Improving Efficiency and Emissions of Small Ships by the Use of Hybrid Electrical Propulsion

2017-04-01BennabiMenanaCharpentierBillardNottelet

N.Bennabi,H.Menana,J.F.Charpentier,J.Y.Billard,B.Nottelet

(1.SEGULA Technology,Le Havre 76600,France;2.French Naval Academy Research Institute,Brest 29240,France; 3.GREEN,Lorraine University,Nancy 54000,France)corresponding author:jean-frederic.charpentier@ecole-navale.fr

Improving Efficiency and Emissions of Small Ships by the Use of Hybrid Electrical Propulsion

N.Bennabi1,2,H.Menana3,J.F.Charpentier2,J.Y.Billard2,B.Nottelet1

(1.SEGULA Technology,Le Havre 76600,France;2.French Naval Academy Research Institute,Brest 29240,France; 3.GREEN,Lorraine University,Nancy 54000,France)corresponding author:jean-frederic.charpentier@ecole-navale.fr

One of the future goals of shipbuilding for small ships is to reduce the impact of ship emissions to respond to existent and future regulations of the International Maritime Organization(IMO)on greenhouse gas and pollutants emissions.This work presents a state of the art of the context and related regulations associated to ship environmental impact.It shows that,electrification of propulsion and particularly Hybrid Propulsion Systems(HPS)are promising solutions to reduce the environmental impact of small ships which are often used near agglomeration areas which are very critical area for pollution and emission.Several hybrid and electric propulsion systems for small vessels are presented.The paper includes a general description of the future challenges for shipbuilding and a description of the possible topologies of HPS which can be implemented in small ships.The key features of the HPS components are also described and examples of small electric and hybrid ships are presented.

hybrid electric ship;series hybrid;parallel hybrid;fuel cell;battery;supercapacitor;CO2emissions; electrical power.

1 INTRODUCTION

The transport sector represents about 25%of the total commercial energy consumed in the world[1].

More than 80%of freight is transported by sea, and maritime transportation is responsible of more than 30%of the CO2emissions of the transportation sector and about 3%to 4%of the human CO2emissions.Greenhouse gas emissions related to ships are important and rapidly growing.Without action,these emissions will be more than double by 2050 due to the expected growth of the global economy and the associated transport demand[2].This is why stringent international regulations have been established or are in project to limit ship emissions.

In this context,minimization of fuel consumption and reduction of emissions is one of the main objectives for designing future generations of ships[3].One of the main challenges is to improve efficiency and optimally manage the energy/propulsion chains in order to reduce fuel consumption and environmental impact with an investment as low as possible[4].In this perspective,electrification and hybridization of the propulsion chains are one of the solutions for the development of more efficient ships and environmental friendly ships[5-6].

In this paper which is an extended version of[7],we will present firstly the global challenges of reducing ship pollution and emissions.We focus in the second part on the hybrid energy for propulsion of small ships.We present the various hybrid configurations and the criteria of choice of the energy generation and storage systems.Indeed,even if in many cases,small ships are devoted to operate in very critical area in terms of pollution (harbor,city,rivers), till today,due to technical and economic reasons,little interest was granted to electrification and hybridization of small ships.

2 SHIPS IMPACTS AND REGULATORY ASPECTS

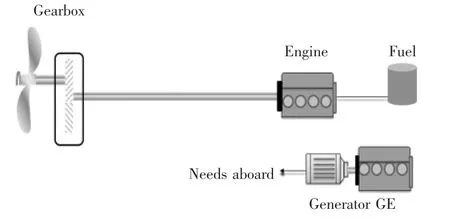

Diesel engines remain currently the most used for ships in conventional propulsion systems as shown in Fig.1.

图1 传统推进系统结构Fig.1 Conventional propulsion schema

Diesel engines are characterized by a high level of autonomy compared to other sources.They are however characterized by a high level of greenhouse gases and pollutants emissions,particularly if they work bellow their rated power.The exhaust gases of diesel engines mainly include nitrogen(N),oxygen(O), carbon dioxide(CO2)and water vapor(H2O),with small amounts of carbon monoxide(CO),sulfur oxides(SOx), nitrogen oxides(NOx),hydrocarbons(HC)and particles materials(PM)[2-3].

Fig.2 illustrates the emissions of exhaust gases in a diesel engine[8].As can be noticed,CO2is the most part of the pollutant elements rejected,followed by nitric(NOx)and sulfur(SOx)oxides.

图2 柴油引擎排放废气Fig.2 Contents of diesel engine exhaust gas[8]

The emissions of ships are directly related to the rejections of their engines.These emissions are all oil combustion products which can be classified as primary or secondary pollutants[4].The primary pollutants are pollutants formed directly during the combustion process(sulfur oxide,oxide of carbon,nitrogen oxide,…)while secondary pollutants are formed results of chemical reactions in the atmosphere(nitrogen dioxide, ozone,secondary particles,…)[5].

Without action,CO2emissions will be more than double by 2050,due to the expected growth of the global economy and the associated transport demandas shown in Fig.3[2].

图3 船舶二氧化碳排放量Fig.3 Evolution of CO2emissions in shipping[2]

Marine Pollution(MARPOL)73/78 adopted by the International Maritime Organization(IMO)aims to prevent and mitigate global marine pollution[9].For example,the annex VI of MARPOL defines strict limitations and Emission Controlled Areas(ECAs)for sulphur and nitric oxides covering the English Channel,the North Sea,the North American coast and the Caribbean under US control area as shown in Fig.4[10].In these protected areas(ECAs)the maximum permissible sulphur content of marine fuels fell to 0.1%in 2015 as shown in Fig.5.In other areas these sulphur contents are subject to a limit of 3.5%.This overall limit will probably fall to 0.5%in 2025 while awaiting the results of a review to be completed in 2018.Table 1 gives the NOxlimitations for ship construction,defined by MARPOL VI[2].

The objectives of limiting the environmental impacts are particularly difficult to reach for small ships.Indeed,in one hand these small ships(pleasure boat,tugs,naval buses,river shuttles,…)are often used near or in agglomeration areas which correspond to the highest restrictions in terms of pollution and emissions,and in the other hand,in such small boats, the volume and the number of components of the energy chains are strongly limited,reducing the possibilities of implementing innovative energy/propulsion systems.This is why the second part of the paper will focus on the solutions to reduce the impacts of small ships and particularly on the solutions based on electrification and hybridization of the energy chain.

图4 硫排放受控地区Fig.4 Emission controlled areas for sulphur[10]

图5 硫化物排放限制的发展Fig.5 Sulphur content limits through time[11]

表1 氮氧化物的排放限值Table 1 NOxlimitations MARPOL VI[2]

3 WAYS OF REDUCTION OF SMALLSHIP ENVIRONMENTAL IMPACTS

1)Reduction of ships emissions by the use of alter native fuels

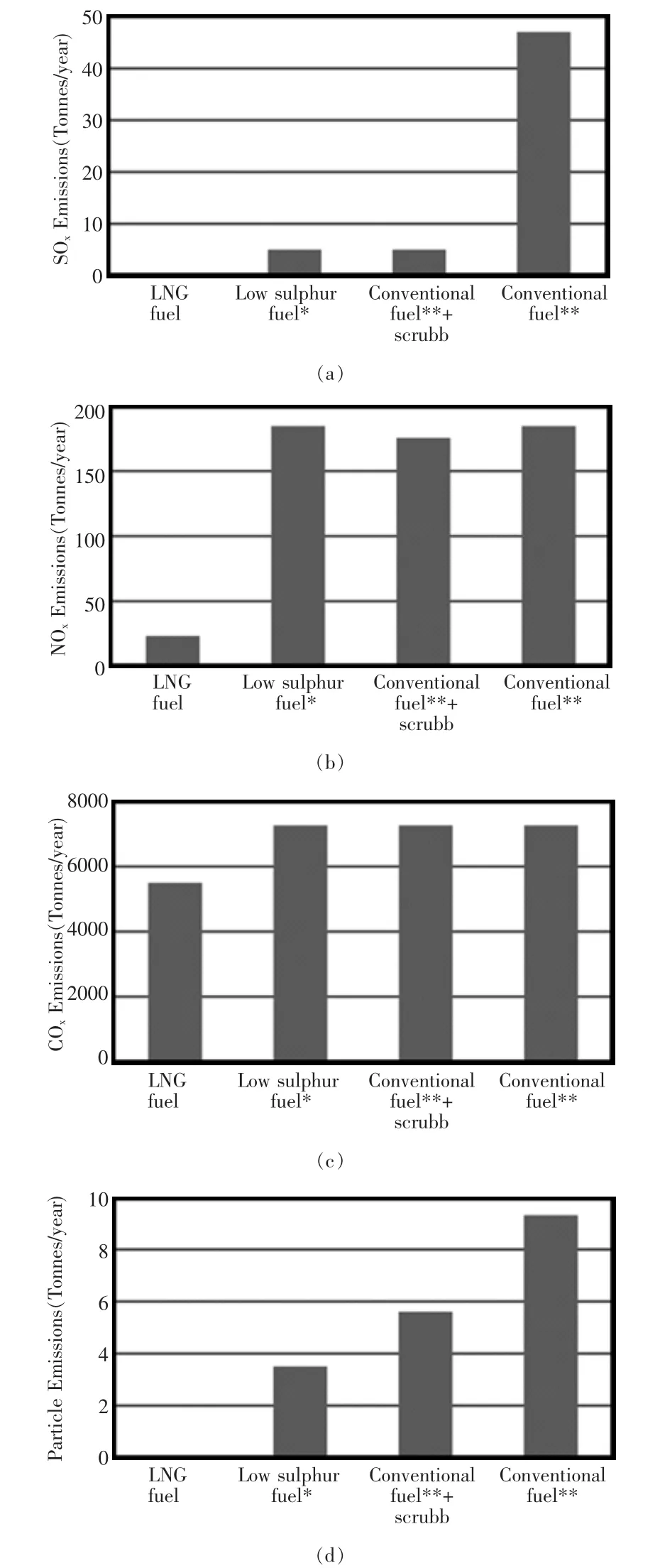

Table 2 represents a summary of the different conversion factors of CO2emission for different types of fuel[9].These data underline in particular the interest of biofuels compared to fossil ones.In recent years,the Liquefied Natural Gas(LNG)has been considered as an alternative fuel for ships[13].Fig.6 shows a compar-ison between several types of fuel in terms of emissions.These results show that LNG is a very interesting alternative to diesel allowing a reduction of about 85%~90%of NOxemissions,almost 100%of SOxemissions and about 15%~20%of CO2emissions.

图6 典型船舶不同类型燃料的排放Fig.6 Emissions of different types of fuel for typical ships[13]

表2 燃料排放转换因子Table 2 Conversion factors for fuel emissions[9]

2)Electrification and hybridization of ship propulsion for small ships

New electric and hybrid propulsion architectures,allowed by innovative and high performance components(batteries,fuel cells,supercapacitors)are a very promising track to strongly reduce pollutants and greenhouse gas emissions.If some studies are conducted for the integration of such architectures in large vessels,small ships benefit only marginally today ofthis kind ofsystems.Actually,the integration of these new propulsion architectures on small ships operating on shorts cycles is a real technicalchallenge.Indeed,in such ships,the volumesdevoted to energy storageand energy/ propulsion systems are strongly reduced.Furthermore they often operate in transient involving strong power demand.The available times for charging energy systems are also often limited.

In thefollowing,wedescribethedifferent hybrid energy/propulsion topologies and give some elements related to the adequacy of these topologies to meet the specific requirements of small ships. A.General Advantages of electric and hybrid propulsions

Hybrid Propulsion Systems(HPS)are interesting when there is a large variation in power demand during operations.The design rules of this type ofsystems can differ significantly for different types of vessel,mainly due to the different types of mission profiles and operation requirements.Hybrid propulsion systems are very promising technologies to design high efficiency and environmental friendly small ships[14-15].

·HPS provide a better energy efficiency and significant greenhouse gas and pollutants emissions reduction than classical mechanical systems[15-16].

·Hybrid systems are modular,and offer a power redundancy.

·The use of electrical propulsion systems(POD system and thrusters)allows to improve maneuverability with important reduction of noise and vibrations[15].

·Electrical propulsion systems offer more degree of freedom for naval architecture and allow to free onboard available space.

·HPS allow reducing of the level of vibration transmitted to the structure of the ship.

·HPS lead to a reduction of maintenance operations on the combustion engines because the combustion engines are more often optimally used.

However,all technologies are not mature and a satisfying compromise among cost,mass,and energy management performance is not yet reached. B.Hybrid propulsion topologies

Hybridization of the propulsion chains is a promising approach to minimize fuel consumption;especially for vessels that requires a high degree of maneuverability and very varied operating cycles[14-17]. It is based on the combination of several different energy sources.The choice of the sources and their combinations is adapted to the ship power and energy requirements which include the needs of low and high power,the needs of flexibility in operating modes and the needs of redundancy and reliability.

Three main HPS architectures are encountered:

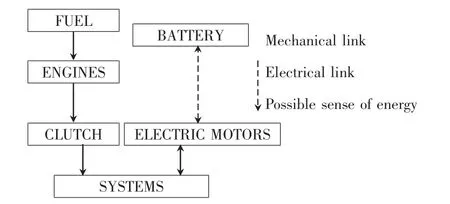

a.Series hybrid architecture

In this type of HPS architecture(Fig.7),two kinds of energy systems(combustion engines and electric systems)are used in series[16].The propulsion is done by a variable speed electrical drive(propulsion motor and power converter).The electrical power of the propulsion motor is generally supplied by a set of generators driven by combustion engines.Another option is to use fuel cells to provide electricity or a combination of fuel cells and generators driven by combustion engine.Energy Storage Systems(ESS)such as batteries,supercapacitors,etc.can be connected to the electrical bus.This ESS can be used separately or with the generators[17].

图7 典型串联混合结构Fig.7 Typical series hybrid architecture[19]

In this configuration,electricity is used as an energy vector between the combustion engine and the propulsion motor,so there is no direct mechanical connection between the combustion engine and the propeller[18].This configuration allows dissociating the operating points of the combustion engine and of the propeller.This is why it allows increasing the global efficiency of the system by optimizing the operating point of combustion engine and propeller in efficiency point of view.Of course,this advantage would be more significant if several generators and ESS are used,because it allows providing the required propulsion power by choosing an optimal combination of sources in order to keep the running combustion en-gines in their optimal operating area.This is why this structure is massively used for high power ships as military or passenger’s vessels.However,for small ships,the possibility of multiplying the sources is very limited by volume and mass constraints.

b.Parallel hybrid architecture

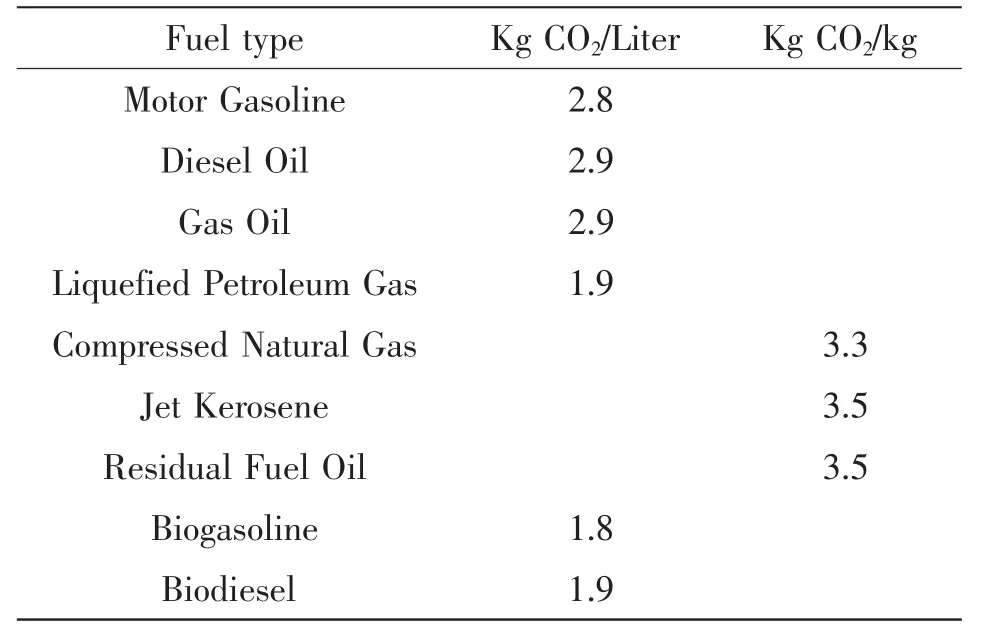

A typical parallel HPS is shown in Fig.8.Parallel hybrid architecture combines two kinds of propulsion motors:electric motors and combustion engines which are mechanically coupled by the same shafts through gearboxes and clutches.The electrical motors and drive are supplied by electrical ESS and/ orindependentpowersources(generatorsdrivenbycombustion engines and/or fuel cells for example).The two propulsionsystemscanbeusedtogetherorseparately[20].

In most cases,one of the propulsion systems is devoted to low speed operations(classically the electric system)and the other one(classically the combustion engine)is used for high speeds.The first system can also be used as a boost system to provide a supplementary power during transient(starting,acceleration, etc.).This architecture reduces the number of elements compared to the series hybridization and allows optimizing the sizing of each of the energy sources[21].

Table 3 gives a comparison between the series and parallel hybridization architectures,in terms of coasts,redundancy and efficiency.

图8 典型并联混合推进系统Fig.8 Typical parallel hybrid architecture[19]

表3 混合结构拓扑的性能比较Table 3 Performances comparison of hybrid architectures topologies[16,18,20,22]

c.Series-Parallel hybrid architecture

The series-parallel architecture combines both ar-chitectures defined previously.This association allows the switching from the parallel to the serie HPS[18,22]. C.Power sources in HPS

This section presents the main power sources and energy storage systems which can be used in HPS.The minimization of the fuel consumption on operating cycle requires the knowledge of the behavior of these different energy sources.

a.Unconventional power generation systems

Fuel cells can be an interesting alternative for power production on small ships with very low emissions.It is an electrochemical device that converts chemical energy of a fuel into electrical energy[23-25]. It has the life expectancy of a diesel engine.

Fuel cells are classified according to operating temperature and the nature of the used electrolyte. There are two categories of fuel cells:high-temperature and low-temperature fuel cell[25-26].Low temperature fuel cell categories include the Alkaline Fuel Cells(AFC),the Proton Exchange Membrane Fuel Cells(PEMFC),the Direct Methanol Fuel Cells(DMFC)and the Phosphoric Acid Fuel Cells(PAFC).These fuel cells are characterized by an operating temperature from 50 to 250°C[18,25,27].High temperature fuel cells include the Solid Oxid Fuel Cells(SOFC)and the Molten Carbonate Fuel Cells(MCFC).Their operating temperatures are comprised between 650 and 1 000°C[23-25].

The Fig.9 shows a comparison between the different elements of generation of energy,and shows that PEMFC have an efficiency up to 45%(efficiency of PSCF is about 40%and diesel engine efficiency is about 35%).It can provide high efficiency power with zero emission.

It can be also noticed that PEMFC technology is characterized by relatively low operating temperature which ensures an easy and quick start which could be interesting for vessels with a variable duty cycle[20,28]. Another advantage is its significant lifetime compared to other fuel cells types.All the points indicate that PEMFC can be a very attractive element for HPS for low power small ship.

图9 内燃机系统及燃料电池系统的电力效能比较Fig.9 Comparison of the efficiency and electrical power installed for the combustion-based systems and fuel cell systems[28]

b.Electric storage system

An intermediate energy storage device can be used to better manage the energy and reduce the effects of peak power level on the sizing of the energy sources.The integration of energy storage systems offers interesting solutions for the efficiency and optimal use of energy.It can also lead to a significant reduction in noise and vibration compared to conventional systems[28].

Fig.10 gives a comparison of different energy storage systems in terms of specific energy and peak power.

图10 几种储能系统的Ragone图Fig.10 Ragone diagram of several storage systems[29]

Batteries are the most used systems.As shown in Fig.10,lithium-ion batteries present significant advantages compared to other battery types,particularlyin term of energy density and efficiency[28].However, like fuel cells,batteries are characterized by a low dynamic and thus cannot manage transitional regimes.

Supercapacitors are interesting intermediate energy storage systems for small ships with short power transients.They are characterized by a high value of charge and discharge peak power and can be used to rapid dynamic storage with very low specific energy. They are usually associated with batteries and fuel cells,to manage high power short transients[28].They can operate at very low temperatures at which many types of electrochemical batteries stop working.

Flywheels can also be used in some particular cases.Like supercapacitors,they are characterized by a high power density but a relatively low energy density.However using flywheels leads to implement safety systems to protect crew and passengers from possible flywheel failure.So their use in small ship context seems very limited.

D.Examples of electrical and hybrid vessels

a.Zempships“Atlterwaser”

This vessel is the result of Zemships-EU project(Zero Emission Ships)[30,31].It has been launched in Hamburg in 2008 and it is one of the first boats developed using fuel cells.A picture of this boat is given in Fig.11.Table 4 summarizes its specifications.

图11 Zemships Atlterwaser船(http://www.proton-motor.com/zemships/)Fig.11 Zempships Atlterwaser boat(from http://www.proton-motor.com/zemships/)

表4 Zemships Atlerwaser船舶参数Table 4 Parameters of the Zempships Atlterwaser boat[30-31]

This boat uses PEM FC as main power source and lead batteries as ESS as shown in Fig.12[23].This hybrid system allows meeting the requirement of a short power cycle with high power transients as shown in Fig.13.

图12 Zemships Atlterwaser船舶电能/推进系统Fig.12 Energy/propulsion architecture for Zempships Atlterwaser boat from[23]

图13 Zemships Atlterwaser船舶的典型负载曲线Fig.13 Typical load cycle of Zempships Atlterwaser boat from[23]

b.Nemo H2

This project is quite similar to“Atlterwaser”boat.The ship was launched in Amsterdam in 2009. Nemo H2(shown in Fig.14)is 22 meters in length and can carry 86 passengers.The propulsion is based on a series architecture where the power is supplied by a PEMFC(60~70 kW)[22,32].When the ship is not at full power,lead-acid batteries(30~50 kW)are charged.These batteries can then provide extra power when needed[32,33].

图14 Nemo H2游船,阿姆斯特丹Fig.14:Nemo H2 Amsterdam[19]

c.HybridTUGRTAdrian[34]

Anewgenerationofhybrid propulsion tug has been built in 2011.This first European hybrid tug,called RT Adrian(Fig.15)isusedintheportofRotterdam.Thetug hybrid architecture,called “XeroPoint Hybrid Propulsion System”is a series/parallel hybrid architecture combining diesel engines,battery pack and diesel generators as shown in Fig.16.The propulsion system can be used in all-electric or diesel electric mode(for low power modes),conventional mode in the mid power range or in combined mode for full power.In this combined mode,diesel propulsion engines,and electrical motors are used simultaneously.

图15 混合推进的TUG RT Adrian驳船,鹿特丹港口Fig.15 Hybrid TUG RT Adrian in the port of Rotterdam[34]

图16 Xeropoint Schematic船舶推进系统Fig.16 Xeropoint Schematic propulsion system[34]

d.Bus electro-solar sea in La Rochelle(France)

This hybrid architecture boat can carry 75 passengers’at a speed of 6 knots(Fig.17).It is equipped with photovoltaic panels to assist the diesel engine to charge the batteries.

图17 法国La Rochelle的太阳能电力客轮Fig.17 Bus electro-solar sea in La Rochelle from[35]

e.Ar Vag Tredan

This boat of 22.1 meters in length and 1.7 meters in draft,shown in Fig.18,has been built by the STX France shipyard in Lorient.Ar Vag Tredan is powered by supercapacitors used to provide power to two azimuth thrusters of 70 kW.The ship can cruise at 10 knots during 2x7mn and ensure zero emissions operations.At each stop the 8 sets of 16 supercapacitors are recharged in 4 minutes[36].

f.BatCub/Keolys project in Bordeaux(France)

BatCub project consists in using two catamaranshape water buses of 19 meters in length(Fig.19). This particular hull shape allows increasing seakeeping.The energy/propulsion system is based on series hybrid propulsion(diesel-electric),which mainly operates on the electric mode.Each shuttle is equipped with a 140 kWh lithium-ion battery system[37].The system powers two electric motors for propulsion and auxiliary systems such as lighting and communications. Coupled to diesel engine/generator,the battery is able to store the energy produced by the generator and provide additional propulsive power when needed. Battery can be combined to diesel/generators during the boost phases.

图18 法国Ar Vag Tredan超级电容客轮Fig.18 The Ar Vag Tredan[36]

During night,when the boat is docked,the batteries are charged by the harbor power grid.When they are fully charged the batteries can provide 6 hours of autonomy in all-electric operations.

图19 法国布尔多BatCub Keolys客船Fig.19 The BatCub/Keolys[38]

g.The Green Calanques(Marseille,France)

This tourist boat of 24 meters long by 6.7 meters wide,the"Green Calanques"(shown in Fig.20)is able to sail at a speed of 20 knots in the Calanques(scenic steep-walled inlets)of Marseille in France. Callanques are touristic natural marine sites located in the south of France near the city of Marseille.To meet the requirements of low level emission which are related to these protected areas,this little ship is equipped with two Hélion fuel cells and two solar panels to recharge auxiliary batteries[39].

图20 法国马赛 Callanques海湾Green Calanques游船Fig.20 The Green Calanques in Marseille’s Callanques[40]

4 CONCLUSION

Thispapershowsthatelectric and hybrid propulsion systems are very interesting solution to optimize the behavior of small and low power ship in terms of efficiency and pollutant emissions.

After a brief description of the main challenges for the design of the energy/propulsion systems for small ships,hybrid architectures are presented,highlighting the key components.The study is supported by examples of small ships with hybrid and electric propulsion.

REFERENCES

[1]Trieste S,Hman S,Olivier J C,et al.Techno-economic optimization of a supercapacitor-based energy storage unit chain:Application on the first quick charge plug-in-ferry[J].Applied Energy,2015,153,3-14.

[2]2ndIMO GHG study 2009 for emissions until 2007;MEPC 63/INF 2 for average scenario projections 2010-2050.

[3]Dedes E K,Hudson D A,Turnock S R.Assessing the potential of hybrid energy technology to reduce exhaust emis-sions from global shipping[J].Energy Police,January 2012: 204-218.

[4]Laurence S,Christa S,Thierry V,Edwin van H.Is new emission legislation stimulating the implementation of sustainable and energy-efficient maritime technologies[J].Research in Transportation Business&Management,2015, 17:14-25.

[5]Vodovozov V,Lehtla T.Power Accounting for Ship Electric Propulsion[D].In:Doctoral School of Energy and Geotechnology II:Closing Conference of the Project,“Doc-toral School of Energy and Geotechnology II”January 12-17, 2015,Pärnu,Estonia.Tallinn:Faculty of Power Engineering at Tallinn University of Technology,33-37,2015.

[6]Breucker S De,Peeters E,Driesen J.Possible applications of plug-in hybrid electric ships[C].In Proc.IEEE Electric Ship Technol.Symp.,Apr.20-22,2009:560-567.

[7]Bennabi N,Charpentier J F,Menana H,et al.Hybrid propulsion systems for small ships:Context and challenges[C]. 2016 XXII International Conference on Electrical Mac-hines(ICEM).Lausanne,Switzerland,2016:2948-2954.

[8]Marine Exhaust Emissions Research Programme.Lloyds Register of Shipping,1995.

[9]Cefic E C T A.Guidelines for Measuring and Managing CO2Emission from Freight Transport Operations[Z],2011.

[10]Song S.Ship emissions inventory,social cost and eco-efficiency in shanghai yangshan port[J].Atmos Environ,2014, 82:288-97.

[11]International Maritime Organization,Second IMO GHG Study,Technical Report MEPC 59/INF.10,2009.

[12]Fagerholt K,Gausel N T,Rakke J G,et al.Maritime routing and speed optimization with emission control areas[J]. Transportation Research Part C:Emerging Technologies, 2015,52:57-73.

[13]Det Norske Veritas.Greener Shipping in the Baltic Sea[R].Managing Risk DNV,2010.

[14]Capata R,Coccia A.Procedure for the design of a hybridseries vehicle and the hybridization degree choice[J].Energies,2010,3,450-461.

[15]Lu Hengrong.Design on IPNCS of electrical propulsion ship based on real-time Ethernet[J].Energy Procedia,2012, 16:1707-1713.

[16]Chan C C,Bouscayrol A,Chen Keyu.Electric,hybrid, and fuel-cell vehicles:architectures and modeling[J]. IEEE transactions on vehicular technology,2010,59(2): 589-598.

[17]Chen Jia-Shiun.Energy Efficiency Comparison between hydraulic hybrid and hybrid electric vehicles[J].Energies 2015,8(6):4697-4723.

[18]Capata R.Lethe@-UDR1 Passenger Sedan Final Proposed Configuration[J].Journal of Transportation Technologies, 2001,1(04):83-93.

[19]Florian Dupriez-Robin.Dimensionnement d’une propulsion hybride de voilier,base sur la modélisation par les fluxdepuissance[D].Thèsededoctorat.UniversitédeNantes, French,2010.

[20]Hebner R E.Electric ship power system-Research at the University of Texas at Austin[C].in Proc.IEEE Electric Ship Technol.Symp.,2005:34-38.

[21]Wang Enhua,Guo Di,Yang Fuyuan.System design and energetic characterization of a four-wheel-driven seriesparallel hybrid electric powertrain for heavy-duty applications[J].Energy Conversion and Management 2015,106: 1264-1275.

[22]Application marines et sous-marines des piles à combustible.Mémento de l’Hydrogène,Fiche 9.4.2 French, Mars 2014.

[23]Han J,Charpentier J F,Tang T.An energy management system of a fuel cell/battery hybrid boat[J].Energies,2014, 7(5):2799-2820.

[24]Yrd Doç,M Turhan Çoban,Y Müh Kd Bnb,Cüneyt Ezgi. Design and analysis of diesel fueled solid oxide fuel cell system onboard surface ship[J].Journal of Naval Science and Engineering,2010,6(1):59-7.

[25]Jose J de-Troya,Carlos Alvarez,Carlos Fernandez-Garrido,Luis C.Analysing the possibilities of using fuel cells in ships[J].International Journal of Hydrogen Energy,2016, 41:2853-2866.

[26]Wang Enhua,Guo Di,Yang Fuyuan.System design and energetic characterization of a four-wheel-driven seriesparallel hybrid electric powertrain for heavy-duty applications[J].Energy Conversion and Management,2015,106: 1264-1275.

[27]Meek-Hansen B.Fuel cell technology for ferries[C].In IMTA Conference.Gold Coast:Marintek,2002:1-12.

[28]Mehmeti A,Santoni F,Della Pietra M,et al.Life cycle assessment of molten carbonate fuel cells:State of the art and strategies for the future[J].Journal of Power Sources, 2016,308:97-108.

[29]McPhail S J,Leto L,Della Pietra M,et al.International status of molten carbonate fuel cell(MCFC)technology[R]. IEA,2015.Annex 23.

[30]Zemships-Zero Emission Ships.One Hundred Passengers and Zero Emissions:The First Ever Passenger Vessel to Sail PropelledbyFuelCells[D].Availableonline:http://ec.europa. eu/environment/life/project/Projects/index.cfm?fuseactionhome. showFile&rep=file&fil=Zemships_Brochure_EN.pdf(accessed onNovember2016).

[31]http://www.seanews.com.tr/news/63885/First-Hybrid-Tugin-Europe-Port-of-Rotterdams-RT-Adriaan.html last consulted on November 2016.

[32]Scozzari R,&Santarelli M.Techno-economic analysis of a small size short range EES(electric energy storage)system for a PV(photovoltaic)plant serving a SME(small and medium enterprise)in a given regulatory context[J].Energy, 2014,71:180-193.

[33]McConnell V P(2010).Now,voyager?The increasing marine use of fuel cells[J].Fuel Cells Bulletin,2010(5):12-17.

[34]http://www.civitas.eu/sites/default/files/1b_ev_in_la_rochelle _graindorge.pdf last consulted on Nov.2016.

[35]Chakraborty,Sumit,Dzielendziak,Agnieszka S,Koroglu, Turgay and Yang,Kun.Evaluation of smart eco-friendly public transport options in coastal cities:towards a green future for the city of Southampton[D].University of Southampton,2013,158.

[36]http://www.stxeurope.com/FR/stxfrance-reference-23-AR% 20VAG%20TREDAN.awp last consulted on February 11 2016.

[37]http://www.infotbm.com/bat-le-bateau-de-bordeaux-metropole-pour-naviguer-d-une-rive-l-autre last consulted on november 2016(in French).

[38]http://www.orion-naval.com/en/projects/key-project last consulted on nov 2016.

[39]http://www.meretmarine.com/fr/content/gatto-livre-une-vedette-de-24-metres last consulted on Nov 2016(in French).

[40]http://www.3-0.fr/actu-evenements-responsables/ieu-insolite-sur-la-cote-mediterran%C3%A9e last consulted on nov 2016(in French).

未来小型船舶建造的目标之一是减少船舶排放,以符合国际海事组织(IMO)关于温室气体和污染物排放现行和将来的规定。首先介绍了船舶对环境影响的背景和相关规章,指出电力推进,特别是混合动力推进系统(HPS)是减少小型船舶环境影响的具有前景的解决方案。小型船舶常常在人口密集区域附近使用,这些区域是减少污染和排放的非常关键的区域。然后提出了几种小型船舶混合动力和电力推进系统,包括综述了对未来船舶建造的挑战,以及描述了可能用于小型船舶的HPS拓扑结构。最后介绍了HPS的主要特征,并给出了小型电力混合船舶的实例。

混合电力船舶;串联混合;并联混合;燃料电池;蓄电池;超级电容;二氧化碳排放;电力电能

TK01

A

N.Bennabi

基于混合电力推进的小型船舶能效改进

N.Bennabi1,2,H.Menana3,J.F.Charpentier2,J.Y.Billard2,B.Nottelet1

(1.SEGULA科技公司,勒阿佛尔76600,法国;2.法国布雷斯特海军学院研究所,布雷斯特29240,法国; 3.洛汉纳大学GREEN电气实验室,南希54000,法国)

10.13234/j.issn.2095-2805.2017.2.012

N.Bennabi(1985-),女,博士研究生,研究方向:船舶电力推进、交流电机调速,E-mail:nacera.bennabi@ecole-navale.fr。

H.Menana(1976-),男,博士,讲师,研究方向:电磁检测技术、电磁装置分析,E-mail:hocine.menana@univ-lorraine.fr。

J.F.Charpentier(1969-),男,通信作者,博士,副教授,研究方向:电磁装置分析、多相永磁电机、新能源发电系统,E-mail:jean-frederic.charpentier@ecolenavale.fr。

J.Y.Billard(1955-),男,博士,教授,研究方向:船舶流体力学、船舶制造,E-mail:jean-yves.billard@ecole-navale.fr。

B.Nottelet(1989-),男,硕士,工程师,研究方向:机械力学及材料工程,E-mail:benoit.nottellet@segula.fr。