Bubble dynamics and its applications *

2019-01-05ShiPingWang王诗平ManZhang张阿漫YunLongLiu刘云龙ShuaiZhang张帅PuCui崔璞

Shi-Ping Wang(王诗平), A-Man Zhang(张阿漫), Yun-Long Liu(刘云龙), Shuai Zhang(张帅), Pu Cui(崔璞)

Abstract: Bubbles have very important applications in many fields such as shipbuilding engineering, ocean engineering, mechanical engineering, environmental engineering, chemical engineering, medical science and so on. In this paper, the research status and the development of the bubble dynamics in terms of theory, numerical simulation and experimental technique are reviewed, which cover the underwater explosion bubble, airgun bubble, spark bubble, laser bubble, rising bubble, propeller cavitation bubble, water entry/exit cavitation bubble and bubble dynamics in other fields. Former researchers have done a lot of researches on bubble dynamics and gained fruitful achievements. However, due to the complexity of the bubble motion, many tough mechanical problems remain to be solved.Based on the research progress of bubble dynamics, this paper gives the future research direction of bubble dynamics, aiming to provide references for researches related to bubble dynamics.

Key words: Bubble, cavitation, underwater explosion bubble, high pressure airgun bubble, spark bubble, laser bubble, rising bubble

Corresponding authors' Biography

A-Man Zhang, Male, born in March 1981,Jiangxi Province, Ph. D., Professor and Doctoral tutor at Harbin Engineering University, National “Ten Thousand Talent Program” Science and Technology Innovation Leading Scientist, Young Scholar of the Changjiang Scholar Program of China, recipient of National Science Foundation for Excellent Young Scholars and Young Top-Notch Talent Program of Organization Department of CPC Central Committee.He graduated as Bachelor from Dalian University of Technology in 2003 and Ph. D. from Harbin Engineering University in 2007 and researched at University College London as a visiting scholar in 2011. Research interests: Bubble Dynamics, Fluid-Structure Interaction, Impact Dynamics. He has undertaken over 40 projects including key projects of National Key Research and Development Projects,National Science Foundation Projects and National Defense Basic Research Projects, etc. He is a recipient of the 14thChina Youth Science and Technology Award, the Young and Middle-aged Science and Technology Innovation Leading Scientist of the Ministry of Science and Technology, the New Century Excellent Talents Support Program of the Ministry of Education, nomination for the Top 100 National Outstanding Doctoral Dissertations, the Fok Ying-Tong Young Teacher Fund of the Ministry of Education, the second prize of Fok Ying-Tong Young Teacher Award of the Ministry of Education, the“Longjiang Scholar” Distinguished Professor, the Heilongjiang Outstanding Youth Science Fund and other academic honors. He has applied for over 20 invention patents, published 2 monographs and over 100 articles in peer-reviewed SCI journals, such as Journal of Fluid Mechanics, Physics of Fluids, Journal of Computational Physics, CMAME and Computational Mechanics, etc., including 5 ESI Highly Cited Papers, with over 1700 citations within the recent 5 years. His research achievement has been awarded a second prize of the National Science and Technology Progress Award of China, 2 first prizes, 4 second prizes and 3 third prizes of provincial and ministerial level awards. He has given conference/theme/invited reports at international academic conferences for over 10 times in the recent 5 years. He is appointed as a vice director of the Ship Mechanics Academic Committee of the Chinese Society of Naval Architecture and Marine Engineering, a vice director of the 5thYouth Science and Technology Commission of the China Communications and Transportation Association, a member of the Ship’s Anti-shock Group of the Military Ship Academic Committee, a member of the Naval Ship Anti-shock Research and Test Center, a member of the 8thSPH and Particle Method Professional Group in Computational Mechanics Committee of Chinese Society of Theoretical and Applied Mechanics, a Review Meeting Expert of the National Natural Science Foundation of China, a guest professor of Institute of Fluid Physics of Chinese Academy of Engineering Physics, an associate editor of the Computer Modeling in Engineering and Sciences journal and a member of the editorial boards of multiple SCI journals including “Applied Ocean Research” and “Journal of Hydrodynamics”, etc..

Introduction

Bubble dynamics has many important applications in the fields of shipbuilding engineering[1-3],ocean engineering[4-7], mechanical engineering[8-12],chemical engineering[13-15], medical science[16-18]and so on. For example, in the field of shipbuilding engineering, when a charge explodes underwater, a shockwave will firstly occur which would cause local damage to ship structures. After the shockwave, a bubble with high temperature and pressure is generated which would expand and collapse underwater with the maximum diameter about (10)O m. The pulsating pressure generated by the bubble motion and the high-speed jet generated during its collapse will cause overall damage to the ship structure, causing the ship to lose its total longitudinal strength, which could break the ship from the middle[19]. Cavitation bubbles would be generated by the propeller, and the high-speed jets generated by the cavitation during collapsing may cause erosion to the propeller[20-21]. In the field of ocean engineering, engineers use the high pressure airgun (array) bubble to generate far field pressure waves for the seabed exploration[22-23].During the exploitation of the combustible ice, the rising bubble cluster is formed during the mining process. It may change the floating state of the mining equipment, cause crisis to the combustible ice mining system, and cause difficulties in combustible ice mining[24-25].

The above mentioned bubble (cluster) motion underwater is a multiphase problem[26]involving very complex mechanical behavior such as large deformation of bubble surface, heat and mass transfer effects,phase change and so on which bring great challenges to the traditional theoretical analysis, numerical simulation and experimental study[27-28]. The above mentioned bubble can be divided into two categories,equivalent pressure bubble and violent pulsating bubble (high pressure bubble or unbalanced bubble),according to the difference between the bubble’s inner pressure[29]and its ambient pressure[30]. For the equivalent pressure bubble, the influence of the fluid compressibility is very small and negligible[31], while the fluid viscosity and the surface tension play an important role in the bubble behavior which should be considered in the theoretical analysis and numerical simulations[32-33]. For a violent pulsating bubble, such as an underwater explosion bubble or a high pressure airgun bubble and so on, the influence of the fluid compressibility is relatively large[34], which should be taken into account in the theoretical analysis and numerical simulation[35-36], especially for the bubble’s inner fluid domain. In theoretical analysis, most theories are corrected based on the Rayleigh-Plesset equation which are suitable to predict the motion of spherical or nearly spherical bubble[37]. For numerical simulations, there are traditional methods to predict the bubble motion, such as boundary element method(BEM)[38-39], finite element method (FEM)[40-41], finite volume method (FVM)[42-43]etc., and new methods such as lattice Boltzmann method (LBM)[44-46], smoothed particle hydrodynamics method (SPH)[47-48],peridynamics method (PD)[49]and so on. For experimental studies, there are real physical experimental methods for engineering applications, such as TNT charge underwater explosion generated bubble[50],high pressure airgun generated bubble[51], high speed propeller rotation generated cavitation bubble[52]and so on, and alternative experimental methods such as spark[53], laser[54]generated bubbles, and so on.

The applicability of the theoretical analysis,numerical method and experimental methods to study the bubble dynamics generated by different sources will be described separately in the following sections.Aiming at the main engineering applications of bubble dynamics, the main theories and methods in studying the bubble dynamics are reviewed. On this basis, the future development trend on bubble dynamics is proposed, which provides a reference for the study of bubble dynamics.

1. Underwater explosion bubbles

Underwater explosion loads include two part,shockwave load and bubble load. The duration of shockwave is on the order of milliseconds, and then the large scale bubble with high temperature and high pressure is formed. For example, when a 1 000 kg TNT equivalent mine explodes underwater, the bubble’s diameter is about 25-30 m and its period is on the order of seconds. When the bubble collapses, a high speed liquid jet is formed and the jet speed reaches about (100)O m/s[55]. For a TNT charge, the energy of the shockwave and bubble are comparative.The shockwave load mainly causes severe local damage to ship structures[56], the bubble pulsating load has a low frequency that is close to the ship's vertical first-order natural frequency and will cause severe global damage to the ship. The high speed liquid jet during the collapsing stage will aggravate the local damage to the ship structure, which would possibly break the ship from the middle cross section[19].Presently, the international research on underwater explosion shockwaves is relatively abundant[57-60]. The bubble’s large shape deformation in a relatively long term, asymmetric jet, and strong impact load to its nearby boundary during its collapsing stage bring great challenges to theoretical analysis, numerical simulations and experimental techniques[39,61-62].

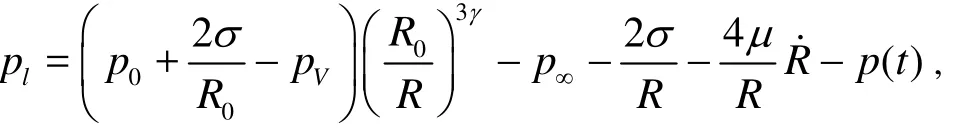

In the theoretical study of the underwater explosion bubble dynamics, inertial force plays an important role. The Reynolds number is very large and the viscous force and surface tension are neglectable[2].During both the initial bubble expanding stage and the late bubble collapsing stage, the compressibility of the bubble’s outer fluid domain affects the bubble dynamics and should be considered[36,63]. In theoretical analysis of bubble dynamics, most theories are corrected based on the Rayleigh[64], Plesset’s[65]theoretical framework. For example, Noltinglc[66],Gilmore[67], Prosperetti[68], Zhang et al.[69], Smith and Wang[70]corrected the R-P equation to take into consideration of the influences the fluid compressibility,entropy difference, viscosity, surface tension, relative slip velocity of the bubble and fluid, gas contents and so on. A variety of improved formats of bubble motion equations have been obtained, enriching the theoretical research of bubble dynamics. For example,the theoretical equation of bubble motion considering the fluid viscosity, surface tension, and fluid compressibility is as follows[71-72]

where

In addition, Geers et al.[73]proposed a semianalytical formula to predict the bubble motion and the pulsating pressure load according to doubly asymptotic approximation theory. The pressure wave emission, bubble motion, as well as bubble’s migration effect under buoyancy in free field can be calculated using this model. There are still other works on the prediction of the bubble motion and pressure wave emission which can be found in Ref.[55], Zamyshlyayev[74]and Kedrinskiy’s[75]contributions. The limitations of the above theoretical models are the spherical bubble assumption for the simplicity of theoretical derivations. The theoretical method such as the spherical function expansion of the bubble wall can be adopted to simulate the bubble motion whose shape is not deviated from the spherical shape when pulsating near the boundaries, referring to White and Carnie’s[76]works. However, there are still no good ways to solve the bubble motion that deviates from the spherical shape. Therefore, theoretical study lays a foundation for studying the motion and load characteristics of bubbles, but it is difficult to obtain theoretical solutions for the evolution characteristics of large deformation motion, high-speed jet, and splitting of bubbles near different boundaries. It is necessary to study the non-spherical motion near different boundaries through experiments and numerical simulations[53,77-78].

In the numerical simulation of underwater explosion bubble, the successful methods include BEM[35,39,79-82], Eulerian FEM[41,83-84], FVM[85-88]and so on. These methods can simulate the bubble’s nonlinear phenomenon such as non-spherical motion,high-speed liquid jet and so on. These numerical methods above are based on meshes and have their own advantages and disadvantages in dealing with the bubble motion simulation. In the early stage, Blake and Gibson[89-90]build a numerical model using BEM to simulate the bubble motion. The main formula is listed in Eq. (2). Later, Zhang et al.[91], Wang et al.[35],Klaseboer et al.[62], Zhang et al.[39,78]have made a lot of contributions and made several improvements to this method to solve different problems and to enhance the calculation stabilities. Because of its advantages of dimensionality reduction, the BEM method has high computational efficiency, but one must find a suitable Green's function for a specific problem. However, the BEM is difficult to simulate the bubble motion close to boundaries and bubble splitting due to mesh distortion[2]. The numerical result of the expanding,collapsing, jetting and rebounding motion of a bubble created by detonating 200 kg TNT at a depth of 100 m in the free field under buoyancy effect using BEM is shown in Fig. 1. Eulerian FEM and FVM can solve the bubble motion close to boundaries and the splitting phenomenon very easily but the computational efficiency is much lower than the BEM, referring to Zhang, Liu and Wang’s works[40-42]. Presently,LBM[44]and PD[92]methods are also beginning to be used to solve the bubble dynamics, but there are still many key difficulties in the simulation of underwater explosion bubble to be overcome.

Fig. 1 (Color online)The expanding, collapsing, jetting and rebounding motions of the bubble created by detonating 200 kg TNT at a depth of 100 m in the free field using BEM

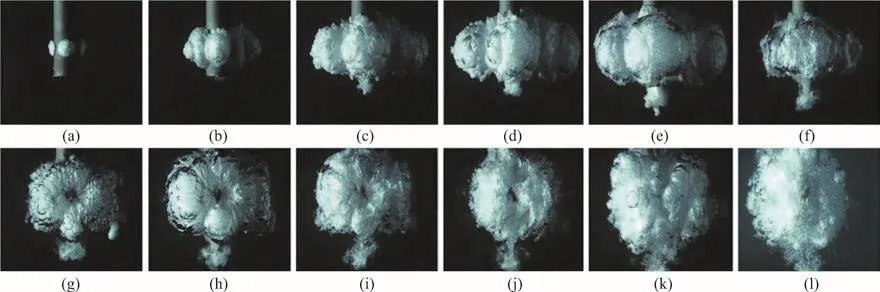

Fig. 2 The experimental data of a charge exploding near a vertical plate with a circular hole in the center[77]

where G is the Green function, A, B are the spatial position of the boundary points, c is the solid angle, φ is the velocity potential, n is the normal vector of the boundary andis the fluid boundary.

In the experimental study of the underwater explosion bubble, the real underwater explosion experiment, especially the offshore explosion experiment is rather expensive and difficult to carry out, so the experiment conducted in a pool or a water tank is an effective way[50,62,77]. Cole’s[55]classic work still provides a good reference to the nowadays experimental studies. In recent years, with the rapid development of high-speed photography technology, PIV technology and sensor technology, it has been possible to accurately capture the bubble behavior,and the underwater explosion measuring and testing technology has been greatly improved[93]. There are few published literatures on real scale underwater explosion bubble experiments, while instead, there are many published literatures on reduced scale ones,such as Khoo, Hung, Zhang, Gauch, Brett et al.’s[50,56,62,77,93-95]works. The bubble motion near different boundary conditions and its load characteristics are studied in these literatures which give very valuable experimental data for the theoretical analysis and numerical simulations. The motion of an underwater charge explosion bubble near a vertical plate with a circular hole in the center is shown in Fig. 2. A more complex collapsing pattern is formed during bubble collapsing under the combined effect of the buoyancy and the vertical broken boundary. Due to high risk,poor repeatability and difficulty in performance for underwater explosion experiments, even for reduced scale experiments, researchers began to replace real scale underwater explosion experiments with alternative experiments in recent years, using spark,laser or gas to generate bubbles, such as that in Chahine, Khoo, Zhang, Lauterborn, Farhat et al.’s works[53,96-102]. Using the alternative methods, bubble motion characteristics near complex boundary conditions are obtained and the mechanism of the bubble motion is uncovered systematically, which would be reviewed in detail in Section 3. However,due to the scaled effect between the alternative methods and the underwater explosion method, the alternative methods can only partially replace the real underwater explosion experiment, and the high energy bubble technology needs further development.

2. High pressure airgun bubble

High pressure airgun is a main and indispensable excitation source for deep-sea scientific research and deep-sea resources exploration[103-106]. The working process of the airgun is as follows. The airgun tank is filled with highly compressed air and its working pressure is about 14 MPa. The airgun is triggered by an electromagnetic valve, and when the valve opens,the high pressure gas leaks out of the airgun and a high pressure bubble is generated, as shown in Fig.3[51]. Similar to the underwater explosion process, a pressure wave is generated during the motion of the bubble. The pressure wave transmits and reflects on the seabed, and the distribution of marine resources such as submarine oil, gas and combustible ice is detected by receiving and analyzing the seabed reflected pressure wave signals. The typical types of airguns include Sleeve gun, Bolt gun, G gun, GI gun etc.[107-111]. With the development of ocean engineering equipment and technology, the exploration of marine resources has gradually moved from shallow sea to deep sea, and as a consequence, the requirement for high quality of the pressure wave generated by airguns is increasingly higher. For example, it is required to suppress the bubble pulsation phenomenon to the maximum extent, and the pressure wave needs to have the features like high energy, low frequency and smooth spectrum and so on[103]. To achieve the requirements above, airgun array is normally used instead of single airgun in practical engineering application[112]. According to the needs of real seabed exploration, engineers can design the pressure wave by controlling the exciting interval of individual airgun and their spatial position in the array. This process is also called the optimization of airgun array.Using the optimized airgun array, the seabed resources in a preassigned working sea could be detected more accurately[113]. Due to the complexity of the airgun bubble motion, so far, there are still many difficult mechanical problems to be overcome,such as the design of low-frequency and high pressure airgun, the law of the interaction of the airgun array bubbles, the bubble pulsation suppression method, air gun array pressure wave optimization and high precision numerical model for the airgun bubble simulation. The above problems are the difficulties and hotspots of the airgun study[7,114].

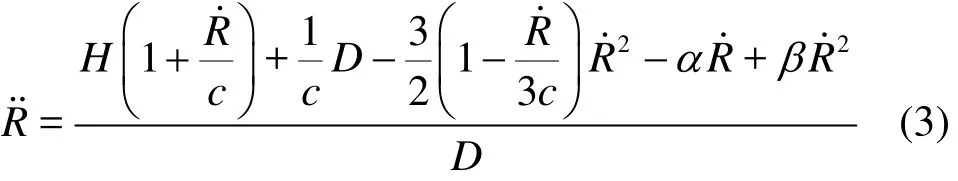

In the theoretical study of the airgun bubble,similar to the theoretical model of underwater explosion bubble, a classical airgun bubble model is based on the Gilmore equation[67]. Based on Gilmore equation, Ziolkowski[22]built a theoretical model to simulate the motion of a single bubble. With this model, the far field pressure of the airgun can be accurately predicted using the airgun’s the firing pressure, volume, depth parameters. Later, Ziolkowski et al.[115], Schulze-Gattermann[104], Safar[116], Landrø et al.[117-118], Zhang et al.[23]developed theories that takes into account the influence of the airgun body[104,119],bubble migration[120], bubble cluster interaction[115],vaporization and condensation rate[121-122], heat and mass transfer[118], energy damping etc.[123]to the pressure waves. For example, the equation concerning the energy damping of the airgun is shown in Eq. (3),where α and β are constants controlling the damping speed and H is the entropy difference. Based on the airgun theory, engineers developed the commercial software named Nucleus and Gundalf,which have very broad application in the seabed exploration. But the theoretical method has limitations in simulating the nonlinear phenomenon such as the bubble’s non-spherical motion, liquid jet, splitting and so on. The detailed bubble motion and the near field pressure wave cannot be predicted according to the current theoretical model.

Fig. 3 (Color online) The airgun generated bubble pulsating process[51]

Fig. 4 (Color online) The motion of the bubble under the effect of the airgun body using BEM

where

Similar to the numerical simulation of underwater explosion bubble, the BEM, FVM and Eulerian FEM are normally used methods[7,124]. The BEM can simulate the characteristics such as interaction between bubble and airgun body, and bubble liquid jet,it is suitable to predict the far field pressure wave with high efficiency, referring to Zhang, Cox et al.’s works[7,125]. But BEM has limitations in simulating the 3-D interaction between airgun body and bubble,and the bubble coalescence and splitting phenomenon due to mesh distortion[51]. FVM and Eulerian FEM have advantages in simulating the complicated process of the airgun bubble motion including the gas outflowing when the electromagnetic valve opens, the bubble coalescence and splitting, etc. in 3-D case. The motion of the bubble under the effect of airgun body is shown in Fig. 4 using BEM. FVM and Eulerian FEM have advantages in aid of the detailed design of the airgun body. However, their computational efficiency is lower and it is not easy to simulate the far field problem with these methods. This is one of the problems to be solved in this field in the future.

The process of gas transfer from the airgun chamber to bubble is very complex and the bubble changes violently as shown in Fig. 4, but this process has little influence to the far field pressure wave[115].In the experimental study of airgun bubble, more attentions are paid on measurement and analysis of the far field pressure[106,109,126-127]and few attention is paid on the near field bubble pulsation[51,128-129]. The motion of real airgun bubble in the sea is very difficult to be captured, and few literatures are published. In order to study the mechanism of the bubble and airgun coupling, bubble motion and pressure characteristics,reduced scale model tests and spark bubbles are adopted in labs, referring to Graaf, Zhang et al.’s works[5,51,130]. Besides, in order to reduce the unexcepted danger and high costs of experiments, in the experiment of ship dynamic response under shock and its measurement of the shock environment,researchers make a preliminary try to test a ship’s shock environment using the airgun with high volume instead of the real underwater charge explosion[131].To sum up, few literatures focus on the experimental study of the airgun bubble motion which needs to be strengthened in the future.

3. Spark and laser bubble

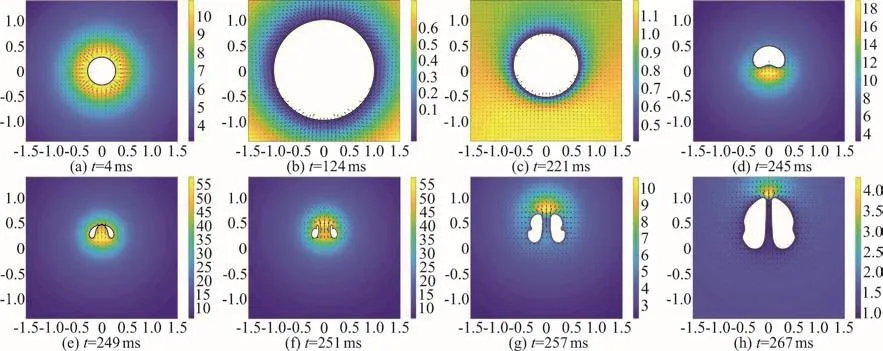

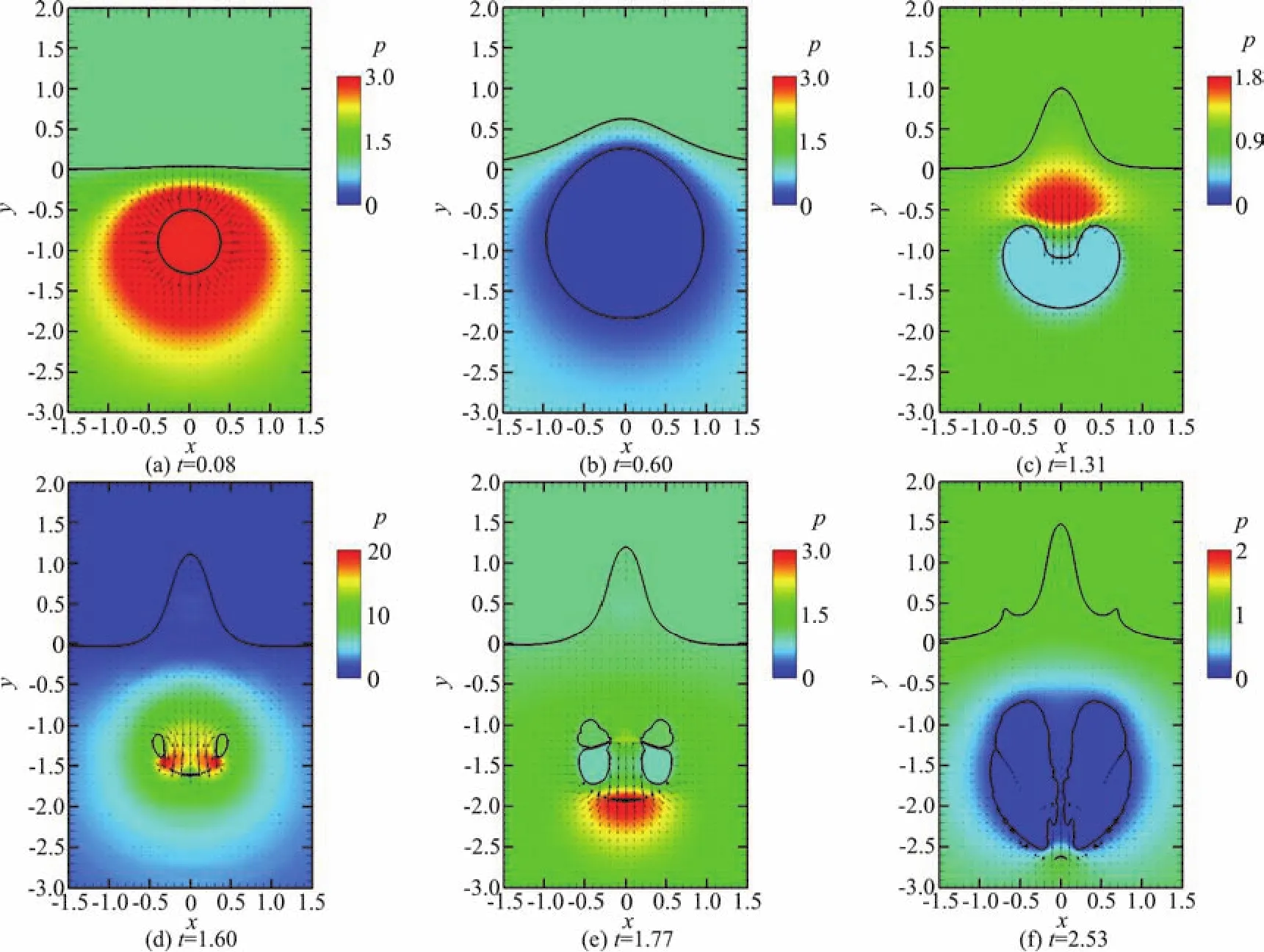

Spark bubble and laser bubble have important applications in many engineering fields include ocean engineering, mechanical engineering, environmental engineering and medical science. For example, they can be used in ice breaking, washing and so on[53,68].Because the spark and laser bubble generating techniques are easier to implement and the results are easy to analyze, researchers use them to replace the underwater explosion bubble and cavitation bubble to study the mechanism of bubble pulsation[132-134]. Spark bubble and laser bubble are important branches in the field of bubble dynamics research. The spark bubble and laser bubble belongs to the high pressure pulsating bubble and their theoretical study is similar to that of underwater explosion bubble and airgun bubble. Most theories are corrected based on the R-P equation to fit different conditions. Similar to the underwater explosion bubble, the numerical method of spark bubble and laser bubble include BEM[78],FVM[42], Eulerian FEM[41]and so on. For example, the kernel equation for Eulerian FEM is as follow[40], and the simulated results for a bubble near the free surface using Eulerian FEM is shown in Fig. 5. The free surface is pushed upwards and a high speed liquid jet against the free surface is formed during its collapsing stage. The jet penetrates the lower bubble surface and begins to expand after it reaches its minimum volume,and the water skirt is formed at the free surface during the second expansion of the bubble.

where p is the fluid pressure, x is the spatial coordinate,is the acceleration vector, φ is the test function, g is the gravity acceleration,=x∇,Ω is the integration domain, Γ is the boundary of the integration domain,is its unit normal vector.

There are two methods to generate a spark bubble. The first one is called the high voltage spark generating method, referring to Chahine, Zhang,Buogo, Xu et al.’s works[96,130,135-138], and the other one is called the low voltage spark generating method,referring to Khoo, Zhang et al.’s works[139-140].Although both methods use spark to generate bubbles,the mechanism of generating a bubble behind them is different[96-97,141]. The high-voltage spark generator normally uses non-flammable metal tungsten as the electrodes. The capacitor voltage when discharging is above 1 kV. The high voltage breaks down the water to generate an electrical tunnel. A bubble with high pressure and high temperature is then generated[96,130,135].Because the high voltage spark bubble generator is very expensive and dangerous due to the high voltage,a low voltage spark bubble generator with very simple setup is given by Khoo, Zhang et al.[97,132]. Thin copper wire with lower melting point is used as the electrodes of the spark generator. The electrodes cross and touch each other. The resistance at the touching point is very large, and the high current formed by the short circuit passes through the high resistance in a short time. The thin copper wire will be melted by the high temperature formed at the touching point of the electrodes, and a bubble with high temperature and inner pressure is generated. The voltage of the generator can be very low (about 36 V) which ensures the safety of the experiments[97]. Currently, both spark bubble generators have wide applications in the study of bubble dynamical features.

Fig. 5 (Color online) The bubble motions near a free surface using Eulerian FEM with the dimensionless distance between bubble and free surface equaling to 0.9

The spark bubble has the advantages of lower cost and simple operation, but the generated bubble is not spherical due to the disturbance of the electrodes and the burning products of the copper wires.Moreover, the synchronism of multi bubble excitation and the repeatability is the shortcoming of the spark bubble generator, which makes the detailed analysis of the bubble motion difficult[98]. While the laser bubble generators have the advantages of the high purity, high sphericity, good repeatability and good synchronism[142]. A laser bubble is generated by focusing the high energy laser beam through an optical lens system to a point in the pure water. The duration of the laser pulse is about (10)O ns and the pulse energy is about (1)O Joule. When the laser energy and power density at the focusing point in liquid exceed the threshold of the energy and power required to break through the liquid medium, the liquid will be break down to form a laser bubble[99]. Researchers around the world have made a great deal of researches on bubble motion in different environments and boundary conditions, and fruitful results are obtained,referring to Lauterborn, Farhat et al.’s works[100,133,143-144].But normally, the laser energy is not large enough to generate a large bubble. In order to get a large scale bubble, one method is to generate a bubble in a reduced pressure environment[132], another method is to increase the energy of the excitation such as to increase the discharging voltage or the capacitance[130]. These methods can be used to partially replace the underwater explosion and the airgun bubble to study the motion features and mechanism of high pressure bubbles. The bubble motions near free surface induced by laser are shown in Fig. 6.

4. Rising bubbles

Fig. 6 The motions of laser bubble near the free surface[100]

A rising bubble, whose inner pressure is equivalent to its surrounding pressure, rises up in the fluid under the buoyancy effect[32,145]. A rising bubble is different from the violent bubble like underwater explosion bubble, airgun bubble and so on[5,50]. It is a fundamental problem concerned in multiphase fluid mechanics and has important applications in the fields of ocean engineering, mechanical engineering,chemical engineering[8,21,68,146]and so on. Viscous force and surface tension play dominant roles in the rising bubble motion and the complex wake, and make the trajectory of the bubble very complicated. The trajectory of the rising bubble is often not a straight line, but a zigzag or spiral line. This problem in fluid mechanics is very complex and has not yet been fully revealed[68].

Fig. 7 (Color online) The typical zigzag motions of a rising bubble. (a) The trajectory of the bubble centroid and the zigzag motion. (b) Iso-surfaces of the vorticity component in the z direction of a rising bubble at two typical time based on FVM[27]

In experimental studies, there have been many publications concerning the bubble rising speed,bubble shape, rising trajectory, bubble coalescence,bubble splitting, bubble breaking up at the free surface and so on, referring to Tripathi, Shew, Biesheuvel et al.’s works[27,147-150]. The shape and trajectory of a rising bubble have a great relationship with the initial condition when the bubble is released. For example,when the bubble is relative large, it has been non spherical during the release process[151]. With the development of the high speed photography, particle image velocimetry and electronic sensor technique,the experimental measurement of the rising bubble is more detailed[152-156]. However, due to the complexity of the motion of the rising bubble, the initial formation and release of the bubble, the accurate measurement of the wake, multi bubbles (cluster)interaction mechanism are still difficult problems in experimental researches[27,157].

The theoretical study of rising bubbles mainly analyze the mechanical problems such as the bubble’s rising speed, path instability, final shape and so on[158].But due to the complexity of the bubble motion,especially the bubble wake, the theoretical models are not able to get the details of the bubble motion and the refined flow field features. In terms of numerical study, there are many numerical methods to simulate rising bubbles, such as BEM, FVM, LBM, SPH methods, refering to Li, Albert, Alizadeh, Zhang et al.’s works[24,25,159-160]. These methods can simulate the dynamic features of the rising bubble as well as the features of its surrounding flow field. The typical zigzag motion of a rising bubble in the fluid domain simulated by FVM is shown in Fig. 7. The complex mechanical behaviors such as interaction, coalescence,splitting features of multi rising bubbles (clusters) are the development direction of the future numerical simulation[161].

Fig. 8 Cavitation phenomenon during the rotation of the propeller[163]

5. Cavitation generated by a propeller

The dynamic characteristics of propeller cavitation bubbles are an important fundamental problem for shipbuilding and ocean engineering. The high speed rotation of the propeller reduces the hydrodynamic pressure of its surrounding domain, and the cavitation bubbles are formed[26,162-165], as shown in Fig. 8. The formation of cavitation bubbles will degrade the propeller’s performance, and the highspeed liquid jet and the shockwaves emitted in bubble collapsing will cause the erosion damage to the propeller[166]. The noise generated by the cavitation bubble collapsing and the trailing tail behind the propeller will reduce the stealth performance of the surface ship, the submarine and other underwater vehicles. Therefore, the reducing or suppressing the cavitation bubble is the key technique of the propeller design[167-168]. Although the researchers have long been concerned with and studying the cavitation problems generated by propeller, and have obtained fruitful research results, due to the complexity of the propeller cavitation problems, there are still many problems to be solved, such as the mechanism of the formation and evolution of the cavitation bubble,accurate forecast of cavitation excitation force, suppression of the cavitation phenomenon and so on.

Early theories on propeller cavitation are mainly based on the potential theory[169]. It has made great progress and lays a foundation to the later fine researches on the propeller cavitation. The viscous effect has great influences to the propeller cavitation,and the potential theory has a limitation in analyzing the dynamic features of propeller cavitation. It is difficult to obtain the analytical solution of propeller cavitation motion under the framework of viscous fluid mechanics. The main numerical simulation methods are BEM, FVM etc., referring to Baltazar,Peters, Ji et al.’s works[12,170-171]. BEM has difficulties in simulating the formation, oscillating and collapsing of cavitation in detail. FVM can be used to do fine simulations of the cavitation and its surrounding fluid,but how to establish an accurate model, acquire an accurate shock load during cavitation collapsing and wake simulation are still the hot points in the research[172-174]. The transient fluid structure coupling model and the calculating method taking into account the elastic-plastic damage to the propeller under the collapsing load of the cavitation are the focus of the future research[52].

In the experimental study of propeller cavitation,real scale propeller experiments are difficult to perform, and the measurement of the cavitation’s dynamic features and the fluid pressure are also very difficult[175-176]. If the results of reduced scale model experiments or the mechanism experiments are extended to the real scale model, the similarity of the cavitation number should be satisfied. Normally, the experiments are carried out in a reduced pressure environment (for example, reduced pressure water tank)[20,177]. The cost of the experiment is very expensive. With the development of the experimental technique, a large number of experiments focusing on the features of the propeller cavitation are carried out and fruitful results are obtained, referring to Asnaghi,Aktas et al.’s works[178-179].

6. Cavitation (cavity) induced by water entry and exit problem

The water entry and exit problem is a widespread problem in the field of shipbuilding and ocean engineering, such as the wave slamming on a ship,underwater launching, high-speed water entry of missile[180-182]and so on. The cavitation problem caused by water entry and exit is similar to the propeller cavitation problems. The high speed motion of the structure will lower the dynamic pressure of its surrounding fluid which causes the cavitation phenomenon[26,183-184], as shown in Fig. 9, the cloud cavitation is generated by a polyvinyl chloride sphere inside a variable-pressure water tunnel. The theory of analyzing the cavitation phenomenon of the water entry and water exit is almost the same and without loss of generality, this paper describes the cavitation problem caused by the water entry problem. The cavitation problems caused by water are related to the velocity, shape and the coarseness of the structure into the water[185-187].

Fig. 9 (Color online) The cavitation phenomenon attached on the underwater vehicle[183]

There are similarities between the water entry problems and propeller cavitation problems in both theoretical and numerical methods. Many great progresses have been achieved in both theoretical and numerical methods, referring to Lee, Paryshev,Faltinsen, Zhang et al.’s works[188-191]. In analyzing the water entry problem, the compressibility of the surrounding fluid should be taken into account. On the one hand, when the structure touches the water surface,the water will splash and form a cavity, and the cavity will close under gravity. On the other hand, due to the high entry velocity of the structure, cavitation will appear locally surrounding the structure. The cavity and the cavitation form a cavitation bubble. A very complex flow domain including gas-vapor-liquid is formed surrounding the structure. Strong elastoplastic coupling occurs between the complex flow and the structures, which brings huge challenge to the traditional theoretical and numerical method[192]. At present, there are few literatures focusing on the fluid compressibility, phase transition effect, the coupling model and simulating methods of complex gas-vaporliquid fluid and structure, which needs further study.

Fig. 10 The water entry of a highspeed bullet and the cavity shape[185], the time interval between each frame is 0.1 ms

In terms of experimental study of water entry problems, with the development of experimental technique such as sensor, PIV etc., great progresses have been made and fruitful results have been achieved,referring to Abelson, Aristoff, Wang, Chen et al.’s works[193-196]. The typical process of water entry is shown in Fig. 10. However, the real scale experiments of the water entry are difficult to carry out, measure and analyze. In terms of a reduced scale model or some mechanism experiments, researchers normally design water entry experiments with cavitation numbers, Mach numbers and Froude numbers to satisfy the similarity criteria[197-198]. However, these similar parameters are difficult to satisfy at the same time. If the damage of the structure is concerned, the March number should be similar. If the cavitation problem is concerned, the cavitation number should be similar. If the closure of the cavity and the free surface flow is concerned, the Froude number should be similar. The water entry problems of a rigid body water entry have been studied a lot and fruitful results are obtained, referring to Truscott, Neaves, Zhang et al.’s works[191,199-200]. There are few experimental studies on the high speed water entry problem considering the structural elastoplastic damage, which is one of the research directions that need to be focused on in the future.

7. Applications of bubbles in other fields

As mentioned above, the bubbles have wide applications in various engineering fields. There are also many applications of bubbles in other fields which are listed below: drag reduction (such as supercavitating torpedo[26], bubble boat[201-202], nanobubble drag reduction[203]), shock resistance using bubble cluster[204], bubble cleaning[68], ice breaking using violent bubble[53], combustible ice mining generated bubble[25], bubbles generated by broken waves which are an important source of carbon dioxide absorption[68], cavitation bubbles in hydraulic machinery and engineering[12], sonoluminescence bubbles[205], ultrasonic bubble breaking stones in kidney[206], drug delivery using bubble capsule[17,207], high contrast medical imaging[208], bubbles in food industry[209-211]and so on.

8. Future works

As mentioned above, the researchers have carried out a lot of researches in the fields of underwater explosion bubble, airgun bubble, cavitation bubble,rising bubble, etc., and have achieved fruitful results.However, due to the complexity of bubble motion,there are still many difficult mechanical problems to be further studied. Part of them are listed as follows:the motion and load characteristics when the bubble is super close to the complex boundaries and the corresponding theoretical and numerical methods, the fluid structure coupling theory of the elastoplastic damage of structures due to the underwater bubble,the interaction of bubble and composite or brittle materials, numerical model and calculating method of the multi bubbles, the coupling effect and coalescence mechanism of bubble cluster, accurate model of cavitation bubble, bubble internal temperature evolution and heat transfer problem, accurate measurement technique of bubble jet pressure, experimental technique of large scale bubble, bubble dynamic behaviors in non-Newtonian fluid, stability and motion mechanism of the nanobubbles, bubble splitting and crushing process and its motion at later stages,bubble suppression and comprehensive utilization techniques.

9. Conclusion

Bubble motion and its load characteristics are basic mechanical problems concerned in different engineering fields and have important applications in the fields of ocean, mechanics, environment and medicine, etc.. In this paper, the bubble dynamic features in the fields of shipbuilding engineering and ocean engineering are focused on. The latest development and research trends in theoretical analysis,numerical modeling and experimental study of different types of bubbles such as underwater explosion bubble, airgun bubble, cavitation bubble,rising bubble and so on are reviewed and discussed.On this basis, the applicability and limitations of different theories, numerical methods and experimental techniques on different types of bubbles are concluded and the work that needs to be carried out in the future are discussed.

Acknowledgement

The authors would like to thank Fu-Ren Ming,Shuai Li, Xiao Huang for their great help on this work.

猜你喜欢

杂志排行

水动力学研究与进展 B辑的其它文章

- Call For Papers The 3rd International Symposium of Cavitation and Multiphase Flow

- Experimental investigation of flow past a circular cylinder with hydrophobic coating *

- Transient peristaltic diffusion of nanofluids: A model of micropumps in medical engineering *

- High-speed experimental photography of collapsing cavitation bubble between a spherical particle and a rigid wall *

- Flow induced structural vibration and sound radiation of a hydrofoil with a cavity *

- Unsteady flow structures in centrifugal pump under two types of stall conditions *