device, a high voltage power supplier and a receptor, as shown in Fig. 2. Two groups of solutions were loaded into two syringes respectively. Both of syringes were connected to high voltage power supply with positive charged and the receptor was negative charged.

The polymer solutions were electrospun at room temperature under a voltage of 18 kV. The needle tip’s diameter of the syringe used in this experiment was 0.7 mm. The distance between the tips of the two needles was 8 cm. The negative receptor was placed under the syringes and was 20 cm from the tips to center of two needles. The air flow setup was placed at the side of the syringe. With the action of the air flow, continuous nanofibers were deposited onto the receptor and collected in the form of uniform nanofibers mats.

First, the PVDF and PAN solution by weight were electrospun together. The flow rate of the two syringes were 1 mL/h and 0.8 mL/h respectively. The obtained electrospun composite nanofiber were coded as PVDF/ PAN nanofiber.

Then, PVDF/SiO2and PS solutions were electrospun together. Both of the flow rate of syringes were 1 mL/h. The obtained electrospun composite nanofiber was coded as PVDF-SiO2/PS nanofiber.

Fig. 2 Double needle electrospinning setup

2 Results and Discussion

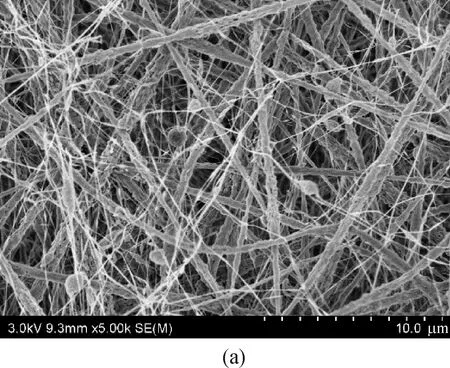

The morphologies of the composite nanofibers were studied by a scanning electron microscope (SEM, Hitachi S-4800, Tokyo, Japan). The SEM images of PVDF/PAN nanofibers were shown in Fig. 3. The electrospun composite nanofibers exhibited multi-morphologies, and randomly distributed in the fibrous mat with a dense structure. Overall, the size and morphology of the nanofibers were affected by the properties, concentrations and solvents of the solutions.

Fig. 3 SEM images of the PVDF/PAN nanofibers at different magnification

In Fig. 3, the polymer solutions produced hierarchical structure fibers with rough surfaces, beads and spheres. Their surfaces are porous becase acetone was a highly volatile, with the action of the air flow, the solvent was evaporated rapidly in the electrospinning process.

Furthermore, the two solutions had different concentrations, and the solution with high concentration resulted in fibers, while the solution with low concentration resulted in beads or spheres with filaments.

The SEM images of PVDF-SiO2/PS nano fibers were shown in Fig. 4. The polymer solutions produced hierarchical structure fibers with pores surface and beads. The PVDF/SiO2nanofibers were thin with nanobeads. The PS fibers had a porous surface with big and small pores, and the fiber diameters were much thicker than the PVDF-SiO2/PS nano fibers.

Fig. 4 SEM images of the PVDF-SiO2 /PS nano fibers at different magnifications

Because of the low dielectric constant, chlorobenzene (CB) alone was not an appropriate solvent for electrospinning. So the addition of DMSO (high dielectric constant solvent) as cosolvents was an efficient way to increase the overall conductivity[29]. On one hand, the electrospinnability of the solution and produce bead-free fibers can be enhanced. On the other hand, it changed the solvent quality to polymers, the viscosity as well as the surface tension of solutions, which were all critical parameters for electrospinning. DMSO also played an important role in the formation of the pores. Moreover, with the action of the air flow, the high dielectric constant solvent was evaporated rapidly in the electrospinning process resulting in a hollow pea-like structure with various sizes pores on the surface. The pores grown along the fiber axis, and the shape and orientation of the pores were affected by the stretching forces. The PVDF-SiO2/PS solution with low concentration and particles resulted in beads with filaments. And the two different morphologies fiber were distributed uniformly with a dense structure.

Moreover, energy disperse spectroscopy (EDS, TM3030, Hitachi, Japan) elemental mappings [Figs. 5(a)-(f)] proved that the carbon, oxygen, fluorine and elements are homogeneously dispersed in the matrix of the fibers mat, which indicated the excellent distribution of PVDF-SiO2/PS fibers. Due to the external effect action of the airflow, the repulsive interference of electric field could be avoided, and the two different polymer fibers could be blended together evenly with multi-morphologies and hierarchical structures in the double needle electrospinning process. At the same time, the effect of airflow can increase the evaporation rate of solvent in the air and made the fibers form special pore morphologies, which is beneficial to obtain a high performance of the hierarchical structure fibers.

Fig. 5 EDS elemental mappings: (a) SEM image of PVDF-SiO2/PS nano fibers; (b) carbon; (c) oxygen; (d) fluorine; (e) silicon

3 Conclusions

Electrospinning is a promising technology for mass-production of nanofibers with composite structures. Here, it exhibits a modified electrospinning setup with two needles and an auxiliary airflow device. It provides a new, effective and inexpensive method to control spinning process, fiber morphology and its output. This modified double needles electrospinning is very much suitable for producing composite nanofibers with hierarchical structures. Moreover, the action of the airflow plays an important role in the electrospinning process. On one hand, it can make two differently morphological nanofibers mixed evenly. On the other hand, it can increase the solvent evaporation and promote the formation of the special surface with pores. The results showed that the obtained nanofiber membrane had a good hierarchical structure with different morphologies.

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Polyacrylonitrile/Graphene-Based Coaxial Fiber-Shaped Supercapacitors

- Highly Stretchable and Transparent Hydrogel as a Strain Sensor

- Effect of Processing Parameters on Morphology and Mechanical Properties of Hollow Gel-Spun Lignin/Graphene Oxide/Poly (Vinyl Alcohol) Fibers

- Characteristic Analysis and Harmonic Feature Identification of Micro-Vibration on Flywheels

- Defect Detection Algorithm of Patterned Fabrics Based on Convolutional Neural Network

- Tufting Carpet Machine Information Model Based on Object Linking and Embedding for Process Control Unified Architecture