Advances in Technologies of Piezoelectric Pumping with Valves

2016-09-05ZhangJianhuiWangYingFuJunYanKangLiZhimingZhaoChunsheng

Zhang Jianhui, Wang Ying, Fu Jun, Yan Kang,Li Zhiming, Zhao Chunsheng

1. College of Mechanical and Electrical Engineering, Guangzhou University, Guangzhou 510006, P. R. China;2. State Key Laboratory of Mechanics and Control of Mechanical Structures,Nanjing University of Aeronautics and Astronautics, Nanjing 210016, P. R. China;3. College of Mechanical and Electrical Technology, Taizhou Polytechnical Institute, Taizhou 225300, P. R. China

(Received 15 December 2015; revised 20 April 2016; accepted 25 April 2016)

Advances in Technologies of Piezoelectric Pumping with Valves

Zhang Jianhui1,2*, Wang Ying3,2, Fu Jun2, Yan Kang2,Li Zhiming2, Zhao Chunsheng2

1. College of Mechanical and Electrical Engineering, Guangzhou University, Guangzhou 510006, P. R. China;2. State Key Laboratory of Mechanics and Control of Mechanical Structures,Nanjing University of Aeronautics and Astronautics, Nanjing 210016, P. R. China;3. College of Mechanical and Electrical Technology, Taizhou Polytechnical Institute, Taizhou 225300, P. R. China

(Received 15 December 2015; revised 20 April 2016; accepted 25 April 2016)

Piezoelectric pump faces unprecedented challenges when higher expectation and requirements need to be met in their applications mainly to medical treatment, hygiene and public health, and preventive healthcare. Specifically, the piezoelectric pump with valve has the disadvantages of complex structure, high duty cycle of valves, and valve movement lagged behind piezoelectric ceramics oscillation. In an attempt to inhibit its shortcomings, some researchers presented novel concepts for structural design of piezoelectric pump with valve, which could become a new research focus. Among them, the investigation into various soft valves, represented by soft structure valves made of rigid materials and soft material valves made of flexible materials, has been fruitful in recent years. The integrated design of both material and structure can tackle the problems encountered in the study of piezoelectric pump with valve, thus simplifying the pump structure, reducing the duty-cycle of valves, and improving the lagging of valve motion. In addition, new inventions of pump structure have sprung up, such as the pumps containing a single-chamber with double-drive, single-chamber with single-drive in series and single-chamber with single-drive in parallel, as well as the mixed-chamber in series and parallel. After surveying the recent progresses made by dominant academia in the development of piezoelectric pump encompassing valve, with a particular emphasis on structure design of both valve and pump body, we also summarize and identify the future research directions.

piezoelectric; pumps; valves; swing oscillator

0 Introduction

In recent years, piezoelectric actuators have been widely used in power and fluid transmission fields[1-4]. In 1978, Spencer, Corbett and Dominguez from Sandia National Laboratories in America published the paper ″An electronically controlled piezoelectric insulin pump and Valves″[5]. At the same time, Narasaki of Japan Aerospace Exploration Agency published his paper, entitled ″Layered type bimorph vibrator pump″[6], and subsequently patented the invention in Japan[7]. This marked a new generation pump combining burgeoning piezoelectric ceramic and traditional pump & valve. After 37 years, when we review the history, it is not hard to find that researchers initiated the exploitation of piezoelectric pumps from then on via compromise and graft. The following content will center on the subject of piezoelectric pumps with valve.

The presentation of piezoelectric pumps is analogous to an intermarriage of traditional European aristocrats and American newly rich. On the one hand, the vibration of new functional material, i.e., piezoelectric ceramics, can replace motor driving with enormous potentials. Then piezoelectric pumps become a new branches of pump history dating back to five thousand years ago (e.g. in the 17th century B.C. Egyptian invented chain pump and Chinese used shadoof). Certainly obstacles appeared between the new pump functions and existing pump theories. As an actuator, piezoelectric ceramics reconstruct the energy transformation pattern from electric energy to piezoelectric deformation energy, and then to dynamic energy or potential energy of fluids through pump and valve, in contrast to the one from electric energy to mechanical kinetic energy converted by motor energy (or other mechanical energy), and finally to kinetic energy or potential energy of fluid in a working cycle of conventional pumps with valves. The energy transformation flow has changed after using piezoelectric ceramics oscillators. On the other hand, the forms of conventional valves, pump chambers, flow channels were designed to adapt to the latest version of motors, so were other structures for linking, mounting and supporting. The longer the history of design and manufacture is, the poorer the ability of adapting to new functional drive is. Piezoelectric ceramics actuation is similar to diaphragm oscillatory, with no relative motion on link surface. Moreover, piezoelectric ceramic diaphragm can vibrate with a high frequency which is orders of magnitude higher than that of traditional motors. At the same time, the micro amplitude of piezoelectric ceramic diaphragm vibration generally cannot reach the millimeter level. Therefore, the criterions of clearance, fixed bearing and linking in traditional pumps design are not appropriate for piezoelectric pumps, and the structures of valves, pump chambers and flow channels as well.

Piezoelectric ceramic and pump chamber with valve walked into the wedding hall with both their advantages and disadvantages considered. (Introducing piezoelectric ceramic into a pump chamber & valve creates a piezoelectric pump with valves) Did they live a happy married life like a fairy tale? Were any design principles or geometries proposed for piezoelectric pumps with valves? To answer all these questions, we write this paper after looking into the development of piezoelectric pump with valves. Besides, we analyze and classify the piezoelectric pumps by roles and functions, and try to present an outlook of their future development.

1 Conventional Valves Actuated by Piezoelectric Vibrator

Converse piezoelectric ceramic is brittle. In a free state without constrains, a converse piezoelectric ceramic will distort in the direction perpendicular to voltage when the voltage is applied in polarization direction. In this process, electrical energy is transferred into the deformation energy of converse piezoelectric ceramic. If voltage reaches a threshold, converse piezoelectric ceramic (hereinafter referred to as piezoelectric ceramic or ceramic) will be punctured, causing an irreversible damage. A piezoelectric ceramic in the free state cannot be used in practice. So in piezoelectric pump with valve, piezoelectric material is bonded on, deposited on or embedded in a metal diaphragm, which functions as seat, shield and amplifier concurrently. The composite is called piezoelectric oscillator. The metal edge of the piezoelectric oscillator is fixed on pump chamber or body. Since the movement of ceramic is limited by metal and pump chamber, the periodical bend of a piezoelectric oscillator under voltage actuation is similar to the vibration of a diaphragm with a fixed boundary. The strain at each point in ceramic varies gradiently, and the geometrical center can thus be destroyed more easily. If actuated by an alternative voltage, the maximum ceramic deflection can be obtained at the resonant frequency of the system. Therefore, the oscillatory motion of vibrator can be described by the amplitude of resonant frequency.

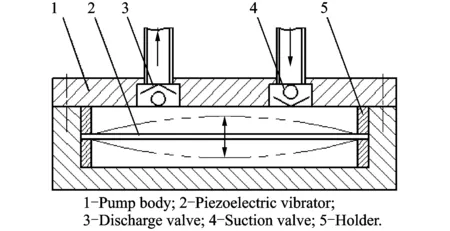

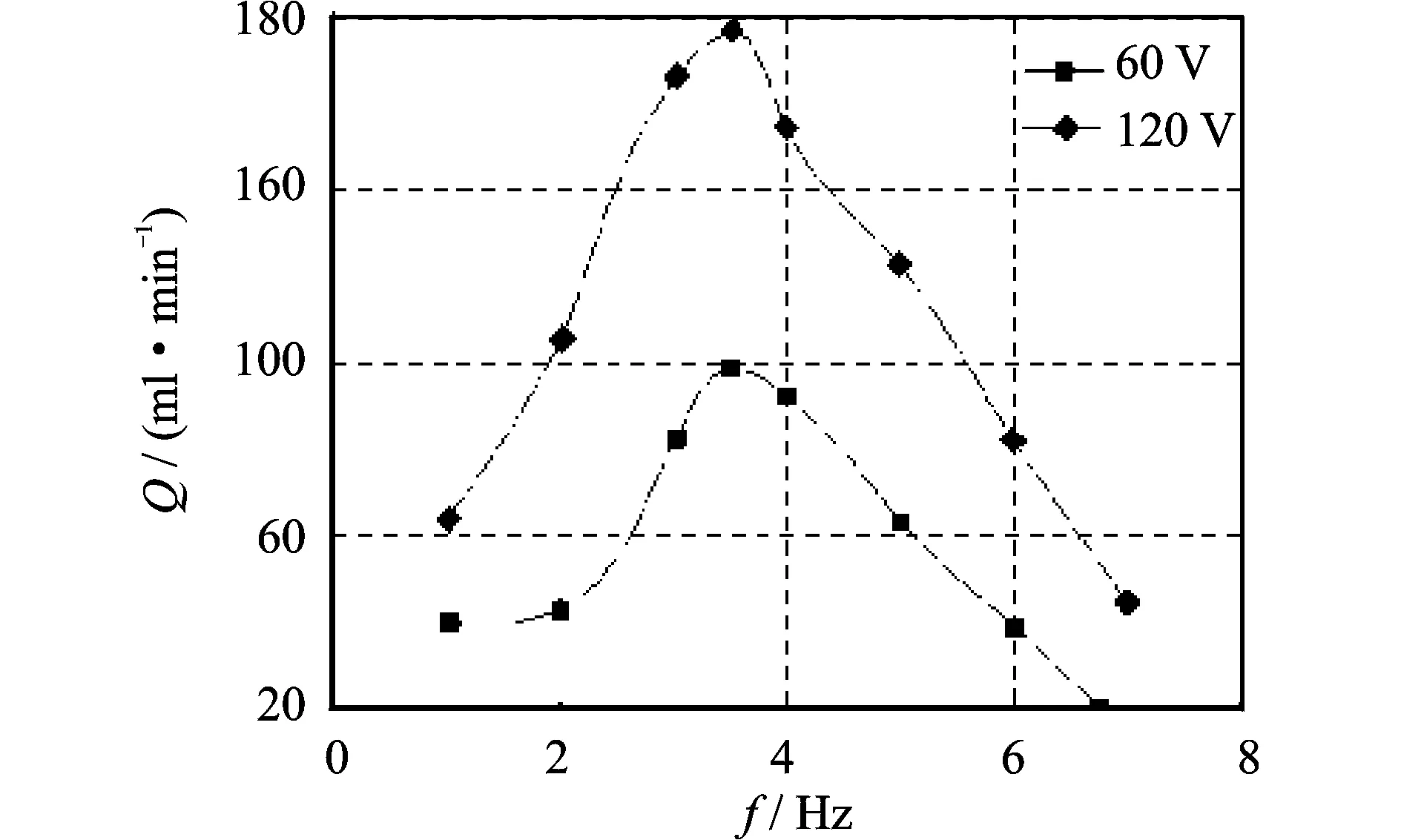

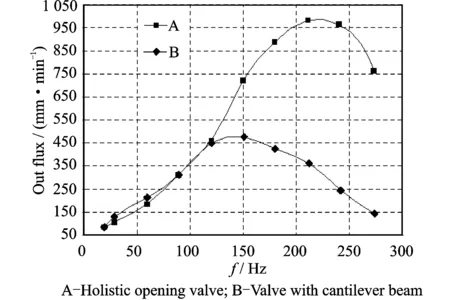

In 1996, the team of Zhou in Tsinghua University reviewed the piezoelectric actuators diaphragm pump developed by Tohoku University, whose maximum flow was 20×10-6L when actuation voltage was 90 V and frequency was 20 Hz[8]. In 2000, Suzuki et al. in National Yamagata University, Japan, tried to incorporate the structure of conventional valve (ball valve, cone valve, butterfly valve and plate valve), as well as the corresponding structure of pump and flow channel, into the piezoelectric-ceramics-driving pump (see Figs.1, 2)[9-12]. They also conducted a series of experiments, and the results demonstrated that the pump had a ″small flow rate with low pressure difference″, which were undesirable (Fig.3). A traditional valve with fixed-geometry evolves from the adaptation to conventional motors, pump bodies and flow channels, which seems massy, large-space-occupied, high-passive-pressured and slow responding to actuation when applied to piezoelectric actuation pump. In 2005, Kan and his coworkers of Jilin University investigated the features of micro cantilever valve[13]. In the same year, Cheng et al. of Jilin University conducted experiments on the micro piezoelectric pump with the micro cantilever valve[14-15]. Nextyear, Sun et al. in Jilin University tested the cantilever structure in a quasi plate valve (Fig.4)[16]. All the aforementioned valves are conventional, which can be distinguished from each other in pump chamber sizes, geometric and physical parameters of piezoelectric vibrator, and valve bodies. Although the flow rate and pressure difference of these valves were unable to be compared effectively, they all characterized a sharp decrease in pump flow rate when working frequency increased.

Fig.1 Structures of ball valve, cone valve, plate valve and butterfly-shaped valve

Fig.2 Structure of piezoelectric pump with valve

Fig.3 Frequencies and volume flow rates of piezoelectric pump with cone valve

Fig.4 Structure of cantilever valves regarded as quasi plate valves

In the subsequent experiments on the actual amplitude decrease of piezoelectric vibrators at a high frequency, Zhang et al. reported that piezoelectric vibrator′s amplitude indeed decreased at a high frequency, but the amplitude reduction failed to achieve a sharp drop in flow rate. They also pointed out that this drop of flow rate with the increase of frequency was an inevitable result of valve hysteresis, a inherent dynamic nature of piezoelectric pumps[17].

A piezoelectric pump with valve should have at least one effective valve, otherwise, it cannot be classified into the category of pumps with valve. In theoretical analysis, fluid flowing in the pump is considered as ideally incompressible for simplification.

The traditional cantilever valves installed in the piezoelectric pumps with valves are passive valves, such as ball valves, cone valves, butterfly-shape valves, plate valves and quasi plate valves. The passive valve is a valve that requires no energy for activation. Its opening and closing actions are driven by pump actuation source, rather than the valve body itself which is not able to take the initiative to complete the opening and closing actions. The energy transfer between the driving sources of the piezoelectric vibrator to the valve body is by means of the fluid in the pump chamber. Increased by the piezoelectric vibrator′s deformation, the pressure transfers to the valve body and have it passively opened completely. Here time is needed for the energy to flow through the fluid. When opening, negative pressure exists between the contact surfaces of the valve body and the pump body cavity, and direct forces exerted by fluid are applied to valve body, which are delivered by the piezoelectric vibrator from the outside surface of valve′s cavity. It also needs time to balance these two reverse forces. Hence, the force exertion after balancing can open the valve. Energy consumption corresponding to the accumulated time above may be converted into a portion of the pump volume change.

To improve the pump′s driving frequency, the time of pump′s half driving cycle should be reduced. When the pump′s driving frequency is increased to a certain extent, if the aforementioned accumulated time becomes close to the time of pump′s half driving cycle, the pump will be unable to complete the driving function, and pump flow rate thus tends to be zero.

The lagged movement of pump valve manifests that there exists an original sin in piezoelectric pumps with valves which are simply integrated by piezoelectric vibrator plus pump cavity and valve body. And it is proved theoretically and experimentally that the piezoelectric pumps with valves cannot obtain pump flow and pressure difference consistent with its actual volume variation due to the lagged movement of pump valve. Although it is impossible to completely eliminate this lagging phenomenon, it still can be alleviated and decreased.

2 Soft Valve Body Actuated by Piezoelectric Vibrator

Piezoelectric vibrators replace motors for driving and become a part of pump cavity and pump body. From a view of piezoelectric vibrator, this replacement is the application of new materials to the traditional fluid transmission; while from another view of pump and valve, it is a self revolution, and all designs and methods accustomed to us in traditional process will not fit anymore. Then changes follow. Piezoelectric vibrator only corresponds to valve body and pump body. The following words will first discuss the valve body after the introduction of its piezoelectric actuation.

2.1Soft structure valve body in rigid material

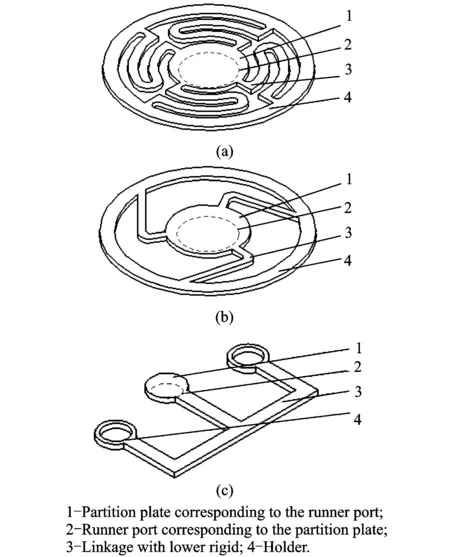

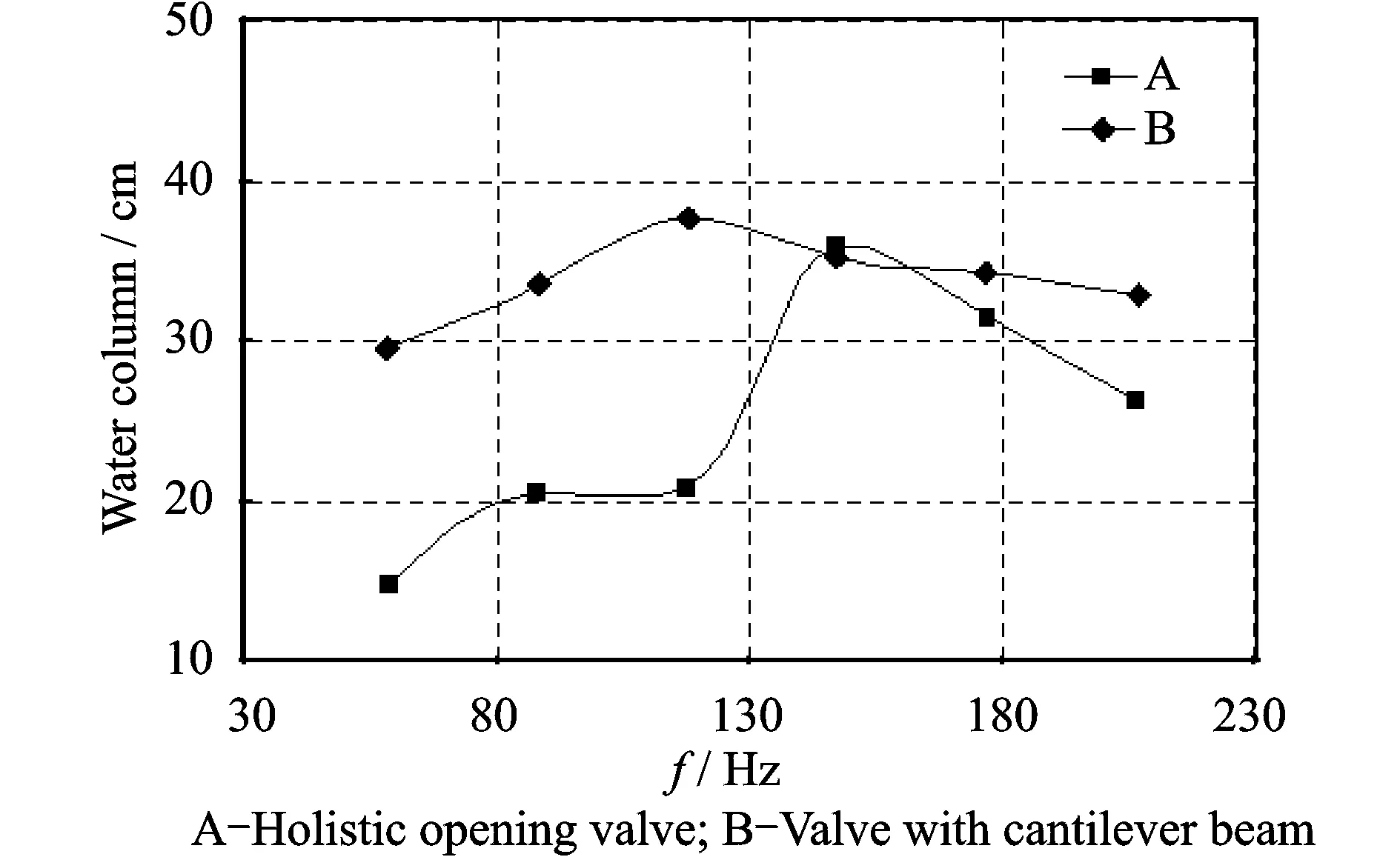

In 2006, Ham et al. from Korea Machinery and Materials Research Institution developed a piezoelectric pump with the flexible hinge valve in which the cooling liquid of electric equipment is recycled. When this pump ran at the driving voltage of 100 V and frequency of 11 Hz, its maximum flow is up to 1 850 ml/min, see Fig.5 (a)[18]. In 2006, Sun et al. in Jilin University published papers on the performance of overall opening valve and piezoelectric pump with cantilever valve, in which they studied the holistic opening valve and compared the valve with cantilever valves (see Figs.5(a,b), Fig.6 and Fig.7)[16]. In the same year, Zeng et al. from Jilin University discussed mechanical and fluidic properties of the holistic opening valve in detail[19].

Fig.5 Schematic diagram of structure of soft valve body made of rigid material

Fig.6 Comparison of self-absorption capacity

Fig.7 Comparison of output flow

In 2009, Zhang et al. in Nanjing University of Aeronautics and Astronautics developed an ″E″ type valve and applied it to piezoelectric pumps with valves, see Fig.5 (c)[20]. The structure of the ″E″ type valve differed from butterfly valve, traditional plate valve, ball valve and cone valve. In the ″E″ shaped elastic thin plate used by authors, vertices of upper and lower two ″horizontal″ plates were fixed, and the circular plate in the middle of long ″horizontal″ was taken as the partition plate of the channel port corresponding to the inlet and outlet ports. When fluid pressure is applied to the partition plate, the plate with the addition of upper and lower horizontal plates warped and elastic deformation happened, so that the valve was opened quickly. Flow passed quickly when the valve was opened. It is because no object impedes the flow around the partition plate, thus being energy-saving. Contrarily, when the pressure decreases, the elastic deformation of the ″three horizontal″ plates of ″E″ recovered, responding more quickly than that of butterfly valves and plate valves with single partition plate. Closure of the valve is also fast.

In 2011, He′s team from Changchun Institute of Technology did further meticulous research on the integrally-moving check valve when studying the application of new metal valve to small-sized piezoelectric pumps[21]. They thought ″the integrally-moving check valve could reduce the yield deformation, and the reliable working time of the piezoelectric pump was thus lengthened. The fine lapping characteristics of valve plate were mainly used in improving dynamic response of the pump″.

In order to facilitate the analysis, we define the above several valves as soft structure valves made of rigid materials, which commonly feature that rigid materials are used and special design is adopted to reduce the rigidity of the materials. The soft structure valves made of rigid materials fit better to piezoelectric pumps with valve, compared with conventional ball valves, cone valves, butterfly valves, and plate valves. Moreover, their fluid indexes, such as output flow rate, pressure differential, are also superior to those of conventional valves, see Figs.6, 7.

Analyzed and summarized the structural characteristics of ball valves, cone valves, butterfly-shaped valves and plate valves in Fig. 1, the quasi plate valves with cantilever beams in Fig.4, and soft valves made of rigid materials in Fig.5, the following points are concluded: (1) Ball valves, cone valves, butterfly-shaped valves and plate valves are generally lack of fixed fulcrum, whose valve body weights are directly involved in the opening and closing processes of valves. (2) The absolute rigidity of ball valves, cone valves, butterfly-shaped valves and plate valves are totally independent of the opening threshold of actuation spring. (3) Mechanical structures of ball valves, cone valves, butterfly-shaped valves and quasi plate valves are complex. In the valves each component has its specific function. (4) Parts of the weight of a quasi plate valve with cantilever beam structure are involved in the opening and closing processes of the valve. (5) The quasi plate valve with cantilever beam structure is not absolutely rigid but elastic, whose elasticity contributes to providing an opening threshold. (6) Mechanical structure of a quasi plate valve with cantilever beam is simple, where each component′s function becomes obscure. (7) Soft structure valve made of rigid materials has fixed fulcrum. Parts of the valve body′s own weight are indirectly involved in the valve′s opening and closing process; (8) The component part of a soft structure valve made of rigid materials involved in flow resistance is absolutely rigid, and the part providing opening threshold is absolutely elastic. The two parts are physically connected. Therefore, the rigidity and elasticity of the valve exhibit inter-transition states. (9) Mechanical structure of soft structure valves made of rigid materials is complex with specific function for each component.

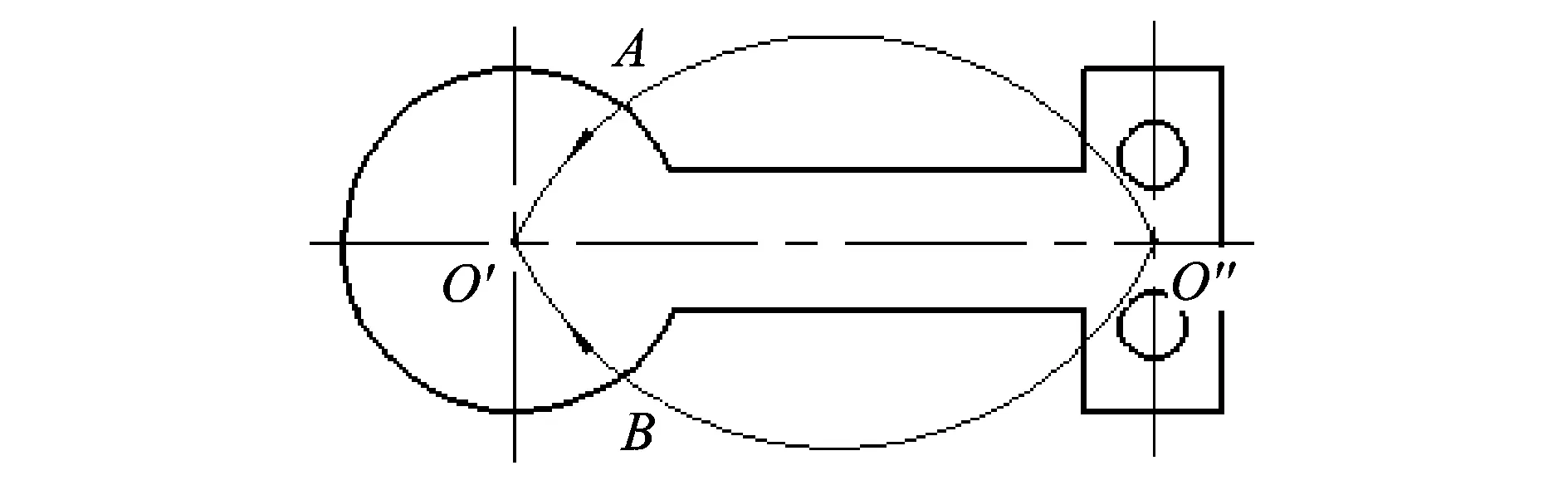

In further analysis, we find that in a quasi plate valve with cantilever structure, the line (called heart solid line) connecting the geometric center of a flow channel corresponding to a blocking plate and the geometric center of its fixed points coincides with their physical connection path line (Fig.8). But in a soft structure valve made of rigid materials, the two aforementioned lines do not coincide, which leads to the inconsistency of flexibility origination and variation (Fig.9).

Fig.8 Valve body of a quasi plate valve with cantilever structure whose heart solid line overlaps physical path line

Fig.9 Soft structure valve body with inconsistent heart solid line and physical path line

When the heart solid line coincides with the physical path line, forces transmit directly and conveniently, and vice versa. For a quasi plate valve with cantilever structure, the opening and closing processes are almost similar to that of a ball valve, a cone valve, a butterfly-shaped valve or a plate valve. Nevertheless, for a soft structure valve body made of rigid materials, in the opening process, the reverse elastic force produced by valve body deformation against opening gradually increases, while in the closing process, the accumulated elastic force instantly releases and causes rapid closing. Besides, the plate barrier in a quasi plate valve with cantilever structure also deforms due to its elasticity, thus affecting the process of shutdown. Generally speaking, the soft structure valve made of rigid materials is superior to the quasi valve with cantilever structure.

Fig.10 Force diagram of traditional cone valve before and after opening

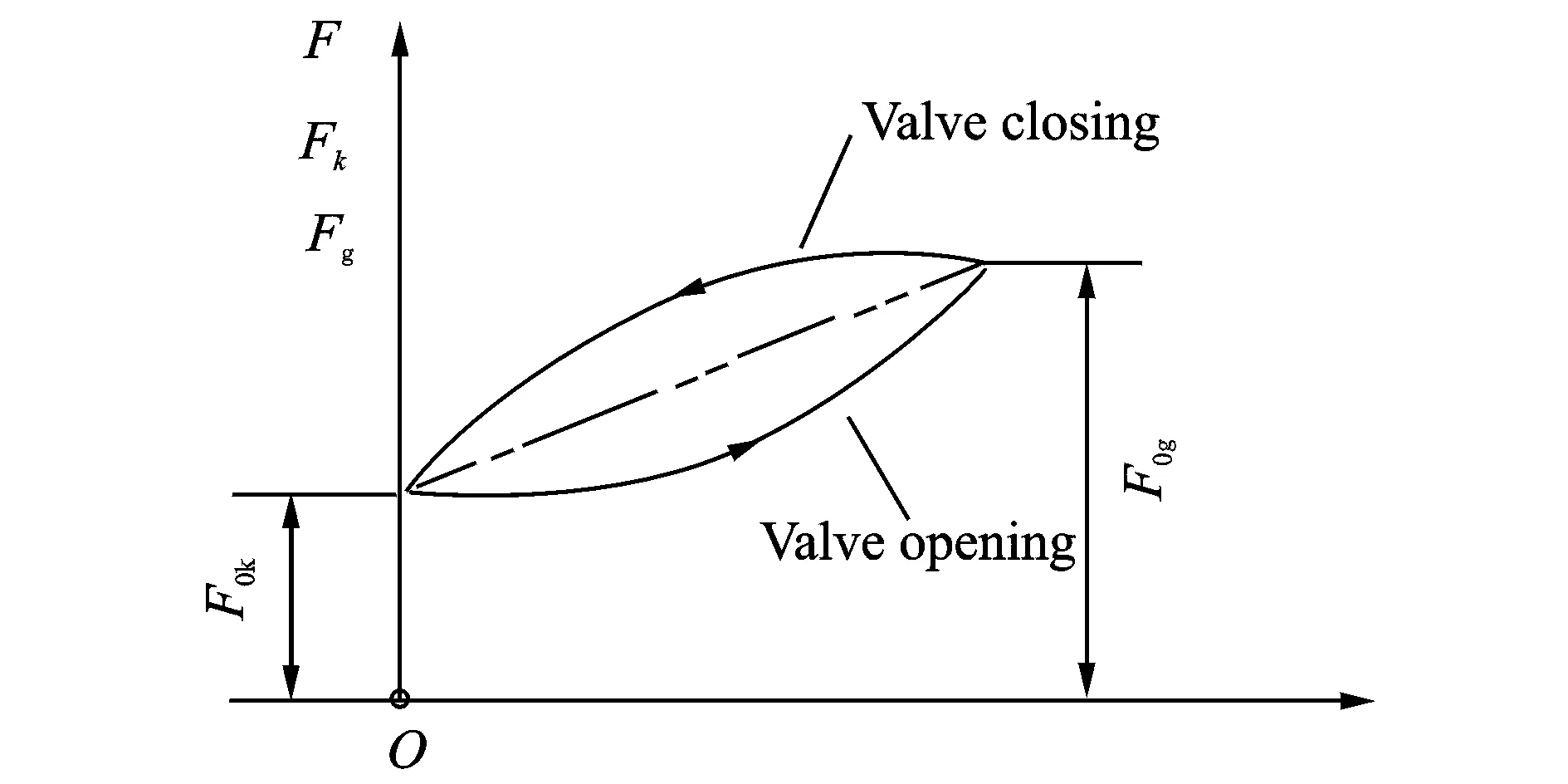

Fig.10 represents the forces applied to a traditional cone valve before and after opening, where x0is the spring length before deflection, x the length of deflection, k the modulus of spring deflection, Fwthe fluid pressure outside chamber, G the self weight of valve, Fnthe negative fluid pressure inside chamber, Fkthe opening force, F0kthe original opening force, Fgthe closing force, and F0gthe original closing force.

In an opening process, we have

(1)

And in a closing process,

(2)

Eqs.(1), (2) indicate that the self weight of valve body interferes with the valve opening and closing. Noticed that self weights of the conventional ball valve, cone valve, butterfly-shaped valve, and plate valve are heavy with regard to a direct actuation of spring, it is unfavorable for integration into small-sized piezoelectric pump with valve.

In general, regarding the application to a conventional piezoelectric pump with valves, the quasi plate valve with cantilever structure is inferior to the soft structure valve made of rigid materials, followed by the ball valve, cone valve, butterfly-shaped valve and plate valve.

2.2Soft-material-fabricated valve body in flexible materials

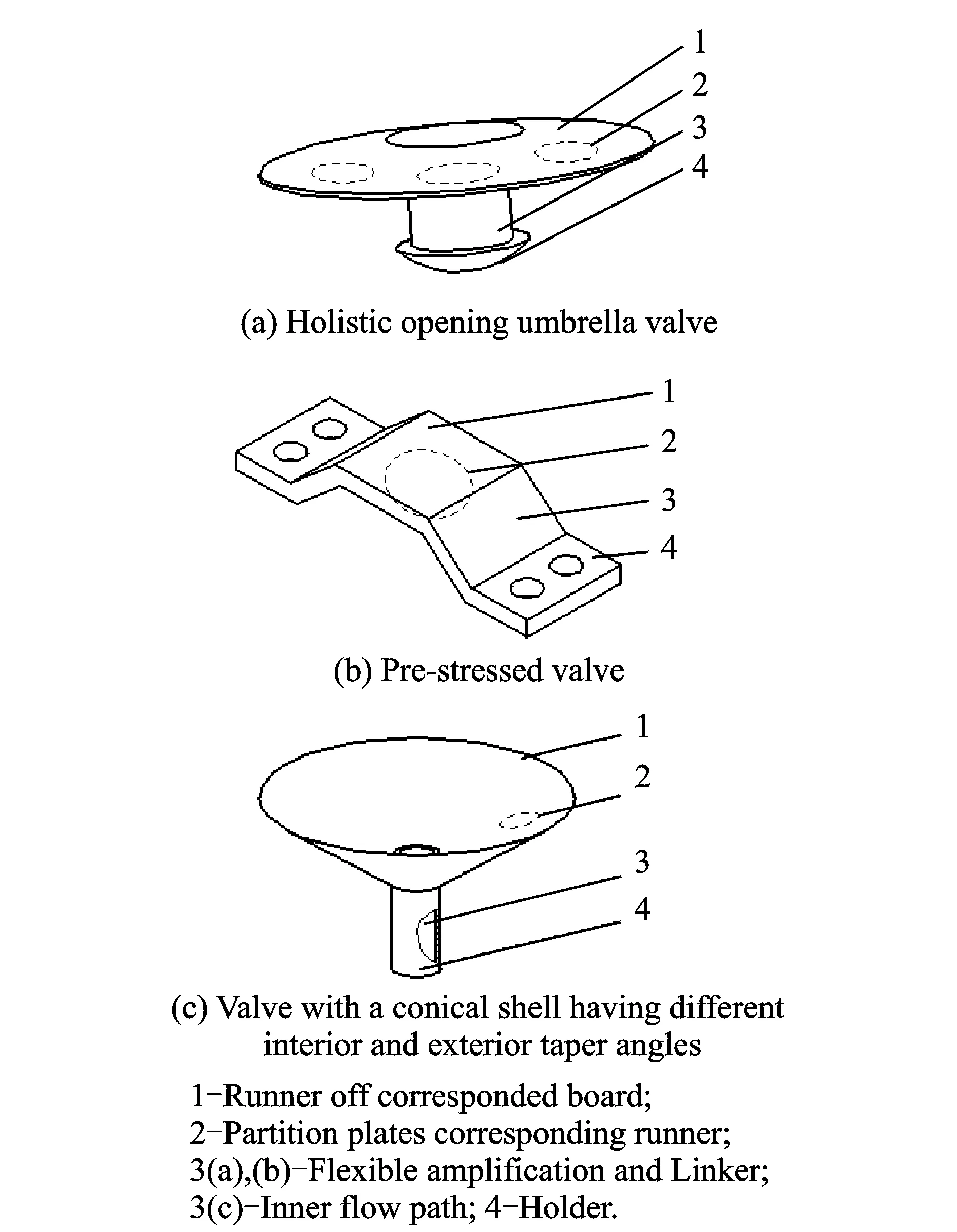

In 2005, Zeng et al. in Jilin University developed a rubber diaphragm valve and conducted experiments by mounting it into a piezoelectric pump with valve. The result illustrated that the flow rate reached 520 ml/min at the voltage of 120 V and actuation frequency of 180 Hz[22]. In 2007, He et al. designed the holistic opening umbrella valve, and experiments on a piezo electric pump showed that a 700 ml/min flow rate could be obtained at the voltage of 110 V and driven frequency of 150 Hz (Fig.11(a))[23]. In 2009, Chang et al. from University of Shanghai for Science and Technology and Minimally Invasive Medical Devices (Shanghai) Co. Ltd. designed the pre-stressed valve and integrated into the piezoelectric micro-pump. Their experimental results showed that the pre-stressed valve was stable and reverse-suction-preventing. The flow rate was up to 5.5 ml/min when driven by 250 V, 200 Hz voltage (Fig.11(b))[24]. In 2010, Zhang et al. in Nanjing University of Aeronautics and Astronautics proposed a single valve with a conical shell having different interior and exterior taper angles. This simple-structured valve can be individually installed in a piezoelectric pump. The experiments demonstrated that the pressure differential between pump inlet and outlet can reach 170 millimeters of mercury at 150 V voltage with a driven frequency of 475 Hz (Fig.11(c))[25]。

These valves are classified as the soft-material-fabricated valve made of flexible materials for analytical simplicity, which are more adaptable to the piezoelectric pumps with valvesthan traditionalball valves, cone valves, butterfly-shaped valves and plate valves, providing better fluid property indexes like flow output, pressure differential, etc. These soft-material-fabricated valves all characterize a valve body made of organic polymer materials in common, thereby being flexible. Thanks to the characteristics of fabrication materials, the valve body becomes simpler than traditional ones. However, since both the flexibility of valve body and the force transmission of fluid are passive, the couplings between the flexible valve body and the flowing fluid increase. Therefore, control becomes nearly impossible because of unrealizable decoupling or approximate decoupling, leading to a state of drifting with the flow. Furthermore, the organic polymer materials run the risk of fatigue failure and fluid corrosion in its short operation life, which limits the performance of valve.

Fig.11 Soft-material-fabricated valve body made of flexible materials

Soft-material-fabricated valve have already been widely used, especially for gas delivery, for instance, gas pump of automatic hemdynamometer[26], air-feeding pump for ornamental fish, and aroma spay pump[27-29], etc. In all these cases, flow control is a non-strict demand, or provided by another control system. So far, the design philosophy system of soft-material-fabricated valve body has not yet been established, due to the lack of theories in coupling between a nonlinearly-deforming flexible body with irregular geometry and a non-laminar intermittently-flowing fluid currently. Hence, for a soft-material-fabricated valve body, we only empirically determine the co-relation of pump chamber geometry and actuation force, and optimize it via experimental data until meeting the application demand. Otherwise, we exert an extra feedback control regardless of the above boundary conditions.

The coupling problem is beyond the research field of fluid machinery. In 2000, a paper published in Nature addressed this problem by discussing the interaction of wind and a flag[30], which become an international hot topics shortly afterwards.

After analyzed the superficial characteristics of the soft-material-fabricated valve body used widely, the functional regions and their corresponding structure of this type of valve are difficult to be distinguished from each other, since almost all the regions involve in functioning. Taking the structure of soft-material-fabricated valve body made of flexible materials (see Fig.11(a)) for example, component 3 is for flexibility amplifying and linking. In addition to linking and fixing, the column functions as an actuator representing valve opening threshold and valve closing speed in the elastic deformation of the partition plate (component 1). Although the structure is against the traditional design concept of independence components with different functions unified in one system, it claims a modern design idea, i.e., to achieve embedding and integrating of all components by breaking down barriers built by the old traditional design concept.

Despite of the shortcomings of simple structure, coarse model, and inability to precisely control, the soft-material-fabricated valve exhibits the modern mechanical design and manufacturing concept, presenting the development trend of valves for the piezoelectric pump.

2.3Summary of soft valve body

We can get an ideal model of the piezoelectric pump with valve by analyzing the soft structure valve made of rigid materials and the soft-material-fabricated valve made of flexible materials (Fig.12). In Fig.12, the horizontal axis is the distance between a valve and fully closed dead center, i.e., opening distance, and the vertical axis is the force applied to the valve. The essential points of the ideal model describing valve opening and closing are: (1) There are initial opening force F0kand initial closing force F0gat the beginning, where the closing force is greater than the opening one. (2) The opening and closing paths of valve are different. The opening path rises slowly while the closing path decreased rapidly, which is due to the lagging movement loop of piezoelectric ceramics; (3) The valve can only be opened and not instantly fully-opened when the opening force applied to the valve accumulates to a certain extent; (4) During the closing process, the valve and valve pad do not rebound and valve pad ring does not tilt, which means the valve is fully closed instantly.

Fig.12 Opening and closing model of an ideal valve

3 Pump Structure

We have discussed above the two kinds of pumps with soft bodies, i.e., the soft material valves made of flexible material and the soft structure valve made of rigid material. Piezoelectric vibrator only corresponds to the function structure of valve body and pump body, so changing the structure of pump body can also change the pump′s output. If a pump consists of a driving system, a pump cavity system, and a valve system in a traditional manner, single chamber with single drive will become its standard form. However, the following discussion of the pump body structure of the piezoelectric pump with valve will include the form of single chamber with dual drives, single chamber with single drive connected in series, single chamber hybrids with single drive, and their hybrid combinations.

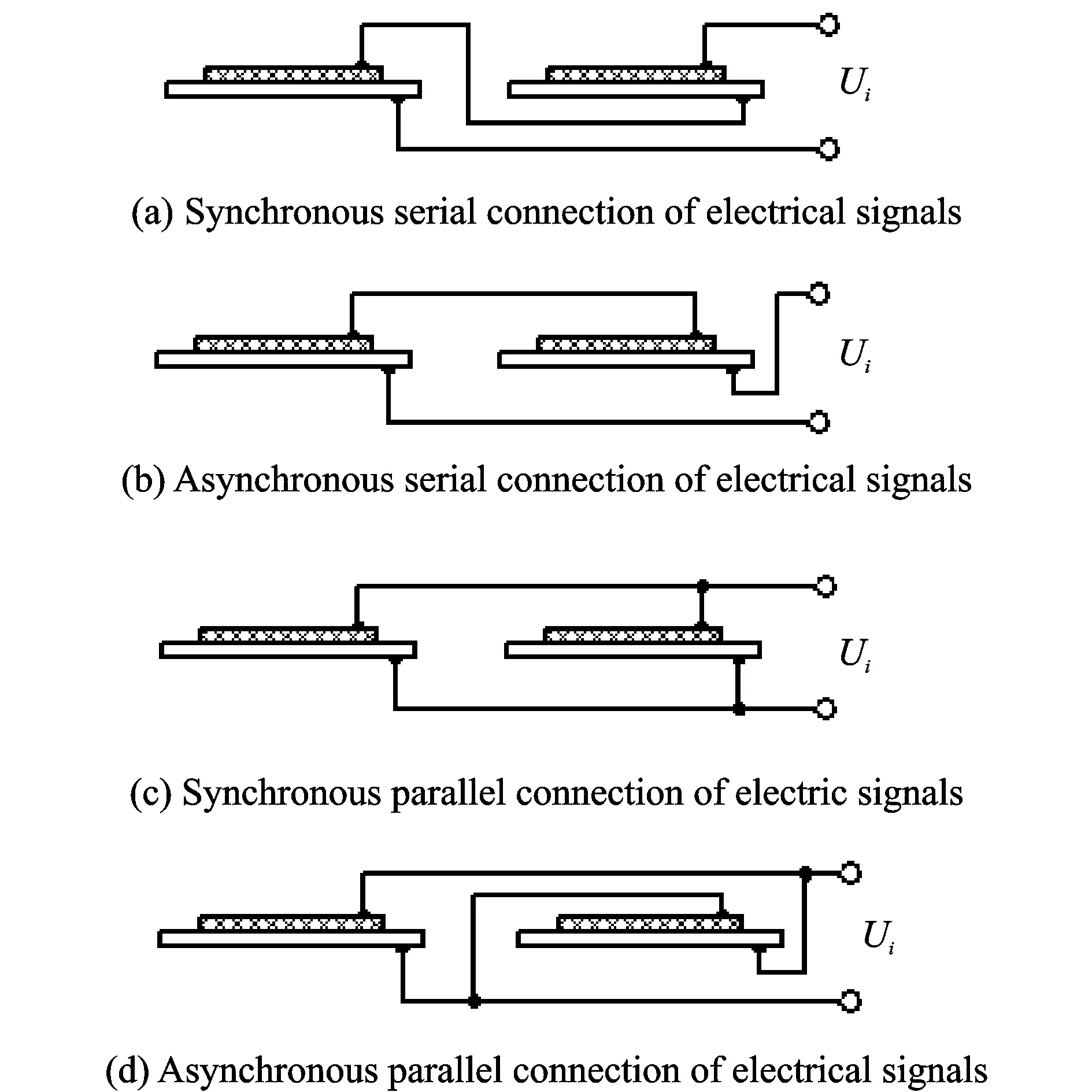

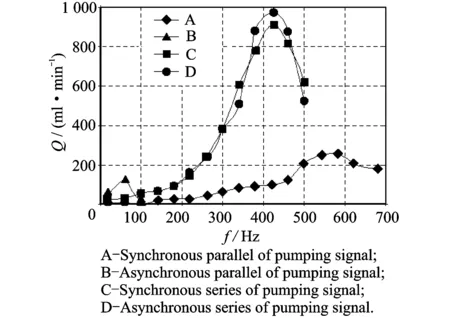

Serially and parallelly connected pumps with multi chambers should be indeed driven by multi piezoelectric vibrators, which can provide synchronous actuation in series, asynchronous actuation in series, synchronous actuation in parallel, and asynchronous actuation in parallel with respect to the characteristics of electrical signals (see Fig.13).

Fig.13 Combining and driving forms of piezoelectric oscillator

3.1Body structure of single cavity pump with double oscillators

In 2007, Sun et al. from Jilin University designed a new piezoelectric pump with the structure of single cavity and dual oscillators, and carried out experiments actuated by synchronous and asynchronous sources, respectively. The results manifested that the output performance of pump with dual oscillators was better than that with a single oscillator, and the pumping flow rate actuated by a synchronous source was larger than that actuated by an asynchronous source, see Figs.14, 15(a)[31]. At the same operating frequency, the output flow rate of the pump with dual oscillators is approximately two times as high as that of the pump with a single oscillator.

In 2013, Sun et al. in Jilin Institute of Chemical Technology optimally designed a new single-chambered piezoelectric pump with dual actuatorsThey staggered two piezoelectric vibrators, and shortened the flow channel between the inlet/outlet valve and piezoelectric vibrator. It was found in their experiments that the output flow of the new structure was two times of that of the original structure. Besides, when operating at 40 Hz frequency and 110 V voltage, the piezoelectric pump with new structure provided the maximum flow rate of 800 ml/min[32], as shown in Fig.15(b).

Fig.14 Output flow of piezoelectric pump in different driving modes

Fig.15 Structure of single-chamber piezoelectric pump with dual actuators

The pump chamber volume variation of single-chamber piezoelectric pump with dual actuators was two times of that of the pump with single-actuator each cycle, and its flow rate gained a 100% increase. The flow channel of optimized single-chamber piezoelectric pump with dual actuators became shorter, and the volume of pump cavity was one time smaller than that of the original structure. The volume variation caused by the same actuator was two times as much as that of the original structure, and its flow rate was two times higher as well.

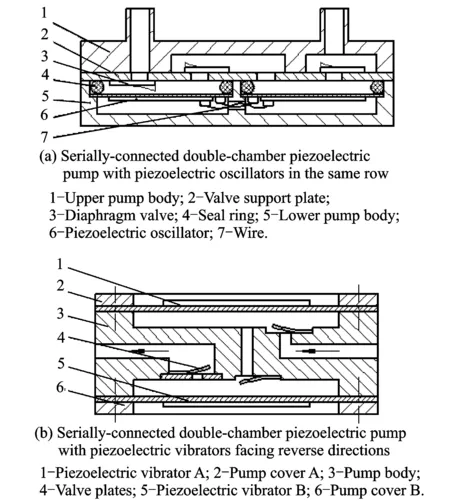

3.2Structure of pump bodies connected in series

In 2005, Zeng et al. in Jilin University designed a piezoelectric pump with double-chambers connected serially, as shown in Fig.16 (a), and tested it. Results showed that when the height of the pump′s working chamber was 0.8 mm, the output flow of the pump reached its maximum. Given a 120 V AC signal, the pump performed the best at working frequency of 180 Hz with the output parameters of 520 ml/min, 22 kPa[22].

In 2006, Kan et al. from Jilin University also designed a piezoelectric pump with serially-connected double chambers, as shown in Fig.16(b). With the same driven voltage and frequency, its output pressure was two times as large as that of a single-chamber due to the alternate working of two chambers. Furthermore, the flow rate increased significantly, which was about 1.4 times of that of the single-chamber[33].

Fig.16 Structure of serially-connected double-chamber piezoelectric pump

In the piezoelectric pump with double-chamber connected in series, the fluid is driven by the pumping pressure of two-level pump chambers before flowing out, so the fluid output pressure can reach two times of that of piezoelectric pump with a single chamber.

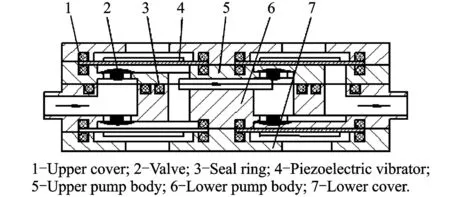

3.3Structure of pump bodies connected in parallel

In 2006, Kan et al. in Jilin University designed a parallelly-connected double-chamber piezoelectric pump, as illustrated in Fig.17, and compared it with the serially-connected double-chamber piezoelectric pump in experiments. At the frequency of 20 Hz and voltage of 80 V, flow rate of the pump reached its maximum, 55 ml/min, which was 1.57 times as much as that of serially-connected pump (36 ml/min)[33].

In the parallelly-connected double-chamber piezoelectric pump, two pump chambers are separated by two unidirectional valves, whose structure is similar to the single-chamber piezoelectric pump with dual actuators. And as a result of blockage of the unidirectional valve, its flow rate increases significantly.

Fig.17 Structure of piezoelectric pump with double-chamber connected in parallel

3.4Structure of pump bodies in hybrid connection

In 2013, He et al. in Jilin Institute of Chemical Technology designed a gas piezoelectric pump (Fig.18) with dual-chamber quadri-vibrator in hybrid connection and conducted experiments. Taking air as a working medium, the optimal operating frequency of the pump was about 360 Hz, and the maximum output flow rate was up to 3 405 ml/min; while taking water as a working medium, the optimal operating frequency became 140 Hz approximately and the maximum output flow rate reached 1 078 ml/min. When flow rate was zero, the output pressure was up to 49 kPa[34].

Fig.18 Structure of pump bodies in hybrid connection

3.5Summary of pump structure

All structural forms of piezoelectric pumps mentioned above, i.e., the pump with serially-connected dual drives and single chamber, the pump with serially-connected single drive and single chamber, the pump with parallelly-connected single drive and single chamber, and the pump in hybrid connection, can effectively increase the pressure output and flow rate. First of all, multi-drive strengthens the driving capability. Secondly the structure of multi-pump chamber connected parallelly increases the effective volume change of the pump chamber, namely, the pressure change of fluid per unit time, thereby enhancing the output capability. In a serially-connected multi-chamber pump, the pressure of the inlet is gradually increased, so that the output capability of the valve is enhance by increasing the flow rate of the valve in unit opening time.

For the pump chamber with the same form and different structure, the integrated effect depends on the volume change of pump chamber (or fluid pressure). The greater the volume change rate of pump chamber, the higher the pressure output or flow rate. Moreover, the asynchronous actuator in parallel also has an analogous function to the electrical signal rectifier, which can effectively reduce output fluctuation, and stabilize the pulsant pressure output and flow rate.

Nevertheless, the pumps with different structures mentioned above, that is the pump with single chamber and dual oscillator, the pump with serially-connected pump bodies, the pump with parallelly-connected pump bodies, the pump in hybrid connections can only achieve the effect that one plus one is less than or equal to two, which means when two pump chambers are integrated together, their maximum output are limited by the output sum of the two separate pump chambers before integration.

4 Development Trend of Piezoelectric Pump with Valve

(1) Thanks to the bold attempt of Yamagata University research team to discover the characteristics of piezoelectricpumps with valve[9-12], this paper reviews the origination and evolution of piezoelectric pumps with valve. From the above analysis, we presume that if there was not a great breakthrough in the development of piezoelectric oscillator, the research teams would choose the topics of conventional piezoelectric pump with valve discreetly. In the next years, there would be no team applying conventional valves (plate valve, ball valve, cone valve) to the piezoelectric pumps with valve.

(2) Soft structure valve body made of rigid materials and soft-material-fabricated valve body made of flexible materials have flexible applications in piezoelectric pumps with valve. With the use of organic materials or rigid materials and the specific design to reduce the material rigidity, output flow rate, pressure difference and other parameters of the piezoelectric pump are better than those with the traditional valve body.

(3) The piezoelectric pump with actively-opening and -closing valve will become the focus of research and application. By using the functional or intelligent material, such as piezoelectric ceramic, shape memory alloy, and ionic polymer metal composite (IPMC) etc., actively-opening and -closing valve may completely eliminate the lagging of pump valve movement, called the original sin of piezoelectric pump with valve. Hence, the piezoelectric pump valve overcoming its original sin will be likely to have a huge application demand.

(4) Piezoelectric pumps with indefinite concepts of valve and valveless will be invented by the scholars in the future. If the valveless piezoelectric pump is defined as a piezoelectric pump that cannot be completely blocked by any instantaneous flow path during a working cycle, the flow path of valve stem end or similar valve stem end will be completely blocked because of the signal change in piezoelectric vibrator drivers, and vice versa, which obscure the concepts of valve and valveless. When merely changing the driven input of piezoelectric oscillator with other conditions remaining unchanged, the pump can obtain adjustment of the balance and selection between macro output capability (flow, pressure) and output quality (shock, fluctuation, and noise).

5 Conclusions

(1) After review the development history of the piezoelectric pump with valve, the structural design of the classified valve body embodies the piezoelectric-oscillator-driven traditional valve body, the soft structure valves made of rigid materials, the soft-material-fabricated valve body made of flexible materials. The structural design of the classified pump body includes the dual-drive single pump chamber, the serially-connected single drive single pump chamber, the parallelly-connected single-drive single pump chamber and pump in hybrid connections.

(2) We analyze the role and function of various types of valve body structures and pump body structures for piezoelectric pump, and summarize and analyze new directions that the piezoelectric pumps with valve may develop in the future.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No.51375227), the Scientific Research Project of Guangzhou University (No.ZJH3-2001), and the Higher Vocational College Domestic Senior Visiting Scholar Project of Jiangsu Province (No.2015FX076).

[1]ZHAO Chunsheng. Ultrasonic motors: technologies and applications[M]. Verlag Berlin Heidelberg: Springer, 2011.

[2]CHEN Qianwei, JU quanyong, HUANG Weiqing, et al. Stick-slip tower-shaped piezoelectric actuator[J]. Transactions of Nanjing University of Aeronautics & astronautics, 2015, 32(2):156-162.

[3]LIU Weidong, ZHU Hua, ZHOU Shengqiang, et al. Structural design and control of variable camber wing driven by ultrasonic motors[J]. Transactions of Nanjing University of Aeronautics & Astronautics, 2015, 32(2):180-186.

[4]LIU Xiangjian, CHEN Renwen. Analysis on output power for multi-direction piezoelectric vibration energy harvester[J]. Transactions of Nanjing University of Aeronautics & Astronautics, 2014, 31(6):668-674.

[5]SPENCER W J, CORBETT W T, DOMINGUEZ L R. An electronically controlled piezoelectric insulin pump and valves[J]. IEEE Transactions on Sonics and Ultrasonics, 1978,25(3):153-156.

[6]NARASAKI T. Layered type bimorph vibrator pump[C]∥Intersociety Energy Conversion Engineering Conference. [S.l.]:[s.n.],1978:2005-2006.

[7]NARASAKI T. A pump driven by piezoelectric ceramic:137671[P]. Japanese Patent,1982:1982-1986.

[8]LI Yong, ZHOU Zhaoying, YE Xiongying. An over view of research on micro-valves and micro-pumps [J]. Chinese Journal of Scienti, 1996,17(1):56-60.

[9]FUKAZAWA H. The research of piezoelectric pump[D]. Yamagata: Japan Yamagata University, 1997.

[10]ITO M. The research of piezoelectric pump[D]. Yamagata: Japan Yamagata University, 1998.

[11]SUZUKI K, FUKAZAWA H. The research of piezoelectric pump[M]. Northeast Branch of the Japan Society of Mechanical Engineers Iwaki, 1997: 193-194 .

[12]SUZUKI K, NAKANISHI T. The research of cone valve piezoelectric pump[M]. Japan: Society of Japan Design Engineering Northeast Branch, 2000:16-17.

[13]KAN Junwu, WU Yihui, YANG Zhigang, et al. Study on the performance of micro-cantilever valve[J]. Journal of Harbin Institute of Technology, 2005,37(2):190-193.

[14]CHENG Guangming, LIU Guojun, YANG Zhigang, et al. Experimental research on piezoelectric micro-pump using cantilever check valve [J]. Mechanical Science and Technology, 2005,24(10):1181-1183.

[15]YANG Shuchen, CHENG Guangming, LIU Guojun. Design of piezoelectric micro-pump[J]. Optics and Precision Engineering, 2005,13(3):318-323.

[16]SUN Xiaofeng, YANG Zhiqiang, LIU Xiaolun. Performance research on piezoelectric pumps based on holistic opening valve and cantilever valve[J]. Optics and Precision Engineering, 2006,14(4):648-651.

[17]ZHANG Jianhui, WANG Dayin, WANG Shouyin, et al. Study of the piezoelectric pump: the hysteresis of the pump & valve[J]. Chinese Journal of Mechanical Engineering, 2003,39(5):107-110.

[18]HAM Y B,SONG J J,PARK J H. A study on the small size PZT pump for cooling water circulation[J]. SICE-ICASE International Joint Conference, 2006,10:18-21.

[19]ZENG Ping, LIN Jingguo, CHENG Guangming. A study on testing for micro piezo-pump with integral valve[J]. Piezoelectectrics & Acoustooptics, 2006,28(5):594-597.

[20]ZHANG Jianhui , HUANG Jun, HU Xiaoqi. A novel piezoelectric pump with E-shaped valve found from the subdivision experiment[C]∥[S.l.]: IEEE,2009.

[21]HE Lin, JI Xiu, ZHENG Wen, et al. Application of new type of metal check valve to compact piezoelectric pump[J]. Piezcielectrics & Acoustooptics, 2011,33(1):72-75.

[22]ZENG Ping, CHENG Guangming, LIU Jiulong. Experimental research on double-chambered piezoelectric pump with membrane valves[J]. Optics and Precision Engineering, 2005,13(3):311-317.

[23]HE Lihong, HOU Tiecheng, HU Yiwei. Structure studyof a novel passive valve for piezoelectricpump[J]. Micro Computer Information, 2007,23(12):118-119.

[24]CHANG Kunyong, GU Xuelian, WANG Qin. Structure design and experimental research of per-stressed piezoelectric pump[J]. Transducer and Micro system Technologies, 2009,28(8):30-32.

[25]ZHANG Jianhui, GUO Zongxin, HUANG Yi. Theory and experiment on the soft texture and conning shaped single valve piezoelectric pump with different interior and exterior taper [J]. Journal of Mechanical Engineering, 2010,46(24):143-149.

[26]LI Jun. Sphygmomanometer & gas pump, utility model patent: 201120107438.1[P].The People′s Republic of China Patent,2011.

[27]ZUO Leipeng, ZUO Yanchao, ZUO Pengfei, et al. An aromatherapy machine: 201310590650.1[P]. The invention patent application, The People′s Republic of China Patent,2013.

[28]LU Shaoquan, ZUO Leipeng, ZUO Pengfei, et al. An aromatherapy machine:201410410080.8[P].The invention patent application, The People′s Republic of China Patent,2014.

[29]CHEN Hongwen, MA Guoyu. Intelligent steam bath aroma therapy machine, utility model patent:201120107438.1[P].The People′s Republic of China Patent,2011.

[30]ZHANG J , CHILDRESS S , LIBCHABER A, et al. Flexible filaments in a flowing soap film as a model for one-dimensional flags in a two-dimensional wind[J]. Nature,2000,408(6814):835-839.

[31]SUN Xiaofeng, YANG Zhigang, CHAI Congliang. Structural design and experimental research on single-chambered piezoelectric pump with double actuators[J]. Piezoelectectrics & Acoustooptics, 2007, 29(5):593-595.

[32]SUN Xiaofeng, SHAO Zebo, HE Ye,et al. Structural design of a new single-chambered piezoelectric pump with double actuator[J]. Fluid Machinery, 2013,41(4):12-15.

[33]KAN Wujun, PENG Taijiang, TANG Kehong, et al. The strucrure and performance of double-chamber piezoelectric pumps[J]. Piezoelectectrics & Acoustooptics, 2006,28(1):39-42.

[34]HE Sen, SUN Xiaofeng, JIANG Delong. Performmance analysis on dual-chamber series-parallel gas piezoelectric pump with four-vibrator[J]. Machinery Design & Manufacture, 2013,10:152-154.

Dr. Zhang Jianhui is a professor and doctoral supervisor in Guangzhou University. He earned his Ph.D. degree from the Yamagata University, Japan in 2001. His research mainly focuses on mechanical design and theory of piezoelectric actuator.

Ms. Wang Ying is an associate professor of Taizhou Polytechnical Instiute. In 2006, she earned her M.SC. degree of Engineering from Yangzhou University. From Sep. 2015, she served as a senior visiting scholar in State Key Laboratory of Mechanics and Control of Mechanical Structures, Nanjing University of Aeronautics and Astronautics (NUAA). Her main research focuses on mechanical design and theory.

Mr. Fu Jun is a postgraduate student in Guangzhou University. His research mainly focuses on the development of piezoelectric actuator and fluid machine.

Mr. Yan Kang is a postgraduate of NUAA, His main research area is mechanical design and its theory, piezoelectric driving.

Mr. Li Zhiming is a postgraduate of NUAA. His research interests lie in development of piezoelectric actuator and fluid machine.

Dr. Zhao Chunsheng is the academician of the Chinese Academy of Sciences, professor, and doctoral supervisor in NUAA. In 1961, he earned his Bachelor′s Degree from NUAA, and in 1984 he received his ph.D. degree from the Paris Higher School of Mechanical Engineering. His main research interests cover mechanical design and theory.

(Executive Editor: Zhang Tong)

, E-mail address: zhangjh@nuaa.edu.cn.

How to cite this article: Zhang Jianhui, Wang Ying, Fu Jun, et al. Advances in technologies of piezoelectric pumping with valves[J]. Trans. Nanjing Univ. Aero. Astro., 2016,33(3):260-273.

http://dx.doi.org/10.16356/j.1005-1120.2016.03.260

TH35Document code:AArticle ID:1005-1120(2016)03-0260-14

杂志排行

Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Numerical Optimization on Aerodynamic/Stealth Characteristics of Airfoil Based on CFD/CEM Coupling Method

- Kinematic Calibration of Asymmetricly Actuated 6-DOF 3-PPPS Parallel Mechanism

- Kinematic Optimization of Bionic Shoulder Driven by PneumaticMuscle Actuators Based on Particle Swarm Optimization

- Dynamic Modeling and Adaptive Fast Nonsingular Terminal SlidingMode Control for Satellite with Double Rotary Payloads

- A Comprehensive Review on RNA-seq Data Analysis

- Joining Force of Heterogeneous Titanium Alloy in Linear Friction Welding Process