寒潮天气表冷器-风机集放热系统对连栋大棚热湿环境的影响

2021-11-26宗成骥王平智陈先知何雪颖王建玉宋卫堂

宗成骥,王平智,2,陈先知,李 明,2,何雪颖,王建玉,徐 丹,2,宋卫堂,2

寒潮天气表冷器-风机集放热系统对连栋大棚热湿环境的影响

宗成骥1,王平智1,2,陈先知3,李 明1,2,何雪颖1,王建玉1,徐 丹1,2,宋卫堂1,2※

(1. 中国农业大学水利与土木工程学院,北京 100083;2. 农业部设施农业工程重点实验室,北京 100083;3. 温州科技职业学院,温州市设施蔬菜工程技术中心,温州 325000)

设施;温度;连栋大棚;表冷器-风机;热湿环境;加温;除湿

0 引 言

塑料大棚是中国南方地区蔬菜越冬生产主要使用的设施类型,其结构简单、安装方便、建设成本低,连栋塑料大棚在其基础上增加了设施空间,提高了土地利用率,但棚内部依旧仅靠土壤蓄热,保温性能也较差,近年来随着南方地区阶段性寒潮(根据现行冷空气等级国家标准[1],寒潮划分指标为:使某地日最低气温24 h内降温幅度大于等于8 ℃,或48 h内降温幅度大于等于10 ℃,或72 h内降温幅度大于等于12 ℃,而且使该地日最低气温下降至4 ℃或以下)的侵袭,棚内作物遭受冻害的现象时有发生[2-4]。为应对寒潮的侵扰,生产上通常采用燃烧生物质块或者大量蜡烛等方式对大棚进行加温[5],大面积的燃烧可燃物存在着火灾等安全隐患,产生的大量烟气污染了棚膜,降低了棚内透光率,同时增加了碳排放,严重影响棚内外的空气环境;并且加温过程不可控,大量的热能被浪费。因此寻求一种安全、低碳、可控的加温技术对保证连栋塑料大棚安全越冬生产具有重要意义。

有关设施加温技术的研究多集中在日光温室和大跨度外保温型塑料大棚[6],可分为水循环集放热[7-12]、空气循环蓄热[13-15]、岩床蓄热[16-17]、相变材料蓄热[18-20]以及热泵加温[21-22]等,以水循环集放热系统最具代表性,通过水循环将白天温室内盈余的热能收集并储存,夜间再通过循环将储存的热能释放到温室内,从而达到加温的目的。这种技术不仅提高了温室的蓄热能力,也使得热能释放过程可控,放热效率大幅提高。其中表冷器-风机集放热系统具有成本低、占用空间小、换热效率高等优点,可以实现对温室或大棚内温度环境的调控[23-27]。表冷器-风机作为集放热系统的换热器,主要由风机、盘管等构成,原理就是让水流过盘管内腔,而待处理的空气流过盘管外壁进行热交换来达到加热或冷却空气的目的,而风机引起的强制对流可以增加热交换的效率。孙维拓等[24]将表冷器-风机与热泵相结合,夜间平均气温升高了2.8~4.4 ℃,相对湿度降低了8.0%~11.5%;李明等[25]针对外保温塑料大棚,利用表冷器-风机集放热系统在晴天和多云天气下将室内气温分别提高(2.5±0.4)和(1.1±0.3)℃;何雪颖等[26]基于响应面法研究了风速、水流速度和水气温差等参数对表冷器-风机集放热系统性能的影响。

1 材料与方法

1.1 试验条件

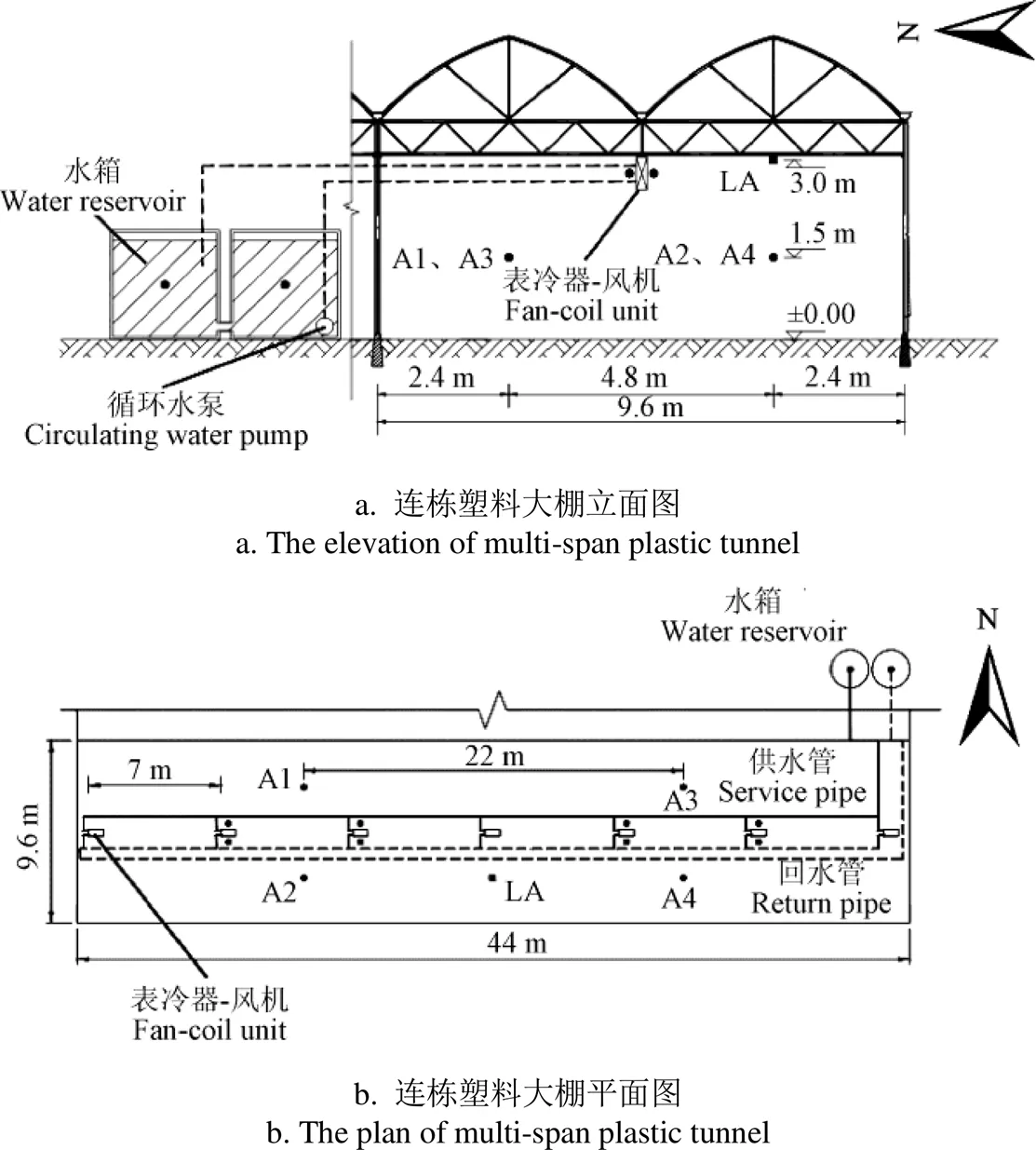

本试验在温州市鹿城区藤桥镇温州种子种苗科技园(28.1°N,120.5°E)内进行,试验所用连栋塑料大棚东西走向,长度44 m,共两跨,一跨有2个双坡形屋顶,单跨跨度9.6 m,屋脊高度5.5 m。大棚覆盖0.1 mm厚PO膜,在棚内3 m高处悬挂一层0.1 mm厚PO膜,四周自然垂落至地面,以作二道膜。白天打开两侧通风口及顶部天窗进行自然通风,夜晚关闭。试验期间大棚内土壤栽培番茄。

表冷器-风机集放热系统由表冷器-风机、蓄热水箱、循环水泵、供回水管路及控制系统等组成。表冷器-风机集放热系统运行过程包括集热阶段和放热阶段,在白天集热阶段表冷器-风机集放热系统将空气中盈余的热量收集并储存,使蓄热水箱中的水温升高;在夜间放热阶段表冷器-风机集放热系统向棚内空气释放热量,使蓄热水箱中的水温降低。夜间放热阶段结束后蓄热水箱中的水温偏低,在白天集热阶段开始时,冷水进入表冷器-风机中,棚内热湿空气流经表冷器后发生冷凝相变析出冷凝水,这一过程可看作系统对湿空气进行冷凝除湿。试验系统配置表冷器-风机共7台(型号为FNH42,嵊州华昱制冷设备有限公司),均仅悬挂在南侧跨大棚桁架下方,每隔4 m设置一台。根据试验连栋塑料大棚的大小、覆盖材料等参数估算冬季采暖系统的热负荷,并以此为依据计算得到试验系统配置的蓄热水箱容积为10 m3,在棚外东北角安装2个容量为5 m3的圆形不锈钢保温水箱用作蓄热水箱,保温层为50 mm聚胺脂发泡层,2个水箱通过底侧管道联通。安装一个型号为40WZB13-18自吸泵作为循环水泵(流量13 m3/h,扬程18 m),各部分由规格为DN63的PPR管连接,采用同程式供回水。

表冷器-风机集放热系统启闭条件设定为:当白天棚内气温t达到15 ℃或者较蓄热水箱中水温t高5 ℃时,系统运行7台表冷器-风机,通过表冷器-风机收集空气中盈余的热能并储存在蓄热水箱中,直到气温t降至10 ℃或者水气温差|t−t|小于2 ℃时,系统关闭;夜晚棚内气温t低于2 ℃或者比蓄热水箱中水温t低4 ℃时,系统运行4台表冷器-风机,将蓄热水箱中的热量释放到棚内,直到棚内气温t达到5 ℃或者水气温差|t−t|小于2 ℃时,关闭系统。

1.2 测点布置

本试验中空气温度使用Pt100铂电阻(量程:−50~200 ℃,精度:±0.1 ℃)测量,空气湿度采用SHT35湿度传感器(量程:0~100%,精度:±2%)测量,如图1所示,棚内空气温湿度由图中标号A1~A4处传感器测量数(包括北侧跨)取均值所得;从东到西方向上第2、3、5、6台表冷器-风机进、出风口0.5 m处均各设置一套Pt100及SHT35测量表冷器-风机进、出风口的空气温湿度;棚内太阳辐射由图中标号LA处的YGC-TBQ总辐射传感器测量(量程:0~2000 W/m2,精度:±10 W/m2);2个圆形保温水箱中部各安放一个Pt100铂电阻,取均值作为蓄热水箱水温;循环管路的进出水口各安装一个管道温度传感器(Pt100,4分螺纹,杆长100 mm,量程:−50~200 ℃,精度:±0.1 ℃),用以测量系统的进出水温;棚外气象条件由气象站采集,主要包括棚外气温、太阳辐照值、湿度以及风速和风向等。以上数据由YC1003型数据采集仪转化为信号,由RS485通讯传输并储存,采集时间间隔均为5 min;主管道水流量由水表(宁波市三江仪表股份有限公司,精度±2%)测量,手动记录;系统总耗电量由三相导轨式电能表(量程:45~55 Hz,精度:1级)测量。

注:“A1~A4”表示空气温湿度测点,“LA”表示太阳辐射测点。图示仅为南侧跨,北侧跨测点布置与南侧跨一致。

1.3 评价指标

1.3.1 系统集放热性能计算方法

表冷器-风机集放热系统的集放热性能可以采用集热量、集热流量、放热量以及放热流量来进行评价,系统的节能性则采用性能系数进行评价[26]。

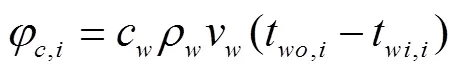

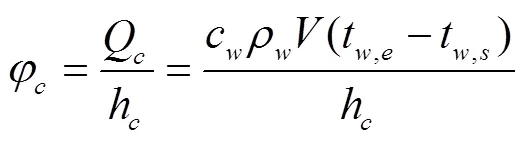

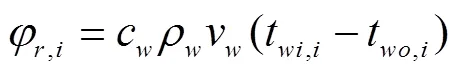

系统的集热量与集热流量按照以下公式进行计算[11]:

式中Q为系统集热量,J;c为水的比热容,取4 200 J/(kg∙℃);为水的密度,取1000 kg/m3;为蓄热水箱的体积,m3;t为系统开始运行时的蓄热水箱水温,℃;t为系统结束运行时的蓄热水箱水温,℃;φ为第时刻的系统集热流量,W;v为系统内循环水流量,m3/s;t为第时刻的系统进口水温,℃;t为第时刻的系统出口水温,℃;φ为系统平均集热流量,W;h为集热时长,s。

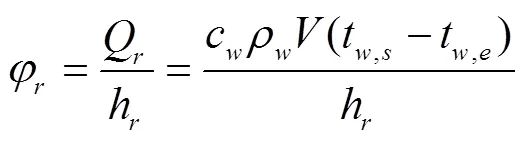

放热阶段可视作集热阶段中能量传递的逆向过程,各个因素对放热阶段的影响规律与集热阶段相同,因此系统的放热量以及放热流量可以按照下式计算[11]:

式中Q为系统放热量,J;φ为第时刻的系统放热流量,W;φ为系统平均放热流量,W;h为放热时长,s。

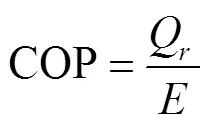

性能系数(Coefficient of Performance,COP)体现了表冷器-风机集放热系统的节能性,COP越高系统耗能越低,则节能性越好。COP可按照下式计算:

式中为系统运行的耗电量,J。

2 结果与分析

2.1 寒潮下的加温效果

取2021年1月8日9:00-1月13日9:00共5 d中收集的数据进行分析,这5 d受寒潮连续影响,是气温最低的几日。试验期间定义白天时间段为7:30-17:30,夜间时间段为17:30-次日7:30。如图2a所示,受寒潮影响,棚外气温较往年记录低,试验期间有4 d夜间棚外气温在0 ℃以下,后半夜至太阳升起前棚外气温逐渐降至最低,最低低至−6.3 ℃,而随着太阳的升起气温会迅速升高,最高可达到14.3 ℃;而白天光照较好,棚内可接收到的最大太阳辐射量为363~446 W/m2,出现在12:00-13:00期间。在这种天气状况下,仅靠二道膜保温已经无法满足大棚越冬生产的温度需求。

棚内气温变化情况如图2b所示。随着太阳升起棚内气温迅速增高,达到集热条件后,系统开始运行将空气中的热能收集并储存,此时气温会出现短时间的陡降,接着再继续上升,随着两侧和顶部通风窗的打开,棚内气温出现一定的波动,最高可达到26~30.6 ℃,有利于表冷器-风机集放热系统进行集热;随着太阳辐射的减弱,棚内气温也开始下降,下降至系统关闭条件时,集热阶段结束。由于连栋塑料大棚保温性能较差,受棚外低温影响,日落后棚内气温迅速下降,当气温下降至设定条件时,系统开始运行,放热阶段开始。

1月10日夜间大幅回暖,未启动表冷器-风机集放热系统,在棚外最低气温2.8 ℃的情况下依靠二道膜保温使夜间棚内气温高于棚外3.3 ℃;其余4夜均进行了放热,使棚内外温差达到5.2~7.8 ℃,棚内最低气温在2~2.8 ℃,因此表冷器-风机集放热系统具有良好的加温效果,可以使棚内作物免遭寒潮等气温骤降的不利天气引起的冻害。

当系统运行时,表冷器-风机出口气温远低于棚内气温,由于风机工作加速棚内顶部空气流动,表冷器-风机的进出口气温混合后,进口气温t和棚内气温t会出现较大的温差(图2b),且随着气温的升高温差逐渐变大,白天棚内气温t高于表冷器-风机进口气温(3.1±2.2)℃,夜间棚内气温t则低于表冷器-风机进口气温(1.6±1.5)℃,而系统未运行时表冷器-风机进口气温t和棚内气温t基本没有差异,为了保证准确性,在后文性能计算时,水气温差指的是表冷器-风机进口气温t和蓄热水箱水温t的差值|t−t|,而不是系统设定条件中的棚内气温t和蓄热水箱水温t的差值|t−t|。

2.2 系统集放热性能分析

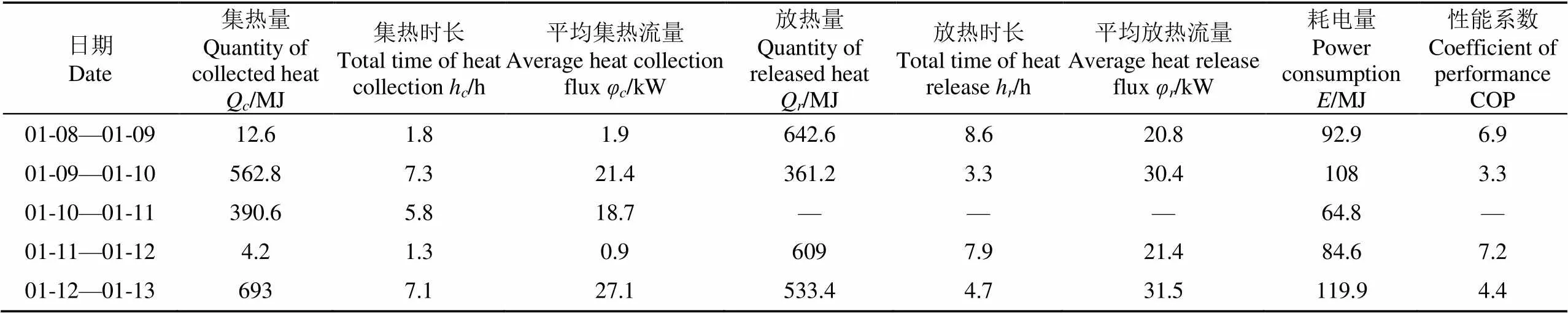

试验期间水温变化如图2b所示,白天随着系统的运行,系统水温迅速上升,可达到19.3~22.6 ℃,夜间系统放热后,水温最低降至5.2 ℃。系统性能如表1所示,1月7日和10日夜间未进行放热,水温保持在20.7和19.1 ℃,在白天系统仅集热1.3~1.8 h,集热量分别为12.6和4.2 MJ,其余3 d均进行了长时间的集热,集热时长为5.8~7.3 h,集热量达到了390.6~693 MJ,平均集热流量为18.7~27.1 kW;夜间放热时长为3.3~8.6 h,放热量为361.2~609 MJ,平均放热流量为20.8~31.5 kW;系统COP达到了4.4~7.2。

表1 系统性能参数

系统集放热性能主要被水气温差、风速以及水流量影响,采用系统的集放热流量来评价系统集放热性能,热流量越大,则单位时间里系统换热量越大[26],试验期间风速和水流量基本保持恒定,因此水气温差成为影响系统集放热性能的关键因素。棚内逐时集热流量和放热流量如图3a、3b所示,热流量与水气温差呈正向线性相关,即水气温差越大,热流量越大。放热阶段水气温差在5.9~18 ℃时,放热流量为3.4~9.83 kW,拟合结果如图3b所示,20.991 9,相关性较高,水气温差每增长1 ℃,放热流量增加0.58 kW,当水气温差降至0时,系统不再放热;集热阶段热流量与水气温差变化关系的拟合结果如图3a所示,20.894 1,集热阶段水气温差在1.6~12 ℃之间时,集热流量为0~8.53 kW,根据拟合关系方程水气温差每增长1 ℃,集热流量增加0.82 kW,在水气温差为2.9 ℃时,系统集热流量为零,而系统运行条件中设定水气温差小于2 ℃,在这段气温变化时间内,表冷器-风机集放热系统处于做无用功状态,耗电量增加,从而降低了系统COP,需要调整集热阶段的关闭条件以提高系统COP。

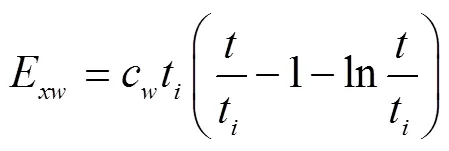

集热阶段热流量与水气温差拟合关系方程相关性较放热阶段低,是由于在集热阶段存在空气中水蒸气遇冷凝结的相变过程,系统并非全程是在干工况下运行。在除湿冷却过程中,冷凝水析出程度可由析湿系数反映,析湿系数可按照下式计算[31]:

式中为析湿系数;,h分别为表冷器-风机进口空气、出口空气的焓,kJ/kg;,t分别为表冷器-风机进口空气、出口空气温度,℃。

试验中空气定压比热c取恒值1.003 kJ/(kg·℃),结合公式(11)可知表冷器-风机进出口空气温差和焓差呈线性相关,在干工况下析湿系数为1。表冷器-风机进出口空气温差和焓差关系的拟合结果如图3c所示,其斜率可认为是系统集热阶段表冷器-风机析湿系数的数值,即析湿系数为1.70,表明表冷器-风机集放热系统在集热阶段是湿工况运行,具有一定的冷凝除湿效果。

2.3 系统的除湿效果

表冷器-风机集放热系统具有一定的除湿效果,尤其是在白天集热阶段。含湿量和相对湿度均是用来表征空气中水蒸气含量的物理量,相对湿度表示了空气接近饱和的程度,而含湿量表示了空气中水蒸气的含量[33],空气除湿过程中降低了含湿量,因此可以根据焓湿图来确定表冷器-风机进出口空气的含湿量,再通过比较含湿量来分析表冷器-风机冷凝除湿的效果,图4为1月9日、1月10日和1月12日白天集热阶段表冷器-风机进出口空气含湿量的变化情况。以1月9日白天集热阶段为例,如图4a所示,上午9:00系统刚开始集热时,由于进口水温远低于棚内空气露点温度,析出了大量的冷凝水,表冷器-风机进出口空气含湿量差达到了1.2×10-3kg/kg,随着集热的进行,水温升高逐渐逼近棚内空气露点,在10:00左右冷凝水停止析出,此时含湿量差为0.3×10-3kg/kg。太阳辐射逐渐强烈后,棚内植物的蒸腾作用加剧,空气中的含湿量迅速上升并在10:40达到了峰值13.8×10-3kg/kg,表冷器-风机进出口空气含湿量差达到了1.3×10-3kg/kg,在10:40打开通风口后棚内空气含湿量陡降,冷凝除湿效果也大幅下降,并逐渐保持在一定范围内小幅波动;关闭通风口后棚内湿度开始增加,经过长时间集热水温已经超过棚内空气的露点温度,进出口空气含湿量相等,此时集热阶段空气中水蒸气不发生冷凝相变。1月10日和1月12日白天集热阶段表冷器-风机进出口空气含湿量也表现出了相似的变化趋势。

2.4 系统的除湿性能分析

3 讨 论

本文表冷器-风机集放热系统中表冷器-风机成本约为0.8 万元,蓄热水箱成本约为1.0万元,循环水泵、供回水管路及控制系统成本约为0.4万元,合计建造成本约2.2万元。试验期间系统运行总耗电量130.6 kW·h,根据温州当地农业用电价格0.7280元/kW·h,该系统在试验期间的运行成本共95.1元;总放热量为2146.2 MJ,折算为天然气[25]需消耗57.1 m3,按当地非居民用户天然气价格3.12元/m3,折合天然气供暖成本为178.2元,由此可见表冷器-风机集放热系统虽需一定的前期建造成本,但运行成本大幅度降低。

本试验中系统参数仅按照试验连栋塑料大棚南侧跨体积进行配置,北侧跨则作为对照组不设置加温装置,但由于试验期间遭遇寒潮,为使作物免遭冻害绝产,表冷器-风机集放热系统同时为南北侧跨进行加温,在这种超负荷运行的情况下,系统配合二道膜保温仍然能让棚内气温保持在一定的水平,仅在两侧棚头位置由于冷风渗透而引起的小部分作物冻害,因此表冷器-风机集放热系统还具有较大的集放热潜力。另外相较于日光温室,连栋塑料大棚的保温性能较差,在加温过程中会有大量的热损失[33-34],热负荷较大,因此在本文试验条件下还无法应对白天阴天(即白天棚内气温较低,系统集热时间短或不集热)且夜间寒冷的极端天气,同时未对表冷器-风机集放热系统供暖的均匀性进行考虑,如何减小供暖的不均匀性在之后的研究中也需要深入探索。

总的来说表冷器-风机集放热系统使夜间棚内气温较棚外高5.2~7.8 ℃,保护棚内作物免遭冻害,并且系统的能量来源于空气余热,属于一种清洁能源,且控制灵活、成本低、不占用棚内空间,可以作为南方连栋塑料大棚中应对寒潮侵袭的有效加温措施,在生产实际中,增设保温性良好的保温幕布等提高连栋塑料大棚的保温性能,是一种辅助表冷器-风机集放热系统应对连阴天的解决方案[27]。

表冷器-风机集放热系统具有一定的除湿效果,在前人研究中也有提及[24],尤其是在集热阶段初期的冷凝除湿过程,在本研究中,冷凝除湿过程会随着集热时间的延长而逐渐消失,这是因为进入表冷器-风机的水温逐渐升高而逼近或超过棚内空气露点温度,因此寻找一个稳定的冷源来提供恒温的冷水,是可以在表冷器-风机集放热系统的基础上开发出一种表冷器-风机冷凝除湿系统,怎样低耗、高效地制备恒温的冷水以及冷凝除湿对棚内气温水平的影响也将在后续的试验中进行。

4 结 论

1)在寒潮下,表冷器-风机集放热系统可以使夜间棚内气温较棚外高5.2~7.8 ℃,保护棚内作物免遭寒潮等气温骤降的不利天气引起的冻害。

2)白天集热量达到了390.6~693 MJ,夜间放热量为361.2~609 MJ,系统性能系数(COP)达到了4.4~7.2,因此表冷器-风机集放热系统具有良好的加温效果和节能性,但是受连栋塑料大棚保温性能较差的影响,热损较大。在本试验条件下,集热阶段在水气温差低于2.9 ℃时,系统处于做无用功状态,可适当调整系统设定条件,如集热阶段水气温差小于3 ℃时关闭系统,缩短系统运行时间,提高COP。

3)表冷器-风机集放热系统在集热阶段具有一定的除湿效果,表冷器-风机进出口空气含湿量差最高可达1.3×10-3kg/kg,但随着水温的升高,除湿效果会减弱至消失。

[1] 国家气象中心. 冷空气等级:GB/T 20484-2017[S]. 北京:中国国家标准化管理委员会,2017.

[2] 王克磊,朱隆静,苏世闻,等. 新型大跨度单体塑料大棚温光性能分析[J]. 中国农机化学报,2021,42(2):45-50.

Wang Kelei, Zhu Longjing, Su Shiwen, et al. Analysis of temperature and light characteristics of new large span single plastic greenhouse[J]. Journal of Chinese Agricultural Mechanization, 2021, 42(2): 45-50. (in Chinese with English abstract)

[3] 朱隆静,王克磊,陈先知,等. 浙南单体塑料大棚内冬季温光性能特征研究[J]. 农学学报,2020,10(6):81-85.

Zhu Longjing, Wang Kelei, Chen Xianzhi, et al. The characteristics of temperature and light properties of single plastic greenhouse in winter of southern Zhejiang[J]. Journal of Agriculture, 2020, 10(6): 81-85. (in Chinese with English abstract)

[4] 杨再强,朱凯,赵翔,等. 中国南方塑料大棚气象灾害风险区划[J]. 自然灾害学报,2012,21(5):213-221.

Yang Zaiqiang, Zhu Kai, Zhao Xiang, et al.Meteorological disaster risk zoning for plastic greenhouse in south China[J]. Journal of Natural Disasters, 2012, 21(5): 213-221. (in Chinese with English abstract)

[5] 魏莎莎,李清斌,孙军波,等. 强寒潮天气南方塑料大棚防御冰冻灾害措施[J]. 中国农学通报,2017,33(29):135-139.

Wei Shasha, Li Qingbin, Sun Junbo, et al. Preventing frozen disaster in plastic greenhouse in South China[J]. Chinese Agricultural Science Bulletin, 2017, 33(29):135-139. (in Chinese with English abstract)

[6] 鲍恩财,曹晏飞,邹志荣,等. 节能日光温室蓄热技术研究进展[J]. 农业工程学报,2018,34(6):1-14.

Bao Encai, Cao Yanfei, Zou Zhirong, et al. Research progress of thermal storage technology in energy-saving solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(6): 1-14. (in Chinese with English abstract)

[7] Attar I, Naili N, Khalifa N, et al. Parametric and numerical study of a solar system for heating a greenhouse equipped with a buried exchanger[J]. Energy Conversion and Management, 2013, 70: 163-173.

[8] Attar I, Farhat A. Efficiency evaluation of a solar water heating system applied to the greenhouse climate[J]. Solar Energy, 2015, 119: 212-224.

[9] 张义,杨其长,方慧. 日光温室水幕帘蓄放热系统增温效应试验研究[J]. 农业工程学报,2012,28(4):188-193.

Zhang Yi, Yang Qichang, Fang Hui. Research on warming effect of water curtain system in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(4): 188-193. (in Chinese with English abstract)

[10] Xu Weiwei, Song Weitang, Ma Chengwei. Performance of a water-circulating solar heat collection and release system for greenhouse heating using an indoor collector constructed of hollow polycarbonate sheets[J]. Journal of Cleaner Production, 2020, 253: 119918.

[11] 徐微微,马承伟,宋卫堂,等. 日光温室中空板水循环集放热系统设计与集热性能试验[J]. 农业机械学报,2018,49(7):326-334.

Xu Weiwei, Ma Chengwei, Song Weitang, et al. Test on heat-collecting performance of solar heat collection and release system with water cycling inside hollow plates in Chinese solar greenhouse[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 326-334. (in Chinese with English abstract)

[12] 马承伟,姜宜琛,程杰宇,等. 日光温室钢管屋架管网水循环集放热系统的性能分析与试验[J]. 农业工程学报,2016,32(21):209-216.

Ma Chengwei, Jiang Yichen, Cheng Jieyu, et al. Analysis and experiment of performance on water circulation system of steel pipe network formed by roof truss for heat collection and release in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(21): 209-216. (in Chinese with English abstract)

[13] Santamouris M, Mihalakakou G, Balaras C A, et al. Energy conservation in greenhouses with buried pipes[J]. Energy, 1996, 21(5): 353-360.

[14] 张勇,高文波,邹志荣. 日光温室主动蓄热后墙传热CFD模拟及性能试验[J]. 农业工程学报,2015,31(5):203-211.

Zhang Yong, Gao Wenbo, Zou Zhirong. Performance experiment and CFD simulation of heat exchange in solar greenhouse with active thermal storage back-wall[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(5): 203-211. (in Chinese with English abstract)

[15] 赵淑梅,庄云飞,郑可欣,等. 日光温室空气对流蓄热中空墙体热性能试验[J]. 农业工程学报,2018,34(4):223-231.

Zhao Shumei, Zhuang Yunfei, Zheng Kexin, et al. Thermal performance experiment on air convection heat storage wall with cavity in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(4): 223-231. (in Chinese with English abstract)

[16] Öztürk H H, Başçetinçelik A. Energy and exergy efficiency of a packed-bed heat storage unit for greenhouse heating[J]. Biosystems Engineering, 2003, 86(2): 231-245.

[17] Gautam A, Saini R P. A review on sensible heat based packed bed solar thermal energy storage system for low temperature applications[J]. Solar Energy, 2020, 207: 937-956.

[18] Chen Shuqin, Zhu Yipan, Chen Yue, et al. Usage strategy of phase change materials in plastic greenhouses, in hot summer and cold winter climate[J]. Applied Energy, 2020, 277: 115416.

[19] 陈淑琴,朱毅攀,谢静超,等. 相变材料在南方塑料大棚中的冬季使用策略及效果研究[J]. 太阳能学报,2020,41(11):205-211.

Chen Shuqin, Zhu Yipan, Xie Jingchao, et al. Study on winter application strategy and effect of phase change material in southern plastic greenhouse[J]. Acta Energiae Solaris Sinica, 2020, 41(11): 205-211. (in Chinese with English abstract)

[20] 凌浩恕,陈超,陈紫光,等. 日光温室带竖向空气通道的太阳能相变蓄热墙体体系[J]. 农业机械学报,2015,46(3):336-343.

Ling Haoshu, Chen Chao, Chen Ziguang, et al. Performance of phase change material wall with vertical air channels integrating solar concentrators[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(3): 336-343. (in Chinese with English abstract)

[21] Yang S, Rhee J. Utilization and performance evaluation of a surplus air heat pump system for greenhouse cooling and heating[J]. Applied Energy, 2013, 105: 244-251.

[22] Chai L L, Ma C W, Ni J Q. Performance evaluation of ground source heat pump system for greenhouse heating in northern China[J]. Biosystems Engineering, 2012, 111(1): 107-117.

[23] 王志伟,杨佳佳,刘义飞,等. 南疆日光温室表冷器主动蓄放热系统设计与应用效果[J]. 北方园艺,2019(12):47-54.

Wang Zhiwei, Yang Jiajia, Liu Yifei, et al. Research on the design and application effect of active extracorporeal heat storage system for solar greenhouse surface air cooler in southern Xinjiang[J]. Northern Horticulture, 2019(12): 47-54. (in Chinese with English abstract)

[24] 孙维拓,郭文忠,徐凡,等. 日光温室空气余热热泵加温系统应用效果[J]. 农业工程学报,2015,31(17):235-243.

Sun Weituo, Guo Wenzhong, Xu Fan, et al. Application effect of surplus air heat pump heating system in Chinese solar greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(17): 235-243. (in Chinese with English abstract)

[25] 李明,耿若,宋卫堂,等. 外保温塑料大棚表冷器-风机集放热系统性能分析[J]. 农业机械学报,2020,51(10):371-378.

Li Ming, Geng Ruo, Song Weitang, et al. Performances of thermal collecting and releasing system developed with fan-coil units in plastic tunnel covered with thermal blanket[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(10): 371-378. (in Chinese with English abstract)

[26] 何雪颖,王平智,李明,等. 基于响应面法的表冷器-风机集放热系统参数优化[J]. 农业机械学报,2020,51(12):315-323.

He Xueying, Wang Pingzhi, Li Ming, et al. Parameters optimization of greenhouse air-cooled condenser heat collection and release system by response surface method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(12): 315-323. (in Chinese with English abstract)

[27] 宋卫堂,王平智,肖自斌,等. 表冷器-风机集放热系统对四种园艺设施室内气温的调控效果研究[J]. 农业工程技术,2020,40(4):38-48.

[28] 李世姣,王令. 高温冷水表冷器除湿系统的㶲分析[J]. 制冷与空调,2016,30(4):436-440.

Li Shijiao, Wang Ling. Exergy analysis of cooling coil with higher temperature of cold water[J]. Refrigeration and Air Conditioning, 2016, 30(4): 436-440. (in Chinese with English abstract)

Luan Zhiyong. Analysis of condensing heat recovery exergy for central Heating[J]. Energy and Energy Conservation, 2013(9): 18-21. (in Chinese with English abstract)

[30] 吕艳. 热湿独立处理空调系统的能耗模拟与实验研究[D]. 镇江:江苏科技大学,2010.

[31] 乐有奋,王清平. 表冷器热工计算新方法——水侧热交换效率法[J]. 暖通空调,2005(7):122-126.

Le Youfen, Wang Qingping. New thermodynamic calculation method for surface air coolers: heat-exchange efficiency of waterside method[J]. Heating Ventilating & Air Conditioning, 2005(7): 122-126. (in Chinese with English abstract)

[32] 田向宁,杨毅,丁德,等. 空气冷却除湿过程的理论研究[J]. 暖通空调,2014(1):121-124.

Tian Xiangning, Yang Yi, Ding De, et al. Theoretical research on air cooling dehumidification process[J]. Heating Ventilating & Air Conditioning, 2014(1): 121-124. (in Chinese with English abstract)

[33] Kim H, Kang G, Moon J P, et al. Estimation of thermal performance and heat loss in plastic greenhouses with and without thermal curtains[J]. Energies, 2018, 11(3): 578.

[34] Teitel M, Barak M, Antler A. Effect of cyclic heating and a thermal screen on the nocturnal heat loss and microclimate of a greenhouse[J]. Biosystems Engineering, 2009, 102(2): 162-170.

Influences of air thermal energy utilization system with fan-coil units on the thermal and humid environment of multi-span tunnel in cold wave

Zong Chengji1, Wang Pingzhi1,2, Chen Xianzhi3, Li Ming1,2, He Xueying1,Wang Jianyu1, Xu Dan1,2, Song Weitang1,2※

(1.100083; 2.100083;3.325000)

Multi-span plastic tunnel greenhouse has widely been used in the cultivation of vegetables, fruits, and flowers. However, it is easily suffered from freezing damage to crops, particularly from cold waves in winter. In this study, an air thermal energy utilization system was developed with the fan-coil units to effectively control the thermal and humid environment in the shed. A field experimented was also performed on a two-span plastic tunnel in Wenzhou city of China during the cold wave from January 8 to January 13, 2021. The system was composed of fan-coil units, water reservoir, circulating water pump, supply and return water pipes, as well as control devices. The circulation of water in the system was utilized to collect and then store the surplus heat in the shed during the day, while finally released at night to heating the two-span plastic tunnel. In the collected phase, once the air temperature in the shed reached 15 ℃ on the day, or it was 5 ℃ higher than the water temperature in the water reservoir, the system was started until the air temperature dropped to 10 ℃, or it was 2 ℃ lower than the water temperature. In the released phase, once the outside air temperature was below 2 ℃ at night, or it was 4 ℃ lower than the water temperature, the system was started to operate until the air temperature reached 5 ℃, or it was only 2 ℃ higher than the water temperature. The collected and released performance of the system was evaluated using the collection and discharge heat, as well as heat flow, according to the change of water temperature in the experiment. The difference between water and air temperature was taken as the main influencing factor to analyze the heat flow in the collected and released phases. An exergy analysis of condensation dehumidification was also made during this time. The results showed that the system ensured the temperature inside the shed was 5.2-7.8 ℃ to protect crops from freezing damage, higher than that outside the shed in cold waves. The heat collection was 390.6-693 MJ, while the heat release was 361.2-609 MJ. The Coefficient of Performance (COP) of the system was 4.4-7.2, indicating quite remarkable energy saving. When the difference in water temperature increased by 1 ℃ during the operation of the system, the heat collection flow rate increased by 0.82 kW, while the heat release flow rate increased by 0.58 kW, indicating a larger heat transfer rate per unit time. In addition, the moisture absorption coefficient of the system was about 1.70 in the heat collected phase, due mainly to the presence of condensation and dehumidification. Meanwhile, the exergy efficiency tended to increase rapidly, up to 82.8%, as the temperature difference between water and air increased, indicating high energy utilization performance in the process of condensation and dehumidification. Nevertheless, the condensation and dehumidification gradually weakened until stopped, and concurrently the exergy efficiency decreased significantly, with the increase of water temperature. Consequently, the air thermal energy utilization system with fan-coil units can be expected to serve a safe, low carbon, and controllable heating technology. The finding can provide a potential application to ensure the safe production of multi-span plastic tunnels in winter.

facility; temperature; multi-span plastic tunnel; fan-coil units; thermal and humid environment; heating; dehumidify

10.11975/j.issn.1002-6819.2021.15.026

S625.2; S625.4

A

1002-6819(2021)-15-0214-08

宗成骥,王平智,陈先知,等. 寒潮天气表冷器-风机集放热系统对连栋大棚热湿环境的影响[J]. 农业工程学报,2021,37(15):214-221.doi:10.11975/j.issn.1002-6819.2021.15.026 http://www.tcsae.org

Zong Chengji, Wang Pingzhi, Chen Xianzhi, et al. Influences of air thermal energy utilization system with fan-coil units on the thermal and humid environment of multi-span tunnel in cold wave[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(15): 214-221. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.15.026 http://www.tcsae.org

2021-06-21

2021-07-29

国家重点研发计划项目(2020YFD1000300);浙江省科技计划项目(2019C02009);现代农业产业技术体系建设专项资金项目(CARS-23-C02)

宗成骥,博士生,研究方向为设施园艺环境工程。Email:Zongchanging@163.com。

宋卫堂,教授,研究方向为园艺设施环控技术和装备研发。Email:songchali@cau.edu.cn。

中国农业工程学会会员:宋卫堂(E040100004M)