制动工况下液力偶合器流场湍流模型分析与验证

2016-03-21柴博森马文星寇尊权吉林大学机械科学与工程学院长春300吉林省产品质量监督检验院长春3003

柴博森,项 玥,马文星※,遇 超,寇尊权(.吉林大学机械科学与工程学院,长春 300; .吉林省产品质量监督检验院,长春 3003)

制动工况下液力偶合器流场湍流模型分析与验证

柴博森1,项玥2,马文星1※,遇超1,寇尊权1

(1.吉林大学机械科学与工程学院,长春 130022;2.吉林省产品质量监督检验院,长春 130103)

摘要:合理选择湍流模型是获取准确和可靠数值模拟结果的关键。该文采用3种湍流模型(标准k-ε模型、分离涡模型、大涡模拟模型)仿真制动工况下方形腔液力偶合器流场,提取流速场和涡量场。基于粒子图像测速(particle image velocimetry,PIV)技术测量液力偶合器制动工况下流场,将数值模拟结果与PIV试验结果进行对比,以PIV试验测量结果作为评价基准,分析采用3种湍流模型计算流场结果的差异性,完成湍流模型的适用性分析。结果表明,标准k-ε模型仿真结果与PIV试验结果误差较大;采用大涡模拟模型模拟主流区域流场结构分布更加真实,仿真结果能够较好地解释主流区域多尺度涡旋运动规律和能量耗散机理;采用分离涡模型能够更准确地捕捉近壁面和角涡区高梯度流场结构分布。研究结果可为液力偶合器流场精确计算与性能预测提供参考。

关键词:计算机仿真;可视化;模型;液力偶合器;粒子图像测速;流速场;涡量场;涡旋

柴博森,项玥,马文星,遇超,寇尊权. 制动工况下液力偶合器流场湍流模型分析与验证[J]. 农业工程学报,2016,32(3):34-40.doi:10.11975/j.issn.1002-6819.2016.03.006http://www.tcsae.org

Chai Bosen, Xiang Yue, Ma Wenxing, Yu Chao, Kou Zunquan. Analysis and experimental verification of turbulence models in flow simulation for hydrodynamic coupling under braking condition[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(3): 34-40. (in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.03.006 http://www.tcsae.org

Email:chaibs2012@jlu.edu.cn

0 引 言

液力偶合器具有减缓冲击、隔离扭振、轻载启动和防护过载的优点,广泛应用在工程机械、矿山机械、建筑机械和起重运输机械等领域[1-3]。

研究液力偶合器内部流场结构分布对于其性能改进和结构优化设计具有重要意义。数值模拟与试验测量是研究液力偶合器内部流场的主要手段[4-7]。在数值模拟方面,计算流体动力学(computational fluid dynamics,CFD)能够实现液力偶合器流场计算,但是采用不同湍流模型的计算结果差异性较大。正确选择合理的湍流模型是获取准确和可靠数值模拟结果的关键[8-9]。在试验测量方面,粒子图像测速技术(particle image velocimetry,PIV)占据液力偶合器流场测量的主流地位[10-13]。国内外学者在液力偶合器流场计算与试验测量方面开展了大量研究,H. Huitenga等[14-15]基于CFD研究了满充液下液力偶合器内部流动规律,给出启动特性最优的结构参数组合方案。F.Magagnato等[16]分别采用大涡模拟(large eddy simulation,LES)模型和分离涡(detached eddy simulation,DES)模型仿真涡轮内部流场,在相同网格数量下采用DES模型计算结果更加接近试验结果。褚亚旭等[17]采用大涡模拟仿真355 mm循环圆直径的液力偶合器流场,与激光多普勒测速(laser doppler velocimetry,LDV)试验结果对比后证实LES模型可以较准确地模拟牵引工况下液力偶合器流场。柴博森等[18-20]基于PIV技术测量并分析了液力偶合器在多种工况下的内部流场,识别并提取了流场时空演化特征,为验证液力偶合器内部流场仿真结果提供了大量试验依据。虽然国内外学者对液力偶合器内部流场进行了大量研究工作,但是对于处在特殊工况条件下工作的液力偶合器流场研究还不够深入,对于液力偶合器流场仿真湍流模型适应性分析的相关文献却鲜见报道。因此,开展液力偶合器流场湍流模型分析与验证研究具有重要的工程应用意义。

本文采用3种湍流模型仿真制动工况下满充液液力偶合器流场,将仿真结果与PIV试验结果进行对比,针对湍流模型的适应性进行分析,以期将为液力偶合器流场精确计算与性能预测提供参考。

1 湍流模型

1.1标准k-ε模型

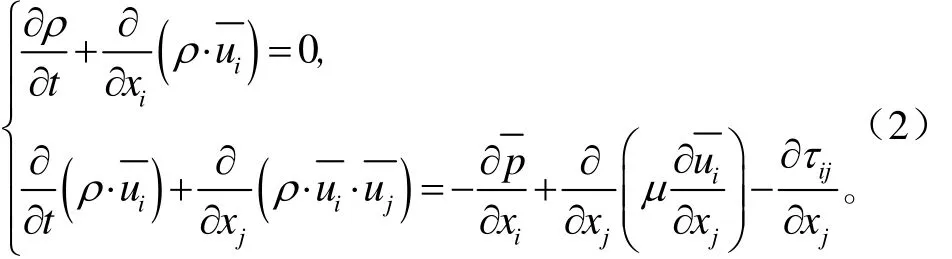

标准k-ε模型是通过求解湍流动能k方程和湍流耗散率ε方程,以k和ε值来计算湍流黏度,并通过Boussinesq假设获得雷诺应力的解[21]。标准k-ε模型方程为

式中t为时间,s;ρ为流体密度,kg/m3;k是紊流脉动动能,J;ui为时均速度,m/s;μ为流体黏度,Pa·s;μt为湍流动力黏度,Pa·s;Gk为由层流速度梯度而引起的湍流动能,J;ε 是紊流脉动动能的耗散率;xi和xj为张量表示的指标符号;C1ε,C2ε,σk,σε为模型常数,具体取值为C1ε=1.44,C2ε=1.92,σk=1.0,σε=1.3。

1.2LES模型

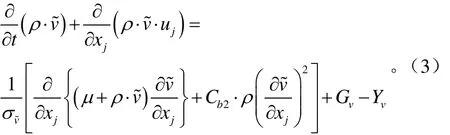

大涡模拟(large eddy simulation,LES)将流场中涡旋分为大尺度涡和小尺度涡,通过滤波函数将湍流瞬时运动方程中小尺度涡旋滤去,大尺度涡旋用瞬时运动方程直接计算,而小尺度涡旋对大尺度涡旋的影响则通过在大尺度涡旋运动方程中引入附加应力项来体现,该应力项被称为亚格子尺度应力[22]。LES模型的控制方程组为

式中ui和uj为张量形式的时均速度(i和j的取值范围为1、2、3),m/s;xi和xj为张量表示的指标符号;p为压强,Pa;τij为亚格子尺度应力,带有上划线的量为滤波后的场变量。

1.3DES模型

分离涡(detached eddy simulation,DES)模型是将LES和雷诺平均N-S方程(RANS方程)的优点相结合的一种混合模型[23],其主要思想是在近壁面附近求解RANS方程,构建Spalart-Allmaras 湍流模型(SA方程),在其他区域采用大涡模拟计算大尺度涡旋。DES模型克服了高雷诺数下LES模型对网格要求太高的缺点。其中SA涡黏性方程如下

式中v~为涡黏系数;uj为时均速度,m/s;Gv为由流体流动涡黏性引起产生项,J;Yv为由流体流动涡黏性引起的耗散项,J;Cb2,vσ~为模型常数,具体取值Cb2=0.622,vσ~=2/3。

2 流场仿真分析

2.1模型建立

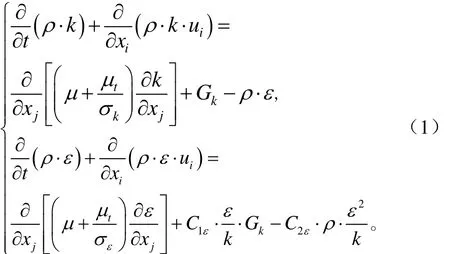

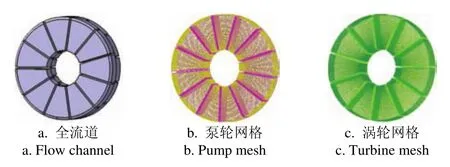

建立循环圆直径为230 mm的液力偶合器三维模型,其中泵轮叶片数为13,涡轮叶片数为11。提取全流道流动计算域,通过ICEM软件对全流道模型网格划分,采用六面体网格,总体网格数为470 944,节点数为521 887,其中泵轮网格为275 392,涡轮网格数为195 552,流道模型及网格模型如图1所示。

图1 流道模型及网格模型Fig.1 Flow channel model and mesh model

2.2流场计算

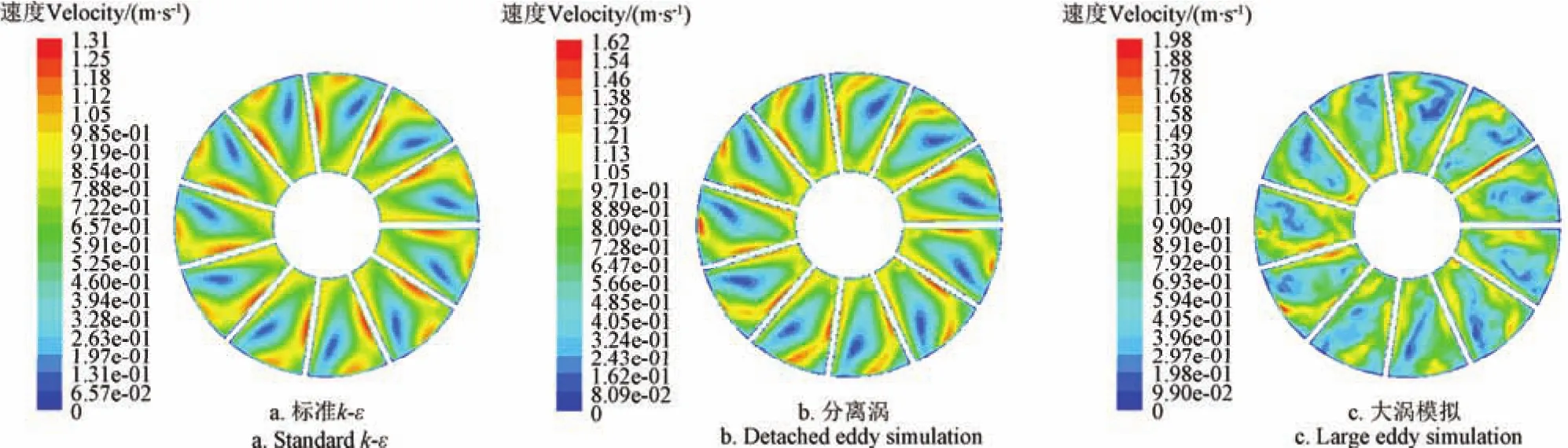

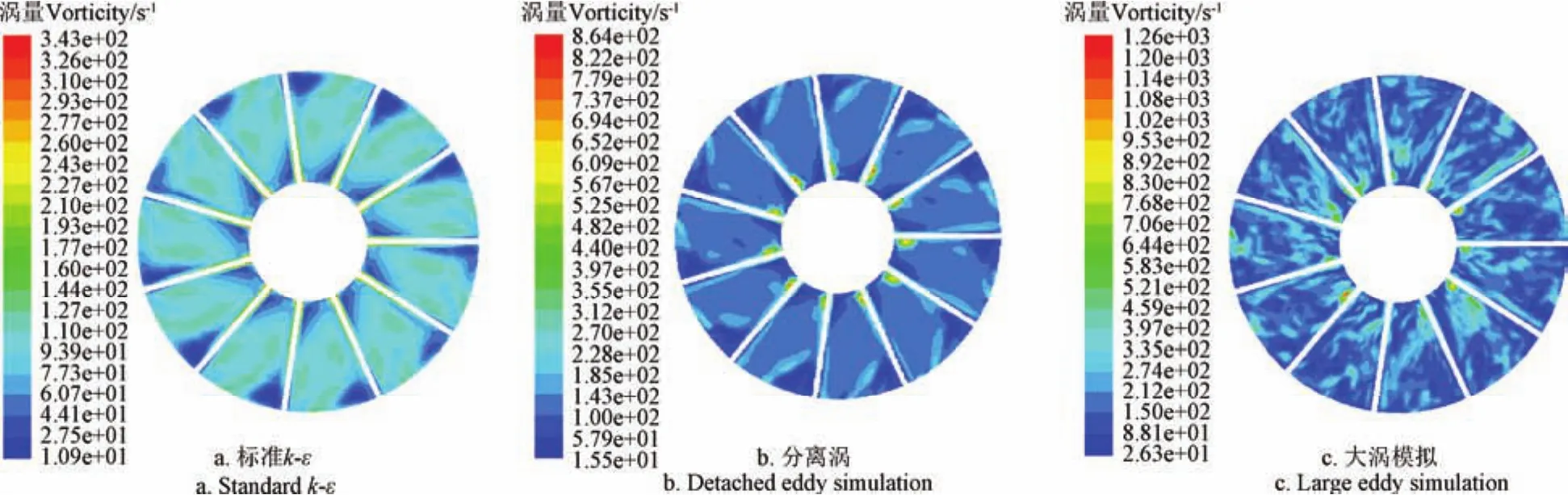

忽略温度变化和泄漏影响,并作流动周期对称假设,在制动工况(i=0)下,采用标准k-ε模型、DES模型和LES模型计算满充液状态下液力偶合器流场。流动介质为蒸馏水,假设其密度和黏度都是常数,取ρ=998.2 kg/m3和μ=0.001003 Pa·s。泵轮输入转速为200 r/min。为了详细对比分析液力偶合器典型流动区域上3种湍流模型计算结果,截取涡轮流道1/2处径向切面结果作为分析对象,图2为不同湍流模型下的流速场,图3为不同湍流模型下的涡量场。

图2 不同湍流模型下流速场Fig.2 Velocity field of different turbulent models

图3 不同湍流模型下涡量场Fig.3 Vorticity field of different turbulent models

3 PIV试验

3.1试验测量系统

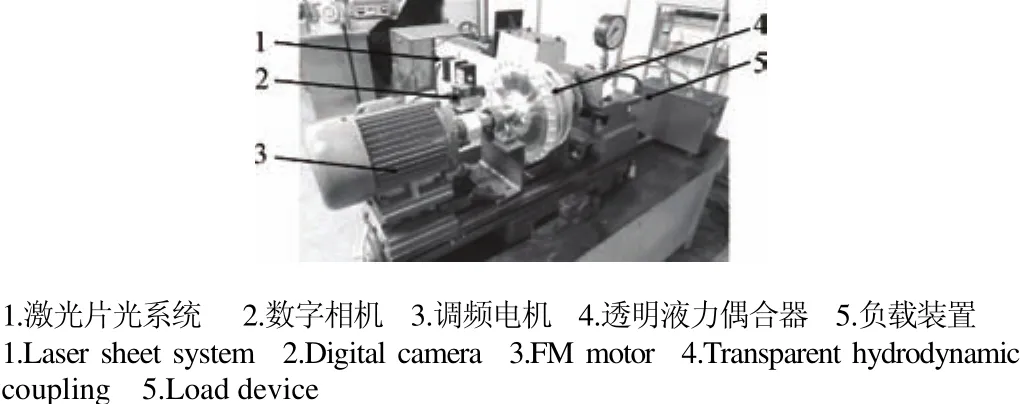

PIV试验测量系统主要由机械部分、激光片光系统和图像采集部分构成,如图4所示。机械部分主要由天津市林普机电有限公司生产的YS7124 型号三相异步变频调速电机、上海摩亿公司生产的EMT260型号激光转速测量仪、长春通用机械厂生产的CLZ型号联轴器以及2CY型号齿轮泵负载装置组成。激光片光系统由中国西安远讯光电科技有限公司制造,激光光源型号FIBER-21,可提供最大输出功率为1.5 W的激光片光,片光厚度约1~2 mm。图像采集部分主要由中国大恒集团有限公司生产的BM/BB-141GE数字相机及配套采集软件组成,相机帧频为30 fps。透明型液力偶合器样机由大连市腾达机械设备技术公司制造,循环圆直径为230 mm,泵轮叶片数为13,涡轮叶片数为11。数值模拟计算模型与试验测量模型在几何机构上保证一致。

图4 粒子图像测速试验系统Fig.4 Particle image velocimetry test system

3.2图像采集及试验结果

以蒸馏水作为液力偶合器内部流动介质,选择铝粉作为示踪粒子均匀投入待测流场,粒子直径约为10~20 μm。制动工况下在泵轮输入转速为200 r/min时采集涡轮径向流场图像。由于原始图像采集试验是在黑暗的环境下开展的,为了提高原始采集图像中粒子流动图像特征参数识别质量,需要经过图像亮度增强、中值滤波、图像降噪完成图像预处理,使得流场中粒子形态及运动轨迹更加易于识别,有利于获得更好的流动图谱。经过图像预处理后的连续2帧粒子图像如图5所示。

图5 连续2帧粒子图像Fig.5 Two successive frames of particle image

从图5中可以清晰地看到绕漩涡中心的环流运动,此时涡轮受到来自泵轮流道内高速液流的冲击,在涡轮的主流区域形成明显的顺时针方向旋转的大尺度湍流漩涡,大尺度漩涡流动承载着涡轮内流动能量交换的主循环。

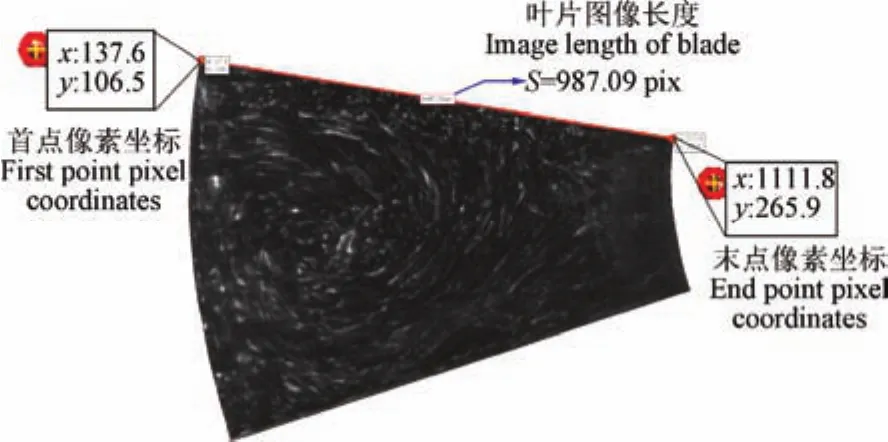

实测液力偶合器试验样机叶片实际长度为75 mm,基于图像处理技术提取图像上叶片的首、末点坐标,单位为像素(pix),如图6所示,首点坐标为(137.6,106.5),末点坐标为(1111.8,265.9),根据两点之间距离公式计算图像上叶片长度S为987.09 pix。将叶片实测长度与图像测量长度相除,获得图像放大率,经图像标定后1 pix约为0.08 mm。

图6 图像标定Fig.6 Image calibration

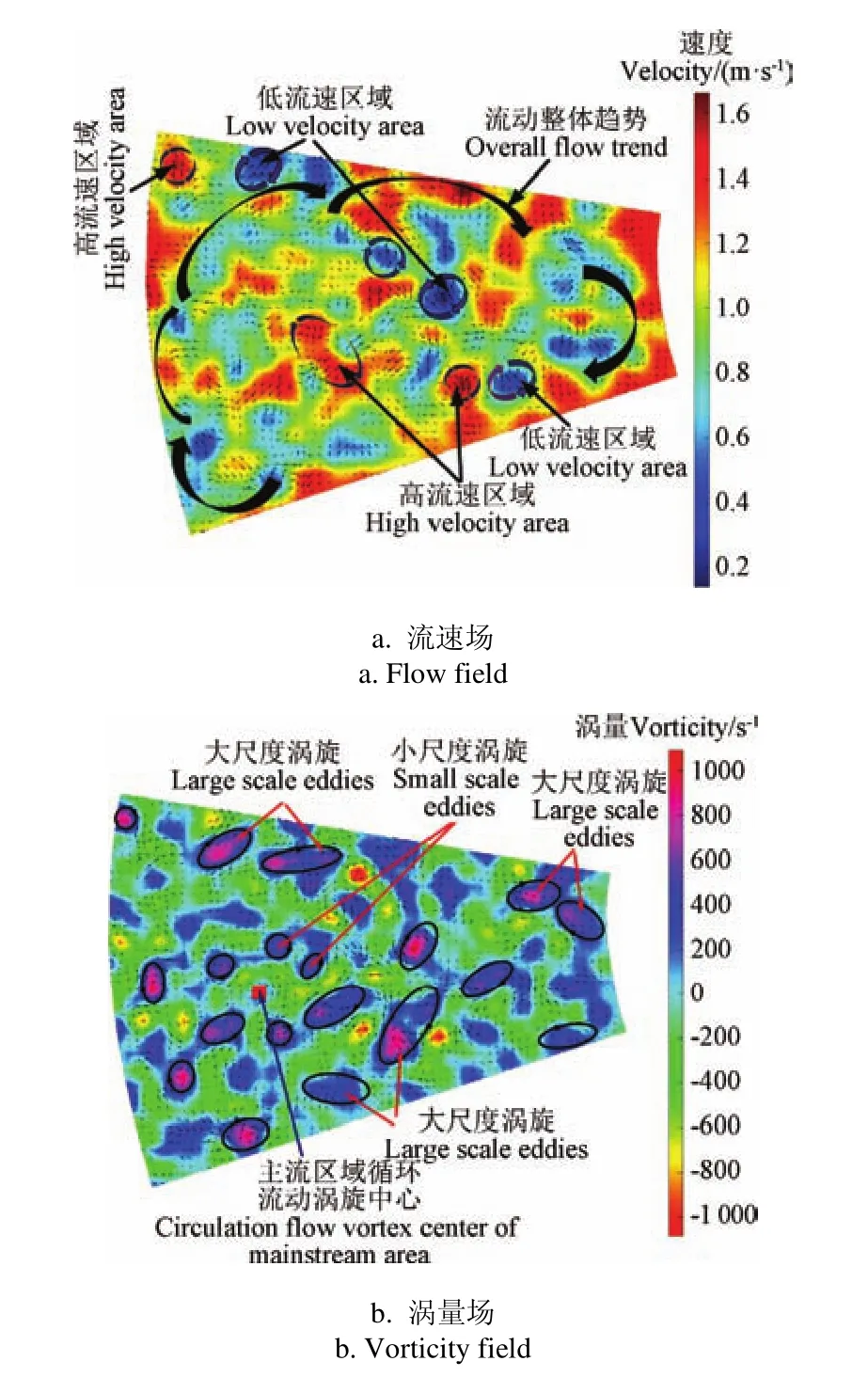

基于灰度图像互相关算法识别并提取流场矢量图[24-25],获得流速场和涡量场流动图谱,如图7所示。从整体上看,流动趋势呈现为绕主流区域循环流动涡旋中心的大环流。强旋流冲击叶片和外壁面,导致叶片附近和外壁面处出现脱离主循环流动趋势的区域循环流动,如图7a中的高流速区域和低流速区域的流场结构变化。这些区域内的循环流动由多尺度涡旋所构成,如图7b中的大、小尺度涡旋所示。这些多尺度涡旋在自身旋转运动的同时,随着主涡旋运动趋势向主流区域涡旋中心运动,较大尺度涡旋在旋转运动过程中逐渐转变为小尺度涡旋,多尺度涡旋的运动能量最终以热能形式渐渐耗散,并在涡心处归于0。

图7 PIV试验结果分析Fig.7 Results analysis of particle image velocimetry experiment

4 结果与讨论

4.1流速场

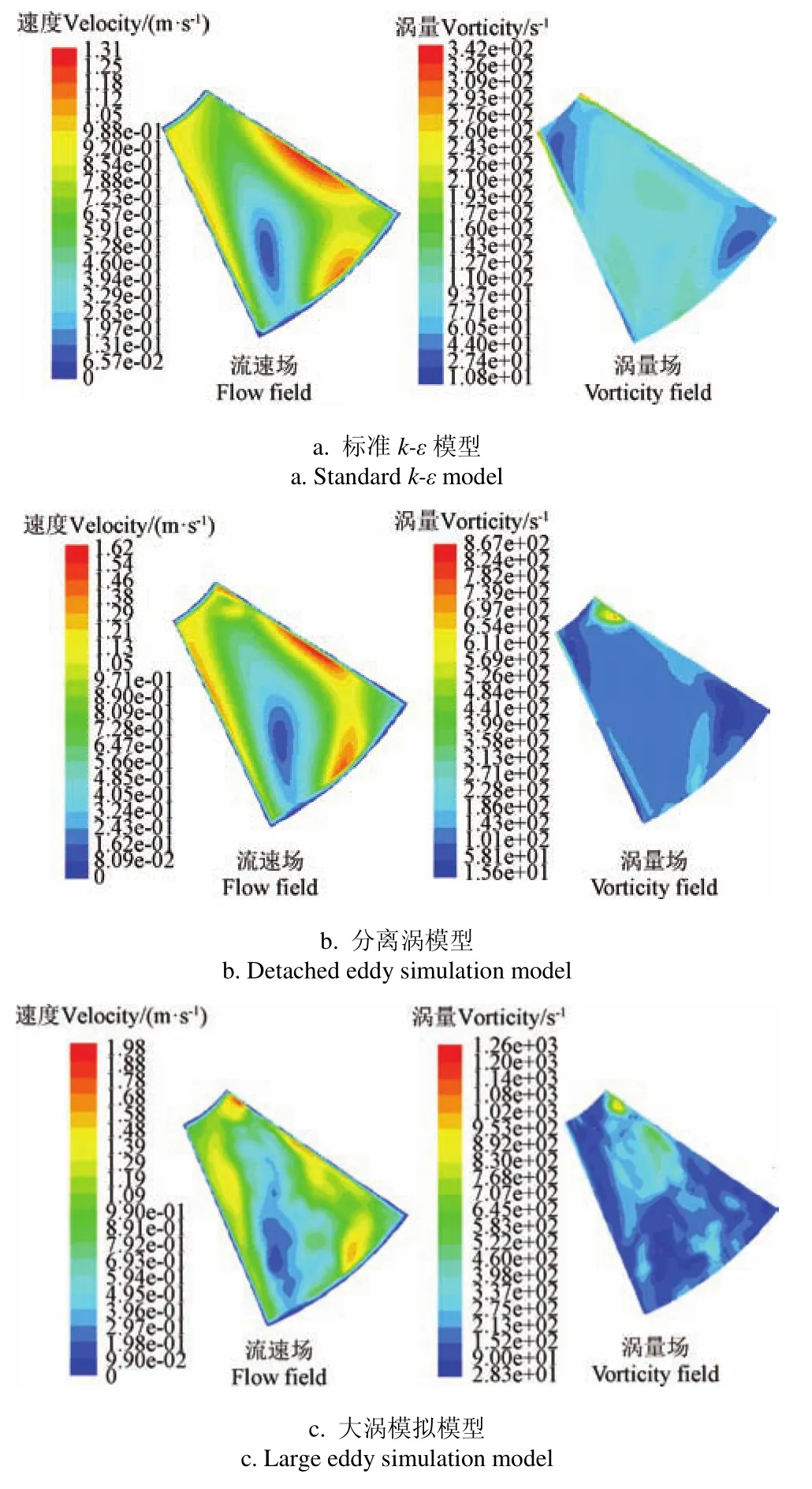

为了清晰地体现流场计算结果的差异性,截取液力偶合器单独流道内二维流场仿真结果,如图8所示,其中左侧图像为流速场,右侧图像为涡量场。为了保证仿真结果与试验测量结果对比有效,截取的仿真流场切面与粒子图像测速试验中的激光切面位置保持一致。

从定性分析流速场结构分布的角度来看,采用标准k-ε模型和DES模型仿真液力偶合器单独流道内主流区域流速场结构分布几乎保持一致,而采用LES模型流速场仿真结果趋于复杂,如图8所示,但是采用LES模型可以模拟出多尺度涡旋结构,这与图7a中的PIV试验流速场测量结果相一致。因此,对于主流区域内多尺度漩涡流场结构仿真LES模型更加趋于真实。采用标准k-ε模型和DES模型都可以仿真出液力偶合器近壁面区域的高梯度流场结构分布,但是采用标准k-ε模型模拟近壁面高流速区域覆盖的面积更大,流速场结构层次感不够明显,这与图7a中的PIV试验流速场测量结果不一致,出现局部模拟结果失真,而采用DES模型模拟近壁面高流速区域流场结构分布更加接近于PIV试验结果,更能够体现出流速场的高梯度演化规律。由于液力偶合器近壁面区域湍流流动发展并不充分,因此采用LES模型仿真近壁面区域流速场严重失真。

图8 不同湍流模型下单独流道流速场及涡量场Fig.8 Velocity field and vorticity field of single flow channel by different turbulent models

从定量分析流速场中流速矢量大小的角度来看,对于液力偶合器主流核心区域,采用标准k-ε模型仿真流速值的范围为0~0.46 m/s,采用DES模型仿真流速值的范围为0~0.566 m/s,采用LES模型仿真流速值的范围为0~0.693 m/s;对于近壁面高流速区域,采用标准k-ε模型仿真最大流速值为1.31 m/s,采用DES模型仿真最大流速值为1.62 m/s,采用LES模型仿真最大流速值为1.98 m/s,如图8所示。根据图7a中PIV试验测量结果可知,液力偶合器主流区域PIV试验测量流速值的范围约为0~0.7 m/s,PIV试验测量近壁面高流速区域最大流速值范围为1.60~1.65 m/s。通过仿真结果与PIV试验测量结果对比可知,采用DES模型仿真近壁面高流速区域流速大小与PIV试验结果接近,而采用标准k-ε模型和LES模型仿真结果误差较大;采用LES模型仿真主流区域流速值范围趋近于PIV试验结果,采用DES模型仿真结果误差较小,而采用标准k-ε模型误差较大。

4.2涡量场

从定性分析涡量场结构分布的角度来看,采用LES模型仿真主流区域多尺度涡旋结构与PIV试验结果更加接近,LES模型仿真结果能够体现出真实而复杂的湍流演化过程,能够阐明主流区域上多尺度涡旋运动规律和能量耗散机理,如图8所示。采用DES模型和LES模型可以模拟液力偶合器角涡区域的多尺度涡旋,但是采用DES模型模拟漩涡流场结构更加精细,涡旋结构分布层次感更强,更能够体现角涡处多梯度下的涡量场分布,这与图7b中的PIV试验涡量场测量结果保持一致。对于标准k-ε模型,由于它假定湍流动力黏度为各向同性的标量,因此对于湍流为各向异性的角涡区域强旋流的模拟会出现失真。

从定量分析涡量场中涡量大小的角度来看,对于液力偶合器角涡流动区域,采用标准k-ε模型仿真最大涡量值为243 s-1,采用DES模型仿真最大涡量值为654 s-1,采用LES模型仿真最大涡量值为892 s-1。根据图7b中PIV试验测量结果可知,液力偶合器角涡区域PIV试验测量涡量值的范围为800~900 s-1。通过仿真结果与PIV试验测量结果对比可知,采用LES模型对于角涡区域涡量值仿真更加趋于真实,而采用标准k-ε模型和DES模型模拟结果误差较大。

5 结 论

采用标准k-ε模型、分离涡(detached eddy simulation,DES)模型和大涡模拟(large eddy simulation,LES)模型分别仿真制动工况下方形腔液力偶合器流场,将流速场和涡量场仿真结果与粒子图像测速(particle image velocimetry,PIV)试验结果进行对比后发现。

1)采用标准k-ε模型仿真结果失真,流速场和涡量场仿真结果与PIV试验结果误差较大。

2)采用LES模型仿真液力偶合器主流区域上多尺度漩涡流场结构更加真实,通过分析流速场和涡量场的结构分布能够阐明主流区域上多尺度涡旋运动规律和能量耗散机理,但是采用LES模型仿真近壁面流动区域结果失真,对于角涡区域流场仿真结果不够理想。

3)采用DES模型仿真液力偶合器近壁面和角涡区域高流速流场结构更加真实,采用DES模型能够准确体现角涡区域高梯度流场结构,但是采用DES模型对于主流区域的仿真结果不够理想。

[参考文献]

[1] 初长祥,马文星. 工程机械液压与液力传动系统(液力卷)[M]. 北京:化学工业出版社,2015.

[2] 杨贵华. 液力传动节能装置:液力偶合器、液黏调速离合器[M]. 北京:化学工业出版社,2010.

[3] 刘应诚. 液力偶合器实用手册[M]. 北京:化学工业出版社,2008.

[4] Bai L, Fiebig M, Mitra N K. Numerical analysis of turbulent flow in fluid couplings[J]. Journal of Fluids Engineering, 1997, 119: 569-576.

[5] 张德胜,赵继云,刘立宝,等. 基于CFD的桃形腔偶合器流场分析及结构优化[J]. 中国矿业大学学报,2010,39(5):687-692. Zhang Desheng, Zhao Jiyun, Liu Libao, et al. Flow field analysis and structure optimization of peach shaped chamber hydrodynamic coupling based on CFD[J] . Journal of China University of Mining & Technology, 2010, 39(5): 687-692. (in Chinese with English abstract)

[6] 柴博森,刘春宝. 基于粒子图像测速技术的液力偶合器漩涡流动特性研究[J]. 农业工程学报,2013,29(23):86-92. Chai Bosen, Liu Chunbao. Study on vortex flow characteristics of hydrodynamic coupling based on particle image velocimetry technique[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(23): 86-92. (in Chinese with English abstract)

[7] 吴贤芳,刘厚林,杨洪镔,等. 基于粒子图像测速的离心泵叶轮内流动分离测试与分析[J]. 农业工程学报,2014,30(20):51-57. Wu Xianfang, Liu Houlin, Yang Hongbin, et al. Test and analysis on flow separation in centrifugal pump impeller based on particle image velocimetry[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(20): 51-57. (in Chinese with English abstract)

[8] 马文星,何延东,刘春宝. 液力传动研究现状分析与展望[J].农业机械学报,2008,39(7):51-55. Ma Wenxing, He Yandong, Liu Chunbao. Situation and prospects of research on hydrodynamic transmission[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(7): 51-55. (in Chinese with English abstract)

[9] 刘春宝,马文星,朱喜林. 液力变矩器三维瞬态流场计算[J].机械工程学报,2010,46(14):161-166. Liu Chunbao, Ma Wenxing, Zhu Xilin. 3D transient calculation of internal flow field for hydrodynamic torque converter[J]. Chinese Journal of Mechanical Engineering, 2010, 46(14): 161-166. (in Chinese with English abstract)

[10] Westerweel J, Elsinga G E, Adrian R J. Particle image velocimetry for complex and turbulent flows[J]. Annual Review of Fluid Mechanics, 2013, 45(1): 409-436.

[11] Adrian R J. Particle Image Velocimetry[M]. Cambridgeshire: Cambridge University Press, 2010.

[12] Adrian R J. Particle imaging techniques for experimental fluid mechanics[J]. Annual Review of Fluid Mechanics, 1991, 23: 261-304.

[13] 唐洪武. 现代流动测试技术及应用[M]. 北京:科学出版社,2009.

[14] Huitenga H, Mitra N K. Improving startup behavior of fluid couplings through modification of runner geometry: Part I-fluid flow analysis and proposed improvement[J]. Journal of Fluids Engineering, 2000(4): 683-688.

[15] Huitenga H, Mitra N K. Improving startup behavior of fluid couplings through modification of runner geometry: Part II-modification of runner geometry and its effects on the operation characteristics[J]. Journal of Fluids Engineering, 2000(4): 689-693.

[16] Magagnato F, Pritz B, Gabi M. Calculation of the VKI turbine blade with LES and DES[J]. Journal of Thermal Science, 2007, 16(4): 321-327.

[17] 褚亚旭,刘春宝,马文星. 液力耦合器三维瞬态流场大涡模拟与特性预测[J]. 农业机械学报,2008,39(10):169-173. Chu Yaxu, Liu Chunbao, Ma Wenxing. Large eddy simulation of the 3D transient flow field in hydrodynamic coupling and characteristics prediction[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(10): 169-173. (in Chinese with English abstract)

[18] 柴博森. 液力偶合器内部流动可视化与流速识别方法研究[D]. 长春:吉林大学,2012. Chai Bosen. Study on Visualization of Internal Flow in Hydrodynamic Coupling and Recognition Method of Flow Velocity[D]. Changchun: Jilin University, 2012. (in Chinese with English abstract)

[19] 柴博森,马文星,卢秀泉,等. 基于粒子跟踪测速技术的液力偶合器内部流速测定方法[J]. 农业工程学报,2011,27(7):140-145. Chai Bosen, Ma Wenxing, Lu Xiuquan, et al. Internal flow velocimetry of hydrodynamic coupling based on particle tracking velocimetry technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 140-145. (in Chinese with English abstract)

[20] 范丽丹,马文星,柴博森,等. 液力偶合器气液两相流动的数值模拟与粒子图像测速[J]. 农业工程学报,2011,27(11):66-70. Fan Lidan, Ma Wenxing, Chai Bosen, et al. Numerical simulation and particle image velocimetry for gas-liquid two-phase flow in hydraulic couplings [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(11): 66-70. (in Chinese with English abstract)

[21] 雷林,王智祥,孙鹏,等. 计算流体力学k-ε二方程湍流模型应用研究[J]. 船舶工程,2010,32(3):5-8. Lei Lin, Wang Zhixiang, Sun Peng, et al. Application study on the turbulence models of k-ε quadratic equation on CFD calculation[J]. Ship Engineering, 2010, 32(3): 5-8. (in Chinese with English abstract)

[22] 余国保,周云波. 基于大涡模拟法的液力缓速器内流场仿真分析[J]. 机械工程与自动化,2014,2014(1):52-54. Yu Guobao, Zhou Yunbo. Internal flow field analysis based on large eddy simulation for hydrodynamic retarder[J]. Mechanical Engineering & Automation, 2014, 2014(1): 52-54. (in Chinese with English abstract)

[23] 顾春伟,陈美兰,李雪松,等. DES模型在压气机叶栅中的应用研究[J]. 工程热物理学报,2008,29(12):2007-2010. Gu Chunwei, Chen Meilan, Li Xuesong, et al. Application of DES model in the compressor cascade flow[J]. Journal of Engineering Thermophysics, 2008, 29(12): 2007-2010. (in Chinese with English abstract)

[24] 柴博森,王玉建,刘春宝,等. 基于粒子图像测速技术的液力变矩器涡轮内流场测试与分析[J]. 农业工程学报,2015,31(12):92-97. Chai Bosen, Wang Yujian, Liu Chunbao, et al. Test and analysis of internal flow field in turbine of hydrodynamic torque converter based on particle image velocimetry[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(12): 92-97. (in Chinese with English abstract)

[25] 柴博森,马文星,刘春宝. 基于互相关算法的液力偶合器内部流场分析[J]. 农业机械学报,2011,42(12):38-42. Chai Bosen, Ma Wenxing, Liu Chunbao. Analysis of internal flow field in hydrodynamic coupling based on cross-correlation algorithm[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(12): 38-42. (in Chinese with English abstract)

Analysis and experimental verification of turbulence models in flow simulation for hydrodynamic coupling under braking condition

Chai Bosen1, Xiang Yue2, Ma Wenxing1※, Yu Chao1, Kou Zunquan1

(1. College of Mechanical Science and Engineering, Jilin University, Changchun 130022, China; 2. Jilin Province Product Quality Supervision Test Institute, Changchun 130103, China)

Abstract:Hydrodynamic coupling is used for power transmission in heavy duty drives, such as power stations, ship propulsion, band conveyers, mills, and larger transport vehicles. Their hydrodynamic principle enables a low-wear torque to convert from a drive to a load. The flow in a hydrodynamic coupling is one of the most complex problems encountered in engineering fluid mechanics. The external performance of hydrodynamic coupling is determined by its internal distribution of flow field. It is very important to make a deep research on the internal distribution of flow field for the performance improvement and structural optimization in the design of hydrodynamic coupling. Numerical simulation is a main way to study the internal flow field of hydrodynamic coupling. The results of numerical simulation that are calculated by different turbulence models are quite different. In order to obtain accurate and reliable results of numerical simulation, it is a key to choose a reasonable turbulence model. The integrated computer engineering and manufacturing (ICEM) software was used to mesh the whole flow channel model of hydrodynamic coupling by hexahedral grids, and the total mesh number was 470 944 and the number of nodes was 521 887. Numerical simulation of three-dimensional unsteady turbulent flows in hydrodynamic coupling was carried out by numerically solving the Navier-Stokes equations in a rotating coordinate system. In order to analyze the applicability of different turbulence models in the calculation of flow field in hydrodynamic coupling, 3 different turbulence models (standard k-ε model, detached eddy simulation model, large eddy simulation model) were chosen to simulate the internal flow field of square cavity hydrodynamic coupling under braking condition. The quantity and quality of mesh was consistent during the numerical simulation of different turbulence models. The velocity field and vorticity field of radial section in hydrodynamic coupling were simulated and extracted through ANSYS CFX software. In addition, the transparent prototype of hydrodynamic coupling was manufactured and used in the complex flow test experiment, the internal flow field of hydrodynamic coupling under braking condition was tested based on particle image velocimetry (PIV), the characteristics of flow images were extracted by image processing technique, and the velocity field and vorticity field of radial cross-section were calculated by image cross correlation algorithm. Then numerical simulation and PIV experimental results were compared. The PIV test results were used as the evaluation criteria, and the differences of numerical simulation results by 3 kinds of turbulence models were analyzed. Moreover, the applicability of 3 turbulence models was analyzed. The results showed that the simulation results by standard k-ε model were far different from PIV experimental results, the distribution of flow field in main flow region simulated by the large eddy simulation model was much more real than others, the simulation results could be used to explain the law of multi-scale vortex movement and the mechanism of energy dissipation in the main flow region, and the high-gradient flow field distribution of near-wall area and corner area could be captured more accurately by the detached eddy simulation model. The results of analysis will provide a basis for accurate calculation of flow field and performance prediction of hydrodynamic coupling.

Keywords:computer simulation; visualization; models; hydrodynamic coupling; particle image velocimetry; flow velocity field; vorticity field; vortex

通信作者:※马文星,男(汉族),吉林梨树人,教授,博士生导师,研究方向为液力传动与自动变速。长春吉林大学机械科学与工程学院,130022。Email:mawx@jlu.edu.cn

作者简介:柴博森,男(汉族),吉林长春人,讲师,研究方向为液力传动与自动变速。长春吉林大学机械科学与工程学院,130022。

基金项目:国家自然科学基金资助项目(51405184);吉林大学基本科研业务费青年教师创新项目(450060501267)

收稿日期:2015-08-21

修订日期:2015-12-10

中图分类号:TH137.331

文献标志码:A

文章编号:1002-6819(2016)-03-0034-07

doi:10.11975/j.issn.1002-6819.2016.03.006