智能化 精细化

2019-12-04

化纤设备的智能化,也是今后化纤设备发展的趋势。目前,研究用机器人等智能装备代替人工完成卷装外观检测、搬运、包装出入库等工作,可以提高卷装质量和工作效率正在成为新的特点和热点。

除了智能化趋势外,在细化常规产品技术提升外,发展与特种纤维、功能纤维工艺相匹配的设备及成套工程技术,降低消耗、减少污染,正在成为行业发展的新趋势。

Intelligence, Refinement

The intelligence of chemical fiber equipment is also the trend of chemical fiber equipment development in the future. For example, automation, networking, and intelligence of key process equipment and systems; intelligent detection of chemical fiber production and product quality; HCPS of chemical fiber production (smart procurement; intelligent production; intelligent operation and maintenance; intelligent management) and so on. At present, research on the use of intelligent equipment such as robots instead of manually completing the inspection of the appearance of the package, handling, packaging and storage, etc., can improve the quality and efficiency of the package, which is becoming a new feature and hot spot.

In addition to the intelligent trend and refinement of the conventional product technology, the development of equipment and engineering technology matching with special fiber and functional fiber technology to reduce consumption and reduce pollution is becoming a new trend in the development of the industry.

北自科技:纺织行业先进智能物流系统解决方案的提供者

北自所(北京)科技发展有限公司(简称“北自科技”)是北京机械工业自动化研究所有限公司(簡称“北自所”)的控股子公司,以北自所原物流技术工程事业部为核心组建而成,旨在推动智能物流业务的加速发展。

作为国内知名的大型科研单位,北京机械工业自动化研究所有限公司(简称“北自所”)在成立的65年间一直致力于推进国内制造业领域的自动化、信息化、智能化发展。作为国家经济体制规划下的科研单位,推动机械制造行业的自动化发展是国家使命。65年来,北自所专家队伍在不断学习吸取国内外先进技术经验的同时,专注于本职工作,推陈出新,开发出一代代软件和硬件,以及多个行业的智能解决方案。

作为北自所的控股子公司,北自科技至今已成功完成700多个自动化物流系统项目,业务链涵盖了从生产型物流、配送型物流到大型物流配送中心的全物流行业,提供集自动化、信息化、智能化于一体,涵盖加工、搬运、包装、仓储、配送等一系列环节的全面解决方案,已在纤维制造业、食品、医药、家居、冷链等多行业领域成功应用实施。其中,由北自科技自主研发的合成纤维全流程智能物流解决方案为用户提供了纺丝车间从卷绕机落丝、装车、分拣、包装、仓储及MES系统的全方位自动化解决方案,产品覆盖全国10余家化纤龙头企业。

北自科技是国家指定智能制造系统解决方案提供商,已帮助众多企业突破智能制造瓶颈,并促进企业向价值链高端延伸,加快装备制造业智能化发展的步伐。“北自科技”已成为行业著名品牌,并成功走向海外。

R.T.D.: Provider of advanced intelligent logistics system solutions for the textile industry

RIAMB (Beijing) Technology Development Co., Ltd.(R.T.D.) is a holding subsidiary of Beijing Research Institute of Automation for Machinery Industry Co., Ltd. (RIAMB), which is formed with the original logistics technology engineering division of RIAMB as the core, aiming to promote the accelerated development of intelligent logistics business.

As a well-known large-scale scientific research unit in China, Beijing Research Institute of Automation for Machinery Industry Co., Ltd. (RIAMB) has been committed to promoting the automation, informatization and intelligent development of domestic manufacturing industry in the past 65 years. As a scientific research unit under the national economic system planning, it is the national mission to promote the automation development of machinery manufacturing industry. In the past 65 years, the expert team of RIAMB has been learning the advanced technology experience at home and abroad, focusing on their own work, developing generations of software and hardware, as well as intelligent solutions for many industries.

NP4421 top-mounted positive shedding device is characterized by more lifting units, housing of integral structure, strong rigidity, wide weaving patterns. Its especially suitable for double warp looms that produce wide and heavy home textiles.

NP5400B electronic dobby is top-mounted intelligent positive shedding device. The lubrication oil is forced to circulate via oil pump, and oil level sensor is adopted to avoid lacking oil. Its characterized by compact structure and easy operation. Thus, it is especially suitable for fast speed and wide unbalanced fabrics. The device is particularly popular among enterprises with fast changeover of fashion fabrics and advanced technologies.

NP6016 features longitudinal arrangement of 16 lines of components. With the advantages of compact structure, light weight and robustness, the device can meet the needs of highspeed running. NP6016 is equipped with electrical self-check function. Its capable of weaving tie, trademarks, towels, clothing fabric and lining.

TPET:重点推介四款智能化设备

苏州琼派瑞特电子科技有限公司(TPET)重点推介ET-5833全自动全棉毛巾机、TPET家纺智慧工厂、ET-6660全自动床单机,ET-5810全自动超细纤维毛巾机等设备。

ET-5833全自动全棉毛巾机

该全自动全棉毛巾机,获得国家授权发明、实用新型专利11件,实现了裁缝一体化、少人化、无人化的生产工艺。它适用于家用常规尺寸毛巾,浴巾等产品的自动化生产。

该机的主要特点包括:自动缕毛,线头超短(2mm内),高端品质;自动四边折边缝,速度更快;自动上商标(可多标);自动裁剪,自动剪线;自动收料;智能触摸操控系统;SPV数据管理,云端管理;一键启动模式,操作方便;自动切边,实现产品尺寸标准化。

该机日产毛巾1.2万片(注:日产能以24小时计算)前段节省6人/年,可节约人工成本35万;后段节省人工7人/年,可节约人工成本40万。

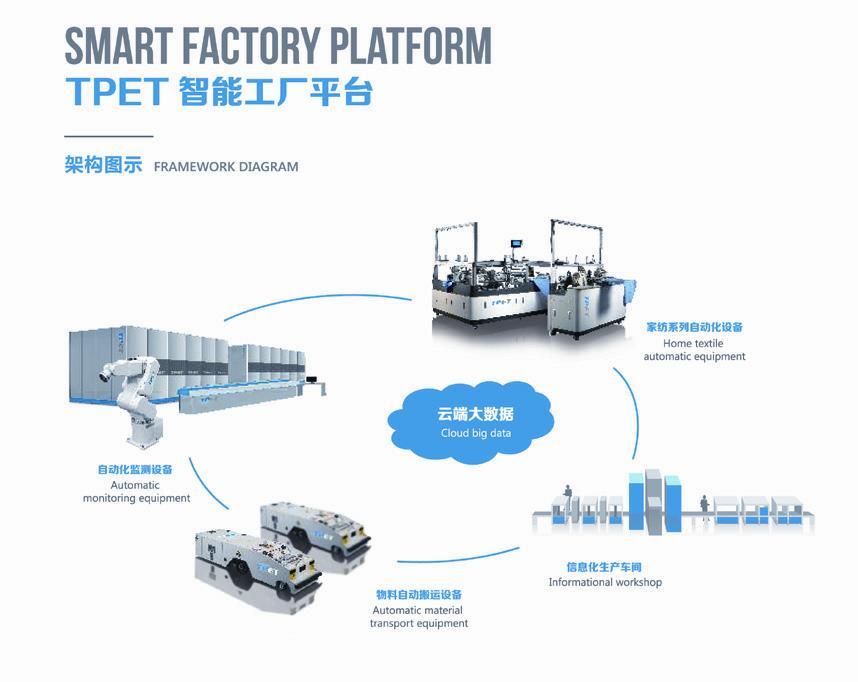

TPET家纺智慧工厂

TPET家纺智慧工厂平台是一套提供生产制造信息化、自动化、智能化的软硬件整体解决方案。通过自动搬运、自动化生产设备、自动化检测设备与信息化软件进行集成,对整个生产过程实现数据采集、过程监控、TPM设备管理、质量管理、生产调度以及数据统计分析,从而实现生产现场的信息化、智能化和柔性化智能制造管理。

TPET全球首創家纺智慧工厂,并付诸实施,目前已实现了床单、被套、枕套、被芯、枕芯;毛巾、浴巾、方巾、餐巾、干发巾、洗碗巾;地毯、地垫、毛毯、凉席、浴帘、窗帘等四边缝产品的自动化生产。通过云管理平台,可以帮助客户实时了解家纺智慧工厂的生产效率、成品率、设备的使用效率、故障报修的及时响应等。

TPET家纺智慧工厂的主要特点为,采用五大模块帮助工厂实现智能生产制造:智慧云管理运营平台实现接单、排单、派单工作与管理;智慧无人运输车实现送料、收料、入库;全自动四边缝制设备,实现自动化生产;生产管理数据实现自动采集、传输、分析并形成报表;可视化无线监控系统,无论您身在何方,车间一目了然。

ET-6660全自动床单机

该全自动床单机实现了裁缝一体化,它获得国家授权发明、实用新型专利6件;实现了少人化,无人化的生产工艺;可一次性完成四边卷边缝制,自动送标,尺寸精准,规格统一,效率高,省人工。

该机适用于常规尺寸床单,它的主要特点在于:自动纠偏,高端品质;自动四边折边缝,速度更快;自动上商标(可多标);自动裁剪,自动剪线;整卷面料直接上机使用,达到准时性、标准化,可消除浪费、减少成本支出;智能触摸操控系统;SPV数据管理,云端管理;一键启动模式,操作方便;自动切边,实现产品宽窄标准化。该机日产量在6000条左右/效率提升2000%(注:日产能以24小时计算)。

ET-5810全自动超细纤维毛巾机

该全自动超细纤维毛巾机全球首创,获得国家授权发明、实用新型专利22件,实现了裁缝一体化,少人化,无人化的生产工艺。其适用范围广泛,可做多种线迹:三线拷边,四线拷边,双针五线,三针六线等包边型产品,可助力工厂转型升级。

其主要特点在于:连续锁双边,自动断切;双层送料,一次两块(时产能1250pcs/h);自动上商标(可多标);自动裁剪,自动剪线;自动收料;SPV数据管理,云端管理。该机可日产毛巾3万片;一台设备节省6个人工/年节约人工成本35万(注:日产能以24小时计算)。

TPET: Focusing on four types of intelligent equipment

Suzhou Transparent Electronic Technology CO., LTD (TPET) will mainly exhibition ET-5833 automatic terry towel machine, TPET home textile intelligent factory, ET-6660 automatic bed sheet machine, ET-5810 automatic microfiber towel machine, etc.

ET-5833 automatic terry towel machine

This automatic terry towel machine has acquired 11 state-authorized patents of utility model. With the global origination of our fully automatic terry towel machine, labor-saving and unmanned production process are achieved by the integration of cutting and sewing.

The main product features of this machine are:

Auto thread cutting (thread-ends within 2 mm) extraordinary quality;

Auto four-side folding and sewing, faster speed;

Auto label feeding (multiple labels available);

Auto fabric cutting and trimming;

Auto stack-up;

Intelligent touch-screen operating system;

SPV data management system (cloud management);

Automatic one-button start system, convenient operation;

Auto edge-cutting, standardized size.

The productivity of this machine is 12,000 pcs/day (24 hours). The front part could save up to 6 labors, which means it will save about RMB 350,000/year. The rear part could save up to 7 labors, which means it could save about RMB 400,000/year.

TPET home textile intelligent factory

TPET intelligent factory platform is a total solution of both software and hardware providing manufacture information, automation and intelligence. Through integrating automatic transport, automatic manufacture equipment, automatic testing equipment and information software, the platform realize data collection, monitoring, TPM equipment management, quality management, production scheduling and data analysis in the production, hereby the intelligent manufacturing management of information, intelligence and flexibility in all work sites.

TPET worlds first intelligent factory and put it into operation, we have realized the automatic production of many foursided sewing products. Through the cloud management platform, we can help customers to understand the production efficiency of home textile intelligent factory in real time, the rate of finished products, the use efficiency of equipment, and the timely response to failure repair.

ET-6660 automatic bed sheet machine

With our automatic bed sheet machine, labor-saving and unmanned production processes are achieved by the integration of cutting and sewing. Get everything done at one time for higher efficiency and less manpower including four-sided hemming, fabric sewing, label-feeding and size-standardized. It has acquired 6 national authorized patents for utility models. It is applicable to the automatic production of standard-sized bed sheet. Daily productivity (24 hours) is 6,000 pcs, efficiency increased up 2,000%.

ET-5810 automatic microfiber towel machine

With the global origination for our fully automatic towel machine, it has acquired 22 national authorized patents for utility models. It has wide scope to do the stitches and promote the upgrading of factories.

The main features of the machines are:

Over locking two edges continuously, cut off automatically;

Double-layer feeding, two pieces at one time (1,250 pcs/hour);

Automatic label-feeding;

Automatic fabric cutting and thread trimming;

Automatic stack-up;

Intelligent touch-screen operating system;

SPV data management system (cloud management);

Automatic one-button start system, convenient operation;

Automatic edge-cutting, size-standardized;

The productivity of this machine is 30,000 pcs/day (24 hours); one set of this machine could save 6 labors which equals RMB 350,000/year.

重慶金猫:七款钢领钢丝圈适纺性强

RFc (黑金) 高速耐磨钢丝圈

选用进口材料,采用高精密设备加工,通过特殊复合表面处理,具有极高的耐磨性和自润滑特性。

无走熟期,纺纱断头、毛羽、飞圈等减少20%~30%; 纺纱速度可达18000 RPM以上, 使用寿命15~20天; 是高速环锭纺、高速紧密纺、赛络纺、包芯纱、色纺等各种纺纱的首选产品, 替代进口。

TPc(黄晶)钢丝圈

选用进口材料, 采用高精密设备加工, 通过具有自主知识产权的TP加工技术处理, 大幅度提高了自润滑性和耐磨性。

无走熟期, 纺纱过程断头、毛羽、飞圈等减少15%~20%,使用寿命达到15~18天,纺纱速度可达17000 RPM以上, 适纺性强, 替代进口。

BSc(蓝宝石)钢丝圈

选用进口材料,采用高精密设备加工, 通过扩散渗透技术处理, 具有很好的自润滑、长寿命特性, 以及性价比优势。

无走熟期, 纺纱过程毛羽、断头、飞圈等减少10%~15%,使用寿命达到10~15天, 纺纱速度可达16000 RPM以上, 适纺性非常强, 替代进口。

GHJ高耐磨精密钢领

采用优质轴承钢材料,通过特殊渗透处理和化学热处理,基体硬度达到84~85 HRA。

耐磨性能是镀铬的1~2倍; 使用寿命5~8年,特别适合高速高耐磨纺纱需求。

JD高精密钢领

采用优质的GCr15轴承钢材料, 圆度、平行度、平面度控制在≤0.010mm,通过精密电镀及研磨抛光处理, 膜层厚度达到10微米以上。

具有很好的耐磨性能,使用寿命5~6年。

BC型锥面钢领

通过对原材料、加工装备、表面处理等方面的升级改造,使得BC型下支承锥面钢领,配用BS BC6 d 钢丝圈,20多年在混纺和化纤领域独占鳌头, 长盛不衰。

D CHgT系列集落钢领

采用轴承钢材料经特殊加工工艺制造;集体落纱留头率提高60%以上。

具有很好的耐磨性能,使用寿命4~5年。

Chongqing Jinmao: Seven products of better spinning performance

RFc ring traveller

With imported material, precision machining, special surface treatment, RFc ring traveller has high wear-resistant and self-lubricating properties.

Easy running in. A reduction of 20% - 30% on breakage, hairiness, flying-off. Spindle speed up to 18,000 RPM or more, life 15 - 20 days. RFc ring traveller is always the first choice for high speed spinning, and for compact, siro, core-spun, color-spun yarn, etc.

TPc ring traveller

With imported material, precision machining, TP processing technology ?, TPc ring traveller has enforced wear-resistant and self-lubricating properties.

Easy running in. 15% - 20% reduction on breakage, hairiness, flying-off. Spindle speed up to 17,000 RPM or more, life 15 - 18 days.

BSc ring traveller

With imported material, precision machining, diffusion technology, BSc ring traveller has good self-lubrication, long life characteristics, as well as competitive cost.

Easy running in. 10% - 15% reduction on breakage, hairiness, flying-off. Spindle speed up to 16,000 RPM or more, life 10 - 15 days.

GHJ ring

With high quality bearing steel material, and special heat treatment at depth, GHJ ring has hardness 84 - 85 HRA.

5 - 8 years life time, ideal for high speed and harsh fiber spinning.

JD ring

With GCr15 bearing steel, roundness and parallelism and flatness tolerance all within 0.010 mm.

5 - 6 years life time.

BC ring

With optimization on raw materials, processing equipment, surface treatment, BC ring, applied with BS BC6 d ring traveller, satisfies synthetic and blended spinner for more than 20 years.

D CHgT ring

With high quality bearing steel material, and special processing, D CHgT ring can reduce end breakage by 60% or more for integrated doffer.

4 - 5 years life time.

宋和宋:国际上最具竞争力的电子提花机品牌

成立于1999年的宋和宋智能科技有限公司,立足国际,走过了20年风雨历程,逐步建立了中国、印度、印尼、土耳其为中心重点市场的产业化布局,具备年产电子提花机5000台(套)、月产提花电磁组件360000个的生产能力,被誉为国际上最具竞争力的电子提花机品牌。

公司生产的“宋和宋”电子提花机产品性价比高、竞争力强,产销量世界第一,其中高端提花市场份额达70%以上,产品覆盖中国、印度、越南、巴基斯坦、土耳其等三十个国家和地区。

在科技创新上,力主自主研发。“技术是企业发展的第一生产力”,宋和宋作为一家高端提花织造装备及其关键零部件的研发、生产、经营、服务于一体的国家级高新技术企业,拥有授权专利四十余项,其中发明专利十项,软件著作权3项,是中国提花织造领域自主创新能力最强、拥有核心专利技术最多的企业。

宋和宋秉承“一切以提升用户体验满意度”的宗旨,贯彻“super”“service”理念,在产品设计上不仅根据市场现时需求,不断突破更从长远发展出发,深耕细作,精益求精,同时不断更新设计,建立了可以满足不同市场不同需求的全系列电子提花机产品库。随时提供引领市场的产品。

产品亮点

近年来,针对纺织市场向高经密、大针数、高附加值产品方向发展,宋和宋科技成功发展了大针数电子提花机,目前最大针数可以做到38000针以上;

针对印度地区低速小剑杆织机推出经济适用机型SA5、SE5,平开口织造,无小拉杆轴承机构,结构更紧凑,可靠稳定性价比高,更低投入、更高回报;新推出的SE5还采用了耐磨塑料齿轮传动结构设计,相对比钢齿轮传动具有重量轻,惯性小,噪音低,自潤滑耐腐蚀的特点,更加适宜印度市场织造环境;

世界首创双侧共轭凸轮驱动SDLX双侧共轭凸轮型电子提花机,双侧凸轮,受力减半,高载荷、高转速、长寿命;

针对非洲布面料开发的专用SEJ168H高速提速型电子提花机设计车速1000转,优化了机身机构,加强了传动部件,低矮的机身提高稳定性,铸造与吸塑相结合减震降噪,全密封运行保证组件使用寿命;

针对宽幅剑杆在原链条结构基础上增加旋转变速装置,正弦曲线与凸轮曲线叠加更便于引纬。

宋和宋提花机具有高可靠、高效率、高回报的特点,无论在产品种类、稳定性还是在市场占有率上,都处于领先地位,得到行业的一致认可。宋和宋智能科技将打造“本地化”、“技术型”、“高效率”、“全领域”、“一站式”五位一体的服务模式,将持续在世界各地组建最高效的本地化服务团队,不断加强服务工程师技术培训,提升专业技能,进一步提升服务效率,第一时间恢复用户现场,针对所有品牌、所有型号的提花机,提供服务并进行优化和升级。

S&S Intelligent Science and Technology: Winning a leading competitive position in electronic jacquard field

Jiangsu S&S Intelligent Science and Technology Co., Ltd., since its establishment in 1999, has gradually established the industrial layout of international markets, focusing on China, India, Indonesia and Turkey. With an annual production capacity of 5,000 electronic jacquard machines(jacquard sets) and 360,000 monthly jacquard electromagnetic components, “S&S”is regarded by the industry as the most competitive electronic jacquard brand in the world.

The “S&S” electronic jacquard products have high cost performance and strong competitiveness, seeing annually doubled production and sales volume for three consecutive years. In 2018, the sales revenue reached about 340 million RMB, and the production and sales volume ranked No.1 in the world. Its high-end jacquard products enjoy a high market share over 70%, covering 30 countries and regions such as China, India, Vietnam, Pakistan, Turkey, etc.

In regard to technological innovation, the company has been always committed to independent research and development.“Technology is the first productivity of enterprise development”. S&S Intelligent Science and Technology, as a national high-tech entity integrating R&D, production, operation and service of high-end jacquard weaving equipment and its key components, has more than 40 authorized patents, including 10 invention patents and 3 software copyrights. It enjoys the strongest independent innovation ability and the most core patent technologies in Chinas jacquard weaving field.

Adhering to the enterprise tenet of“user-experience-improvement centered”, S&S Intelligent Science and Technology always implements the concept of “Super Service”. In product design, according to the current market demand, it constantly updates the design and provides marketleading products at any time from the longterm development. The full range of electronic jacquard machine products can meet various needs of different markets.

Product highlights

Especially in recent years, in response to the development of textile market towards high warp density, large quantities of needles and high value-added products, S&S Intelligent Science and Technology has successfully developed electronic jacquard machines with large needle number, and the maximum number of needles can be more than 38,000 at present;

In view of the low-speed rapier looms in India, the economically affordable SA5 and SE5 were introduced, which are featured with flat open weaving, without small draw-bar bearing mechanism, more compact structure, high reliability, stability & cost-effectiveness, lower investment, and higher return. The newly launched SE5 also adopts the design of wear-resistant plastic gear transmission structure. Compared with steel gear transmission, it is characterized by light weight, low inertia, low noise, selflubricating and corrosion resistance, and is more suitable for the weaving environment in the Indian market;

SDLX double-sided conjugate cam jacquard machine, the worlds first jacquard machine driven by double-sided conjugate cam, is featured with double-sided conjugate cam, halved force, high load, high rotation speed, and long service life;

The SEJ168H high-speed electronic jacquard machine specially designed for African fabrics has a speed of 1,000 rpm, optimizes the machine structure, and strengthens the transmission components. In addition, the low frame improves the stability, and the combination of casting and plastic is for shock absorption and noise reduction, while fully sealed operation can ensure the service life of the components;

For the wide rapier, the rotary shifting device is added on the basis of the original chain structure, and the sinusoidal curve and the cam curve are superimposed to facilitate the weft insertion.

The “S&S” electronic jacquard machines are characterized by high reliability, high efficiency and high return, winning a leading position in terms of product varieties, stability and market share. S&S Intelligent Science and Technology will create a five-in-one service model featured by“localization”, “technology-based”, “high efficiency”, “full range” and “one-stop”, and will continue to build efficient localized service teams around the world to further improve service efficiency and restore the user site in the first time.

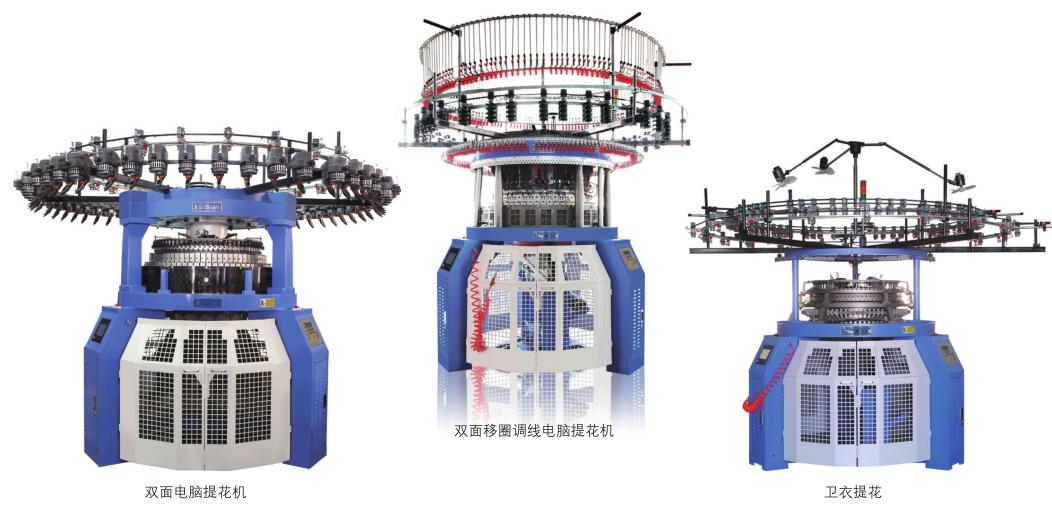

江蘇润山:力推五款针织机

Jiangsu Runshan: Focusing on five knitting machines

江苏润山将重点推出RSDT-SXTH 双面电脑提花机(两面提花)、RS-S/K双面开剖机、RSDT-D/W3 三线卫衣提花机、RSDT-S双面电脑提花机、RSDT-TXYQ 双面移圈调线提花多功能机等五款提花针织装置。

RSDT-SXTH 双面电脑提花机(两面提花)上下针筒均采用8段电子选针系统,USB花型输入接口,操作简单;可编织出两面都带有花型的面料,能省去服装加工后整理的复合工序。可应用于高档服装面料,围巾、床上用品等。另外可根据客户要求改良成高机脚,满足厚织物大卷装需要。

RS-S/K双面开剖机采用全新创意设计及超高精度的安装校准要求,完全经由先进的设计软件和CNC处理,领先同行业设计水准及设计环境,强调机台整体结构稳定性及各部件的配合精度要求,使织出布面高度平整,无隐横条、阴阳板等缺陷,适用于瑜伽、运动等高档服装面料。

RSDT-D/W3 三线卫衣提花机采用智能化电脑选针系统,通过花型设计可编织各种带花型的运动、休闲等三线卫衣面料。通过变换三角等部件,可以编织各类单面提花面料,及网眼提花面料。

RSDT-S双面电脑提花机技术性能经中国纺织工业联合会鉴定为国际先进水平。采用全新创意设计及超高精度的安装校准要求,完全经由先进的设计软件和CNC处理,领先同行业设计水准及设计环境,强调机台整体结构稳定性及各部件的配合精度要求,可织出超薄高密度提花面料,适用于高档提花羊毛衫、T恤、男女西装、运动服等提花面料。

RSDT-TXYQ 双面移圈调线提花多功能机技术性能经中国纺织工业联合会鉴定为国内先进水平。本机是一款多功能一体机,在电脑提花系统中增加选色系统,并加装调线头,同时实现移圈、调线、提花功能,能够编织具有横条纹、网眼、凹凸感等特殊视觉效应的面料,增加氨纶装置,可随心所欲的编织各种花型用于休闲和t恤面料。

自主研发的调线头,已获得多项发明专利,功能上突破解决了普通调线头存在的缺陷。

Jiangsu Runshan mainly promotes RSDT-SXTH computerized double jacquard knitting machine (dial and cylinder both jacquard), RS-S/K double jersey machine open width, RSDTD/W3 computerized three fleece jacquard knitting machine, RSDT-S computerized double jacquard knitting machine, RSDT-TXYQ computerized transfer rib jacquard with auto striper machine (multifunctional).