钢管混凝土结构及钢结构单层单跨框架力学性能分析*

2018-01-08王颖,易坤

王 颖,易 坤

(沈阳工业大学 建筑与土木工程学院,沈阳 110870)

钢管混凝土结构及钢结构单层单跨框架力学性能分析*

王 颖,易 坤

(沈阳工业大学 建筑与土木工程学院,沈阳 110870)

钢管混凝土柱;空钢管柱;框架;工字钢梁;外加强环;节点;有限元;力学性能

1 有限元模型建立

1.1 钢材本构关系

在本文中工字钢梁的钢材采用简化的两段线模型,适用于低碳钢,弹性模量为206 GPa,泊松比为0.262,其双直线模型如图1所示.

图1 双直线模型Fig.1 Double linear model

1.2 核心混凝土本构关系

核心区混凝土受到方钢管柱的约束,其塑性能力得到提高,故普通混凝土单轴应力应变曲线无法反映出核心混凝土塑性性能的提升.为了充分考虑方钢管柱对核心区混凝土的约束效应,本文采用刘威[5]提出的核心区混凝土本构模型,如图2所示.刘威在谭清华等[6]提出的混凝土本构模型的基础上对其峰值和下降段进行了修改,使其更加适用于有限元分析,其应力应变关系的函数表达式为

(1)

1.3 有限元计算模型

图2 核心约束混凝土应力应变曲线Fig.2 Stress-strain curve of core confined concrete

图3 方钢管混凝土柱钢梁框架模型尺寸Fig.3 Model dimensions of concrete filled square steel tube column-I beam frame

1.4 荷载以及边界条件

本文中钢管混凝土框架试验边界条件和荷载的施加形式明确,柱脚固接,两柱顶施加轴向荷载,工字钢梁端右侧施加水平循环荷载.在有限元计算模拟中,对方钢管柱脚采取嵌固的边界条件,加劲板底部同样采用嵌固边界,由于只有柱顶板和底板限制了核心混凝土的轴向位移,所以核心混凝土的边界仅需约束其轴向位移即可.在荷载施加的过程中,梁端右侧水平循环荷载的加载过程采用位移加载控制,加载历程如图5所示,其中,Δ/Δy为试验过程中模型的位移值与模型屈服位移的比值.

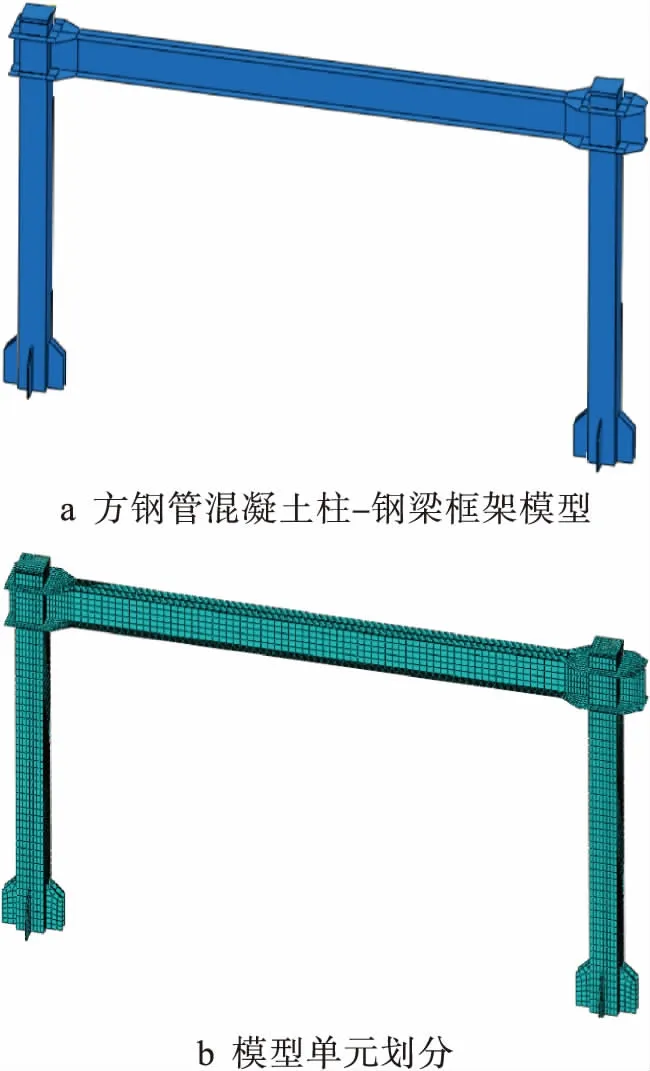

图4 方钢管混凝土柱钢梁框架模型及模型单元划分Fig.4 Model and model unit division for concrete filled square steel tube column-I beam frame

图5 加载历程Fig.5 Loading history

2 有限元结果分析

2.1 荷载位移曲线

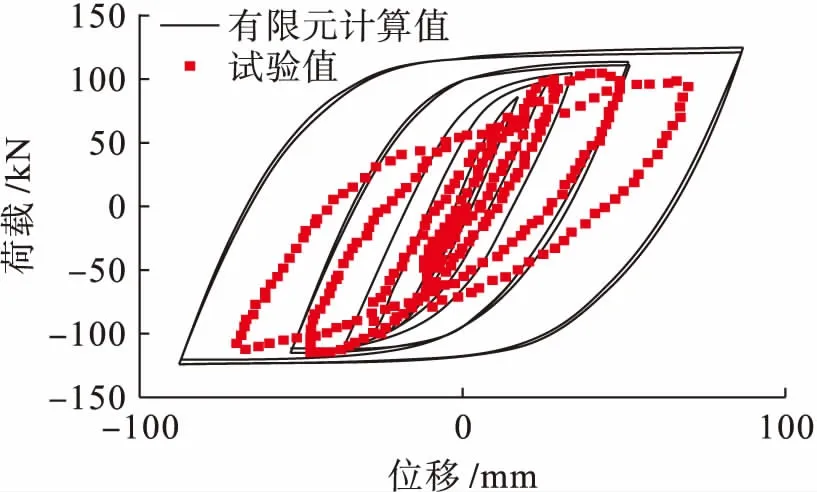

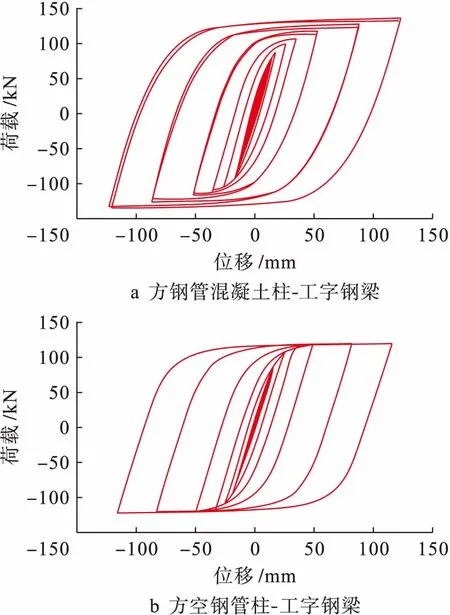

图6 有限元计算和试验滞回曲线Fig.6 Hysteresis loops from finite element calculation and experiment

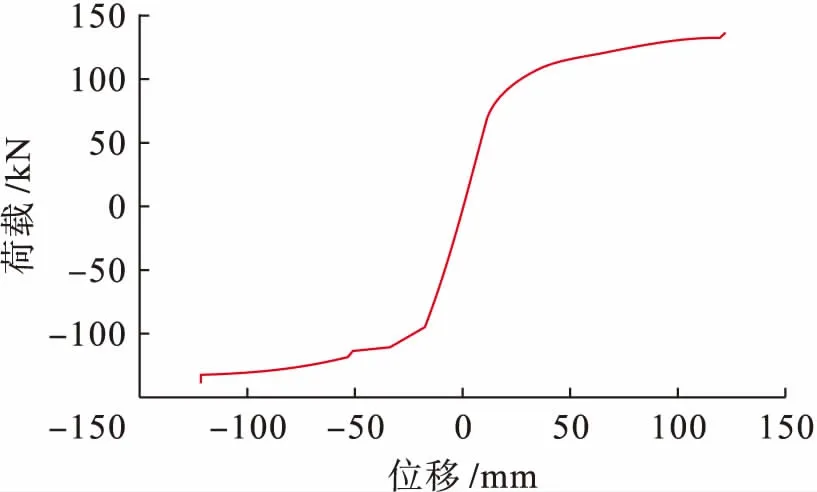

通过滞回曲线得到的骨架曲线如图7所示.

图7 数值模拟所得骨架曲线Fig.7 Skeleton curve obtained from numerical simulation

本文参考文献[8]中确定钢管混凝土柱屈服点的方法,根据骨架曲线来确定框架结构水平承载力.试件水平承载力计算结果与试验结果的比较如表1所示,其中,Pu2/Pue为钢管混凝土模型极限水平荷载模拟值与试验值的比值.

表1 水平承载力计算结果与试验结果的比较Tab.1 Comparison between calculated and experimental results of horizontal bearing capacity

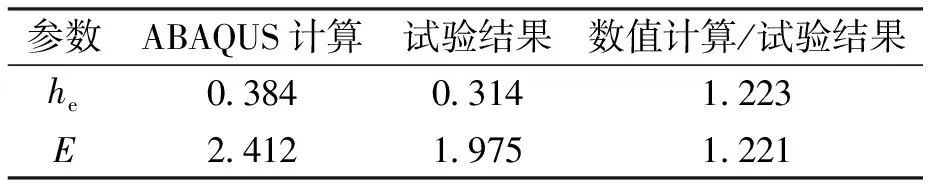

2.2 耗能能力

表2 粘滞阻尼系数和能量耗散系数对比Tab.2 Comparison between viscous damping coefficient and energy dissipation factors

3 两种框架结构力学性能对比分析

3.1 确定方空钢管柱工字钢梁框架模型尺寸

3.2 应力云图

图8 两种框架结构的应力云图Fig.8 Stress nephograms of two frame structures

由图8可知,塑性铰只出现在工字钢梁端部环板外侧和柱脚加劲板上方,而节点区钢管柱壁在加载过程中始终处于弹性阶段,表明采用外加强环连接节点的两种框架结构均满足“强节点、弱构件”的抗震设防要求.

3.3 滞回曲线

3.4 骨架曲线

3.5 强度退化和刚度退化曲线

图9 两种框架结构荷载位移曲线Fig.9 Load-displacement curves of two frame structures

图10 两种框架结构的骨架曲线Fig.10 Skeleton curves of two frame structures

图11 两种框架结构的强度退化曲线Fig.11 Strength degradation curves of two frame structures

刚度退化的定义参照《建筑抗震试验方法规程》(JGJ/T101-2015),同级变形下的割线刚度表达式为

(2)

式中:Ki为割线刚度;+pi,-pi为第i次正、反向峰值点的荷载值;+xi,-xi为第i次正、反向峰值点的位移值.

图12 两种框架结构的刚度退化曲线Fig.12 Stiffness degradation curves of two frame structures

4 结 论

3) 有限元模拟分析得到的两种框架结构的滞回曲线、骨架曲线均未出现明显的下降段,这是由于试验中的最终破坏为方钢管柱脚的焊缝开裂导致框架结构的承载力降低.而在有限元计算分析中,方钢管柱作为一整体建立模型,忽略了钢材焊缝的缺陷,故未产生试验分析中明显的下降段曲线.

[1] 刘林林,屠永清,叶英华.基于ABAQUS的钢管混凝土L形柱有限元分析 [J].沈阳工业大学学报,2011,33(3):349-354.

(LIU Lin-lin,TU Yong-qing,YE Ying-hua.Finite element analysis of L-shaped concrete filled steel tubular column based on ABAQUS [J].Journal of Shenyang University of Technology,2011,33(3):349-354.)

(GONG Yong-zhi,NI Ming,DING Fa-xing,et al.Behavior of axially loaded steel-reinforced concrete-filled square stell tubular stub columns [J].Journal of Building Structures,2014,35(Sup2):120-124.)

[3] 黄远,朱正庚,张锐,等.端部栓钉加强方钢管混凝土柱非线性有限元分析 [J].建筑结构学报,2014,35(增刊2):137-144.

(HUANG Yuan,ZHU Zheng-geng,ZHANG Rui,et al.Nonlinear FEA of square concrete-filled steel tubular solumn strengthened with end studs [J].Journal of Building Structures,2014,35(Sup2):137-144.)

(WANG Wen-da.Study on mechanical properties of concrete filled steel tubular column and steel beam plane frame [D].Fuzhou:Fuzhou University,2006.)

[5] 刘威.钢管混凝土局部受压时的工作机理研究 [D].福州:福州大学,2005.

(LIU Wei.Study on working mechanism of concrete filled steel tube under local compression [D].Fuzhou:Fuzhou University,2005.)

[6] 谭清华,韩林海.火灾后和加固后型钢混凝土柱的力学性能分析 [J].清华大学学报(自然科学版),2013,53(1):12-17.

(TAN Qing-hua,HAN Lin-hai.Post-fire and post-strengthening analysis of steel reinforced concrete co-lumns subjected to fire [J].Journal of Tsinghua Uni-versity (Science and Technology),2013,53(1):12-17.)

[7] 庄茁.基于ABAQUS的有限元分析和应用 [M].北京:清华大学出版社,2009.

(ZHUANG Zhuo.Based on ABAQUS finite element analysis and application [M].Beijing:Tsinghua University Press,2009.)

[8] 韩林海.钢管混凝土结构 [M].北京:科学出版社,2016.

(HAN Lin-hai.Steel tube concrete structure [M].Beijing:Science Press,2016.)

[9] 中华人民共和国住房和城乡建设部.JGJ/T101-2015建筑抗震试验方法规程 [S].北京:中国建筑工业出版社,2016.

(Ministry of Housing and Urban-Rural Development of the People’s Republic of China.JGJ/T101-2015 Specification for seismic test of buildings [S].Beijing:China Building Industry Press,2016.)

[10]王静峰,张琳,戴阳.半刚性钢管混凝土框架梁柱端板连接抗震性能试验研究 [J].土木工程学报,2012,45(11):13-21.

(WANG Jing-feng,ZHANG Lin,DAI Yang.Seismic experimental study of end plate connections for semi-rigid concrete-filled steel tubular frames [J].China Civil Engineering Journal,2012,45(11):13-21.)

Analysisonmechanicalpropertiesofconcretefilledsteeltubeandsteelstructureswithsinglestoryandsinglespanframe

WANG Ying, YI Kun

(School of Architecture and Civil Engineering, Shenyang University of Technology, Shenyang 110870, China)

In order to compare and analyze the mechanical properties of two frame structures including both concrete filled square steel tube column-I beam and hollow square steel tube column-I beam frame structures, the full-scale modeling the above-mentioned two frame structures were carried out with the finite element software, and the nonlinear finite element calculation and analysis were completed.The results show that the calculated results agree well with the experimental data, which verifies the reliability of the established model.In addition, the hysteretic curves of two frame structures are in plump spindle-shape without obvious pinch phenomenon.Furthermore, the horizontal ultimate bearing capacity at the beam ends of concrete filled square steel tube column-I beam frame structure is higher than that of hollow square steel tube column-I beam frame structure.

concrete filled steel tube column; hollow steel tube column; frame; I-beam; external strong ring; joint; finite element; mechanical property

2016-06-28.

日本高校合作基金资助项目(201367025).

王 颖(1975-),女,辽宁丹东人,副教授,博士,主要从事钢混组合结构和工程抗震防灾等方面的研究.

* 本文已于2017-10-25 21∶13在中国知网优先数字出版.网络出版地址:http://kns.cnki.net/kcms/detail/21.1189.T.20171025.2113.036.html

10.7688/j.issn.1000-1646.2018.01.21

TU 398.9

A

1000-1646(2018)01-0115-06

钟 媛 英文审校:尹淑英)