耐洗型疏水疏油丝绸织物的制备及性能研究

2020-12-28DOKhaiLy钟申洁徐浪左甜易玲敏

DO Khai Ly 钟申洁 徐浪 左甜 易玲敏

摘要: 目前所制備的疏水疏油丝绸织物大多难以同时满足疏水疏油及耐洗性,或制备过程过于复杂。因此,文章提出在丝绸表面浸涂一层疏水改性的二氧化硅纳米粒子以提供一定的粗糙度,随之将聚(偏氟乙烯-六氟丙烯)溶液喷涂于其上以提供低表面能,两者的协同作用可使丝绸织物具有高度的疏水疏油性和良好的耐洗性能。结果显示,通过这一简单易实施的两步法,制备所得丝绸织物表面的水接触角高达149.5°、滚动角小至5.5°,色拉油的接触角可达132°,表现出高度的疏水疏油性。经20次标准洗涤后,水接触角仍在140°以上,且滚动角小于10°,表现出优异的耐洗色牢度。

关键词: 丝绸织物;疏水;疏油;耐洗牢度;疏水改性SiO2

中图分类号: TS195.6 文献标志码: A 文章编号: 10017003(2020)12002608

引用页码: 121105 DOI: 10.3969/j.issn.1001-7003.2020.12.005(篇序)

Preparation of hydrophobic and oleophobic silk fabric with good washing durabilityand research on its performance

DO Khai Ly, ZHONG Shenjie, XU Lang, ZUO Tian, YI Lingmin

(a.College of Textile Science and Engineering; b.Key Laboratory of Advanced Textile Materials & Manufacturing Technology,Ministry of Education; c.Engineering Research Center for Eco-Dyeing & Finishing of Textiles, Ministry of Education,Zhejiang Sci-Tech University, Hangzhou 310018, China)

Abstract: It is difficult for current hydrophobic and oleophobic silk fabrics to meet hydrophobic and oleophobic characteristics as well as washing durability at the same time, or the preparation process is too complex. Thus, in this study, we proposed to coat hydrophobic modified silica nanoparticles on the fiber surface to provide certain roughness, and then spray poly(vinylidene fluoride-hexafluoropropylene) (PVDF-HFP) to provide low surface energy. The synergistic effect of the two could make the silk fabric had high hydrophobic and oleophobic properties as well as good washing durability. The results indicated that via this simple two-step method, the prepared silk fabric presented a water contact angle(WCA) of 149.5°, a water sliding angle(WSA) of 5.5°, and an oil contact angle(OCA) of 132.0°, demonstrating the high hydrophobicity and oleophobicity of silk. After standard washing for 20 times, the WCA was still more than 140° and the WSA was less than 10°, showing excellent laundering durability.

Key words: silk fabric; hydrophobic; oleophobic; washing durability; hydrophobic modified silica

During the last decades, researchers have been continuously exploring the functional coatings on textile surfaces, for example, superhydrophobic coatings[1-2], anti-fouling coatings[3-4], self-cleaning coatings[5-6], and so on[7-8]. Silk fabric products have been popular in textile industry due to good mechanical strength, toughness and elasticity[9], as well as the elegant appearance and soft hand touch[10], which have attracted the attention of researchers. However, because of a great number of groups containing carboxyl, hydroxyl and amine groups which caused the poor anti-fouling properties[11], it is an imperious demand for improvement of water and oil repellency of silk fabrics.

Several studies of anti-fouling performances of silk fabrics have been reported. For example, Huang et al[12]. obtained the superhydrophobic and anti-UV silk fabric via single-step in-situ synthesis of ZnO nanorods on the surface of silk fabric and modified by n-octadecanethiol, and the WCA reached 151.9°. Wang et al[13]. blended the POSS with fluorinated alkyl silane, then through the dip coating POSS composites onto fibers to get a superhydrobic textile. However, among these work, most of them used silane with long fluorinated chain, which have potential risk to organic organism. On the other hand, fabrics with only water-repellent behavior still can not meet the demand of textile market. Aslanidou et al[14]. dispersed SiO2 nanoparticles(NPs) into a soluble emulsion of silane, siloxane and organic polymer and then sprayed over the surface of silk fabric, as a result, it showed the outstanding WCA and OCA of 161.0° and 159.0°, respectively, However, the washing durability of the modified silk fabric was not studied. Cheng et al[15]. prepared superhydrophobic silk fabrics using enzyme-etching approach by papain and methyltrichlorosilane(MTCS) via thermal chemical vapor deposition(CVD) process at 70 ℃. The MTCS@papain-etched fabric has a WCA of 153.5° and sliding angle of 8.5°, demonstrating superhydrophobic, but the WCA was dropped to about 140° after 10 washing cycles. Based on above works, it could be recognized that the durability in textile materials is also important. Thus, Chen et al[16]. prepared a water-repellent silk surface with excellent washing durability by depositing TiO2 coatings on the surface of silk fabric via atomic layer deposition(ALD) method. However, because of the complicated and time-consuming procedure to obtain robust silk fabrics, it is particularly urgent to discover a simple and facile method for wide production.

In this work, we report an easy method to fabricate highly hydrophobic and oleophobic silk fabric with outstanding washing durability. Silk fabric was firstly immersed into the modified silica solution to obtain certain roughness, followed by a final coating of fluoric-containing polymer poly(vinylidene fluoride-hexafluoropropylene) (PVDF-HFP) to achieve low surface energy and stable fastness on the surface of silk fabric. The result is useful for the development of self-cleaning silk fabric with desired water and oil-resistant performances as well as laundering durability.

1 實 验

1 Experiment

1.1 材料与仪器

1.1 Materials and instruments

Materials: White commercial silk fabric(Hangzhou Xidebao Co. Ltd), methyltrimethoxysilane(MTMS), 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane(HFOTES), ethanol(Hangzhou Gaojing Fine Chemical Industry Co. Ltd), dimethylformamide(DMF) and poly(vinylidene fluoride-hexafluoropropylene)(PVDF-HFP)(Sigma-Aldrich). SiO2 nanoparticles were synthesized by Stber method[17]. All agents were used without additional purification.

Instruments: Contact angle measurement DSA20(Krüss, Germany), JSM-5610LV scanning electron microscope(SEM) (JEOL, Japan), X-ray Photoelectron Spectrum(XPS) (K-Alpha, Thermo Fisher Scientific, U.S.A), Launder-O-Meter(Labec Co., Taiwan), (Kato-Tech, Japan), Universal Testing(Instron-2365, INSTRON CORPORATION Co.), Numerical Air Permeability Tester YG461E.

1.2 方 法

1.2 Methods

1.2.1 改性SiO2納米粒子的合成

1.2.1 Synthesis of modified SiO2

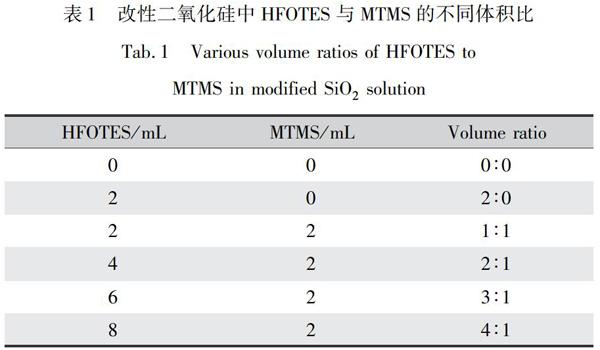

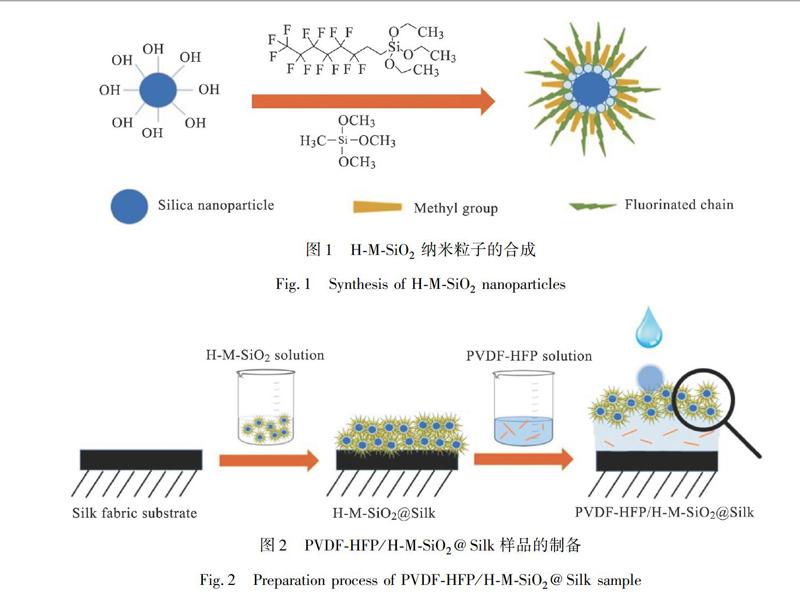

0.5 g SiO2 nanoparticles were ultrasonicated in 100 mL of ethanol at room temperature for 10 min to ensure good dispersion. Afterwards, HFOTES was added to the above dispersed solution, followed by the dropping addition of MTMS. The modified SiO2(named as H-M-SiO2) solution was obtained by maintaining for 24 h at room temperature under magnetic stirring. Different volume ratios of HFOTES to MTMS were described in Tab.1.

1.2.2 丝绸样品的制备

1.2.2 Preparation of silk samples

As described in Fig.1 and Fig.2, silk samples were first dipped into the as-prepared H-M-SiO2 solution at ambient temperature for 12 h then dried at 80 ℃ for 1 h(named as H-M-SiO2@Silk). Afterwards, 0.5 g PVDF-HFP was put into 30 mL of DMF and stirred for 20 min. Finally, this PVDF-HFP solution was sprayed over the surface of H-M-SiO2@Silk samples and dried at 80 ℃ for 1 h(labelled as PVDF-HFP/H-M-SiO2@Silk). One sample which was coated by HFOTES modified SiO2 and PVDF-HFP solution was labelled as PVDF-HFP/H-SiO2@Silk. One controlled sample coated by only PVDF-HFP solution was labelled as PVDF-HFP@Silk.

1.3 测试与表征

1.3 Testing and characterization

1.3.1 接触角测试

1.3.1 Contact angle measurements

Surface wettability of modified silk fabrics was investigated by contact angle measurement device DSA20(Krüss, Germany) at room temperature. The liquid volume in each measurement was 3 μL(water) or 2.4 μL(oil). Average result was recorded by five testing points for each sample.

1.3.2 表面形貌表征

1.3.2 Surface morphology characterization(SEM)

JSM-5610LV scanning electron microscope(SEM) was employed to analyze the surface morphology of modified silk samples. An ultra-thin layer of Au was coated on sample surfaces to observe the surface morphology properly.

1.3.3 表面化学组成分析

1.3.3 Analysis of surface chemical compositions

Energy-dispersive X-ray spectrometer(EDS) attached to SEM and X-ray photoelectron spectroscopy(XPS) system were used to measure the surface elements and investigate the surface atomic compositions of silk samples. Fabric samples were packed onto a standard specimen holder and analyzed by microfocused, monochromated Al Kα X-ray source. Photoelectron emission take-off angle of 90° was utilized to analyze the samples, and hydrocarbon C1s line with the position at 284.8 eV was chosen as a reference to rectify the charging effect.

1.3.4 服用及物理机械性能测试

1.3.4 Wearability and mechanical property tests

Laundering durability was tested by HB 12P(NEWAVE LAB EQUIPMENTS Co., Ltd) based on AATCC 61-2003 Test No.1A. Samples were washed at 40 ℃ in the presence of 10 stainless steel balls. One washing cycle(45 min) is approximate to five times of commercial laundering. Tensile strength was determined by Universal Testing(Instron-2365, INSTRON CORPORATION Co.) due to GB/T 3923.2-2013. Air permeation test was conducted by Numerical Air Permeability Tester YG461E due to GB/T 5453-1997. Water vapor transmission rates were measured due to GB/T 12704.2-2009 by special aluminum cups. Whiteness and lightness were measured by WSD-3C Whiteness Meter due to GSBA67002 standard. All the tested samples were PVDF-HFP/H-M-SiO2@Silk.

2 結果与分析

2 Results and analysis

2.1 润湿性能及影响因素

2.1 Wettability of silk fabrics and its factors

The particle size and volume ratio of HFOTES to MTMS have effect on the wettability of silk fabrics. Tab. 2 shows the effect of volume ratio of HFOTES to MTMS on oleophobic property of modified silk fabric. The result indicated that when the volume ratio of HFOTES to MTMS was increased, the oleophobicity was improved correspondingly. Compared to the ratio of HFOTES to MTMS 1︰1, as the volume ratio reached 3︰1, the salad oil contact angle of PVDF-HFP/H-M-SiO2@Silk sample was improved from 126.0° to 132.0°, and that of mineral oil increased from 122.5° to 129.5°. This was attributed to the existence of fluorine element which supplied low surface energy for good oleophobic performance of modified silk fabric. However, as the volume ratio reached 4︰1, the oil contact angle decreased slightly.

Fig.3-Fig.6 shows the WCA and WSA of silk fabrics modified with different conditions. From Fig.3, it can be seen that the WCA increased with the increase of SiO2 particle size(VHFOTES︰MTMS=1︰1), as the particle size was up to 601 nm, the WCA of H-M-SiO2@Silk can reach 147.0° while the SA was smaller than 10°. This was attributed to the increasing particle size of SiO2 nanoparticles that made the roughness of the surface of the silk increased correspondingly, thus enhanced the hydrophobic property of the silk fabric. However, when the particle size was further increased, the WCA decreased, this phenomenon was due to the particle size was larger, it was easy to fall off from the surface, thus reducing the WCA. Subsequently, the influence of volume ratio of HFOTES to MTMS was also investigated(SiO2 particle size was 601 nm). Fig.4 presents the influence of different ratios of HFOTES to MTMS. We can conclude that the H-M-SiO2@Silk

sample had excellent hydrophobic performance after being coated by the HFOTES and MTMS co-modified SiO2 nanoparticles. As the volume ratio of HFOTES to MTMS was 3︰1, the highest WCA was 149.5°, and the SA was 5.5°. Therefore, the most appropriate value of SiO2 particle size was 601 nm and volume ratio of HFOTES to MTMS was 3︰1.

Self-cleaning ability is one essential factor to evaluate the applications of hydrophobic silk textiles[18]. For the investigation of self-cleaning ability of silk fabric, congo red powder was used for testing. Fig.5 shows that the water drop a space can not remove the powder from hydrophilic silk surface, and the fabric was wet and dirty. Meanwhile, the water drop rolled off quickly from the surface of PVDF-HFP/H-M-SiO2@Silk sample, took away all congo red powder and left the dry and clean silk surface(Fig.6), it was due to the low adhesive force to fabric and powder. This result proved the excellent self-cleaning properties of PVDF-HFP/H-M-SiO2@Silk sample.

2.2 織物表面微观形貌分析

2.2 Surface morphology analysis

SEM images of pristine silk fabric and modified silk fabric were shown in Fig.7. Fig.7(a) exhibits the smooth fiber surface of original silk fabric. After coated by PVDF-HFP, there was a clear layer of PVDF-HFP on the fiber surface of PVDF-HFP@Silk sample(Fig.7(b)). Fig.7(d-f) reveal that as the concentration of HFOTES was increased, more SiO2 nanoparticles were packed onto the fiber surface of PVDF-HFP/H-M-SiO2@Silk, leading to an increase of surface roughness and better hydrophobicity. This was attributed to the concentration of HFOTES was increased, the cross-linked density of modified SiO2 was increased correspondingly, which made the particles stick to the fabric and not fallen off easily. Surface element analysis of PVDF-HFP/H-M-SiO2@Silk sample was presented by EDS and mapping in Fig.7(c、g). The EDS data(Fig.7(c)) showed that the Si and F element had appeared on the surface of PVDF-HFP/H-M-SiO2@Silk, the element content was 2.04% and 13.29 % respectively, which confirmed the successful coating on the surface of modified silk fabric[15]. On the other hand, we can observe from the F mapping(Fig.7(g)) that the F element was covered on the silk fabric surface uniformly, this provided the possibility of stable hydrophobicity of the PVDF-HFP/H-M-SiO2@Silk.

2.3 織物表面化学组成分析

2.3 Surface compositions of silk fabrics

XPS survey confirms the appearance of F 1s on PVDF-HFP@Silk sample, and Si 2p and F 1s on PVDF-HFP/H-M-SiO2@Silk sample with binding energy at 103.5 eV and 688.9 eV, respectively(Fig.8). Those new peaks of Si 2p and F 1s indicate the successful chemical modification on silk fabric surface, which corresponds to EDS result. In Fig.9, three peaks at 284.8 eV, 286.2 eV and 288.5 eV corresponding to —C—C—, C—OH and CO groups of pristine silk fabric, respectively. Furthermore, Si 2p spectrum of PVDF-HFP/H-M-SiO2@Silk sample displayed the larger amount of SiO2 than Si-O, which meaned that more SiO2 nanoparticles were packed onto silk fabric surface and created the surface roughness(Fig.10). After modification, in C 1s spectrum there were three new peaks —CF3, —CF2— and C—F at 293.5 eV, 291.2 eV and 287.9 eV, respectively[19]. The peak-CF3 accounts for 11.39 % and the peak —CF2— was about 48.51 %(Fig.11), which resulting in low surface energy.

2.4 服用及物理机械性能

2.4 Wearability and mechanical properties

Air permeability and water vapor permeability are the important properties of textile fabrics for wearing. It can be seen from Tab.3 that compared to the pristine silk fabric, the water vapor transmission rate of PVDF-HFP/H-M-SiO2@Silk sample was slightly decreased from 0.17 g/(m2·t) to 0.16 g/(m2·t), indicated that there was no significant deterioration of water vapor permeability after surface modification. Simultaneously, the air permeability was also decreased by 10.85%, this was mainly caused by the modified coating which formed a film on the surface of silk fabric and covered the space between two yarns. This result declared that there was almost no negative impact of coatings on the breathability of silk fabric.

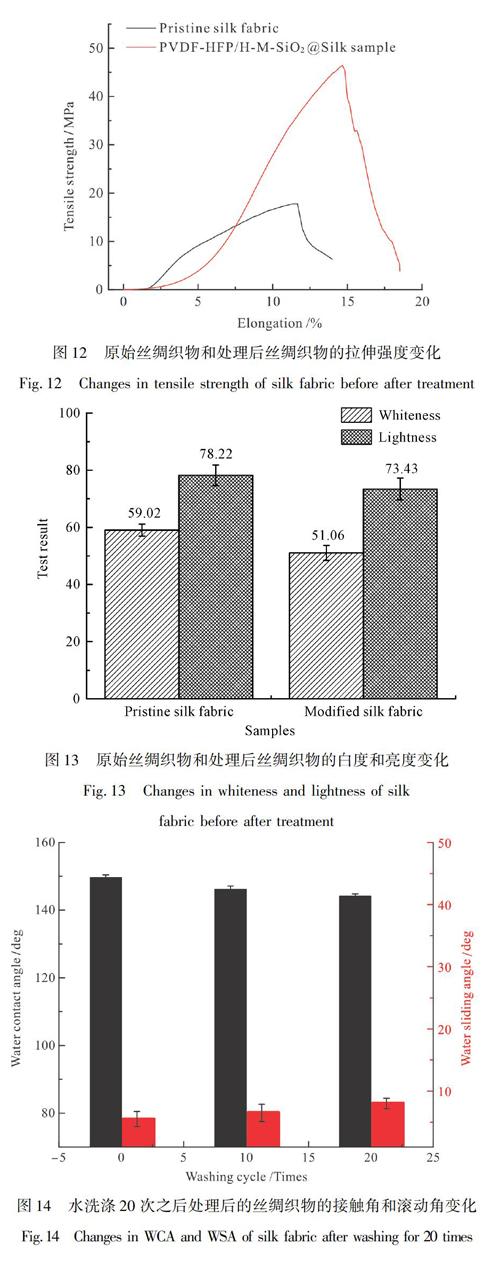

Fig.12-Fig.14 shows the tensile strength, whiteness, lightness and washing durability of pristine silk fabric and PVDF-HFP/H-M-SiO2@Silk sample. After the treatment by PVDF-HFP/H-M-SiO2, there was a sharp growth in tensile strength of fabric sample from 17.78 MPa to 46.46 MPa, as shown in Fig.12. The change in tensile strength of treated silk fabric sample was caused by the deposition of coatings on their surface. This caused an efficient stress transfer form matrix to the particles, which increased the tensile strength of fabric.

Fig.13 presents the changes in original color of whiteness and lightness of silk fabric before and after modification. It can be seen that the whiteness of silk fabric decreases from 59.02 to 51.06, and lightness had a little drop from 78.22 to 73.43 after being treated by PVDF-HFP/H-M-SiO2 coating. These parameters conformed that the coating did not create a negative effect on silk fabric color, and the original color is almost maintained after the finishing process.

Laundering durability is also one important aspect to assess the quality of silk fabrics[20]. Fig.14 shows that after 20 times washing, the WCA of PVDF-HFP/H-M-SiO2@Silk sample was dropped from 149.5° to 144.0° and the WSA was increased to 8.0°. This result demonstrated that PVDF-HFP/H-M-SiO2@Silk fabric has good washing durability.

3 結 论

3 Conclusions

In conclusion, a simple two-step method was presented to fabricate highly hydrophobic and oleophobic silk fabric with good laundering durability by using modified-SiO2 nanoparticles and a final coating of PVDF-HFP. As a result, the most appropriate value of SiO2 particle size was 601 nm and volume ratio of HFOTES to MTMS was 3︰1. PVDF-HFP/H-M-SiO2@Silk fabric sample displayed excellent water and oil resistant performances with WCA of 149.5°, WSA of 5.5° and OCA of 132.0°. After 20 times washing, the WCA of PVDF-HFP/H-M-SiO2@Silk sample was only dropped from 149.5° to 144.0° with the WSA of 8.0. Moreover, there was still more works on preparing the super hydrophobic and oleophobic silk fabric with good washing durability.

参考文献:

[1]WANG F, PI J, SONG F, et al. A superhydrophobic coating to create multi-functional materials with mechanical/chemical/physical robustness[J]. Chemical Engineering Journal, 2020, 381:122539.

[2]PAN G M, XIAO X Y, YU N L, et al. Fabrication of superhydrophobic coatings on cotton fabric using ultrasound-assisted in-situ growth method[J]. Progress in Organic Coatings, 2018, 125: 463-471.

[3]HE Z C, BAO B W, FAN J, et al. Photochromic cotton fabric based on microcapsule technology with anti-fouling properties[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 594:124661.

[4]WU J D, ZHANG C, XU S, et al. Preparation of zwitterionic polymer-functionalized cotton fabrics and the performance of anti-biofouling and long-term biofilm resistance[J]. Colloid and Interface Science Communications, 2018, 24: 98-104.

[5]CHEN K L, ZHOU J L, CHE X G, et al. One-step synthesis of core shell cellulose-silica/n-octadecane microcapsules and their application in waterborne self-healing multiple protective fabric coatings[J]. Journal of Colloid and Interface Science, 2020, 566: 401-410.

[6]KALE B M, WIENER J, MILITKY J, et al. Coating of cellulose-TiO2 nanoparticles on cotton fabric for durable photocatalytic self-cleaning and stiffness[J]. Carbohydrate Polymers, 2016, 150: 107-113.

[7]QIN R H, SONG Y H, NIU M, et al. Construction of flame retardant coating on polyester fabric with ammonium polyphosphate and carbon microspheres[J]. Polymer Degradation and Stability, 2019, 171:109028.

[8]PAN G M, XIAO X Y, YE Z H. Fabrication of stable superhydrophobic coating on fabric with mechanical durability, UV resistance and high oil-water separation efficiency[J]. Surface & Coatings Technology, 2019, 360: 318-328.

[9]OMENETTO F G, KAPLAN D L. New opportunities for an ancient material[J]. Science, 2010, 329: 528-531.

[10]LIU X S, XING T L, XU D M, et al. Study on novel eco-friendly anti-creasing agents for natural silk fabric[J]. Chinese Chemical Lettles, 2012, 23: 665-668.

[11]CHEN F G, LIU X, YANG H Y, et al. A simple one-step approach to fabrication of highly hydrophobic silk fabrics[J]. Applied Surface Science, 2016, 360: 207-212.

[12]HUANG J J, YANG Y Y, YANG L, et al. Fabrication of multifunctional silk fabrics via one step in-situ synthesis of ZnO[J]. Materials Letters, 2019, 237: 149-151.

[13]WANG H, ZHOU H, GESTOS A, et al. Robust, superamphiphobic fabric with multiple self-healing ability against both physical and chemical damages[J]. ACS Applied Materials & Interfaces, 2013, 5: 10221-10226.

[14]ASLANIDOU D, KARAPANAGIOTIS I, PANAYIOTOU C. Superhydrophobic, superoleophobic coatings for the protection of silk textiles[J]. Progress in Organic Coatings, 2016, 97: 44-52.

[15]CHENG Y, ZHUA T X, LI S H, et al. A novel strategy for fabricating robust superhydrophobic fabrics by environmentally-friendly enzyme etching[J]. Chemical Engineering Journal, 2019, 355: 290-298.

[16]CHEN F G, YANG H Y, LIU X, et al. Facile fabrication of multifunctional hybrid silk fabrics with controllable surface wettability and laundering durability[J]. ACS Applied Materials & Interfaces, 2016, 8(8): 5653-5660.

[17]STBER W, FINK A, BOHN E. Controlled growth of monodisperse silica spheres in the micron size range[J]. Journal of Colloid and Interface Science, 1968, 26: 62-69.

[18]NITAYAPHAT W, JIRAWONGCHAROEN P, TRIJATURON T. Self-cleaning properties of silk fabrics functionalized with TiO2/SiO2 composites[J]. Journal of Natural Fibers, 2018, 15: 262-272.

[19]PALCHAN I, CRESPON M, ESTRADE-SZWARCKOPF H, et al. Graphite fluorides: an XPS study of a new type of C-F bonding[J]. Chemical Physics Letters, 1989, 157(4): 321-327.

[20]LIANG Z H, ZHOU Z Z, DONG B H, et al. Fabrication of superhydrophobic and UV-resistant silk fabrics with laundering durability and chemical stabilities[J]. Coatings, 2020, 10(4): 349.

收稿日期: 20200524; 修回日期: 20201107

基金項目: 浙江省基础公益研究计划资助项目(LGG18E030009)

作者简介: Do Khai Ly(1993),女,硕士研究生,研究方向为纺织化学与染整工程。通信作者:易玲敏,教授,lmyi@zstu.edu.cn。