Comparative study of low NOx combustion optimization of a coal-fired utility boiler based on OBLPSO and GOBLPSO

2021-10-21LiQingweiLiuZhiHeQifeng

Li Qingwei Liu Zhi He Qifeng

(College of Energy and Mechanical Engineering, Shanghai University of Electric Power, Shanghai 200090, China)

Abstract:To reduce NOx emissions of coal-fired power plant boilers, this study introduced particle swarm optimization employing opposition-based learning (OBLPSO) and particle swarm optimization employing generalized opposition-based learning (GOBLPSO) to a low NOx combustion optimization area. Thermal adjustment tests under different ground conditions, variable oxygen conditions, variable operation modes of coal pulverizer conditions, and variable first air pressure conditions were carried out on a 660 MW boiler to obtain samples of combustion optimization. The adaptability of PSO, differential evolution algorithm (DE), OBLPSO, and GOBLPSO was compared and analyzed. Results of 51 times independently optimized experiments show that PSO is better than DE, while the performance of the GOBLPSO algorithm is generally better than that of the PSO and OBLPSO. The median-optimized NOx emission by GOBLPSO is up to 15.8 mg/m3 lower than that obtained by PSO. The generalized opposition-based learning can effectively utilize the information of the current search space and enhance the adaptability of PSO to the low NOx combustion optimization of the studied boiler.

Key words:NOx emissions; combustion optimization; particle swarm optimization; opposition-based learning; generalized opposition-based learning

Thermal power remains an important power source around the world. NOxemissions emitted from power plants have been troubling human beings for a long time. As a simple, effective, and cheap technology, combustion optimization can cut down NOxemissions through organizing coal combustion in furnaces[1-3].

For in-service boilers, NOxemissions are influenced by operating parameters like oxygen and wind valve openings. The optimization of these parameters based on artificial intelligence can provide satisfactory operation strategies. Many researchers[4-5]have improved the NOxprediction model, providing the basis for low NOxcombustion optimization. Optimization algorithms like differential evolution[6], vortex search[7], genetic algorithm[8], and particle swarm optimization[9]have been employed to optimize operating parameters to cut down NOxemissions.

Inspired by the birds flocking, Kennedy et al.[10]proposed particle swarm optimization (PSO) in 1995. PSO is famous for its simplicity and effectiveness. However, it is troubled with the premature and convergence problems. To overcome this disadvantage, researchers have been devoted to improvements in aspects of parameter tunings[11], mutations[12], learning strategies[13], multi-swarms[14], and algorithm hybridizations[15].

Opposition-based learning (OBL) strategy evaluates the original solution and its opposite solution simultaneously[16]. A better solution is retained based on a greedy strategy. OBL has been introduced into PSO to enhance performance[17-18]. However, these OBL based algorithms could not make full use of the obtained information. To utilize the shrunken search space, Wang et al.[19]enhanced the PSO using generalized opposition-based learning (GOBL) characterized by dynamically updated interval boundaries.

To the best of the authors’ knowledge, PSO based on OBL and PSO based on GOBL have not been studied in the low NOxcombustion optimization area. This paper studied the adaptability of these two algorithms to the low NOxcombustion optimization systematically.

1 Optimization Algorithms

1.1 Particle swarm optimization

In the PSO algorithm,Nparticles are initialized to form a population in theD-dimensional search space. Each particle has a position vector and a velocity vector, which can be expressed as {xi1,xi2,…,xiD} and {vi1,vi2,…,viD}, respectively. The fitness of each particle can be evaluated by an objective function. In each optimization iteration, each particle records its best position, which is called the historically best positionPi. The best position among all the particles in the population is called the global best positionPg. All particles update their positions and speeds under the guidance of the best position and global best position as

(1)

(2)

1.2 Particle swarm optimization employing an opposition-based learning

To study the adaptability of PSO employing OBL to the low NOxcombustion optimization, only the opposition-based learning[20]is introduced to enhance the PSO without other improvements. This is named OBLPSO. In each iteration, each particle generates an opposite particle based on OBL and its current position with a certain probability as

(3)

1.3 Particle swarm optimization employing a generalized opposition-based learning

GOBL is an improved version of OBL[19], which can utilize the knowledge of the current converged search space. To study the adaptability of PSO employing GOBL to the low NOxcombustion optimization, only the GOBL is introduced to enhance PSO with a certain probability, which is named GOBLPSO. The generalized opposition of the jth dimension ofxican be calculated as below.

(4)

2 Combustion Optimization Based on OBLPSO and GOBLPSO

2.1 NOx emission prediction based on extreme learning machine

For a given boiler,the NOxemission is generally influenced by operating parameters like oxygen in the flue gas, over-fire air valve openings, and the rotating speeds of the dynamic separator of the coal pulverizer. These parameters are taken as inputs of the NOxemission prediction model.

Prediction models of NOxemissions and efficiencies were both established based on the extreme learning machine (ELM)[21]. Differential evolution (DE) was employed to optimize input weights and hidden layer thresholds to enhance performances[22]. Moreover, the normalization method and leave-one-out cross validation were also employed.

2.2 Combustion optimization based on OBLPSO and GOBLPSO

NOxemissions at the inlet of selective catalytic reduction equipment are influenced by operating parameters like oxygen, over-fire air valve openings, and secondary air valve openings. The optimization of these parameters can cut down NOxemissions effectively and reduce the operation cost of the selective catalytic reduction equipment. For the studied boiler, the secondary air valve openings are controlled automatically. Four corner openings of each over-fire air layer are different. These over-fire air valve openings and oxygen are optimized by the OBLPSO and GOBLPSO to reduce NOxemissions. Each particle represents a set of operation parameters. The corresponding NOxemission at the inlet of the selective catalytic reduction equipment is taken as the fitness of each particle. When the operating parameters are optimized to reduce NOxemissions, corresponding efficiencies are kept no lower than the original efficiencies.

3 Field Test

The thermal adjustment test on a 660 MW boiler was carried out. The studied boiler is characterized by tangential combustion, π type, single furnace, balanced ventilation, and solid slagging. Each burner has 6 layers of pulverized coal nozzles, 14 layers of secondary air, and 4 layers of over-fire air. The secondary air valve openings are controlled automatically. Openings of the over-fire air in each corner are different from each other. During each case, the coal quality was kept the same and the element analysis was analyzed. There are 18 cases in the thermal adjustment test, including ground conditions, variable oxygen conditions, the variable operation mode of coal pulverizer conditions, variable first air pressure conditions, and variable rotating speeds of the dynamic separator of coal pulverizer conditions.

4 Results and Discussion

4.1 Related parameters

For PSO,OBLPSO, and GOBLPSO, the inertia weight acceleration factors were set as 0.8, 2.5, and 2.0, respectively. The particle number is 30 and the maximum iteration number is 50. The DE algorithm was employed as the comparison algorithm[22-23]. The number of DE parameter vectors is 30. The mutation and the crossover constants are 0.75 and 0.25, respectively. Each algorithm is tested 51 times independently for each case.

4.2 Related results and discussion

Fig. 1 shows the NOxemissions and efficiencies predicted by ELM. Predicted results are very close to the original values. For the training samples and test samples of NOxemissions, the root-mean-square errors are 5.256 5 and 6.608 2 mg/m3, respectively. For the efficiencies of the training samples and test samples, the root-mean-square errors are 1.29×10-4and 1.34×10-4, respectively. The approximation capability and generalization ability are both satisfactory.

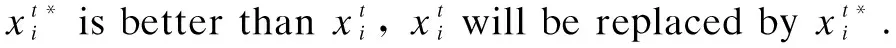

Fig. 2 shows the minimum-optimized NOxemissions based on PSO and DE. It can be seen that the minimum-optimized NOxemissions based on PSO are generally lower than that of DE. This phenomenon is most obvious for Case 6 and Case 13; i.e., PSO is more adaptable for the combustion optimization of the studied boiler than DE.

Fig.2 Minimum-optimized NOx emissions based on PSO and DE

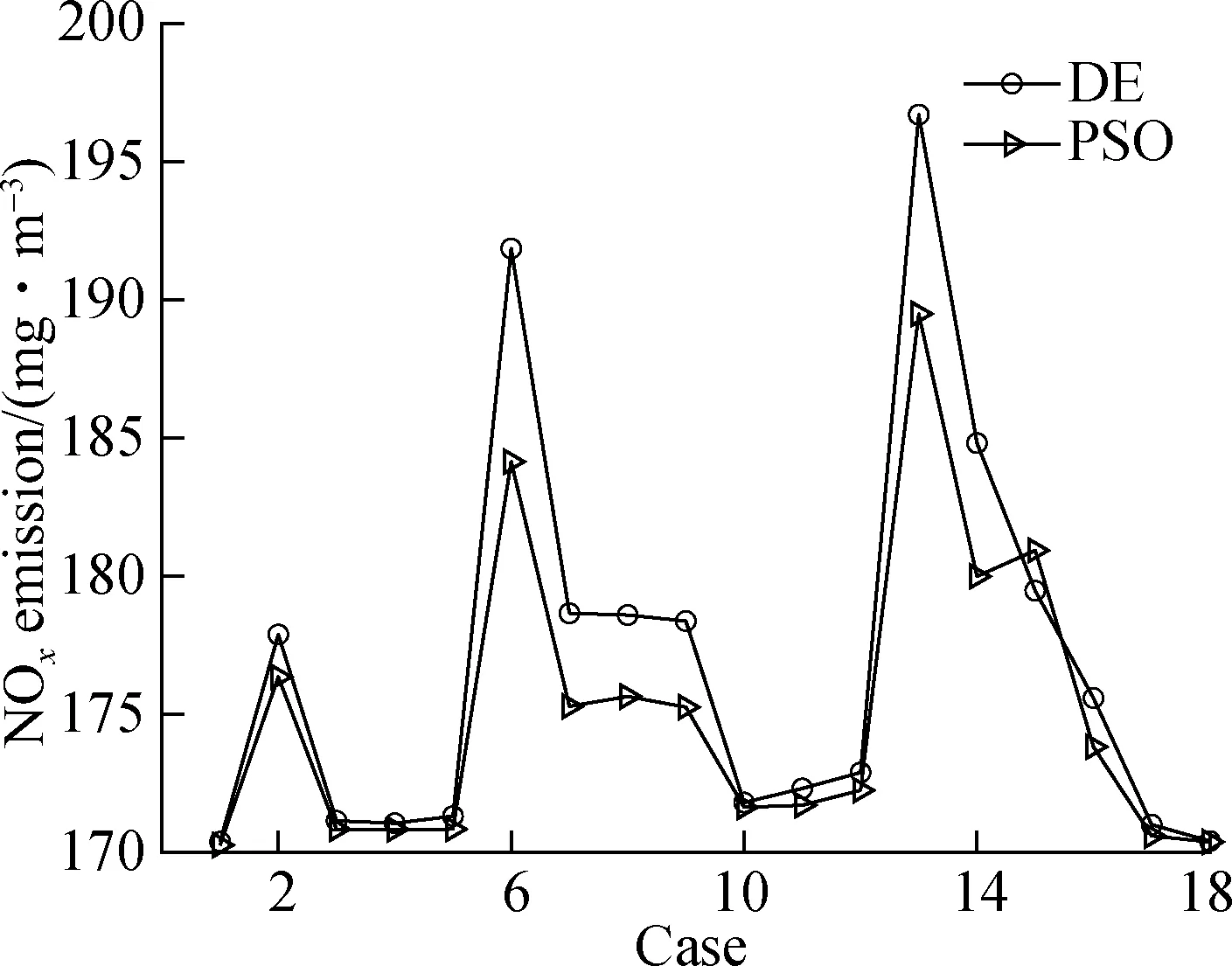

Fig. 3 shows the median-optimized NOxemissions based on PSO, OBLPSO, and GOBLPSO. Generally, the median-optimized NOxemissions based on GOBLPSO are the lowest among the three algorithms. This phenomenon is more obvious for Case 7, Case 8, Case 14, and Case 15. For Case 14, the median NOxemissions optimized by GOBLPSO are up to 15.8 mg/m3lower than the median NOxemissions optimized by PSO. The GOBL can enhance PSO for the combustion optimization of the studied boiler effectively.

Fig.3 Median-optimized NOx emissions based on PSO, OBLPSO, and GOBLPSO

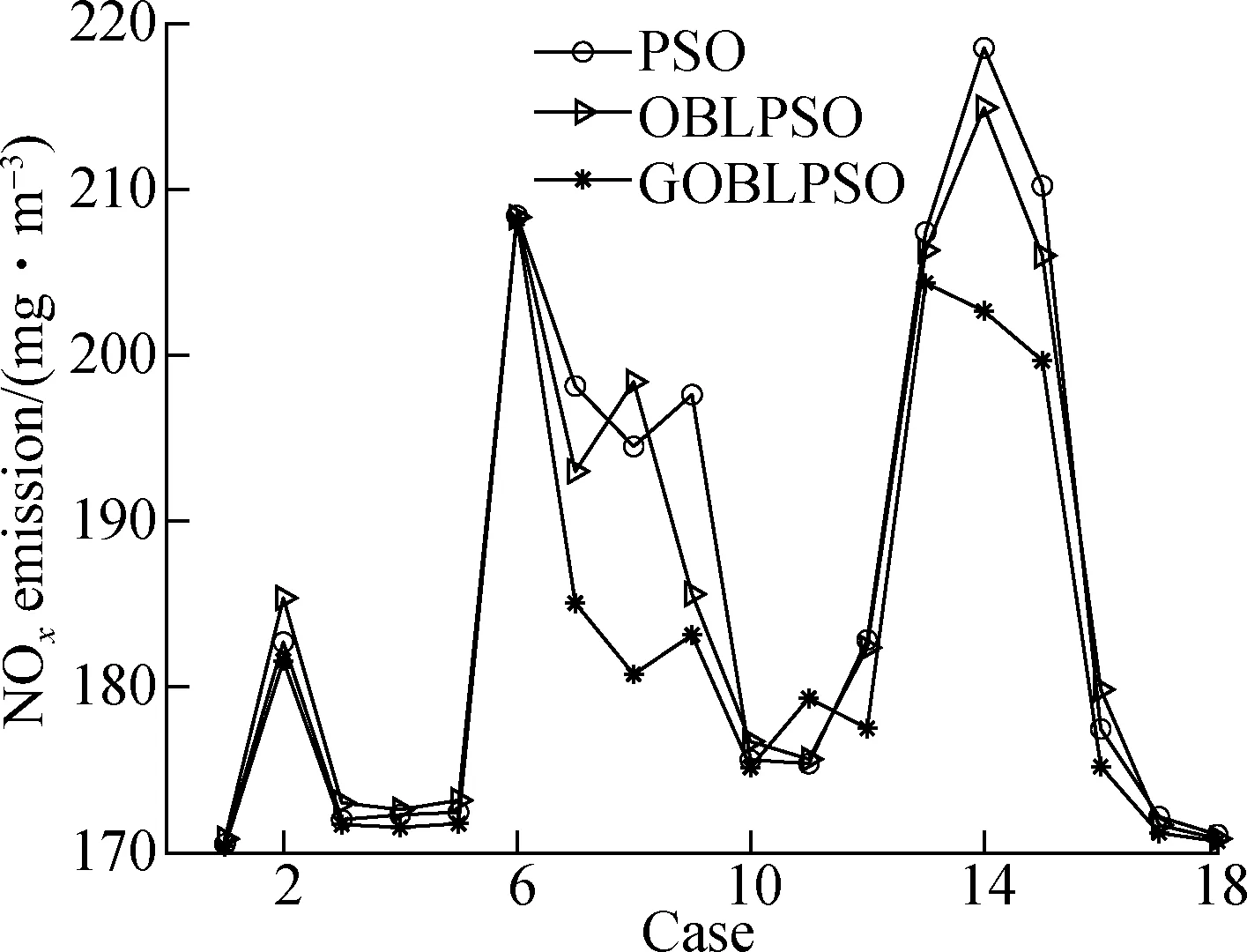

Fig. 4 shows the minimum-optimized NOxemissions based on PSO, OBLPSO, and GOBLPSO. The advantage of GOBLPSO over the other two algorithms is not too obvious for the minimum-optimized NOxemissions.

Fig.4 Minimum-optimized NOx emissions based on PSO, OBLPSO, and GOBLPSO

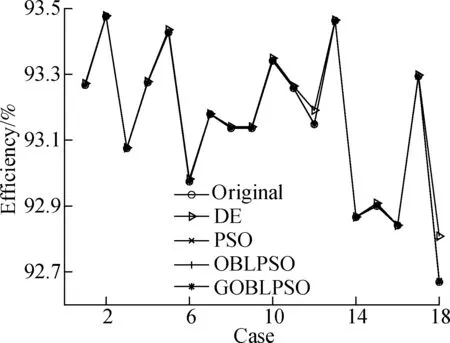

Fig. 5 shows the original efficiencies and minimum-optimized efficiencies based on DE, PSO, OBLPSO, and GOBLPSO. All minimum-optimized efficiencies are not lower than the original efficiencies. When the operating parameters are optimized to reduce NOxemissions, the corresponding efficiencies are kept no lower than the original efficiencies. The optimized results show that this strategy is effective.

Fig.5 Original efficiencies and minimum-optimized efficiencies

Fig. 6 shows the optimized progress of the median-optimized NOxfor Case 8 and Case 14. For both cases, the algorithms can converge in 20 iterations. GOBLPSO can provide the lowest median-optimized NOxemissions among the three algorithms.

5 Conclusions

1)The GOBLPSO outperforms the PSO and OBLPSO in the aspects of median-optimized results. Up to 15.8 mg/m3NOxemissions are reduced further by the GOBLPSO compared with PSO for the median-optimized NOxemissions in Case 14.

2)Median-optimized processes of some cases based on PSO, OBLPSO, and GOBLPSO show that the processes based on GOBLPSO are satisfactory.

3) GOBL can enhance PSO for the combustion optimization of the studied boiler effectively.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Crossed products for Hopf group-algebras

- TOD typology: A review of research achievements

- Concept and evaluation method of equipment system of systems contribution rate

- Sustainability of health information exchange platform based on information cooperation

- Clay mineral expansion of black cotton soil based on interlayer cation hydration

- Performance analysis of a novel tobacco-curing system with a solar-assisted heat pump