Flavor Characteristic Analysis of Fried Allium tenuissimum L. Flowers by Electronic Nose and Headspace-Gas Chromatography-Ion Mobility Spectrometry

2022-07-07WENYouZHAOXiaoyingWANGChenghuaLIUXiaoling

WEN You, ZHAO Xiaoying, WANG Chenghua, LIU Xiaoling

(College of Light Industry and Food Engineering, Guangxi University, Nanning 530004, China)

Abstract: Flavour characteristics of Allium tenuissimum L. (AtL) flowers processed by the Chinese traditional stir-frying method were investigated by electronic nose (E-Nose) and headspace-gas chromatography-ion mobility spectrometry (HSGC-IMS). E-nose detection with principal component analysis (PCA) revealed that the main volatile components of AtL flowers were nitrogen oxides, terpenes, organic sulfides and sulfur-containing organic compounds, while the stir-frying process distinctly changed the flavor pattern of AtL flowers, resulting in significantly increased levels of sulfur-containing compounds. A total of 56 components were detected across fried AtL (FAtL) and raw AtL flowers, of which 25 were identified as volatile compounds by HS-GC-IMS. The contents of five fat-soluble and two water-soluble compounds in FAtL were far higher than those in AtL, confirming that stir-frying changed the flavor of AtL flowers. In conclusion, the combination of E-Nose and HS-GC-IMS represents an efficient, accurate and sensitive method for the determination of flavor components in Allium plants.

Keywords: Allium tenuissimum L.; flavor; E-Nose; frying; headspace-gas chromatography-ion mobility spectrometry

L. (AtL), also called Zhameng flowers, Zemeng flowers or Mama flowers in China, is a perennial herb belonging to the Allium family and mainly distributed in northern China’s Inner Mongolia, Heilongjiang and Shanxi provinces, in Russia’s Siberia, and in Mongolia.Being a medicine food homology species and versatile biological resources like vitamin C, proteins, dietary fiber, and allicin, AtL has been used as a traditional food seasoning for nomads since antiquity, which is usually processed by stir-frying in common family of China. Once the oil is heated to warm but not to its boiling point, AtL is put into and stir-fried to golden or dark yellow, which can be mixed with other condiments for seasoning. The friedL. (FAtL) not only has unique flavour, but also can be preserved in porcelain or glass containers. Several studies showed that the main flavour component of AtL is sulfide, which is significantly different from leek, but similar to onion. However, to the best of our knowledge,flavour characteristics of the fried AtL processed by Chinese traditional frying processing and the underlying flavour changes have never been reported.

Electronic nose (E-Nose) is a common flavour detector, also known as an odor scanner that can detect and distinguish different kinds of volatile flavour compounds in food, and usually get results consistent with human sensory evaluation. This technology has been widely used in the food inspection industry and used for maturity detection, variety identification, quality assessmentand flavour descriptions of various foods and seasonings. Ion mobility chromatography (IMS) is a very sensitive analytical technique for the separation and detection of trace volatile compounds with a detection limit of ppb level. Recently,the applications of IMS are being extended to food flavour evaluation, food quality evaluation, food ingredient analysis,food flavour, and so on. For example, the combination of a gas chromatography and IMS identifies the quality of olive oil, headspace-gas-ion migration chromatography(HS-GC-IMS) is used to establish fingerprints of volatile substances in Matsutake. However, the IMS method still suffers from the small database with limited references and lack of ability to directly and accurately quantify the samples, which necessitates the union use of other detection technologies.

In this study, the flavour characteristics of the fried AtL flowers processed by Chinese traditional frying processing and the underlying flavour changes were investigated for the first time by the combination of HS-GC-IMS and E-Nose in considering of the convenience and sensitivity of detection technology. The purpose is to establish an efficient, accurate and sensitive method for flavour determination, and provide a reference for the rapid flavour identification of AtL and other Allium crops.

1 Materials and Methods

1.1 Materials

The AtL samples were purchased online from Jinditianyuan (Shanxi Jingle Rural Agricultural Comprehensive Development Co. Ltd., Jingle, Shanxi Province, China). Corn oil used for frying AtL samples was bought from Luhua (Yantai, China).

1.2 Methods

1.2.1 Sample preparation

After dried in the sun, AtL was crushed into powder by DFT-100 wall crusher (Wenling Linda Machinery Co. Ltd.),passed through 60 mesh sieves, and stored in a sealed bag in a dark place at room temperature. The FAtL was prepared by stirring the AtL power in 100 ℃ corn oil for 5 s, and then was filled into a headspace bottle (Haimen Shundian Experimental Equipment Co. Ltd., Haimen, Jiangsu Province, China) and sealed, waiting for testing. All the corn oil samples tested in the headspace bottle were (2 ± 0.05) g; AtL samples tested by E-Nose was (1 ± 0.05) g; and AtL samples tested by HS-GCIMS was (0.1 ± 0.02) g mixed with 2 mL saturated saltwater(26.5%). FAtL samples detected by E-Nose were prepared with the ratio of oil to sample of 2:1, while for HS-GC-IMS detection FAtL samples were prepared with the ratio of oil to sample of 20:1. Each experiment was repeated three times.

1.2.2 E-Nose analysis

E-Nose analysis was performed using a Winmuster Airsense Analytic Inc PEN 3 E-Nose device (Schwerin,Germany). The device consists of a sensor array system(MOS) with ten different metal oxide semiconductors.These sensors have a wide range of sensitivity to aromatic compounds (W1C), nitrogen oxides (W5S), aromatic ammonia compounds (W3C), hydrogen (W6S), alkanes(W5C), methane (W1S), terpenes and sulfur compounds,and organic compounds (W1W), alcohols (W2S), sulfurcontaining organic compounds (W2W) and methane aliphatic compounds (W3S). Data acquisition and, storage was performed by WinMuster v.1.6.2.16 (Airsense Analytics,Schwerin, Germany), and multivariate statistical processing by OriginPro 2020 v.9.7.0.188.

For E-Nose analysis, each sample contained in a 20 mL headspace glass bottle was kept at 40 ℃ with a thermostatic water bath. The gas of each sample was transmitted to the detector at a constant rate of 150 mL/min within 200 s, and the sensor signal can reach a stable value within this time.After each measurement, the detector was cleaned 100 s with clean air until the sensor signals returned to the baseline. A total of 10 sensors were used in electronic nose analysis, and the signal of each sensor was recorded at the 180th second.

1.2.3 GC-IMS Analysis

Samples were analyzed on a combined device of a GC Column FS-SE-54-CB (30 m × 0.53 mm,1 µm) and IMS instrument (FlavourSpec, Gesellschaft für Analytische Sensorsysteme mbH, Dortmund, Germany), equipped with an autosampler unit (CTC Analytics AG, Zwingen, Switzerland)that can be directly sampled from the headspace by using a 1 mL air-tight heated syringe.

One hundred milligrams of AtL samples added to a 20 mL headspace bottle containing 1 mL of saturated saline (AR,Chengdu Jinshan Chemical Reagent Co. Ltd., Sichuan,China). Each sample was incubated at 50 ℃ for 5 min, and 100 μL of the headspace gas was automatically injected into the injector through a syringe heated at 80 ℃. The gas sample was then driven to the HP column by nitrogen using the following procedure: 2 mL/min for 2 min, 30 mL/min for 8 min, 100 mL/min for 10 min, and 150 mL/min for 5 min.The analyte is driven into the ionization chamber and ionized in positive ion mode. The resulting ions were driven into a drift tube (length is 9.8 cm), which was operated at a constant temperature (45 ℃) and voltage (5 kV). The drift gas (high purity nitrogen) was set to 150 mL/min.-ketones C–C(China National Pharmaceutical Chemicals Beijing Co. Ltd.)was used as an external reference to calculate the retention index (RI) of volatile compounds. Volatile compounds were identified by comparing their drift times with that of the standards in the RI and GC-IMS libraries. The identified compound can judge its relative change by the magnitude of the response value. The HS-GC-IMS data were analyzed in LAV v.2.2.1 (Laboratory Analysis Viewer) and its plug-ins.

2 Results and Analysis

2.1 E-Nose analysis of flavour volatile compounds of AtLs under different treatments

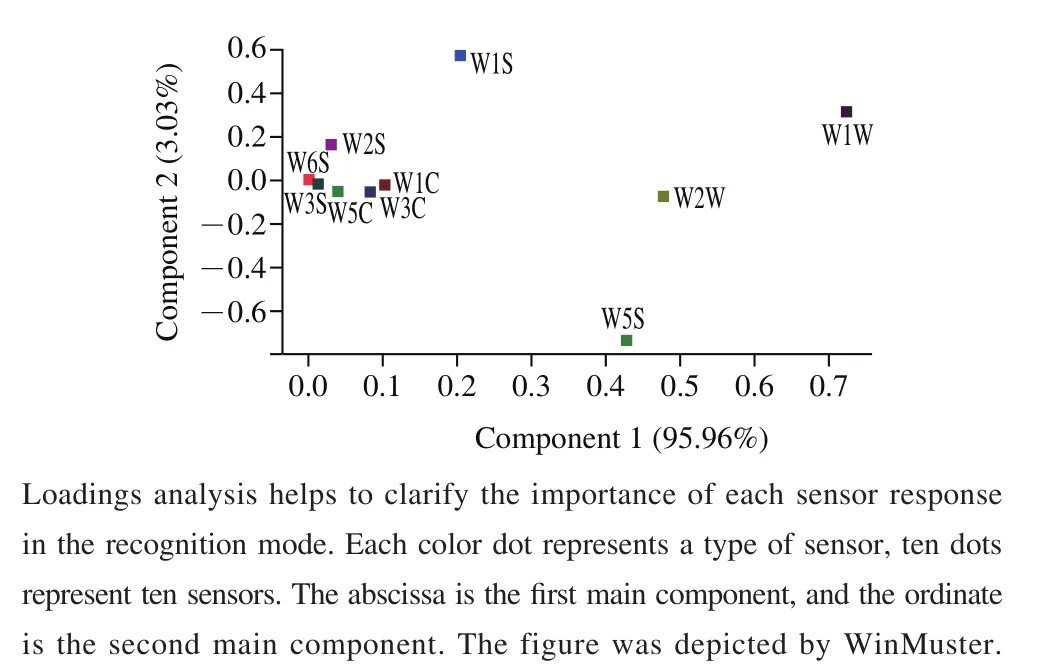

As shown in Fig. 1, the sensor 7 (W1W) and the sensor 9 (W2W) had the largest contribution rates to the first principal component, and Sensor 6 (W1S) showed the greatest contribution to the second principal component. The results indicated that the main contributors to the flavour of AtL were inorganic sulfides, aromatic components, and organic sulfides.

Fig. 1 Contribution of E-Nose sensors to variance on the first and second principal components for flavor characteristics of AtL and FAtL

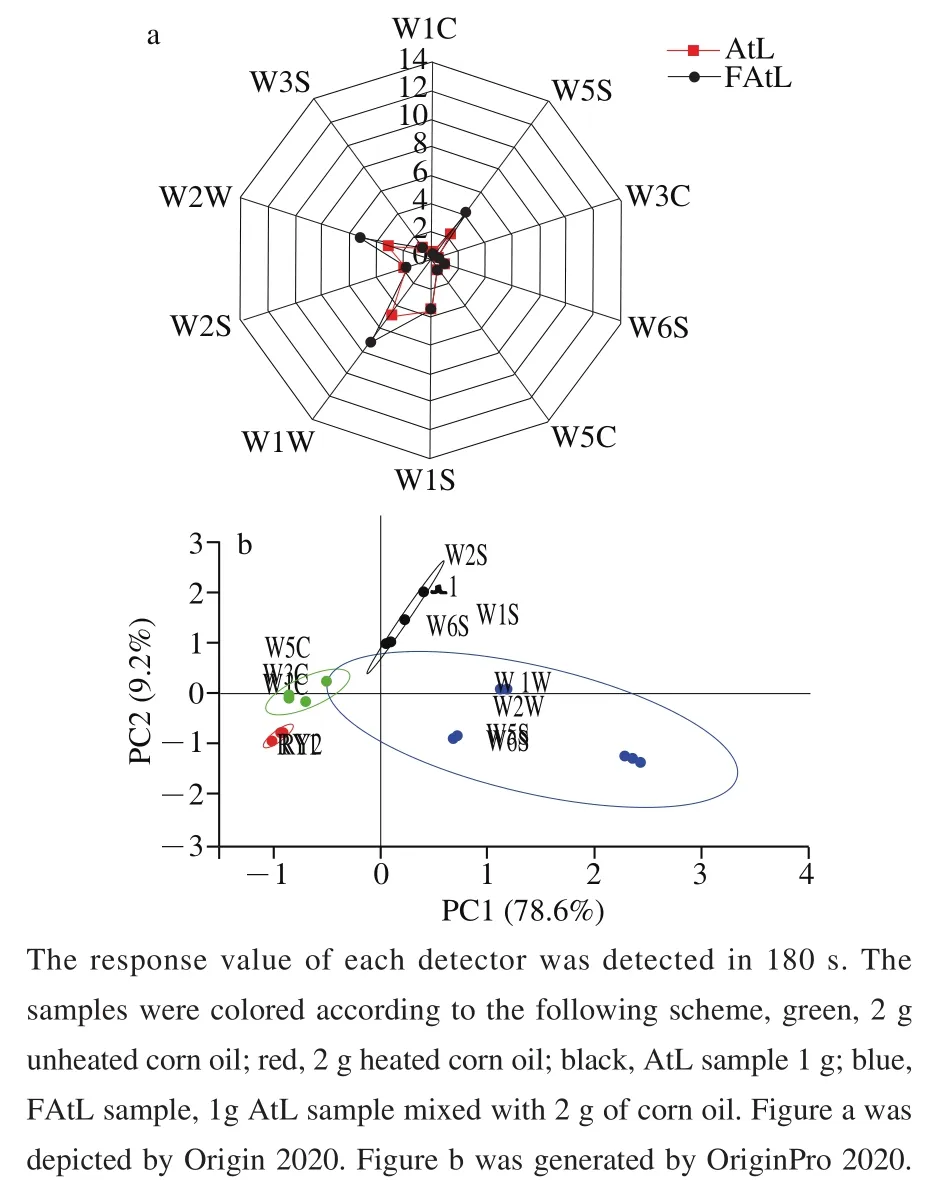

As shown in the radar chart (Fig. 2a), the response signals/of W5S, W1W and W2W of AtL and FAtL were 2.27 and 4.16, 4.88 and 7.18, 3.20 and 5.21 respectively, higher than other sensors. This phenomenon indicated that nitrogen oxides, terpenoids, sulfur-containing organic compounds and organic sulfides play an important role in the flavours of AtL and FAtL. The response signal values of W5S, W1W, and W2W to FAtL were higher than that of AtL, and the different thiosulphate compound characteristics reflected distinct dominating chemical groups, indicating the increase of sulfide content in FAtL by stirfrying processing.

Fig. 2 E-Nose response patterns of volatile organic compounds in AtL and FatL (a) and PCA 2D projection of PC1 versus PC2 (b) of AtL samples under different treatments

The volatile compounds of AtLs under different treatments were further differentiated by using the principal component analysis (PCA). In PCA 2D projection of E-Nose datasets (Fig. 2b), the cumulative contribution rate of the first and second main components (organic sulfide and inorganic sulfide, and aromatic compounds) captured by the sensor was 87.8%, especially the first principal component accounted for as high as 78.6%. As shown in Fig. 2b, there was no significant difference between the corn oil before and after heating,however, AtL and FAtL presented obvious differences (Fig. 2b).Compared with AtL, the contribution rate of the first principal component in FAtL increased, while that of the second principal component decreased. This indicating the great difference of main contributing volatiles between AtL and FAtL, which were brought up by stir-frying processing.

2.2 GC-IMS analysis of flavour volatile compounds of AtLs under different treatments

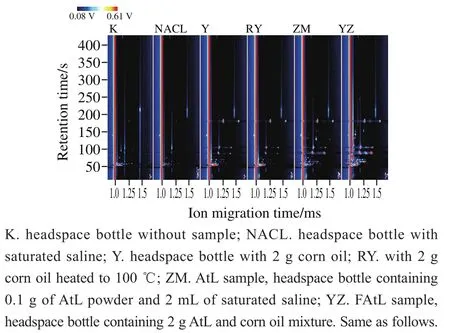

2.2.1 GC-IMS topographic map of AtL

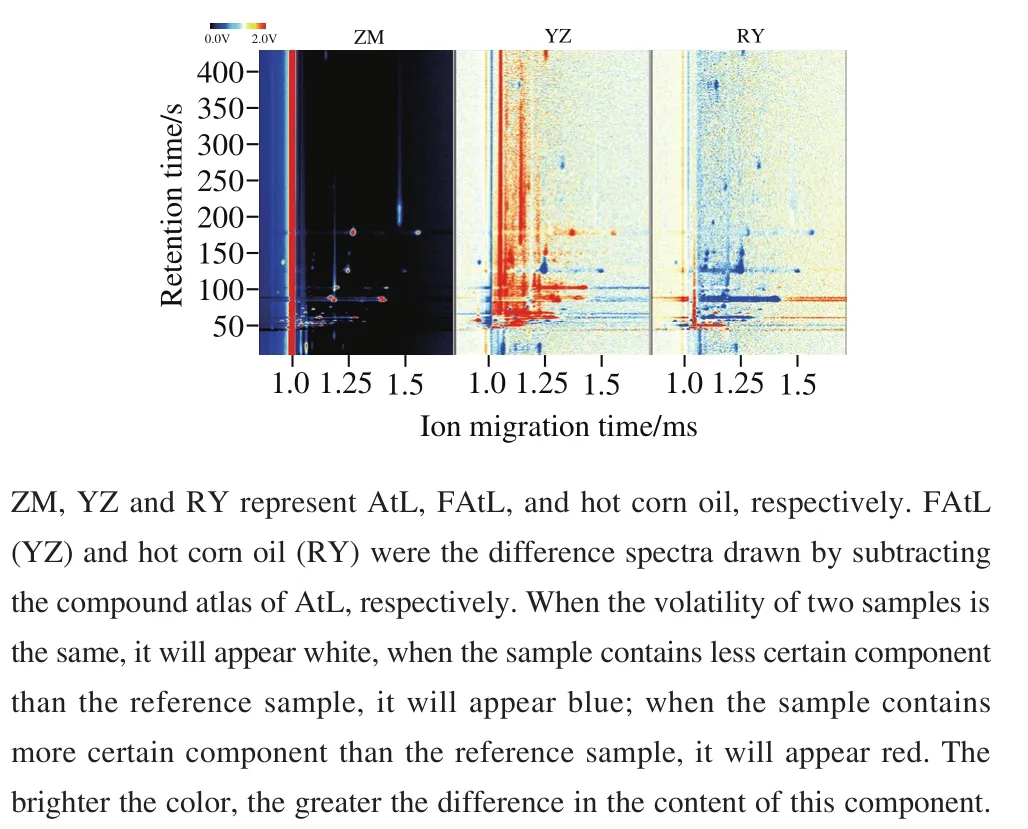

GC-IMS was used to describe the flavour characteristics of the volatile compounds of AtL. As shown in Fig. 3, the data was visually represented by a 2D topographic map,which normalized the ion migration time and the position of the reactive ion peak (RIP). The entire spectrum represents all headspace compounds of the sample. Each dot on the right side of the RIP represents a volatile compound extracted from the sample. The color in the figure represents the signal intensity of the substance, white indicates lower intensity, and red indicates higher intensity. The stronger the signal response value, the greater the concentration of the substance in the sample. By comparing the response values of the volatile components in AtL and FAtL, the trend of the detected volatile components can be known. It can be seen from Fig. 3 that the main flavour components of the corn oil appeared in the range of 1.0 RIP-1.25 RIP, about 50 s, that of AtL and FAtL appeared in the range of 50-100 s.

Fig. 3 HS-GC-IMS topographic maps of AtL samples

A total of 25 target compounds of AtL were identified by comparing the drift time and retention index of each point in the topographic map with the real reference compounds in the GC-IMS Library, there are 16 kinds of fat-soluble compounds and 6 kinds of water-soluble flavor compounds. However, the identification of sulfur-containing compounds failed, which was inconsistent with results of the above E-Nose analysis, the reasons may be due to the lacking of reference sulfur-containing compounds deposited in the GC-IMS inventory.

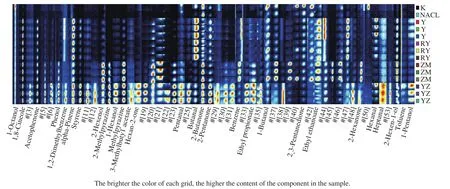

2.2.2 Characteristic of volatile compounds of AtL and FAtL

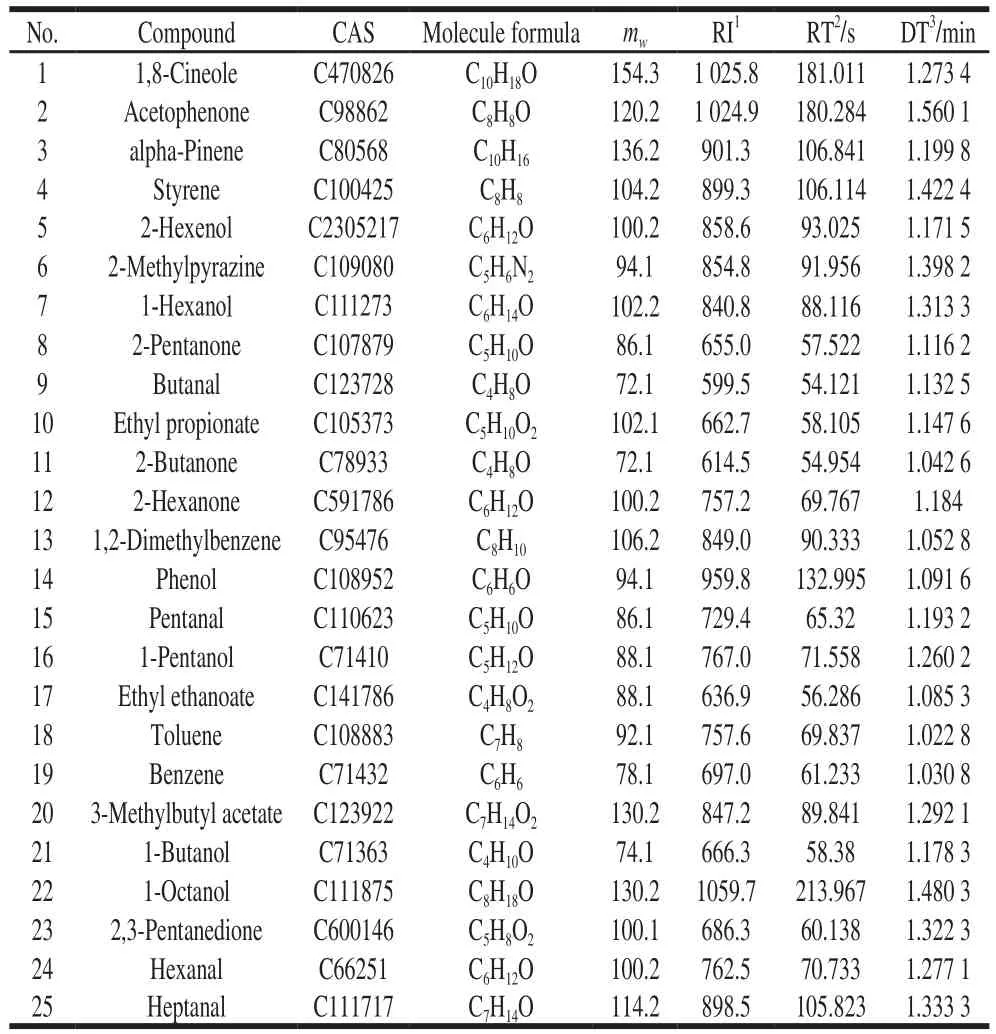

The fingerprint full-spectrum determinations of volatile components were performed on the FAtL samples. A total of 56 chemical peaks could be detected in AtL and FAtL by HSGC-IMS, and 25 of them can be identified in GC-IMS Library(Table 1). The contents of 29 components including heptanal,styrene, and 2-hexanone increased in the FAtL (17 of them could not be identified in the GC-IMS library). The unique volatile components (such as No. 3 in Fig. 4.) in the FAtL cannot be determined in the GC × IMS library. The contents of heptanal, styrene, ethyl propionate, and other components in the FAtL were significantly higher than the AtL, and the increase in pyrazine content may be related to the Maillard reaction. It is important to note that in the identified 25 compounds, there were 16 fat-soluble components associated with flavour. The identified compounds like three fat-soluble common compounds including eucalyptus, acetophenone and alpha-pinene existed in very similar way in AtL, oil and AtL mixed with corn oil, indicating their independence on stirfrying processing. Comparatively speaking, in FAtL, seven response values of five fat-soluble components including styrene, ethyl propionate, 1,2-dimethylbenzene, 1-hexanol and heptanal, and two water-soluble compounds 2-methyl pyrazine and pentanal increased significantly (Fig. 4).The response values of styrene increased from 0.33 ± 0.05 to 1.90 ± 0.10, ethyl propionate increased from 0.55 ±0.02 to 0.83 ± 0.02, 1,2-xylene increased from 0.015 ± 0.005 to 0.33 ± 0.05, 1-amyl alcohol increased from 0.10 ± 0.01 to 0.82 ± 0.05, heptanal increased from 0.004 ± 0.002 to 0.10 ±0.01, 2-methylpyrazine increased from 1.81 ± 0.3 to 2.47 ±0.03, and pentanal increased from 0.10 ± 0.01 to 0.38 ±0.3, respectively. The increased content of heptanal and ethyl propionate might provide fruity aromas for AtL, and the increase in styrene would bring sweetness to the flavour of AtL.Therefore, it can be proposed that the frying process stimulated the overflow of some fat-soluble compounds in AtL.

Fig. 4 Fingerprints of volatile organic components in AtL samples

Table 1 GC-IMS integration parameters of volatile compounds in FAtL

Meanwhile, the contents of 2-hexenol and the other seven components are higher in AtL (Fig. 4). This phenomenon may be attributed to the degradation of edible oil, especially fats with more complex flavours, which produced oxygen-containing compounds after frying. These compounds may obscure the main flavour components in AtL-sulfur-containing compounds, which cannot be characterized in the IMS database.

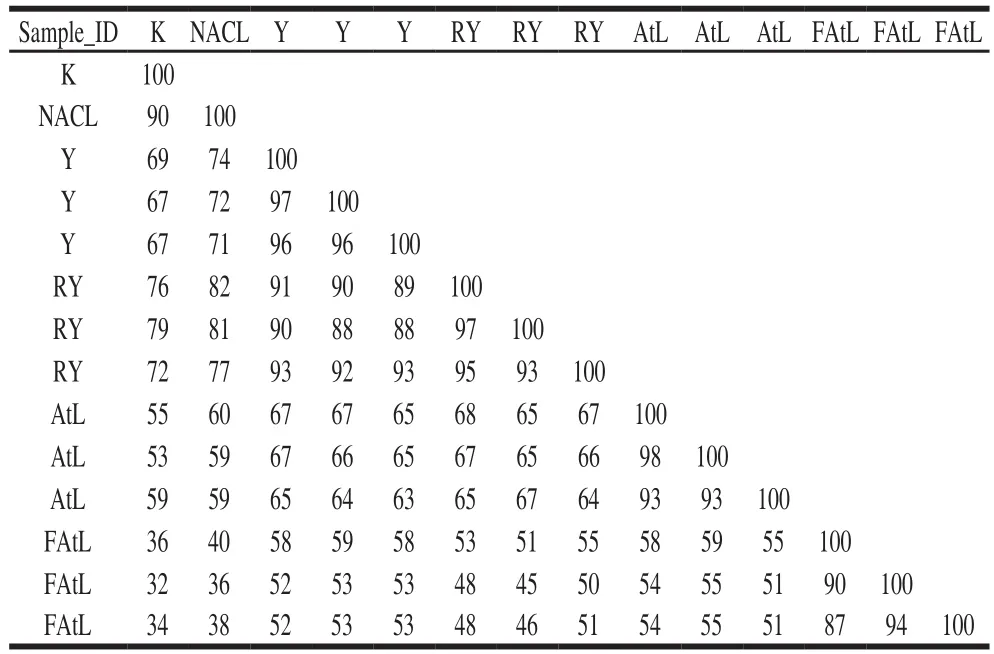

The results of LAV similarity analysis (Table 2)showed that the intragroup similarity of the sample’s flavour characteristics was extremely high, reaching more than 90%,while the intergroup similarities were only 34% (K vs. YZ).After frying, the similarities between FAtL and AtL, FAtL and CO, and AtL and CO became 54.6%, 54.5%, and 65.4%,respectively. These results were consistent with the above observed fingerprints of volatile compounds of AtL before and after stir-frying and reflected the characteristic flavor changes caused by stir-frying processing. The changes after frying can be more clearly observed in the difference maps by substracting the compound atlas of AtL (ZM) from that of the FatL (YZ) samples. As shown in Fig. 5, compared to the hot corn oil (RY) spectra, both AtL (ZM) and FatL (YZ) showed more different type and content of volatile substances. After deduction of AtL (ZM), FAtL showed significant increase in red dots, indicating the increases of response values and contents of volatile components, while the hot corn oil displayed obviously more blue spots, suggesting the lack of volatile components,compared to AtL. The results clearly indicted the volatile compound changes come from the frying process.

Table 2 Similarity analysis between samples

Fig. 5 GC-IMS spectra of AtL samples

3 Conclusion

In this study, the flavour characteristics of the friedL. processed by Chinese traditional stirfrying processing and the underlying flavour changes were investigated for the first time by the combination of HSGC-IMS and E-Nose methods. E-Nose with PCA analyses detected the odor differences between AtL and FAtL and found that the frying process significantly increased the sulfur compounds in AtL flavour. HS-GC-IMS analysis identified 25 volatile compounds from a total of 54 different components between AtL and FAtL, including 16 fat-soluble and 6 watersoluble flavor compounds. There were 5 fat-soluble and 2 water-soluble flavor compounds in FAtL higher than AtL. In addition, LAV similarity between FAtL and AtL was only about 53%, indicating the flavour changes underlying the traditional frying processing. These components constitute the flavour characteristics of AtL, and the main reasons for the changes in the flavour of FAtL are the increase of fatsoluble flavour components and volatile sulfur compounds.The combination method of E-Nose and HS-GC-IMS here characterized the volatile compounds of AtL in minutes by using a one-sample preparation step and a little amount of sample, implying an efficient, accurate, and sensitive method for the flavour determination of allium plants in the future.