Development of diagnosis system based on mixed programming and combined extraction method for switch machine

2014-09-05MohanLEIPingYANG

Mo-han LEI,Ping YANG

School of Mechanical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

Developmentofdiagnosissystembasedonmixedprogrammingandcombinedextractionmethodforswitchmachine

Mo-han LEI†,Ping YANG

SchoolofMechanicalEngineering,LanzhouUniversityofTechnology,Lanzhou730050,China

According to the problems existing in envelope feature extracting methods that were based on Wavelet Packet Transform (WPT) or Empirical Mode Decomposition (EMD),this paper adopts signal decomposition method of EMD and WPT combination in feature extracting.This decomposition method can not only provide high resolution,but also avoid error messages caused by false Intrinsic Mode Functions (IMF) components.After the combination of envelope features are extracted using EMD and WPT method,the most effective characteristics of defected signals will be selected and classified using the data feature selecting method based on Principal Components Analysis (PCA).Based on the above features extracting and selection methods,this paper uses mixed programming of Labview and Matlab to develop a diagnosis system for S700K-C electrical switch machine,and the diagnostic testing experiment in the end proves that this diagnosis system can extract defected signals accurately and rapidly.

Switch machine,Labview,EMD,WPT,Matlab

1.Introduction

S700K-C electrical switch machine was developed to meet the demand of the acceleration of Chinese railway.With the increasing speed and density of trains to pass through turnouts and the adopting of heavy haul train and heavy railway turnouts,working environment of switch machines is also changing.In order to ensure the safety of running trains,the vital parts of switch machines demand higher standard of signals detection for internal cracks.Action bars are the main load-carrying parts of switch machine,and are the crucial parts to assure the safety of railways,so the quality of action bars must be tested after the machining is completed.Hence a diagnosis system for action bars and the whole switch machine is necessary.And in order to be more efficient and easier to use,the diagnosis system needs a friendly interface,the functions of graphical display and powerful data processing and analyzing ability[1].

For non-stationary and non-linear ultrasonic signals in practical applications,the WPT method of signals sampling decomposing cannot always satisfy the demand of high resolution in the time and frequency domain,and the EMD method of original signals sampling analyzing always produces false intrinsic mode function (IMF) component which leads to wrong information of defections due to the sensitivity of EMD method.Therefore the diagnosis system in this paper adopted the method of WPT and EMD combination to process signals and to construct the combined independent and defected feature data set by decomposing the original ultrasonic echo signal,then used the PCA method on the combined feature data set constructed above to reduce dimension of the combined feature data set,and in the end completed the extraction for defected feature in practical application.

Labview can provide a friendly,easy operating interface,and the developing based on Labview can be quite efficient.But the analyzing ability it provided has too many limitations in practical applications.While Matlab is a powerful tool for analyzing,and it provides programs such as wavelet packages that can effectively compensate for the shortcomings of Labview.

According to the characteristics of Labview and Matlab and the actual needs in practical applications,this paper combined the advantages of both Labview and Matlab.First Labview was used to provide graphical programming and a friendly,easy operating interface,and then Matlab script was introduced to enhance the ability of signal processing,in the end a diagnosis system was developed for defected signal that can be used for action bars of the switch machine.After the system was developed,an experiment was run to test the validity of it.In experiment,the diagnosis system processes defected echo ultrasonic signals collected from an action bar of switch machine,and the diagnosed results show that this system can extract defected signals rapidly and accurately.System also has powerful function of graphical display and a friendly,easy operating interface[2-3].

2.Design of the hardware

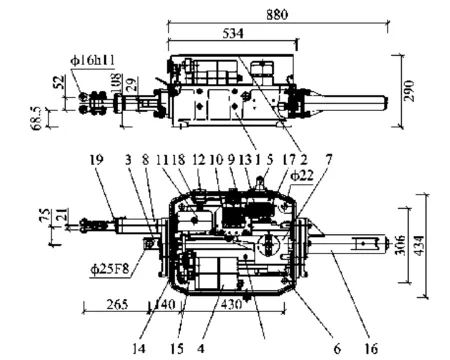

As shown in Figure 1,the diameter of the action bar of electrical switch machine is 25 mm,the length is 8.8 m and the weight is 10 kg.According to the production process of action bars,this diagnosis system must satisfy: the detecting rate reaches 8~9 m/min;ultrasonic coverage rate is over 110%;it is real-time graphical display of the diagnosed results;the data of the diagnosed results can be stored,and then be browsed and queried.Diagnosed results can be sorted to be reports,and also be printed out.

In this diagnosis system,the core part of hardware is the ultrasonic echo signals acquisition device.The diagnosis system first transports and clamps the action bars,launches and receives ultrasonic signals,conditions the received ultrasonic echo signals,then digitalizes the signals rapidly,gets the configuration commands and parameters of industrial control computer,and at last transmits the wave formed data to host computer at the same time of data storing and displaying.

1.base shell;2.cover;3.action bar;4.motor;5.electrical cable sealing device;6.ballscrew driving unit;7.maintaining coupling;8.measuring bar;9.connecting set;10.lockout block;11.obstruction switch;12.switch lock;13.terminal array;14.frictional coupling;15.gear;16.covering cylinder for action bar;17.signposts;18.lockout pin;19.staff

Figure 1.Structure diagram of S700K-C electrical switch machine

To meet the demands of performance and efficiency of the diagnosis system,the hardware adopted PXI (PCI eXtensions for Instrumentation) system which is consisted of PXI box,the zero slot controller,card of data acquisition,TB2750 and BNC2120 terminal.The PXI system is a virtual instrument testing system that the hardware is based on PXI standard bus instrument modules and a Personal Computer (PC).The purpose of introducing the PXI standard is to combine the price advantage of PC and the necessary extensions of PCI bus in the field of instruments,hence to develop a virtual instrument testing platform at good price.

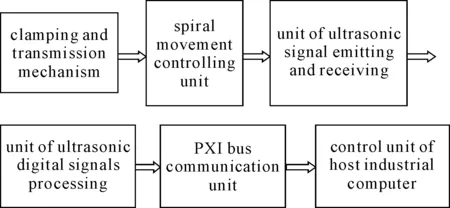

Propose a block diagram of the whole hardware design of the diagnosis system,the block diagram is shown in Figure 2.The hardware of this diagnosis system is mainly composed of the following parts:

Among the parts in Figure 2,the main tasks of clamping transmission mechanism are to clamp and transport the action bars,to grip the front and back part of the action bars,to clamp and adjust angles of the transducer and to dry and identify defected parts of the action bars.Spiral motion controlling unit of the action bars is based on PLC (Programmable Logic Controller),main function of this unit is to control the transportation and spacing of the action bars,the water circulation system,the lifting up and down of the transducer detecting pool etc.The main responsibility of PXI bus communication unit is the interaction between the status information of the spiral motion control unit and the host computer,the command information of PLC and the transmitting and receiving of the ultrasonic signals,and the data transmission between the host computer and the digital ultrasonic or the signal processing unit[4].

Figure 2.Composition of hardware system

3.Design of the software

Software of the diagnosis system is developed by mixed programming of Labview 2010 and Matlab 7.0.The software includes the signal acquisition module,the signal processing module,the database module etc.The main tasks of the software is to drive the lower computer to receive the signals transmitted from lower computer and store them in the database,to call data from the database,to process and extract the information of defected feature of the signals,and to graphically display the processed results.The acquisition of signals is based on DAQ (Data Acquisition) and sub VIs which were provided by Labview.The DAQ and sub VIs are used to complete the parameter configuration of ultrasonic echo signal acquisition and the multi-channel data acquisition;the database module used the sub VIs of LabSQL ADO function and the Access database of Microsoft Office to connect.This database module can effectively complete tasks of data writing,inquiring and calling.

The kernel part of the software is the part of ultrasonic echo signals processing.The processing method is to first combine the EMD and the WPT based extracted data of envelope features,establish the data set of defected features,then use the PCA based dimensionality reducing method for dimension compression of the feature space,in the end select the defected features.The key technology to realize signal processing is to combine Labview and Matlab by using Matlab Script[5].

3.1.Extractionofenvelopespectrumfeaturesignal

Adopting the combination of EMD and WPT method can help diagnosis system to have higher resolution and more accurate spectral structure,and can also avoid the false IMF components due to the presence of strong noises.

3.2.Matlabscriptnodetechnology

Matlab Script node technology can be interpreted as an ActiveX server based on Matlab.In the runtime,Labview will send its commanding messages to Matlab through channel of this ActiveX server,then Matlab will execute the commanding messages in background,in the end the executed results will be displayed in the front panel of Labview.

Run Labview 2010,create a Matlab Script node according to Mathematical/Script and Formula/Script Node/Matlab Script.The programs are already compiled and debugged in Matlab,the operator just need to import the script node and choose how many layers the EMD decomposition have.The data exchanging can be easily operated by simply right clicking the node box and selecting ‘add input’ or ‘add output’,in addition,the matching of data types needs to be paid attention[6].

4.Experiment for practical diagnosing application

A diagnostic testing experiment for an action bar of switch machine is run to prove the validity of the diagnosis system developed above.In this experiment,material of the specimen of action bar is aluminum alloy,outer diameter of the specimen is 60 mm,and the wall-thickness is 8 mm.There are 2 longitudinal cannelures that are 1 mm and 2 mm deep,and 2.5 mm wide on the inner surface.These cannelures are both artificial defection.The sampling frequency of data acquisition is 100 MHz,and the sampling duration is 20.48 μs which can also be interpreted as 2048 of sampling points.The collected data will be stored after high pass filtering by digital ultrasonic signal processing board.The experiment adopted discrete binary WPT of 3 scales and used db4 as the basal function type of the wavelet,extracted the features of signals of each 8 frequency components from low to high in the third layer.

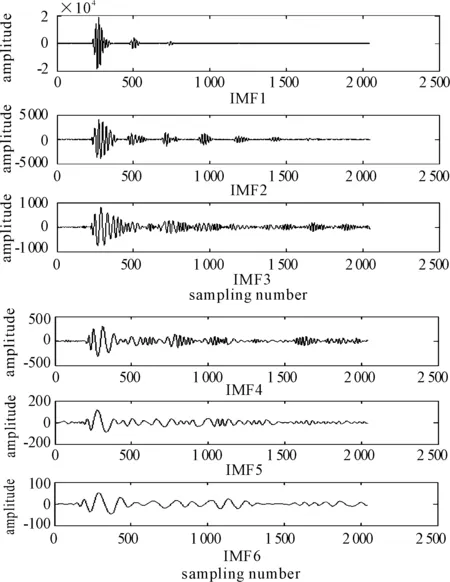

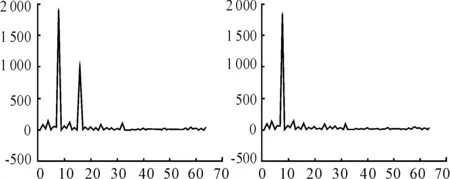

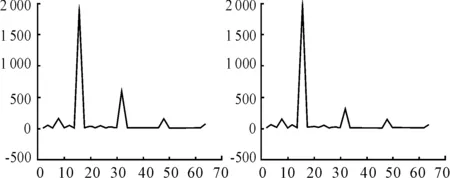

The diagnosis system developed in this paper did a series of processing for these collected ultrasonic echo signals of defections.The ultrasonic echo signals is processed by EMD and WPT at first,then the Hilbert transformation is used to get the envelope spectrum of the signals,at last,a 64×1 dimensional joint group consisting of 64 features and a 32×1 dimensional joint group consisting of 32 features are established.Figure 3 shows the curves of coefficients of the ultrasonic echo signals after 3 layers WPT processing,Figure 4 shows the IMF components after EMD decomposition.Figure 3 and 4 both use the sampling number as the abscissas,and the size of feature value as the ordinate.

Figure 3.Diagram of WPT transformed coefficients of ultrasonic echo signals of 2 mm wide defection

Figure 4.Diagram of EMD decomposed coefficients of ultrasonic echo signals of 2 mm wide defection

After the processing of the ultrasonic echo signals,the feature sequences of the two of defected features will be obtained by WPT transforming.The sequences are shown in Figure 5,the length of these sequences are both 64,and the length of the 2 feature sequences of EMD decomposition are both 32,these 2 sequences are shown in Figure 6.

Then combine the 4 above joint groups with the 8×1 dimensional joint group of features of original signals and the 8×1 dimensional joint group of envelope spectral features of original signals,get a 112×1 dimensional signal parameter space.Select 40 ultrasonic echo signal samples of each defection to compose a 112×80 dimensional data set of defected features.At last select the most effective features of all features by using the feature selecting method based on PCA method and stochastic search,hence to realize the reduction of dimensionality of the space of features.Figures 5 and 6 use the length of sequences of features as the abscissas,and the size of feature value as the ordinate.

Figure 5.Feature values of the third layer of WPT transformed coefficients of two different defections

Figure 6.Feature values of the IMF components of two different defections

Results of the experiment indicate that the feature selecting method that is based on PCA and stochastic search can effectively select the features that reveal the maximal essence information of the defections. This diagnosis system can also effectively recognize the frequency of defected features for non-stationary and nonlinear signals of action bars of switch machine,the recognition ratio of models reaches to 91.7 %.

5.Conclusion

This paper adopted the feature extracting method based on WPT and EMD combined and the feature selecting method based on PCA and stochastic search.The developing platform of mixed programming is Labview 2010 and Matlab 7.0 combination.The diagnosis system developed can be applied for S700K-C electrical switch machine.An experiment of practical application is run in this paper,and this experiment proves that this system not only has a friendly and easy operating interface and powerful graphical display,but also can accomplish tasks of data collecting,storing,calling and analyzing rapidly and accurately,and identify the defections of cracks on the action bars effectively.

In addition,this diagnosis system also has extensive adaptability,the data of ultrasonic echo signals can be simply imported to diagnose according to different needs.

[1]Chai Jinan,Liao Kejian,Pan Dehui,et al.Study and Realization of Labview and Matlab Mixed Programming[J].Computer Measurement &Control,2008,16(5):737-740.

[2]Guo Ruifeng,Chen Xiaowen,He Yinhhui,et al.The Cutter Layout Pattern and Positional Error Analysis of Shield Machine Cutter Head[J].Machine Design &Research,2013(3):245-249.

[3]Liu Yiyan,He Shuanhai,Ju Yongfeng,et al.Feature Extraction Method for Structural Damage Base on EEMD and WPT[J].Journal of Vibration,Measurement and Diagnosis,2012(2):256-260.

[4]Li Jianbao,Peng Tao.Fault Diagnosis for Rolling Bearings Based on Parametric Model of Wavelet Package[J].Journal of Vibration,Measurement and Diagnosis,2012(2):229-233.

[5]Zhang Yi.Study on the Method of Bearing Fault Extraction Based on EMD and Wavelet Packet[D].Shenyan:Shenyang Aerospace University,2010.

[6]Li Juan.Signal Extraction and Selection Based on EMD[D].Taiyuan:North University of China,2011.

基于混合编程和结合特征提取方法的转辙机故障诊断系统开发

雷默涵†,杨 萍

兰州理工大学 机电工程学院,兰州 730050

针对基于EMD、WPT的特征提取方法各自存在的问题,采用将EMD与WPT结合的信号分解方法用于包络特征的提取,保证信号的分解不仅具有较高的分辨率,并且能够避免虚假IMF分量带来的错误信息。在包络特征的提取及结合之后,采用了基于PCA的特征选择方法对缺陷信号的特征数据集进行最有效特征的分类识别。根据以上特征提取及识别方法,使用Matlab以及Labview的混合编程进行了面向S700K-C型电动转辙机的故障诊断系统操作,并通过应用试验证明了该系统能够准确、快速地提取出故障信号。

转辙机;Labview;EMD;WPT;Matlab

TP277

2013-09-26

† Mo-han LEI,E-mail:13919174135@163.com

10.3969/j.issn.1001-3881.2014.06.012

猜你喜欢

杂志排行

机床与液压的其它文章

- A Sort of fusion control strategy for uncertaintycomplex process with large time lag*

- Design and implementation of a wireless electronic inverterwelding machine*

- Design and characteristic research of double-acting aircraftdeicing fluid pump*

- Preliminary research on the design of flexible barriersfor debris flow

- Numerical simulation of the double suction balance type screw compressor working process*

- Control of EPS with regulating factor