添加钢渣恢复厌氧消化酸化系统提高沼气产量

2018-09-03汪群慧任媛媛吴川福

邹 惠,高 明,汪群慧,于 淼,任媛媛,刘 凯,吴川福

添加钢渣恢复厌氧消化酸化系统提高沼气产量

邹 惠1,2,高 明1,2,汪群慧1,2※,于 淼1,任媛媛1,刘 凯1,吴川福1,2

(1.北京科技大学能源与环境工程学院环境工程系,北京 100083; 2. 工业典型污染物资源化处理北京市重点试验室,北京 100083)

针对厌氧消化酸化后传统恢复产气方法成本高,产气率低的问题,该文通过对比研究钢渣和碱对酸化后发酵体系的恢复作用,结果表明酸化体系添加钢渣后累积产气率为285.33 mL/g,较传统法(加碱)提高了25.8%,两组数据差异显著。同时对恢复产气后的pH值,总挥发性脂肪酸(total volatile fatty acid),碱度(alkalinity),挥发性脂肪酸(volatile fatty acids)进行了监测分析,发现两组的上述数据差异并不显著,TVFA/TA和丙酸/乙酸的比值更加有效指示两体系恢复后的稳定性,且添加钢渣体系较加碱体系提前8 d恢复正常。最后分析了恢复产气后消化液中重金属,两体系的重金属含量完全满足NY/T 2065-2011沼肥施用技术规范中的相关要求,此举提供了一种优于传统恢复酸化液渣产气的方式,为解决实际工程易酸化、恢复产气成本高的问题提出了新的解决方法。

垃圾;甲烷;碱;恢复产气;厌氧消化;钢渣

0 引 言

《中华人民共和国住房和城乡建设部》数据显示[1]:中国每年生产超过5 100万t的餐厨垃圾,大部分的处置方式是直接填埋[2]。而餐厨垃圾中含蛋白质、糖类、脂肪等占干物质的90%以上,是一种典型的“放错了地方”的生物质能源[3],通过厌氧发酵,垃圾中40%~50%的有机成分会被转化为生物能源,缓解中国能源紧张的状况。

然而在餐厨垃圾厌氧消化过程中,进料过多会使得挥发性脂肪酸大量积累[4];温度骤变,厌氧条件不够、原料中混入有毒物质等原因都会使产甲烷菌失活[5],导致厌氧消化系统酸化,产气量降低,严重的甚至会停止产气[6-7]。对于失稳或酸化的厌氧消化系统,传统的做法是向发酵体系中添加碱类物质(NaOH、Na2CO3、K2CO3)来调节pH值[8],但Na+和K+添加过多,除费用较高外,还会对厌氧消化系统产生抑制作用(如Na抑制质量浓度为3 500~5 500 mg/L)[9],故实际工程中常用石灰乳(Ca(OH)2)来调节pH值,因石灰乳价廉,同时钙离子对沼气发酵的毒性较小,但其能与系统中有机物降解所产生的CO2发生反应生成碳酸钙,碳酸钙的形成会导致沼渣排除管道的堵塞,同时石灰乳的加入会损失CO2,进而减少氢还原CO2途径生成的甲烷。而石灰乳的微溶性,使得其耗量大且恢复产气周期较长[10]。Angelidaki等[11]向餐厨垃圾中添加矿物材料(如:黏土、沸石、活性炭),利用其良好的吸附性能和粒子交换性能提高消化液的缓存能力,从而提高餐厨垃圾厌氧消化的产气能力,但这种方法缓冲pH值能力有限,且成本较高。因此对于酸化厌氧消化体系,选择一种快速的恢复产气方式很有必要。

钢渣作为炼钢过程中产生的主要副产品,占粗钢产量的12%~20%,含有丰富的钙、硅,被广泛应用于水泥生产、筑路、冶金返回料、玻璃生产中[12]。作为碱性富硅物质,钢渣是一种潜在的厌氧发酵功能促进剂[13],钢渣中含有的Al,Fe,Mn,Mg等多种微量元素,可作为生物催化剂,提高厌氧反应器的缓冲能力和产气量[14]。由于其比表面积较大,可吸附污泥中的重金属,对厌氧消化体系的氨氮也有一定的吸附能力[15]。研究表明钢渣的加入,可以明显提高体系的pH值[16]。因此,将钢渣用于酸化体系,是恢复产气的有效手段之一。

基于此,本文在酸化液渣中分别添加钢渣,氢氧化钠(传统方法),同时设置不加任何物质的对照组。通过对比各试验组恢复产气量,挥发性脂肪酸、碱度,pH值等指标,考察酸化液渣恢复产气情况,以期提出一种优于传统恢复产气的方式,解决实际工程酸化难恢复、恢复成本高等问题。

1 材料与方法

1.1 试验材料

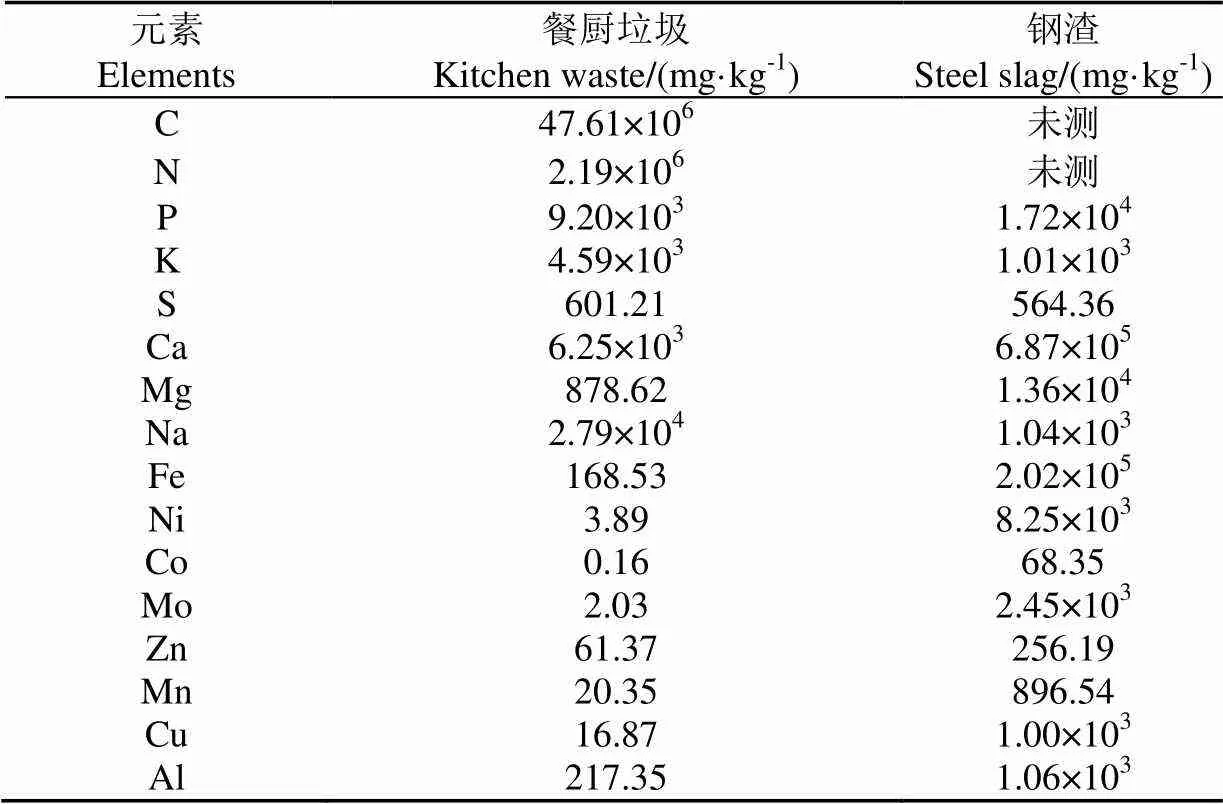

餐厨垃圾取自北京科技大学学生食堂,挑去骨头、塑料袋等难降解物后,垃圾中主要包括米饭、蔬菜、肉、蛋、豆腐、面条等。餐厨垃圾营养元素分析见表1。

表1 餐厨垃圾及钢渣营养元素分析

本试验钢渣取自首钢集团有限公司,钢渣为转炉渣,经破碎-筛分-磁选、破碎-湿磨-磁选、钢渣超细磨,其元素分析见表1,其粒径大小为10为5.12m;50为49.33m;90为101.58m。

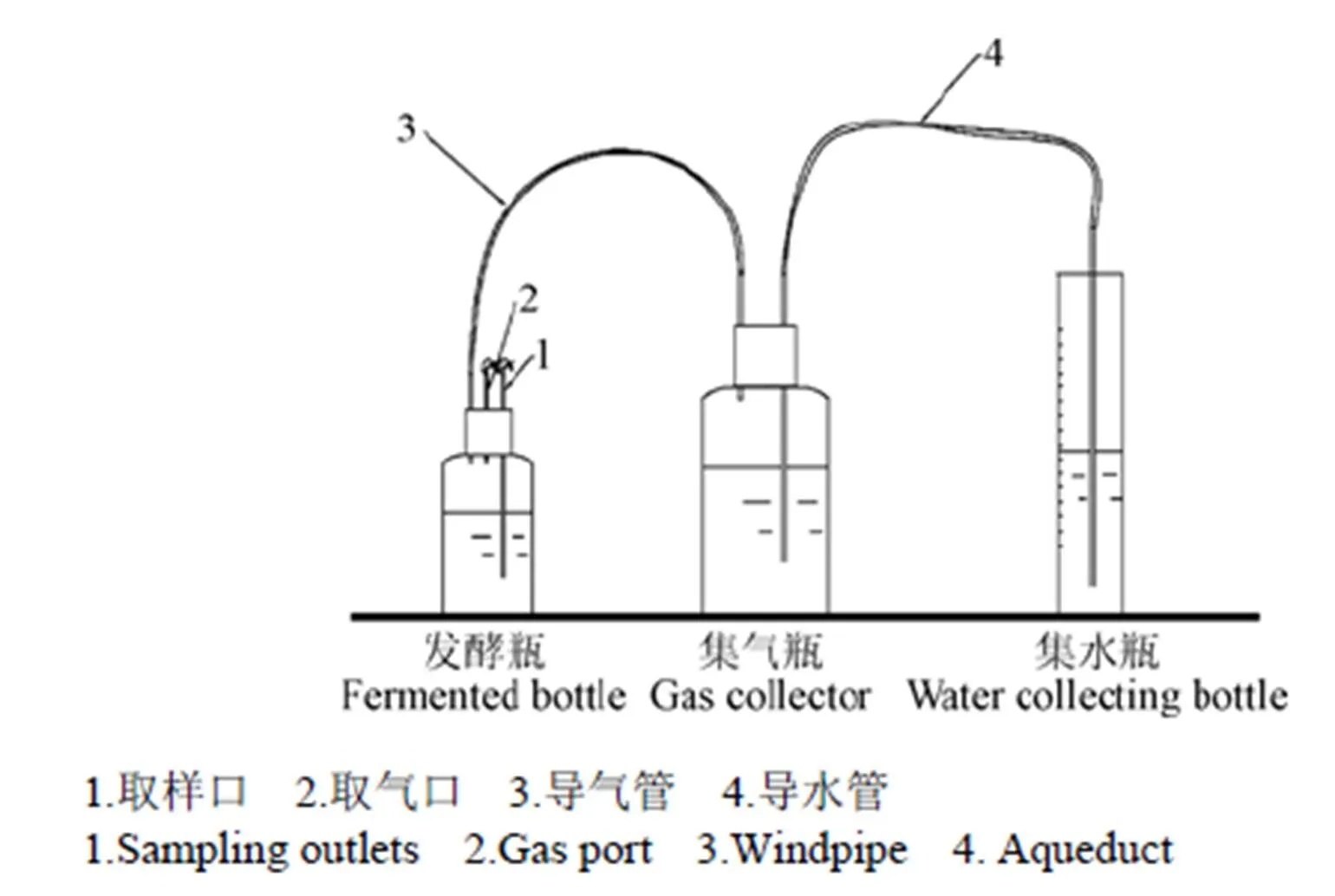

本试验污泥取自北京肖家河污水处理厂厌氧消化池。污泥理化特性见表2。

表2 污泥的理化特性

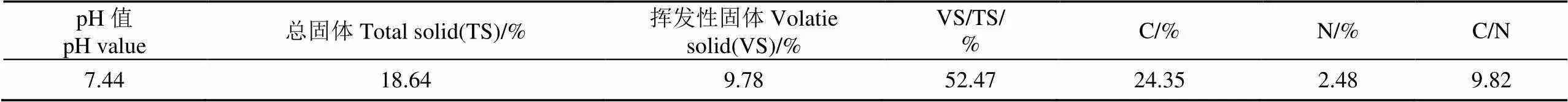

1.2 试验装置和方法

1.2.1 试验装置

厌氧消化系统主要由气浴恒温振荡器、发酵瓶、集气瓶、集水瓶等部分组成。试验分为2步,第1步为制备酸化液渣,10 L玻璃广口瓶为发酵瓶。第2步为恢复产气,2.5 L广口瓶为发酵瓶。发酵瓶均以橡胶塞封口,瓶口处插入玻璃管作为连接口,然后用硅胶管连接管路,并用石蜡密封瓶口。以排水法收集产生沼气。图1给出了试验装置图。

图1 试验装置图

1.2.2 酸化液渣制备

将餐厨垃圾和污泥放入10 L厌氧发酵瓶中,装液量为8 L,其中餐厨垃圾与污泥的接种质量比为2,充分混匀后充氮气10 min以排除残留空气,35 ℃下进行甲烷发酵,第4天的pH值降至6.03,同时产气量锐减,第7天的沼液为备用的酸化液渣。

1.2.3 恢复产气试验

恢复产气有3组试验,每组试验设置3组平行,加碱组,加钢渣组将酸化液渣初始pH值调至7,即:在酸化液渣中分别添加1.6 g钢渣和2.3 g NaOH,对照组不添加任何物质,各组试验同时充入氮气密封于35 ℃,80 r/min下进行恢复产气试验,考察各组能否恢复产气。

定时取样,分别测定挥发性脂肪酸(VFAs)、碱度(TA)、有机酸、pH值等;每天记录产气量。

1.3 分析方法

消化体系中的pH值采用PHS-3C型pH计测定。挥发性脂肪酸组成含量采用气相色谱仪(GC)测定[17]。乳酸含量采用液相色谱仪(LC)测定[18]。总挥发性脂肪酸(TVFA)采用比色法测定[19]。碱度采用APAH的标准方法测定[20]。

2 结果与讨论

2.1 添加钢渣和碱对酸化系统恢复产气效果比较

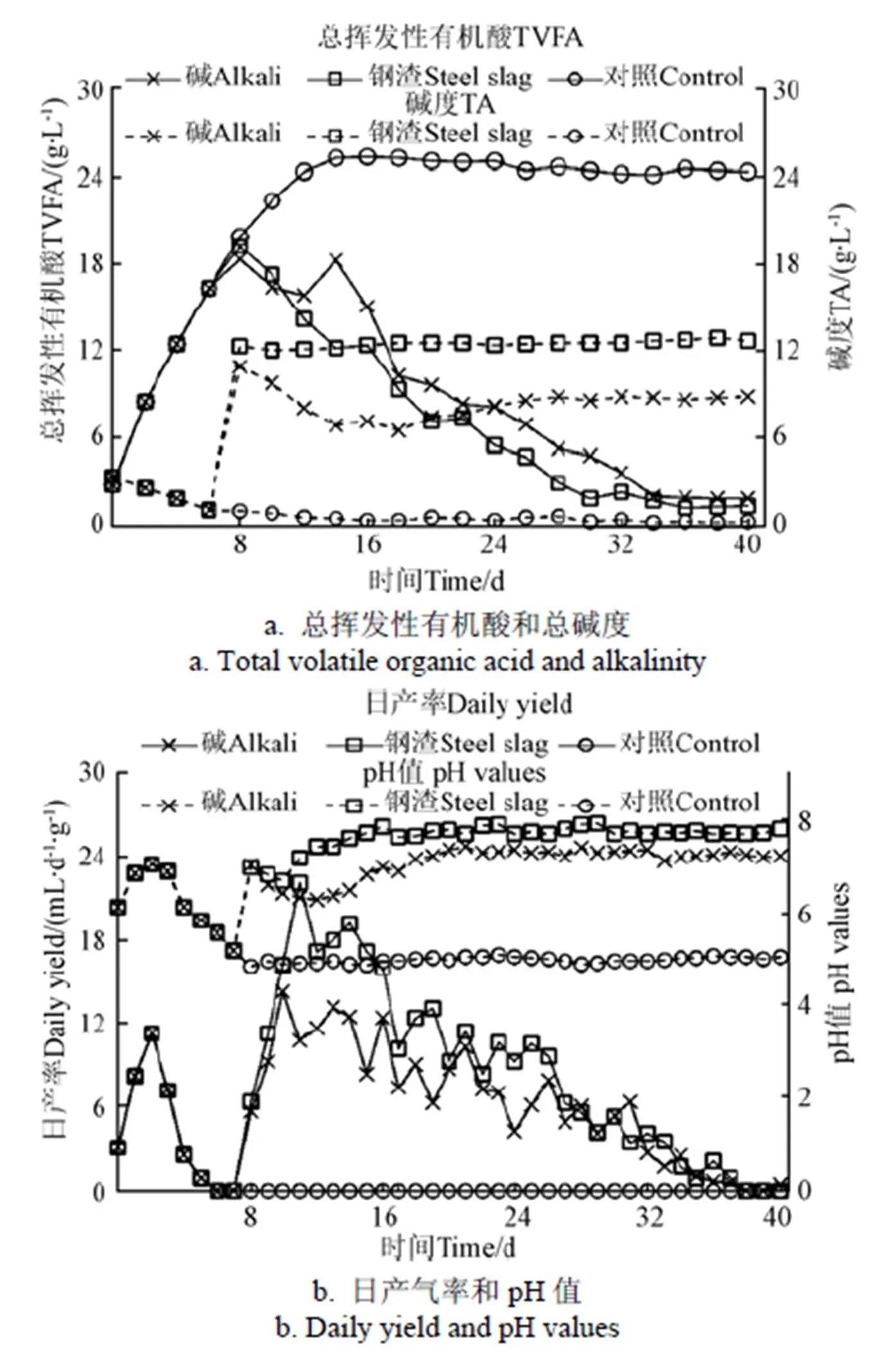

试验分为2个阶段,第1阶段为酸化期(0~7 d),第2阶段为恢复产气(8~40 d)。按1.2.2节制取酸化液渣,在酸化期,餐厨垃圾接种污泥后开始产气,但第7天系统的pH值降至5.18,厌氧消化体系酸化,此时,总挥发性脂肪酸(TVFA)积累到17.21 g/L时,体系的碱度(TA)从3.75 g/L(以CaCO3计)下降1.01 g/L,系统缓冲能力大大降低。图2表示酸化前后厌氧系统pH值、总挥发性有机酸、总碱度及日产气量的变化。

由图2可知,对照组在酸化恢复期始终没有恢复产气,且TVFA上升至25.64 g/L,碱度一直下降直至耗尽。而加碱或钢渣的2组当天均恢复产气,且pH值缓慢上升,加钢渣组的pH值上升速度和TVFA的下降速度均显著大于加碱组,恢复期第4天的pH值就上升至7.18,且TVFA下降至12.83 g/L,而加碱组在恢复期第10天才上升至7.14,且TVFA下降至15.81 g/L。另外,加钢渣组的pH值和总碱度TA在酸化恢复期分别稳定在7.7和12.45 g/L左右,加碱组的pH值和TA分别稳定在7.3和8.72 g/L左右,因此前者的总碱度和系统稳定性均高于后者,导致加钢渣组厌氧发酵40 d的累积产气率为285.33 mL/g,较加碱组提高了25.8%。这说明:①钢渣中所含氧化钙,氧化镁等金属氧化物溶于水后可形成强碱缓冲环境,提高系统的缓冲能力;②厌氧消化过程中起主导作用的是产甲烷菌,产甲烷菌的生长需要很多必需的营养物质,如:氮、磷、钾、硫,以及金属元素铁、镍、钴、钼、锌、锰、铜等[21],这些营养元素在表1的餐厨垃圾及钢渣元素分析中均可找到,餐厨垃圾中不足的微量元素由钢渣的元素补充。Agdag等[22]研究亦表明钢渣中含有的Fe,Zn,Cu等微量元素是多种产甲烷菌和酶系统的重要组成成分[23-24],可提高产甲烷菌活性,进而提高甲烷体系的稳定性[25];Zhang等[26]研究发现石灰渣中含有的Ca,Fe,Mn和碱性物质可提高厌氧发酵过程中氢含量,提高了沼气产量。本试验的结果也证实了钢渣中含有的微量元素是其产气率比加碱组高的重要原因。

同时,利用检验对加碱组和加钢渣组的产气率、TA、TVFA及pH值进行分析,2组各有21个样本,产气率,TA,TVFA及pH值的相关性分别为0.604,0.789,0.732和0.598,显著水平分别为0.005,0.062,0.072和0.083。选取显著水平=0.05,仅产气率达到显著水平<0.05,TA,TVFA及pH值的显著水平均>0.05,因此加碱和钢渣组的产气率存在差异显著,而TA,TVFA及pH值的差异不显著。

图2 酸化前后厌氧系统总挥发性有机酸、总碱度、pH值和日产气率的变化曲线

2.2 添加钢渣和碱对酸化系统有机酸组分的影响

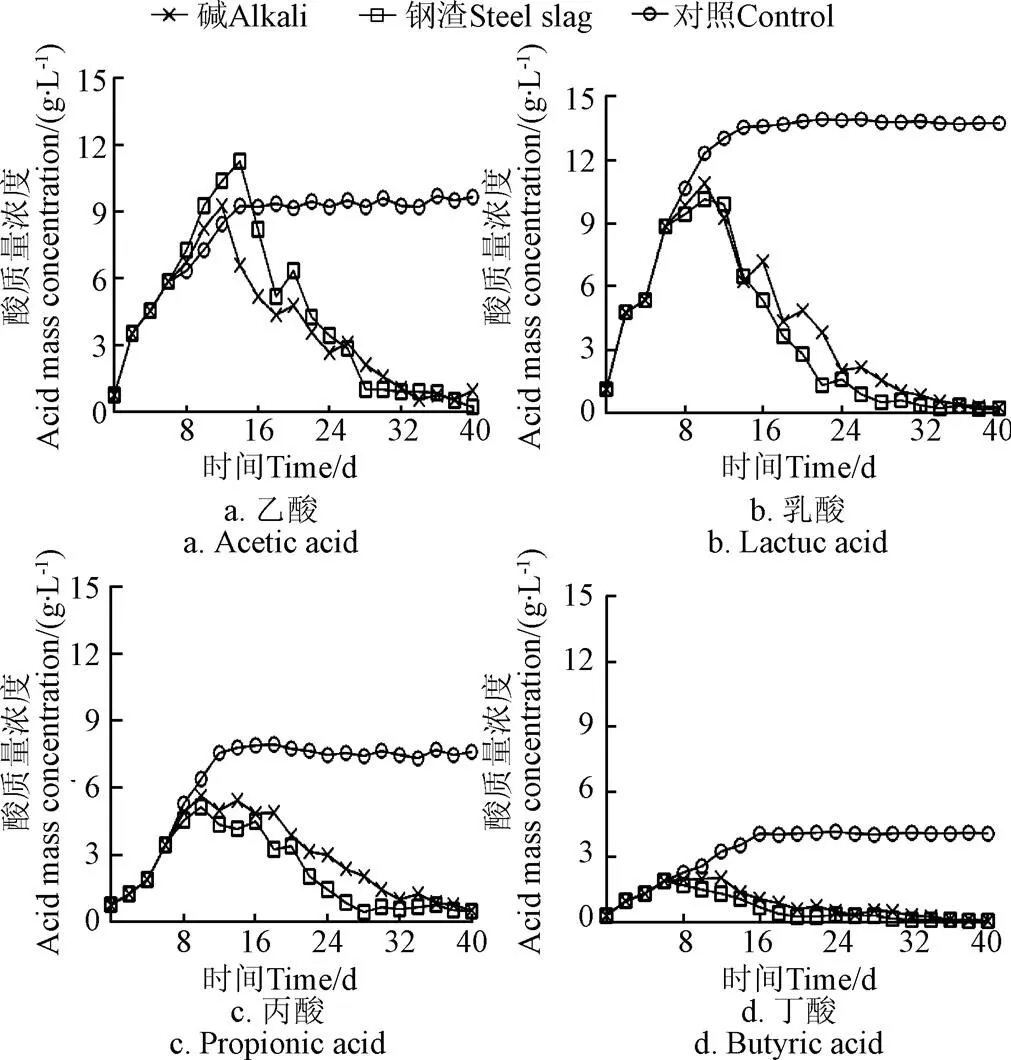

由2.1节可知,厌氧消化体系中酸化最直接的结果就是挥发性脂肪酸(VFAs)的显著增加,其中,乙酸、丙酸、丁酸等低分子VFAs对厌氧体系反应较为敏感[27]。在一般单相厌氧体系稳定运行时,乙酸应是最主要的中间代谢产物,约占VFAs的70%[28]。但本试验发现,在酸化期第7天,乳酸、乙酸、丙酸、丁酸质量浓度分别为9.08,5.86,3.45和1.87 g/L,其中乳酸含量占脂肪酸的45%。

添加钢渣和碱后,3组中各种酸的变化不同,根据Boe等[29]所报道的酸化阈值。对比图3中各酸的浓度可知,添加钢渣各酸的恢复速度均比添加碱的恢复速度快3~4 d。酸化恢复期,恢复最快的是丁酸,其次分别是乳酸、乙酸、丙酸。乳酸恢复速率快是因为可以较快代谢为丙酸,这导致丙酸的降解速度最慢,较其他参数恢复到正常水平要慢5~6 d。从热力学角度来看,乳酸转化为丙酸的吉布斯自由能为−80.45 kJ/mol,是自发过程,非常容易,而丙酸转为乙酸的吉布斯自由能为76.1 kJ/mol,同其他中间代谢产物(如乙酸、丁酸等)相比,向甲烷转化速率最慢[30],只有在其他酸恢复正常后,丙酸的浓度才能逐渐恢复至正常含量。乙酸恢复速率相比略慢,这是由于其他的脂肪酸首先降解产生乙酸,而后才被产甲烷菌所利用。

利用检验分析了乙酸、乳酸、丙酸和丁酸在恢复产气阶段2组间(加碱和加钢渣)数据变化,统计结果表明在21个样本中,乙酸、乳酸、丙酸和丁酸的显著水平值分别为0.064,0.068,0.076和0.098,4种酸的值均大于0.05,表明2组间4种酸在恢复产气阶段差异并不显著。

图3 恢复产气后乙酸、乳酸、丙酸及丁酸浓度的变化曲线

2.3 添加钢渣和碱对酸化系统多因子综合评价参数的影响

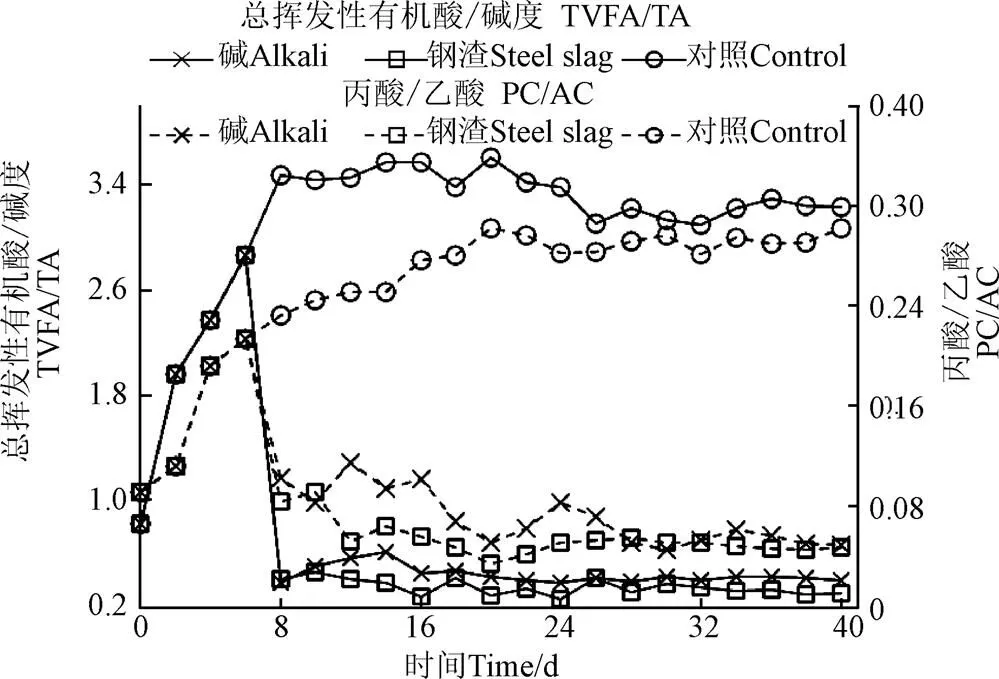

图2和图3表示酸化发生时体系的pH值、碱度、TVFA会发生明显的改变,可见常规的单一因子可以在一定程度上反映厌氧消化体系过程不平衡,但国内外对单因子参数的阈值报道不一[31],可见单一参数并不是理想的厌氧消化系统稳定性评价指标。Li Lei等[32]研究表明,在厌氧消化过程中,总挥发性脂肪酸与碱度的比值(TVFA/TA)表明了保持系统内碱度的化合物与引起pH值降低的化合物之间的比例,可以更好、更灵敏地反映厌氧消化系统承受酸化的能力。从代谢方向来看,丙酸通常是转化为乙酸和氢气,Moller等[33]评价了丙酸和乙酸浓度之比(PC/AC)在反应器运行失衡时的敏感性和可靠性。因此多因子综合评价参数(TVFA/TA和PC/AC)可作为衡量厌氧消化体系稳定性的参数。

如图4所示,酸化发生时系统内酸形成和碱消耗之间的平衡被打破,VFA/TA从0.83迅速增至2.86。同时,乳酸、丙酸的大量生成,使得PC/AC比值从0.092迅速增至0.21。添加钢渣和碱后,体系的碱度瞬时被提高,加钢渣组8 d内的TVFA/TA和PC/AC比值分别降至0.38和0.081,随后继续下降到0.05以下;加碱组有同样的下降趋势,只是稍比加钢渣组下降缓慢。

图4 总挥发性脂肪酸/碱度(TVFA/TA)及丙酸/乙酸(PC/AC)的变化曲线

前人研究表明厌氧消化最适宜的TVFA/TA应维持在0.3~0.4之间,TVFA/TA如果超过0.8则会导致发酵状态恶化[33];另一方面,若PC/AC比值超过0.08时系统也会开始出现抑制现象,高于0.10则会对甲烷菌产生50%的抑制[34]。加钢渣和加碱体系产气量与TVFA/TA、PC/AC比值的相关性与文献报道的相似,且加钢渣组恢复产气稳定后的TVFA/TA,PC/AC较加碱组低,说明钢渣的加入使得体系更加稳定,这与图2的结论一致。

通过显著性分析可知:加碱和加钢渣组VFA/TA和PC/AC显著水平值分别为0.15和0.26,2组的值均大于0.05,表明2组VFA/TA和PC/AC变化差异不显著,这正好说明2体系恢复产气后能较快达到稳定状态。

2.4 恢复产气后沼渣、沼液利用分析

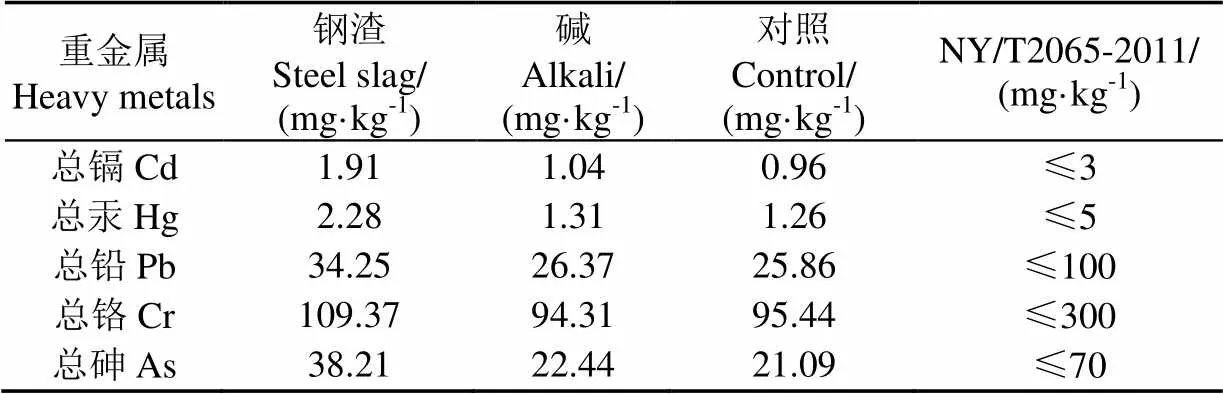

钢渣中含有部分重金属,根据NY/T 2065-2011沼肥施用技术规范中相关技术参数,沼渣、沼液的利用对重金属含量有严格要求,因此表3分析了相关几种重金属的含量。

表3 不同恢复产气下消化液中重金属变化

由表3分析可知,添加酵母和钢渣恢复产气后所得消化液中重金属含量满足NY/T 2065-2011沼肥施用技术规范中的相关要求,即此2种恢复产气方式不影响沼渣、沼液的利用途径。

3 结 论

1)添加钢渣可以恢复酸化厌氧消化体系产甲烷,累积恢复产气率为285.33 mL/g,相比传统恢复产气方法(加碱),产气量提高了25.8%。

2)餐厨垃圾厌氧消化酸化试验恢复过程中,与单因子指示因子(pH值、总挥发性脂肪酸、碱度等)相比,组合因子(总挥发性脂肪酸/碱度、丙酸/乙酸)具有稳定性佳、指示性全面的特点,且添加钢渣较加碱体系提前8 d恢复正常。

3)添加钢渣恢复产气后所得消化液中重金属含量满足NY/T 2065-2011沼肥施用技术规范中的相关要求,此法可作为一种新的恢复产气方式,解决实际工程易酸化、恢复成本高及产气率低的问题。

[1] Ministry of Housing and Urban-Rural Development of the People’s Republic of China. CJJ 184–2012 Technical code on food waste treatment[S]. China Architecture & Building Press, 2012.

[2] Ma Jingxing, Duong Thuhuang, Smits M, et al. Enhanced biomethanation of kitchen waste by different pre-treatments[J]. Bioresource Technology, 2011, 102(2): 592-599.

[3] Li Panyu, Li Ting, Zeng Yu, et al. Biosynthesis of xanthan gum byLRELP-1 using kitchen waste as the sole substrate[J]. Carbohydrate Polymers, 2016, 151: 684-691.

[4] Liotta F, D’Antonio G, Esposito G, et al. Effect of total solids content on methane and volatile fatty acid production in anaerobic digestion of food waste[J]. Waste Management & Research the Journal of the International Solid Wastes & Public Cleansing Association Iswa, 2014, 32(10): 947-953.

[5] Zhang Jishi, Sun Kewei, Wu Manchang, et al. Influence of temperature on performance of anaerobic digestion of municipal solid waste[J]. Journal of Environmental Sciences, 2006, 18(4): 810-815.

[6] Jang H M, Park S K, Ha J H, et al. Microbial community structure in a thermophilic aerobic digester used as a sludge pretreatment process for the mesophilic anaerobic digestion and the enhancement of methane production[J]. Bioresource Technology, 2013, 145: 80-89.

[7] Appels L, Baeyens J, Degrève J, et al. Principles and potential of the anaerobic digestion of waste-activated sludge[J]. Progress in Energy & Combustion Science, 2008, 34(6): 755-781.

[8] 于雷,彭剑峰,宋永会,等. 厌氧反应器的酸化及其恢复研究进展[J].工业水处理,2011,31(8):1-4. Yu Lei, Peng Jianfeng, Song Yonghui, et al. Research progress in the acidification of highly efficient anaerobic reactor and its recovery[J]. Industrial Water Treatment, 2011, 31(8): 1-4. (in Chinese with English abstract)

[9] 邹小玲,许柯,夏兴华,等.NaCl和KCl盐度对厌氧污泥的驯化及对比产甲烷活性的影响[J]. 中国沼气,2009,27(3):23-25.

Zou Xiaoling, Xu Ke, Xia Xinghua, et al. NaCl and KCl salinity acclimations of anaerobic sludge and their effects on specific methanogenic Activity[J]. China Biogas, 2009, 27(3): 23-25. (in Chinese with English abstract)

[10] 吴美容,张瑞,周俊,等. 温度对产甲烷菌代谢途径和优势菌群结构的影响[J]. 化工学报,2014,65(5):1602-1606.

Wu Meirong, Zhang Rui, Zhou Jun, et al. Effect of temperature on methanogens metabolic pathway and structures of predominant bacteria[J]. CIESC Journal, 2014, 65(5): 1602-1606. (in Chinese with English abstract)

[11] Angelidaki I, Ahring B. Effect of the clay mineral bentonite on ammonia inhibition of anaerobic thermophilic reactors degrading animal waste[J]. Biodegradation, 1992, 3(4): 409-414.

[12] Qian Guangren, Sun D D, Tay J H, et al. Autoclave properties of kirschsteinite-based steel slag[J]. Cement and Concrete Research, 2002, 32(9): 1377-1382.

[13] Yu Xingang, Wang Hongfei, Li Yuexiang, et al. Study on the high performance coal gangue foam concrete[J]. Materials Science Forum, 2009(610/611/6112/613): 185-189.

[14] 张仙梅,云斯宁,杜玉凤,等. 沼气厌氧发酵生物催化剂研究进展与展望[J]. 农业机械学报,2015,46(5):141-155.

Zhang Xianmei, Yun Sining, Du Yufeng, et al. Recent progress and outlook of biocatalysts for anaerobic fermentation in biogas production process[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(5): 141-155. (in Chinese with English abstract)

[15] Patel V, Patel A, Madamwar D. Effects of adsorbents on anaerobic digestion of water hyacinth-cattle dung[J]. Bioresource Technology, 1992, 40(2): 179-181.

[16] 张浩,杨刚,刘秀玉,等. 钢渣微粉对牛粪厌氧发酵产沼气的影响[J]. 非金属矿,2016,39(5):45-48.

Zhang Hao, Yang Gang, Liu Xiuyu, et al. Influences of steel slag powder on anaerobic fermentation of cattle manure for biogas yield[J]. Non-Metallic Mines, 2016, 39(5): 45-48. (in Chinese with English abstract)

[17] 刘艳玲,任南琪,刘敏,等. 气相色谱法厌氧反应器中的挥发性脂肪酸(VFA)[J]. 哈尔滨建筑大学学报,2000,33(6):31-34.

Liu Yanling, Ren Nanqi, Liu Min, et al. Analysis of volatile fatty acid(VFA) in anaerobic bio-reactor by gas chromatography[J]. Journal of Harbin University of Civil Engineering and Architecture, 2000, 33(6): 31-34. (in Chinese with English abstract)

[18] Liu Yanling, Ren Nanqi, Liu Min, et al. Analysis of Volatile Fatty Acid(VFA) in anaerobic bio-reactor by gas chromatography[J]. Journal of Harbin University of Civil Engineering and Architecture, 2000, 33(6): 31-34.

[19] 马瑞,欧阳嘉,李鑫,等. 高效液相色谱法同时测定生物质乳酸发酵液中有机酸及糖类化合物[J]. 色谱,2012,30(1):62-66.

Ma Rui, Ou Yangjia, Li Xin, et al. Simultaneous determination of organic acids and saccharine in lactic acid fermentation broth from biomass using high performance liquid chromatography[J]. Chinese Journal of Chromatography, 2012, 30(1): 62-66. (in Chinese with English abstract)

[20] 任南琪,王爱杰. 厌氧生物技术的原理及应用[M]. 北京:化学工业出版社,2004.

[21] Li Lei, He Qingming, Wei Yunmei, et al. Early warning indicators for monitoring the process failure of anaerobic digestion system of food waste[J]. Bioresource Technology, 2014, 171: 491.

[22] Agdag O N, Sponza D T. Effect of alkalinity on the performance of a simulated landfill bioreactor digesting organic solid wastes[J]. Chemosphere, 2005, 59(6): 871.

[23] Clark P B,Hillman P F. Enhancement of anaerobic digestion using duckweed (Lemna minor) enriched with iron[J]. Water Environment Manage Journal, 1995, 10(2): 92-95.

[24] Demirel B, Scherer P. Trace element requirements of agricultural biogas digesters during biological conversion of renewable biomass to methane[J]. Biomass and Bioenergy, 2011, 35(3): 992-998.

[25] Lei Zhongfang, Chen Jiayi, Zhang Zhengya, et al. Methane production from rice straw with acclimated anaerobic sludge: Effect of phosphate supplementation[J]. Bioresource Technology, 2010, 101(12): 4343-4348.

[26] Zhang Jishi, Wang Qinqing, Jiang Jiamguo. Lime mud from paper-making process addition to food waste synergistically enhances hydrogen fermentation performance[J]. International Journal of Hydrogen Energy, 2013, 38: 2738-2745.

[27] Jacobi H F, Moschner C R, Hartung E. Use of near infrared spectroscopy in monitoring of volatile fatty acids in anaerobic digestion[J]. Water Science and Technology, 2009, 60(2): 339-346.

[28] 贾传兴. 有机垃圾厌氧消化系统失衡预警机制研究[D]. 重庆:重庆大学,2010.

Jia Chuanxing. Study on the Imbalance and Early-warning Mechanism in Anaerobic Digestion of Organic Wastes[D]. Chongqing: Chongqing University, 2010. (in Chinese with English abstract)

[29] Boe K, Batstone D J, Steyer J P, et al. State indicators for monitoring the anaerobic digestion process[J]. Water Research, 2010, 44(20): 5973-5980.

[30] Nielsen H B, Uellendahl H, Ahring B K. Regulation and optimization of the biogas process: Propionate as a key parameter[J]. Biomass & Bioenergy, 2007, 31(11): 820-830.

[31] 吴唯民,胡纪华,顾夏声. 厌氧污泥的最大比产甲烷速率(U_(max.CH4))的间歇试验测定法[J]. 中国给水排水,1985(4):33-38.

Wu Weimin, Hu Jihua, Gu Xiasheng. Maximum specific methane production rate of anaerobic sludge and its measurement by batch test[J]. China Water & Wastewater, 1985(4): 33-38. (in Chinese with English abstract)

[32] Li Lei, He Qingming, Wei Yunmei, et al. Early warning indicators for monitoring the process failure of anaerobic digestion system of food waste[J]. Bioresource Technology, 2014, 171: 491-494.

[33] Moller H B, Nielsen A M, Nakakubo R, et al. Process performance of biogas digesters incorporating pre-separated manure[J]. Livestock Science, 2007, 112(3): 217-223.

[34] Wang Lihong, Wang Qunhui, Cai Weiwei, et al. Influence of mixing proportion on the solid-state anaerobic co-digestion of distiller’s grains and food waste[J]. Biosystems Engineering, 2012, 112(2): 130-137.

Biogas recovery and yield improvement of acidification system by adding steel slag

Zou Hui1,2, Gao Ming1,2, Wang Qunhui1,2※, Yu Miao1, Ren Yuanyuan1, Liu Kai1, Wu Chuanfu1,2

(1.100083; 2.100083)

With the problems of high cost and low biogas yield in traditional acidification recovery method of anaerobic digestion (AD), the paper selected steel slag added in the biogas production recovery method, which was the by-product of steel making, and the effect of steel slag on the recovery after acidification was compared with that of alkali. The results showed that the acidification system could be restored by adding steel slag and alkali on the first day, and the cumulative biogas production rate on the 40thday was 285.33 mL/g with the steel slag adding, which was increased by 25.8% compared with the traditional method of adding alkali. At the same time, the pH values, total volatile fatty acid (TVFA), alkalinity (TA), and volatile fatty acids (VFAs) of the steel slag and alkali groups after recovering biogas production were monitored and analyzed. The TVFA was slowly decreased till exhausted and the TA was basically around 12.45 g/L in steel slag group; on the contrary, the TVFA increased in first 2 days and then decreased and the TA slowed down till 8.72 g/L in alkali group. And thetest was used to analyze the data variation of biogas yield, TA, TVFA and pH value in alkali and steel slag groups (each group had 21 samples), the significant level of the biogas yield (0.005) was less than 0.05, while the significant levels of TA, TVFA and pH value were more than 0.05. Therefore, the biogas yield in the 2 groups was significantly different, but the difference of TA, TVFA and pH value was not significant. Meanwhile, the trend of acetic acid, propionic acid, butyric acid and lactic acid was observed. The results demonstrated that the recovery rate of each kind of acid in steel slag group was 3-4 d faster than that in alkali group, and the order of recovery rate was successively butyric acid, lactic acid, acetic acid and propionic acid; the significant levels of acetic acid, lactic acid, propionic acid and butyric acid were 0.064, 0.068, 0.076 and 0.098, respectively, all greater than 0.05, which indicated that the differences among the 4 kinds of acids were not significant in the recovery stage. The ratio of TVFA to TA and the ratio of propionic acid to acetic acid were studied, and the results indicated the 2 ratios in 2 groups were both at the best level after recovery for 15 d, and on the 8thday the 2 ratios in steel slag group dropped to 0.38 and 0.081, respectively, and then decreased to below 0.05;there was the same trend in alkali group. Thevalues of the ratio of VFA to TA and the ratio of propionic acid to acetic acid between alkali treatment and steel slag treatment were 0.15 and 0.26, respectively, which were all more than 0.05, indicating that the changes of data in these 2 ratios were not significant. This showed that the 2 systems could be recovered quickly in the recovery stage. At the last, the content of heavy metals in the digestive juice after recovery was analyzed, and the results indicated that the 2 kinds of biogas producing methods fully satisfied the requirements of the technical specification of NY/T 2065-2011 biogas fertilizer application. The paper provides a way to recover biogas from the traditional regen acidification liquid, which solves the problems of the easy acidification of the actual engineering and the high cost of the recovery of biogas production.

wastes; methane; alkali; recovery biogas production; anaerobic digestion; steel slag

2018-04-19

2018-07-17

国家自然科学基金资助项目(51578063,51708024)

邹 惠,博士生,主要从事有机废物资源化利用。Email:zhqjxf_163@163.com

汪群慧,教授,博士生导师,主要从事固体废物的资源化与能源化、环境生物技术、污水处理等领域的研究。Email:wangqh59@sina.com

10.11975/j.issn.1002-6819.2018.17.030

X705

A

1002-6819(2018)-17-0229-06

邹 惠,高 明,汪群慧,于 淼,任媛媛,刘凯,吴川福. 添加钢渣恢复厌氧消化酸化系统提高沼气产量[J]. 农业工程学报,2018,34(17):229-234. doi:10.11975/j.issn.1002-6819.2018.17.030 http://www.tcsae.org

Zou Hui, Gao Ming, Wang Qunhui, Yu Miao, Ren Yuanyuan, Liu Kai, Wu Chuanfu. Biogas recovery and yield improvement of acidification system by adding steel slag[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17): 229-234. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.17.030 http://www.tcsae.org