智能化 短流程

2019-12-04

当前,纺纱设备的智能化、连续化、短流程趋势越来越明显。智能化设备不仅将人从繁重的体力劳动以及恶劣的工作环境中解放出来了,而且还会减少人工使用量,提高生产效率,提高产产品的质量。

短流程也是今后的一个发展趋势,其市场需求会越来越大。全自动转杯纺、涡流纺设备将被越来越多的客户接受,转杯纺自动接头成功率和接头效率将进一步得到提升,涡流纺纺纱锭差得到进一步解决。

Intelligence, Short process

At present, the trend of intelligent, continuous and short process of spinning equipment is becoming more and more obvious. Intelligent equipment frees people from heavy manual labor and harsh working conditions, and also reduces workers usage, and improves production efficiency and quality of products.

The short process is also a development trend in the future, and its market demand will become larger and larger in order to achieve this goal. Traditional spinning equipment will have as many connections as possible in different processes.

Fully automatic rotor spinning and vortex spinning equipment will be accepted by more and more customers. The success rate of rotor spinning automatic joints and joint efficiency will be further improved, and the difference of vortex spinning spindles will be further solved.

布雷克、格拉夫、諾维巴、丝丝姆及绪森倾力呈现立达系统解决方案互动展出

Br?cker, Graf, Novibra, SSM, Suessen at ShanghaiTex 2019

2019上海纺机展,立达专件将携五大品牌布雷克、格拉夫、诺维巴、丝丝姆及绪森在其联合展台上展示众多创新成果。立达也将展出自己系统化解决方案。

布雷克创新之作

布雷克将展出全新钢丝圈产品CARBO碳菁钢丝圈,该新产品拥有50%的更长使用寿命和更短的磨合期,而这仅仅是布雷克众多卓越展品的亮点之一。CARBO碳菁钢丝圈专门为人造纤维纺纱设计,它运用了一种全新的涂层技术,可改善钢丝圈滑行性能,使用寿命延长50%,磨合期缩短。推荐应用于人造纤维及其混纺以及包芯纱的纺制,纱线支数不限。

此外,布雷克还将展示其著名的优质系列产品,可以满足纺织市场对纺纱速度和产能不断提升的需求,布雷克钢领和钢丝圈使用寿命长,纱线断头率低,在加工人造纤维时不会造成热损伤。

格拉夫连续推陈出新

格拉夫将推出三款新产品:使用寿命延长30%的新型梳棉针布,高度可调的精梳锡林以及对梳棉针布管理切实有效的解决方案。

● MULTISHARP 应用了独特的耐磨合金,可将锡林的金属梳棉针布的使用寿命最多延长30%。此外,得益于其更长的使用寿命和更少的计划外停机,团队的工作量得以最小化。

● 由于新型精梳锡林的高度无极可调,在满足质量要求的前提下可以提高产能,在每个单独的精梳单元上,钳口和圆梳之间连续且精确的隔距设置为客户带来更高的原料利用率。另外,圆梳易于安装,为维护人员提供了便利。

● 梳棉针布管理方案可以降低总体投资成本,这是基于最大限度减少用于优化设备总体效率等运营费用的解决方案。在确保整个针布生命周期内质量参数满足要求的前提下,格拉夫的针布管理方案可以将弹性盖板针布使用寿命延长三倍。

诺维巴对高速和节能的执着追求

● 节能锭子LENA专为高速纺纱和更低能耗而设计。它是市场上唯一一款锭盘直径为17.5 mm的锭子,平均节能高达6%。

● 新一代的夹纱冠CROCOdoff 龙牙和CROCOdoff Forte低支纱龙牙实现了真正的无管底卷绕落纱。夹纱冠自动运行和匹配锭子转速。由于落纱后的断头率低,并且管底区域清洁工作量得以最小化,夹纱冠拥有显著降低维护成本的突出优势。

诺维巴的目标是为客户带来有益的定制解决方案,以帮助他们保持市场领先地位。诺维巴期待与客户就新产品进行深入探讨,以够满足市场上日益突出的节能和降低维护成本的需求。

SSM 缔造完美卷装的最新贡献

● 有了精密卷绕络筒机PWX,SSM将使纱线染色者获得成功。只需对市场趋势的快速反应和具有成本高效的性能,就能使染纱企业获得竞争优势,取得成功。带上油或不带上油的精密卷绕络筒机,为长丝和短纤纱的松式络筒和倒筒带来明显的优势。

● 在XENO- 平台上,SSM首次展出了全球绝无仅有的自调节背压力系统:preciforce?精密背压力系统,使其卷装的一致性得到保证。此外,下一代的拨片卷绕powerblade?劲动拨叉将会应用在XENO-平台上。

緒森新品,重磅出击

绪森将展示具有高度灵活性的全新紧密纺装置,新型摇架和优质的转杯纺专件,以确保优异纱线质量。

● COMPACTeasy是一款新型机械式紧密纺装置,其即插即用模块设计可应用于任何类型的细纱机,适用于棉,人造纤维和混纺纱等最常见的应用。COMPACTeasy是无需额外能耗的紧密纺解决方案。

● 新型倚丽特是一款集成了创新组件的通用型紧密纺系统,它为客户带来更高的生产率,更佳的纱线质量和更低的运营成本。升级改造包和备件包将使客户的现有设备从中受益。

● 应用于粗纱机的新型摇架HP 4080拥有全新设计,可简化设置并提高稳定性,同时,确保整个使用周期内纱线质量的一致性。

● 关于优质转杯纺专件,新型针环SOLIDRING B 188拥有更短且更高效的齿形,以改善纤维开松并最终提高纱线质量。对于半自动转杯纺纱机,新的纺杯设计以及带凹槽的螺旋阻捻头能改善纱线质量并增强低级棉的可纺性。

立达系统解决方案

根据不同客户需求定制化系统解决方案:立达确保纺纱厂一直保持极高生产效率和强大竞争优势。在本次展览会上,立达将从实用角度出发,以触控电子屏幕互动的方式展示四种纺纱流程,涵盖环锭纺纱机G38、紧密纺纱机G38(最新的立达紧密纺装置)、转杯纺纱机R 70、喷气纺纱机J 26。

At forthcoming ShanghaiTex 2019 (Nov. 25-28), Rieter components with its five brands Br?cker, Graf, Novibra, SSM, Suessen will unveil tremendous innovation on their joint booth. Visit us at Hall E1, A 30.

A novelty from Bracker

Br?cker presents a new traveller with up to 50% longer lifetime and shorter running-in period. This is only one highlight out of the impressing product variety.

A novelty Br?cker shows at ShanghaiTex is the new CARBO traveller for ring spinning machines. It is specially designed for man-made fiber spinners. CARBO is a new coating technology which improves the sliding properties. This results in up to 50% longer lifetime and a shorter running-in period. Recommended applications next to man-made fibers are also their blends, core yarns and all yarn counts.

In addition, Br?cker exhibits its well-known portfolio of highquality products which meets the continually rising demands on the textile market like higher speeds and productivity. The rings and travellers offer long service lives, lowest yarn breaks and no thermal damages when processing man-made fibers.

Continuous Innovations from Graf

Graf introduces at ShanghaiTex three novelties for the textile market: a new card clothing with up to 30% longer lifetime, a height adjustable comb and a helpful solution for card clothing management.

MULTISHARP, the unique wear resistant alloy for card clothings, increases the lifetime of metallic card clothings on the cylinder by up to 30%. Additionally, the work load of the maintenance team can be minimized by providing longer service cycles and less unplanned downtimes.

The yield on raw material can be increased without compromising the quality requirements – thanks to the continuous height adjustability of the new combs series. The continuous and exact gap setting between nipper and circular comb on each individual combing head provides customers a new level on raw material utilization. Additionally, the maintenance people will appreciate the comfortable and easy installation of the circular comb.

With the card clothing management the overall investment costs can be reduced. This is based on minimizing the operational expenses including optimizing the overall equipment effective-ness. Grafs card clothing management prolongs the lifetime of flexible flats by up to three times without comprising on the quality parameters throughout the entire life cycle.

Novibra persistent pursuit of high speed and energy saving

Novibra presents the latest innovations in spindle technology and energy saving measures at the forthcoming ShanghaiTex.

The energy saving spindle LENA has been designed for the highest speeds and lower energy consumption. It is the only spindle in the market with 17.5 mm wharve diameter and energy savings in the average of up to 6%.

The new generation of clamping crowns CROCOdoff and CROCOdoff Forte introduce genuine doffing without underwinding. The crowns work automatically depending on the spindle speed. The major advantages are significant reductions in maintenance costs. That is based on a lower ends down rate after doffing and minimized cleaning of the underwinding area.

Novibras goal is to bring beneficial and customized solutions to the customers helping them to keep their leading position in the market. Novibra is looking forward to discussing the new products that fulfil one of todays biggest demands for energy savings and maintenance costs reduction.

SSM Latest contribution on perfect package

At ShanghaiTex SSM presents solutions for precision package winding and high package consistency and provides a wide range of renowned textile machines.

SSM enables yarn dyers to be successful – with the precision package winder PWX. Only a quick response to market trends in combination with high costefficiency enables customers to be competitive. The winder offers clear benefits to dye package winding and rewinding of filament and staple fiber yarns, with or without lubrication.

For the XENO-platform SSM presents the first and only self- regulating backpressure system in the world: preciforce? for a guaranteed package consistency. Furthermore, the next generation of the blade winding powerblade? will be introduced for the XENO-platform.

Besides the displayed applications, SSM provides a wide range of renowned textile machines.

Everything is new from Suessen!

Suessen presents the new compacting devices for high flexibility, new weighting arms and premium rotor spinning components for excellent yarn quality.

COMPACTeasy is the new mechanical compacting device available as a plug-on/plug-off unit for any ring spinning machine type and suitable for most common applications like cotton, manmade fibers and blends. COMPACTeasy is the solution in compacting without additional energy requirement.

New EliTe is a versatile compact-spinning system with new innovative components. The customers profit from higher productivity, better quality and lower operational costs. Upgrade packages and spare parts packages enable the customers to benefit also on existing installations.

The new Top Weighting Arm HP 4080 for roving frames offers a new design for easy settings and improved stability. In addition, consistent yarn quality over the lifetime is guaranteed.

Regarding premium parts the new SOLIDRING B 188 for rotor spinning machines offers a shorter and more aggressive saber tooth shape for better fiber opening and finally improved yarn quality. For semi-automated rotor spinning machines a new rotor cup design and fluted and spiral navels improve the yarn quality and enhance the spinnability of low grade cotton.

See for yourself the many advantages on offer from Br?cker, Graf, Novibra, SSM, Suessen. Visit us at ShanghaiTex from November 25 to 28, 2019, in the New International Expo Centre: Hall E1, Booth A30.

太平洋科技:智能化产品效率更高

Pacific Electromechanical Group: Intelligent products see higher efficiency

本次展会上,太平洋机电集团(上海)科技有限公司将展出PTZM1702细纱机智能在线监测系统、智能平台功能等智能化产品。

PTZM1702细纱机智能在线监测系统的特点主要表现在:单锭检测,反应灵敏,可选配背磁式或光电式两种探测方式;粗纱自停,2秒响应,可选配氨纶丝断裂自停装置;提高原料制成率,降低能耗,减少用工;智能物联网数据系统,服务用户,可定制化设计;免打孔方式,适应市场各种细纱机安装;降低细纱机生产成本,系统投资回收期1年左右。

智能平台功能:通过现场总线技术,连接所有机台,形成在线大数据库,建立专家分析系统,实现有效质量追溯。通过数据处理,实时计算单锭生产效率,针对性定位故障分析,完善生产考核与管理。可建立网络,或联入企业局域网,使管理层在线實时监控,并可推送到移动端,提升企业管理效率;同时可以实现远程诊断,快捷售后服务。

During the exhibition, Pacific Electromechanical Group (Shanghai) Technology Co., Ltd. is to exhibit its intelligent equipment, such as PTZM1702 intelligent on-line monitoring system for spinning frame and intelligent platform functions.

The main features of PTZM1702 intelligent on-line monitoring system are: Single ingot detection, sensitive response, possible to choose two detection methods: back magnetic or photoelectric; Automatic stop of roving, 2-second response; Optionally, it can be equipped with spandex fiber breaking stop device; Improve raw material production rate, reduce energy consumption and labor consumption; The intelligent Internet of things data system serves users and can be customized; No punching; Suitable for all kinds of spinning machines in the market; Reduce the production cost of the spinning machine, and the system investment recovery period is about one year.

The intelligent platform functions include: Through the field bus technology, connect all machines, form a large online database, establish an expert analysis system, and achieve effective quality traceability. Through data processing, real-time calculation of single spindle production efficiency, targeted fault analysis and improvement of production assessment and management. It can establish a network, or connect to the enterprise LAN, make management online and real-time monitoring, and push it to the mobile terminal to improve the efficiency of enterprise management; at the same time, it can realize remote diagnosis and fast after-sales service.

天门纺机:主打三款设备

Tianmen Textile Machinery: Mainly exhibiting three types of equipment

本届展会上,天门纺机将展出TM5263E型细纱机、TM3809Y和TM3817S并条机。

TM5263E是针对目前市场对高品质、高效率、节能降耗、稳定可靠减少维护等生产需求,而开发的新型全电环锭细纱机,产品从2016年底开发完成后,经过实际批量生产验证多次优化完善,目前已形成第三代成熟产品,拥有10多项自主专利,整机水平达到国内领先,部分独创技术达到国际领先水平,产品已经形成了稳定的批量生产和销售。

主要性能特点:超长锭数,单车头型最长可达1440锭,双车头型最长可达2016锭;高速高效,实纺锭速22000RPM. 独具的10点锭速曲线控制,确保机器在整个纺纱过程中以最高速度进行纺纱生产;新型纺纱断面提高了纺纱质量,减少纺纱断头,紧密纺的配套更加方便;电子加捻,捻度可直接在操作屏幕上设置和调整,精密的电子加捻控制系统,可纺制高捻纱;电子牵伸,多个伺服电机分别驱动前、中、后罗拉,总牵伸倍数、后区牵伸倍数等纺纱参数均可在操作屏幕上设置,智能化的程序控制使牵伸的同步性配合达到完美,提高了牵伸精度,保证了优良的纱线质量以及更少的纺纱断头;集体落纱,可配套乱管自动理管系统,稳定可靠的集体落纱确保每次落纱插拔管率100%,落紗停台时间不超过3分钟,留头率98%以上;双头吸风、直联永磁主电机等,使整机节能20%以上,断头吸棉和紧密纺吸风均采用双头吸风,可有效降低能耗,并且均衡了整机负压;配套H级耐高温等级的永磁同步主电机,保证了电机的使用寿命,极大降低了整机能耗;配套单锭检测、粗纱自停装置;配套零尾纱锭子;可选配模块化的三罗拉或四罗拉紧密纺装置;可粗细络联;可机台联网控制以及物联网,实现工艺换批的快速和安全性、设备数据和纺纱数据的统计分析、远程维护等。

TM3809Y和TM3817S是天门纺机新近开发并推向市场的大圈装并条机。与传统设备相比,这两种机型能有效减少断头,节省人工。TM3809Y是带自调匀整的高速并条机,输出最大条筒为 600×1200;TM3817S是重不匀数字调节的普通并条机,输出最大条筒为 1000×1200。

这两种机型,有以下几个特点:电子断条,多备筒配置,保证设备的连续运行;带传动的广泛运用,气撑恒力张紧,增加了传动的柔韧性;两眼分开传动,上下圈条独立传动,利于高速;吸风系统中间布置,风道独立,风量均衡,大小可调;非接触的在线监测,可以实现设备的远程控制;免加油皮辊随摇架整体起落,自动生头,减轻了操作工的劳动强度;设置定点加油专区,避免油脂污染皮带。通过二年多时间的市场运作,两种机型均已形成稳定的市场规模,逐渐成为公司的拳头产品。

At this exhibition, Tianmen Textile Machinery will exhibit the TM5263E spinning frame, TM3809Y and TM3817S drawing frames.

TM5263E is a new all-electric ring spinning machine developed for the current high-quality, high-efficiency, energysaving and consumption-reducing, stable and reliable maintenance, etc. After the development at the end of 2016, the product has been verified by actual mass production. It has been optimized and perfected many times. It is now the third generation of mature products, with more than 10 independent patents. The whole machine level has reached the domestic leading level, and some original technologies have reached the international leading level. The products have been stably mass-produced and sold.

Its main features: the maximum spindles of single headstock is up to 1,632, the maximum spindles of double headstock is up to 2,016; actual speed of spinning is up to 22,000 rpm; the integral frame, the new cross section; the intelligent electronic lift; the intelligent electronic draft; the intelligent doffing and automatic bobbin feeding; double-head suction and new energy-saving compact spinning; save energy up to above 20%; new innovative efficient drafting system; with single-spindle detection and spindle with yarn gripper; can be combined with roving machine and winding machine. The machine can be connected to the network and the Internet of Things to realize the rapid and safe process batch change, statistical analysis of equipment data and spinning data, and remote maintenance.

The TM3809Y and TM3817S are the drawing frames that Tianmen Textile Machinery has recently developed and put into market. Compared with traditional equipment, these two models can effectively reduce breaks and save labor. TM3809Y is mainly characterized by double uster UQA autoleveller, delivery sliver can (dia. x height) is 600 × 1,200. The TM3817S is an ordinary drawing frame with the uneven weight of digital adjustment function, delivery sliver can (dia. x height) is ? 1,000×1,200.

These two models are summarized with the following features: automatic can-changer with multiple empty cans supplier and electronic sliver breaking system; fixed injecting oil positions designed on the headstock and tailstock are to prevent synchronous belts from contamination of grease; the upper and bottom coilers are driven by servo motor independently; synchronous belt utilizes constant strength to support tensioning; independent air duct, balanced air volume, adjustable size; leather roller with the cradle ups and downs, greatly facilitate the operation; pre-set central intranet interface is to realize remote diagnosis of malfunction. Through more than two years of market operation, the two models have formed a stable market scale, with a total production and sales of more than 50 sets, and gradually become the companys leading products.

金輪针布:多款展品聚焦高效高产

GERON Card Clothing: A variety of exhibits focus on high efficiency and high yield

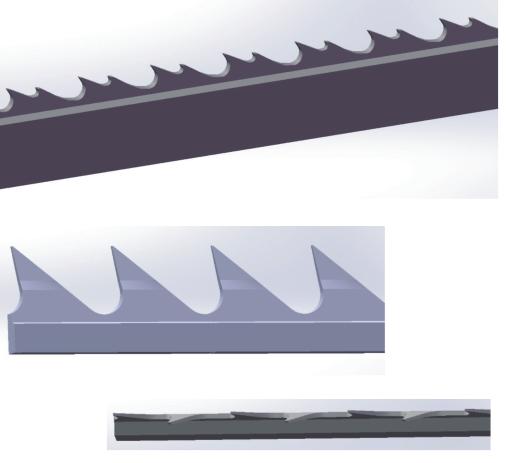

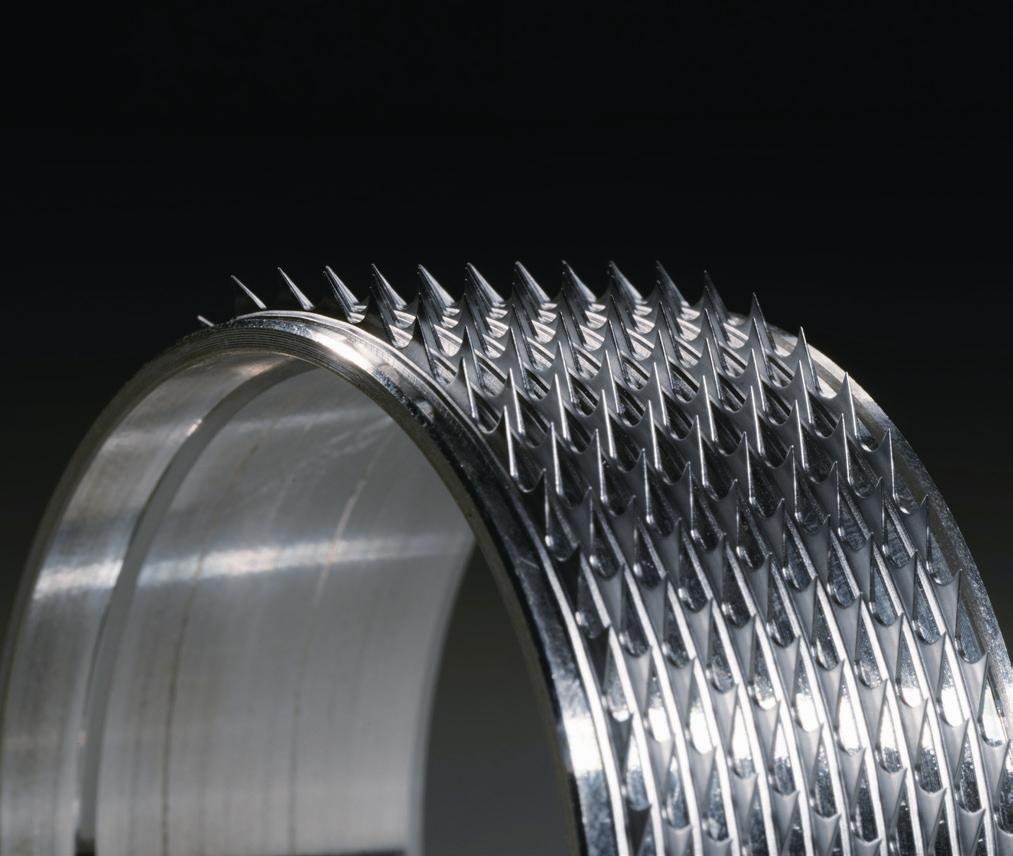

本届展会上,金轮针布带来了双峰锡林针布、清洁道夫针布、错位锡林针布、错位锡林针布、高效刺辊针布、MCBH40/S弹性盖板针布、MCH52/B弹性盖板针布、130度棉精梳机整体锡林系列产品特点、双联固定盖板等产品。

双峰锡林针布是专门为棉纺领域所有流程而研发的(纺棉专用),显著提高纤维“一次分梳”力,独特的齿形设计结构有利于纤维的分梳、交替和转移等作用, 能显著降低棉结;并且是提高效率(同等条件下10%~25%),降低能耗的绝佳选择。

該针布是针对高产环锭纺棉(齿密1190)32~60支纱线、高产气流纺纺棉(齿密950)32支以下清梳联梳棉机的最佳选择。

清洁道夫针布采用特殊的表面处理工艺,切口及表面光洁,能显著提高道夫转移能力,提高棉网质量。适用于高速高产场合。

错位锡林针布的针尖在基部的长度方向上呈错位排列,能有效降低针齿横向的相对间隙,有效增加细小纤维束在梳理过程的分梳几率,提高分梳质量,降低纤维损伤,提高生条质量;适用于生产细号纱和特细号纱的生条梳理。

高效刺辊针布具有一定倾角,使刺辊梳理纤维时改变了现有锯齿采用侧角梳理的弊端,使锯齿采用完全正面迎锋面梳理,不仅能够有效提分梳质量,而且还能最大化降低对纤维的损伤。适用于嵌槽刺辊使用。

MCBH40/S弹性盖板针布的工作角、针尖密度、植针组织参数,根据纤维性状和梳理工艺通过盖板针布理论数学模型建立设计。植针排列结合纤维梳理通道呈渐进稀密分布,减少纤维损伤,使纤维伸直度得到进一步加强,是专为环绽纺普梳或精梳开发的,可应用于化学纤维1.33~1.67dtex的梳理,是生产60支以下纱线并实现高产的最佳选择。

MCH52/B弹性盖板针布是基于皮马棉长度长、细度细、纤维加工过程中易出现扭结,并次生棉结的情形设计研制的专用盖板针布,产品更利于梳棉工序实行“轻定量、慢速度、强分梳”的工艺;适用皮马棉80~120支的纺纱,棉结去除率提高30%。

130度棉精梳机整体锡林系列产品特点:适用于高速高产需求,齿面圆心角在112度的基础上增加18度,能有效满足小卷定量75~80g/m,速度450~500钳次/分的高速高产精梳机配套使用;高质量、低落棉。满足用户高质量要求。锡林总齿数达62000齿以上,梳理更充分,质量指标提升20%以上;7分割的梳理齿条排列,齿条密度分布均匀,齿密变化更缓和,前排穿刺开松更充分,有利于纤维的柔性梳理,减少对纤维的损伤,降低落棉率,为用户更好地节约成本。高适纺性。130度系列整体锡林产品齿条采用模块化设计,齿条可通过互换组合系列密度配套形式,分别适合中短纤维、中长纤维和特长纤维的梳理需求,适纺性强。

双联固定盖板结构适用于JSC326、JSC330(SC60)、JWF1204、JWF1206、JWF1211、JWF1213、DK903、TC11、TC15、C60等高产梳棉机的固定盖板配套,使用的齿条为双排稀密型带夹角的结构齿条,满足齿距、齿密从稀到密的梳理原理,较单联产品增加了一倍的梳理点,提高纤维的梳理效果、成纱质量。

At this exhibition, GERON Card Clothing brings double-peak cylinder clothing, cleaning doffer clothing, misplaced cylinder clothing, high-efficiency roller clothing, MCBH40/S fillet flat clothing, MCH52/B fillet flat clothing, 130-degree cotton combing machine overall cylinder series product features, double fixed flat and other products.

Double-peak cylinder clothing: specially developed for all processes in the field of cotton spinning, significantly improving the “one-time carding” force of the fiber. The unique toothshaped design structure can facilitate the carding, alternation and transfer of fibers, which can significantly reduce the nep. It has an excellent choice to improve efficiency (10% to 25% under the same conditions) and reduce energy consumption. Applicable occasions: it is the best choice for the blowing-carding machine for the ring-spun spinning of 32 - 60-count yarns and rotorspun spinning of less than 32-count yarns.

The cleaning doffer clothing adopts a special surface treatment process, and the incision and the surface are smooth, which can significantly improve the transfer ability of the doffer and improve the quality of the cotton net. It is suitable for high speed and high production occasions.

The needle tip of the misplaced cylinder clothing is in misplaced arrangement in the length direction of the base, which can effectively reduce the relative gap of the lateral direction of the needle teeth, effectively increase the combing probability of the fine fiber bundle during the combing process, improve the combing quality, reduce the fiber damage and improve the sliver quality; it is suitable for sliver carding of fine yarn and super fine yarn.

The high-efficiency roller clothing has a certain inclination angle, which makes the thorn roller comb the fiber and changes the disadvantages of the existing serration using the side corner combing, so that the serration adopts the full frontal face combing, which can effectively improve the comb quality and minimize the fiber reduction the damage. It is suitable for use in grooved lickers.

MCH52/B fillet flat clothing: it is specially designed and developed based on such features of pima cotton as long length, fineness, and easy twist for nep. It is more conducive to the “light weight, slow speed, and strong carding” in carding process. Scope of application: for the 80 -120 count spinning of pima cotton. The removal rate of the nep is increased by 30%.

The double fixed flat structure is suitable for the fixed flat of JSC326, JSC330 (SC60), JWF1204, JWF1206, JWF1211, JWF1213, DK903, TC11, TC15, C60 and other high-yield carding machines. The racks used are double-row and dense. The structural rack with angle is suitable for the carding principle of tooth pitch and tooth density from thin to dense, which doubles the carding point compared with the single product, and improves the combing effect and yarn quality of the fiber.

环球集团:为客户提供最适合的自动包装方式

Qingdao Hicorp Group: Providing customers with the most appropriate packaging system

历经五十年光辉发展历程,青岛环球集团用一颗胸怀天下、包容世界的“环球心”,成长为“中国智造”企业的优秀代表。 青岛环球集团股份有限公司,地处胶州湾西岸国家级经济新区——青岛西海岸新区,靠近国际空港流亭机场和青岛前湾港、董家口港,地理位置优越。

半个世纪来,环球人积极践行“以客户为中心,用创新引领行业先锋”的核心价值理念,注重技术创新,加快提升企业核心竞争力,不断提升产品的科技含量。集团拥有国家企业技术中心、国家认可实验室,不断加快技术创新步伐,先后被授予国家火炬计划重点高新技术企业、国家高新技术企业、国家级“守合同 重信用”企业、山东省优质产品生产基地龙头骨干企业等荣誉称号,成为中国专利山东省明星企业,荣获国家专利187项,国家授权发明专利21项,荣获部、省级科技进步奖52项,有22种机械产品被认定为国家重点新产品。

在全球经济一体化发展的新时期,团结拼搏、学习创新的环球人正在用一颗包容天下、胸怀世界的环球心,竭诚为全球客户推出蕴含中国智的优秀产品,与国内外朋友携手共创双赢互惠的美好未来。

本屆展会,青岛环球集团将隆重展出纸箱侧入式自动包装线、智能配重系统等筒纱智能包装物流系列产品。目前青岛环球集团可以实现编织袋,纸箱,热缩膜,托盘等多种包装形式,可为环锭纺,气流纺,涡流纺,喷气纺等客户提供最适合的自动包装方式。

筒纱智能包装物流系统(纸箱包装),采用立式开箱/卧式开箱(可选),筒纱可以采用2x3、3x3、3x4排列,筒纱直径为170~240mm(立式),170~300mm(卧式),纸箱最大700x490x700mm(立式),特殊可定制;纸箱最小500x350x-350mm,特殊可定制;装箱层数为2~4层;装箱方式为立式装箱/卧式装箱(可选),采用自动封箱方式;光电胶带检测,胶带宽度48、60(常规)、72mm,可自动漏纱检测。

筒纱智能包装物流系统(智能配重系统)适应范围为12或15/组,配重精度±50克/组,配重模式9选N,模式为纺大小纱/标准纱;筒纱直径为170~300mm。

Qingdao Hicorp Group has a glorious history of 50 years and strides ahead to become the industry manufacturing leader with a global vision and an outstanding manufacturer with the“Chinese Intelligence”. Qingdao Hicorp Group is located in Qingdao Economic and Technological Development Zone, and close to Liuting International Airport, Qingdao Qianwan Container Terminal and Dongjiakou Harbor. It is of great geographical advantage: ocean transport, land transport and air transport are all very convenient.

For half a century, with the core values of “Learning, creating and pioneering”, Hicorp Group promotes the core competitiveness of the enterprise, improving science and technology of products continuously. The Group has provincial technology center, national recognized testing laboratory, awarded as national high-tech enterprises, national torch plan key high-tech enterprise etc., becoming Chinas patent Shandong star enterprise, wins 187 national patents, 21 national authorized invention patents, 52 scientific and technical progress reward of department & province, with 22 mechanical products recognized as key new products by the nation.

During the new period of integration with the global economy, united, hardworking, learning and innovational Hicorp people is co-creating the win-win future with friends at home and abroad with “Chinese intelligence, Hicorp confidence”.

During the exhibition, Qingdao Hicorp Group will display a series of intelligent cone packaging logistics system, such as carton side-entry automatic packaging line and intelligent counterweight system. At present, Qingdao Hicorp Group can realize various packaging forms such as woven bags, cartons, heat shrinkable film, trays, etc. It can provide the most suitable automatic packaging methods for customers such as ring spinning, rotor spinning, vortex spinning and air jet spinning.

Intelligent cone packing logistic system (Carton)

Carton unpacking mode: vertical / horizontal (optional);

Array: 2*3, 3*3, 3*4;

Cone dia.: 170 – 240 mm (vertical) , 170 – 300 mm (horizontal);

Max carton size: normally 700*490*700 mm (vertical), special customizable;

Min carton size: 500*350*350 mm, special customizable;

Layer in carton: 2 - 4 layer;

Loading mode: vertical / horizontal (optional);

Seal mode: automatically;

Tape detection: photoelectric;

Tape width: 48, 60 (normal), 72 mm;

Tape rear control by small airflow;

Missing cone detection: automatically;

Intelligent counterweight system in cone packing logistic system

Suitable range: 12 PCS or 15 PCS/group;

Counterweight accuracy range: ± 50g/group;

Counterweight mode: select N from 9 PCS;

Mode: spinning over weight cone/standard cone;

Cone dia.: 170 – 300 mm.

長岭纺电:依靠科技创新 打造纺织智能设备

Changling: Relying on technologicall innovation to create textile intelligent equipment

本届展会上,长岭纺电将展出CA182喷气织机、XJ128A快速棉纤维性能测试仪、XJ129PRO棉结和短绒率测试仪、CT4000条干均匀度测试分析仪等设备和測试仪器。

CA182以高车速、高品质、智能化为设计指导思想,有着丰富的配置和多样的附加配置可选项,根据国内外喷气织机的发展趋势,结合国内喷气织机现状,研制开发的机型达到ZAX机型性能,并具有长岭纺电特色。

全新CA182喷气织机采用金属模、消失模有效提高铸件质量,优化结构设计,车速可达850转/分,较CA082织机转数提高20%;空气消耗量下降10%,地面振动较CA082织机下降35%;PZK600系列电控系统箱体对各单元板重新优化,降低电控箱成本;可选配智能化装置,APR自动纬纱修补装置,气动折入边装置、电子剪纬装置、WBS纬纱制动装置、FDP-V型储纬器;CA182采用智能化电子网络系统,直接在I-Board屏幕上进行多臂花色编辑、FDP自由选色花色编辑,调车工艺指导,后梁张力实时数据曲线、探纬实时数据曲线均可显示。

CT4000条干均匀度测试分析仪是集光、机、电、气等技术于一体的全自动精密纺织测试仪器。它用来测试纱线的条干线密度不匀、直径大小及变化、表面毛羽丰富程度、杂质尺寸及含量等,全面评价纱线质量,是纺织企业进行质量检测和控制必备的测试仪器。

主要特点:电容式与光电式检测并举,线密度不匀(质量变异)与外观不匀(直径变异)同时测量,更加全面科学的评价纱线质量;全自动测量,自动引纱、自动换槽、罗拉自动往复;实时测量CVm%、Um%、H、SH、D、CVD%和各档疵点值;纱条牵引系统采用高速双主动机构,最高测试速度可达800m/min;提供条干和毛羽的不匀曲线图、波谱图、变异-长度曲线、线密度频率分布图、偏移率-门限图;提供杂质测试功能,提供杂质尺寸及分布、杂质含量等指标;波谱图采用170个频道,更加有利于用户准确判断故障或缺陷部位;配有三维织物仿真系统,自动绘制纱线轮廓图、电子黑板以及机织物、针织物效果图,织物组织结构可以任意设定;配有专家分析系统,对各道工序进行自动诊断和分析。

XJ128A 快速棉纤维性能测试仪是一种快速、大容量、多指标的棉花纤维性能综合测试仪器,它集光、机、电、气和计算机等技术于一体,能快速检测出棉花纤维的长度、强度、马克隆、色泽和杂质性能,给出平均长度、上半部平均长度、整齐度指数、短纤维指数、比强度、伸长率、最大断裂负荷、马克隆值、成熟度指数、反射率、黄色深度、色泽等级、杂质粒数、杂质面积百分率、杂质等级和纺纱一致性指数等指标。对棉检部门客观、公正地评价棉花品质、指导棉纺企业配棉、合理利用棉花原料,具有十分重要的意义。

XJ129PRO棉结和短绒率测试仪是一种快速自动测量原棉或棉条的棉结数量及短绒含量的仪器,同时能给出棉结分类及有效长度,主要适用于纺织企业、棉检部门、棉花贸易机构、棉花育种部门及科研院所等需要测定棉花棉结及短绒率指标的部门。

At this exhibition, Changling Textile Mechanical & Electronic Technological Co., Ltd. will exhibit equipment and test instruments such as CA182 air jet loom, XJ128A rapid fiber tester, XJ129 PRO nep and short fiber tester, CT4000 eveness tester.

CA182 is designed with high speed, high quality and intelligent design. It has rich configuration and various additional configuration options. According to the development trend of domestic and foreign air jet looms, combined with the status quo of domestic air jet looms, the developed models reach ZAX model performance, and has the characteristics of Changling Textile Mechanical & Electronic Technological Co., Ltd.

The new CA182 air jet looms use metal molds and lost molds to effectively improve the quality of castings and optimize the structural design. The speed can reach 850 rpm, which is 20% higher than that of CA082 loom; the air consumption is reduced by 10%, and the ground vibration is 35% lower than that of CA082 loom; the PZK600 series electronic control system cabinet re-optimizes each unit board to reduce the cost of the electric control box; optional intelligent device, APR automatic weft repairing device, pneumatic folding edge device, electronic weft cutting device, WBS weft brake device, FDP-V weft feeder; CA182 uses intelligent electronic network system to directly edit the dobby color on the I-Board screen, FDP free color selection, shunting process guidance, real-time data of rear beam tension curves and weft real-time data curves will be displayed.

CT4000 eveness tester is a fully automatic precision textile test instrument integrating light, machine, electricity and gas. It is used to test the unevenness of yarn width, diameter and change, surface hairiness, impurity size and content, and comprehensively evaluate yarn quality. It is a necessary test instrument for quality inspection and control of textile enterprises.

XJ128 rapid fiber tester (XJ128) is the latest cotton fiber performance integrative tester developed by Shanxi Changling Textile Mechanical & Electronic Technological Co., Ltd. It is featured with rapid speed, large sampling amount, and output indices. It can test length, strength, micronaire, color and trash, etc. In addition, it can tell the performances of cotton fiber within half a minute, output average length, top half average length, uniformity index, short fiber index, specific strength, extensibility, max breaking load, micronaire value, maturity index, reflectivity, yellow depth, color grading, trash numbers, trash area percent, trash grading, and spinning consistency index, etc. It can meet the need of structural reform of cotton quality detection. It is important to judge cotton quality for cotton detecting departments objectively and fairly, assort cotton for textile enterprises, understand cotton performances for cotton scientific research institution.

XJ129 nep and short fiber tester is a rapid automatic instrument of measuring nep numbers and short fiber contents of raw cotton or cotton sliver, showing nep classification and linter index at the same time. It is applied to textile enterprises, cotton testing departments, cotton trading organizations, cotton breeding departments, institutes and other units which need to measure nep and short fiber index of cotton.

光山白鲨:展出“境泉”系列针布

Guangshan White Shark: Displaying the “Jintran” series card clothing

本屆展会上,光山白鲨将展出“境泉”系列产品。“境泉”品牌是以白鲨针布创始人——张境泉先生的名字命名,先生为纺织业孜孜以求工作近四十年,表达的是白鲨人对先生的敬爱。张境泉先生研发的表面强化处理针布通过了国家鉴定,达到国际先进水平。以“境泉”命名,是对先生为纺织工业所作贡献的肯定。“境泉”针布的命名,旨在传承和弘扬张境泉先生的民族工匠精神;集中体现在对针布“针针一丝不苟,齿齿精益求精”的品质要求,领导白鲨发展、传承“拼搏奋进,尽善尽美”的企业精神。

境泉产品特点

超耐磨。采用纳米级耐磨材料进行针齿表面强化处理,使针布耐磨性能大幅提高。实验检测数据显示:针布齿尖硬度由860HV提高到1100~1300HV,其表面光滑,粗糙度Ra达到0.15m,摩擦系数μ<0.20,摩擦力降低,磨损均匀,使用寿命可达进口针布的两倍及以上,棉纤维加工量可达1800吨~2000吨。

保护纤维。通过锥齿化工艺处理,针齿棱边被处理成0.02~0.20mm不等的圆弧,齿尖圆锥型,齿体圆锥体,齿体圆润光洁。在基恩士200倍放大镜下观察,境泉表面强化处理针布齿尖犹如6m水滴,表面晶莹剔透,圆润如玉,缓和梳理中对纤维的冲击,充分实现柔性分梳,减少纤维切割性损伤,保护纤维,提高制成率,短绒率可降低0.5~1个百分点(即可节约原料5~10公斤/吨)。

降低棉结效果明显。锥齿工艺处理的金刚镀针布,齿顶面积比普通针布减少,齿尖由原来的0.09mm降至0.08mm,齿尖锋利度高,穿刺分梳性能提高。实验证明,使用境泉表面强化处理针布棉结去除率可达到90%以上。

抗腐蝕性强。将新型防腐技术与特殊工艺完美结合,大幅提高针布抗腐蚀性能。多次盐雾、湿热、酸碱等腐蚀实验表明,境泉表面强化处理针布的点蚀、片状蚀等腐蚀形态呈现不明显,可以无任何防护地裸存于常规环境中。

无磨合期(走熟期)。金刚镀针布生产中,采用锥齿化、耐磨、耐腐蚀等特殊技术和工艺,其制成后期无需进行防护处理,针布上机使用,无需进行磨合。

During this exhibition, Guangshan White Shark Card Clothing Co., Ltd. will promote the products of “Jintran” series. “Jintran”brand is named according to the name of the originator of White Shark Card Clothing - Mr. Zhang Jingquan. Mr. Zhang Jingquan has worked for nearly 40 years diligently in the textile industry. The name just expresses the respect and love of the White Shark people to Mr. Zhang. The surface strengthened treatment card clothing developed by Mr. Zhang has passed the national verification and reached the international advanced standard. With “Jintran” as the name, it is exactly the affirmation of Mr. Zhang to the textile industry. The denomination of “Jintran” card clothing is aimed at inheriting and promoting the national craftsman spirit of Mr. Zhang Jingquan, which is concentrated reflected by the quality requirements of “meticulous stitches and refined teeth” to the card clothing, thus leading the White Shark to develop and inherit the enterprise spirit of “struggling and progressing, dedication and perfection”.

Characteristics of “Jintran” products

Extremely wear-resisting. It adopts the nanoscale wearresistant materials to conduct the strengthened treatment of the stitches and teeth surfaces, so that the wear-resisting performance of the card clothing will be improved dramatically. The experimental data indicates that the tooth top hardness has been improved from 860 HV to 1,100 - 1,300 HV. In addition, it has smooth surface and the roughness Ra has reached 0.15 μm. The friction coefficient μ < 0.20. The frictional force has been reduced and the wear is even. Afterwards, its service life can be two times or more than two times of the imported card clothing. The cotton fiber processing volume can reach 1,800 tons - 2,000 tons.

Protect the fibers. Through the treatment of tapered teeth, the seamed edges of the needles and teeth are processed into the unequal arc of 0.02 - 0.20 m. The tooth tip is in pyramid type and the tooth body is in cone. The tooth body is mellow and smooth. Once being observed under Keyence 200 times magnifying glass, the tooth tines of the Jintran surface strengthened treatment card clothing are as the water drops of 6μm, with crystal and clear surface, mellow and jade-like body. It will relieve the impact to the fiber in carding, so as to fully realize flexible carding and reduce the incised damage to the fibers, thus protecting the fibers and improving the producing rate. The short fiber content can be reduced by 0.5 - 1 percentage point (save the raw materials of 5 - 10 kg/ton).

Have obvious effect of reducing the neps. The diamond covering card clothing which has been processed by the cone tooth technology has a reduced tooth crest area than the ordinary card clothing. The tooth tip has been reduced from 0.09 mm to 0.08 mm, so that the tooth tip is very sharp, thus the puncturing and carding performances have been improved. The experiment result indicates that the neps elimination rate of using Jintran surface strengthened treatment card clothing can reach as high as 90%.

Strong corrosion resistance. It integrates the new corrosion resistance technology and the special craft, so as to improve the corrosion resistance of the card clothing dramatically. After going through the salt mist, damp and hot, acid and alkaline experiments for several times, the corrosive pitting, flake corrosion and other corrosive forms on Jintran surface strengthened treatment card clothing are not obvious. Therefore, it can be naked in the conventional environment without any protection.

No run-in period (breaking-in period). In the manufacturing process of the diamond covering card clothing, the tapered teeth, wear resistance and corrosive resistance as well as other special technologies and crafts are used. After being manufactured, there is no need to conduct any protective treatment in the later period. The card clothing can be directly used on the machine. There is no need of the run-in period.

日照裕華:展出系列细纱专件

Rizhao YUHUA Machinery: Focusing on YUHUA brand series spinning components

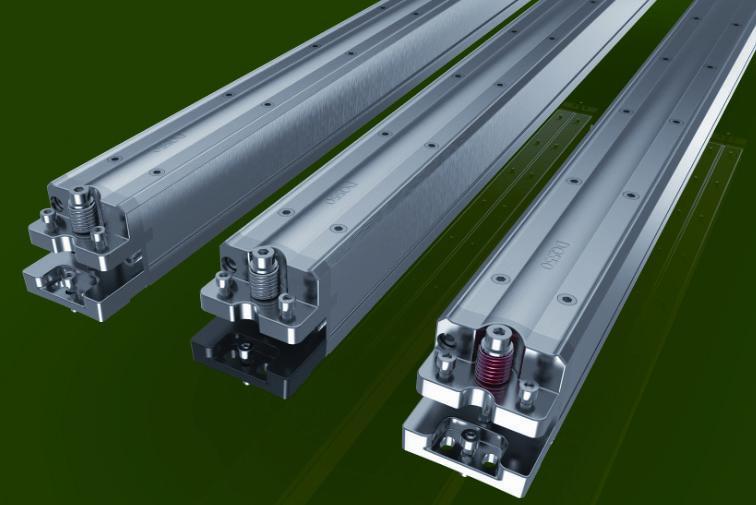

本届展会上,日照裕华机械有限公司将展出“裕华”牌系列--摇架、紧密纺和钢领。

“裕华”牌摇架自上世纪80年代末期开始研发并初具生产。截至目前,该产品已在纺织行业内达到3000万纱锭的销量。裕华牌系列摇架拥有气动V牵、气动平牵、紧密纺摇架和弹簧摇架四大类别。其中的气动摇架具有压力调节精准,高平行度等优点,多年来是众多棉纺厂的优选产品。

“裕华”牌紧密纺产品采用专用节能风机,能耗低,开放式的冷凝系统便于维护,气流反向装置便于集体排风,避免大面积断纱。通过改变纺纱工艺提高皮辊使用寿命。 合作客户(部分):恒丰集团、山东大海、山东华兴、山东如意、联发纺织、三和集团、山东宏业、百隆集团、华孚公司、宜城天舒、新疆信泰等等。

近年来,公司致力于高端钢领的研发,通过数控机床加工的钢领尺寸精准,使用寿命更长,是紧密纺系统的优选配套产品。

Rizhao YUHUA Machinery Co., Ltd. is to exhibit YUHUA brand series top arm, compact, and rings.

“YUHUA” brand top arm have been developed and produced since the end of 1980s. At present, it has achieved the sales of 30 million spindles in textile markets. YUHUA brand series top arm has four series of Vtype draft, flat draft, compact spinning special top arm and spring arm. The pendulum arm has the characteristic of accurate pressure regulation, high parallelism, excellent spinning.

“YUHUA” compact (be negative pressure four roller compact device) adopts special energy saving fan with low energy consumption. Open-type condensing system for easy maintenance. The air flow reverse stop device is convenient for collective exhaust, avoiding the large area yarn breakage. The life of roller is double by shifting spinning technology. Cooperative clients (partly) include HENGFENG GROUP, SHANDONG DAHAI, SHANDONG HUAXING, SHANDONG RUYI, LIANFA TEXTILE, SANHE GROUP, CHANGSHAN, SHANDONG HONGYE, BROSS GROUP, HUAFU, YICHENG TIANSHU, XINJIANG XINTAI, etc.

In recent years, the company is committed to the research and development of high-end ring, the current production of high-precision is processed with CNC machine tools, with high dimensional accuracy,which is 3 -5 times of ordinary steel ring, especially suitable for the production and application of compact spinning.

日照品特裕華:主打纺纱智能装置

PINTER YUHUA China Technologies: Focusing on intelligent spinning devices

本次展会上日照品特裕华纺织科技有限公司将展出EffiSpin高效纺纱监测、粗纱自停、纺纱软件、包芯纱和花式纺纱装置。

EffiSpin系统分为棉纺、毛纺、赛络纺三大系列,电磁和光电两个方式。具有实时收集数据、降低劳动力、改善生产效率,是棉纺厂达到优质管理的最好选择。

粗纱自停装置可以减少粗纱浪费,改善生产环境,提供纱线质量等特点。

高效纺纱软件能实时监控生产状况,管理并分析数据,优化管理。

包芯纱装置能精确控制芯丝张力,芯丝在线监测可以消除空心纱现象。

花式纺纱系统可以同时输入6种不同颜色的纱线。

At the exhibition, PINTER YUHUA China Technologies Co., Ltd. will showcase EffiSpin, Roving stop device, Spinning software management system, Core yarn, and Fancy spinning system. EffiSpin is divided into three series of cotton spinning, wool spinning, siro spinning - electromagnetic type and optical type. This device can collect data in real time, reduce labor, improve production efficiency, is the best choice for company to achieve fine management;

Roving stop device can reduce roving waste, eliminate roller winding, improve production environment, improve yarn quality, and save manufacturing cost.

Spinning software management system can monitor the real-time production information of the current shift of all machines, conduct data collation and analysis, so as to make the management more reliable and more accurate.

Core yarn can precisely control the tension of the core yarn. Core yarn online monitoring can eliminate the empty core yarn and achieve efficient management and perfect control. Fancy spinning system (come from PINTER CAIPO SAU) can input up to 6 different colors of yarn.

濟南天齐:高速节电的“万能平带”

NYBELT CO.: High-speed & power-saving “universal flat belts”

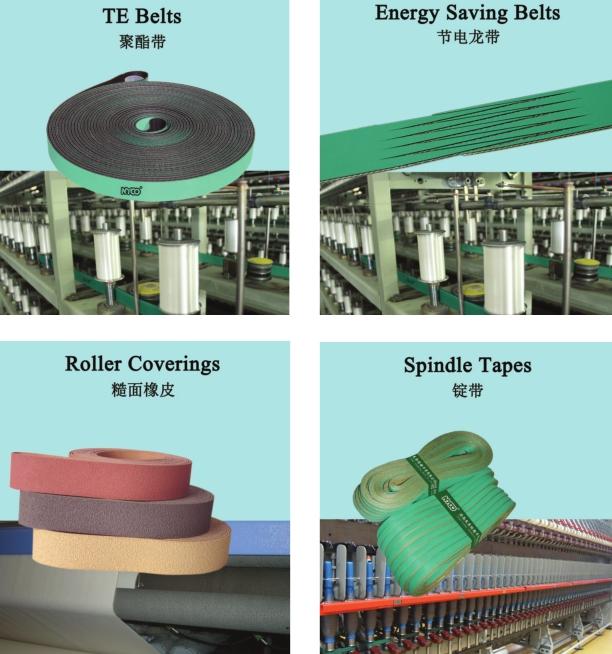

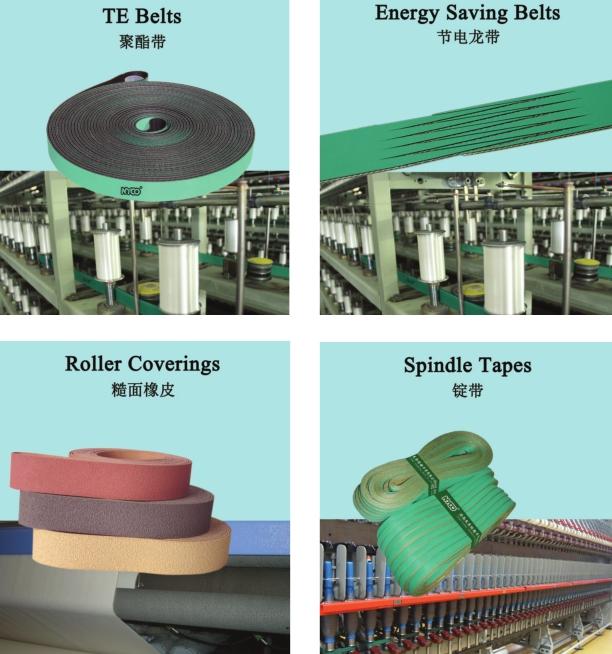

本届展会天齐平带带来诸多备受市场认可的平带拳头产品:

齿接节电聚酯龙带具有轻、薄、柔软、良好的带轮包绕性、弯曲耗能小、尺寸不受环境温湿度影响,特别适用于高速、长车、张紧装置调节范围小的超长细纱机、转杯纺纱机、倍捻机等高速纺机龙带,与传统尼龙片基龙带相比,节电率可达10%~20%。

糙面橡皮(辊包皮)具有耐油、耐磨、耐老化、耐腐蚀等特点。主要适用于织造不同工序织物牵引,在各种喷气、喷水、剑杆、片梭等无梭织机的导布辊、卷布辊上使用,是国内外织机主机公司如必佳乐、日发、经纬咸阳、丰凯等独家配套产品。

节电锭带是天齐新型节电锭带为齿接聚酯锭带CNU,适用于高速新型细纱机,特别适用于15000RPM以上的高速细纱机,相比橡胶锭带综合节电率为6%~10%,广泛用于瑞士立达高速细纱机、经纬细纱长车和其他新型纺纱设备,不仅可以降低纱线捻不匀和强不匀,提高纱线质量,而且能够满足客户的节能减排要求。

Jinan Tianqi Technical Belts Co., Ltd. (NYBELT CO.) will bring many market-recognize knockout belts to the exhibition this year:

The end-jointing power-saving polyester belt, which is light, thin, and soft, is also featured with good wheel wrapping and low bending energy consumption. The size is not affected by the ambient temperature and humidity. It is especially suitable for the high-speed spinning machine belts such as ultralong spinning frame, rotor spinning machine and two-for-one twister. The energy saving rate can be up to 10% - 20% compared with traditional nylon belts.

Roller coverings have the characteristics of oil resistance, wear resistance, aging resistance and corrosion resistance. It is mainly used for weaving fabrics of different processes. It is used on the cloth guide rollers and the batch roller of various shuttleless looms such as air-jet, hydraulic, rapier, and gripper looms. It is the exclusive supporting product of the main loom companies at home and abroad, including Picanol, Rifa, Jingwei Xianyang and Fengkai.

The energy-saving spindle tapes are suitable for high-speed new spinning frame. It is especially suitable for high-speed spinning frame with a capacity of 15,000 RPM or higher. Compared with the rubber belts, the overall energy saving rate is 6% - 10%. It is widely used in Rieter high-speed spinning frame, Jingwei spinning long frame and other new spinning equipment, which can not only reduce yarn twisting unevenness and strength unevenness to improve yarn quality, but also meet customers demand for energy saving and emission reduction.