Contribution to the ageing control of onshore oil and gas fields

2020-04-25BelmazouziYacineDjebabrabarekHadefHefaidh

Belmazouzi Yacine,Djebabra Mébarek,Hadef Hefaidh

a LRPI Laboratory,Institute of Health and Safety - University of Batna 2,Algeria

b LRPI Laboratory and SONATRACH Group,Exploration & Production Activity,Production Division,STAH Field,Algeria

c LRPI Laboratory and Applied Engineering Department,Institute of Technology,University of Ouargla,Algeria

ABSTRACT The ageing of the Algerian oil and gas (O&G)installations has led to many incidents.Such installations are over 30 years old (life cycle)and still in operation.To deal with this O&G crucial problem,the Algerian authorities have launched a rehabilitation and modernization schedule of these installations.Within the framework of this program,many audit operations are initiated to elaborate a general diagnosis of the works to be performed while optimizing production.In other words,industrial ageing risks shall be controlled.

Keywords:Onshore Oil and gas Field Ageing Control Indicators Prioritization

1.Introduction

The ageing control of facilities constitutes a serious challenge for industrial firms [1-3].In fact,researches within data such as (BSEE,PSA,IOGP,OIL RIG,DISASTERS … etc.): shows that,at the international level,the root cause of industrial accidents is mainly due to ageing problem.In this regard,about 60% of industrial installations incidents are caused due to loss of primary containment (LOPC)representing a major hazard linked to technical integrity problems caused by ageing [4].

Other studies have confirmed such findings and focused on ageing control [5,6].In this context,two major scientific tendencies have been explored: the first one is based on Ageing Phenomenon Characterization and the second one oriented towards Ageing Control.

Concerning the first tendency,its interest essentially focused on the exploitation of the definition of ageing (degradation that may undergo an industrial installation equipment's by the effects of time and conditions of use)in order to identify the ageing potential factors [7]such as:the materials properties,equipment operating conditions,operating life and environmental conditions.

In other words,and according to the first tendency,two approaches can distinguish; the first one is Reliable Type relating to equipment under preventive maintenance program (in order to maintain a constant failure rate),and the second one is Physical Type characterized by equipment degradation [8].

The second tendency related to ageing control,studies are essentially focused on ageing main objectives consisting of safety targets and economic objectives.In this context,the various studies carried out have developed optimization methods permitting factors prioritization associated with ageing.The aim of such methods is to optimize industrial installations inspections through industrial ageing risk reduction while avoiding unnecessary inspections [9].

In other words,such methods are requiring Multi-Criteria Decision-Making (MCDM)tools allowing factors prioritization associated with industrial ageing.This paper deals with this context and aims to highlight the benefits of a MCDM method named Technique for Order-Preference by Similarity to Ideal Solution (TOPSIS)for factors prioritization associated with industrial ageing.

The rest of this paper is organized as follow.In the first part of section 2,the industrial ageing problem in Algeria,mainly in the oil and gas (O&G)industry which is considered as important as nuclear industry in developed countries will be briefly presented.However,in the second part is devoted to allocate the developed approach in comparison to the related works.Descriptions of the proposed indicators and selected method as well as its application to a sample of Algerian onshore O&G fields are detailed in section 3.Section 4 is dedicated to results discussion.In conclusion,an assessment of results and its perspectives will be presented.

2.Purpose and related works

2.1.Oil and gas industries ageing in Algeria

Oil and gas industry is a strategic sector in Algeria,dominated by SONATRACH (SH)Group.Its installations are complex and dangerous[10].The ageing of installations increases risks that are translated through potential dangers associated with such installations [11].

In this context,recent studies have shown that materials fatigue and corrosion are the Major Mechanisms of ageing [1,12].In this linkage,the leak caused by equipment's corrosion of Gas Liquefaction Plant of SH Group-Skikda (located at 200 Km East of Algeria)was the main source of the January 09th,2004 tragedy with heavy consequences (27 dead,74 injured not to mention material losses of more than 02 billion dollars).It is worthy to note that the ageing of this Plant equipment's is the main cause of the persistent explosions which were previously occurred [13].

Therefore,different types of equipment are always maintained by exploiters of SH Group in order to control their ageing.To illustrate our concerns,an example of modernization actions carried out by the Production Division of SH Group in 2017 is presented (Table 1).

To address the ageing problems of Algerian O&G installations,the National Authorities is committed to develop a strategic action plan which will be materialized through implementation of two following Executive Decrees: The Executive Decree N° 14-349 (December 23rd,2014)establishing the conditions of installations and equipment compliance associated with hydrocarbons activities,and the Executive Decree N°15-09 (January 29th,2015)establishing terms and conditions of approval specific Hazards Studies of hydrocarbons.

Among the directions of the second Executive Decree is to implement risks control instructions associated with ageing facilities (installations and equipment's).Such instructions are indeed,interesting for industrial ageing control in a sector as strategically important as O&G industry in Algeria.However,the Algerian legislator has let through general instructions a consultation interval open to the O&G industrialists in order to set up procedures allowing such instructions not only,to be operational but to be more effective.This is why it is important to strengthen such instructions with scientific approach based on ageing indicators of O&G installations,as well as their prioritizing to achieve better control of ageing problem of strategic installations.Within this context,section 3 presents an approach allowing concretizing such scientific support to the instructions mentioned below.

2.2.Previous work related to the industrial ageing control

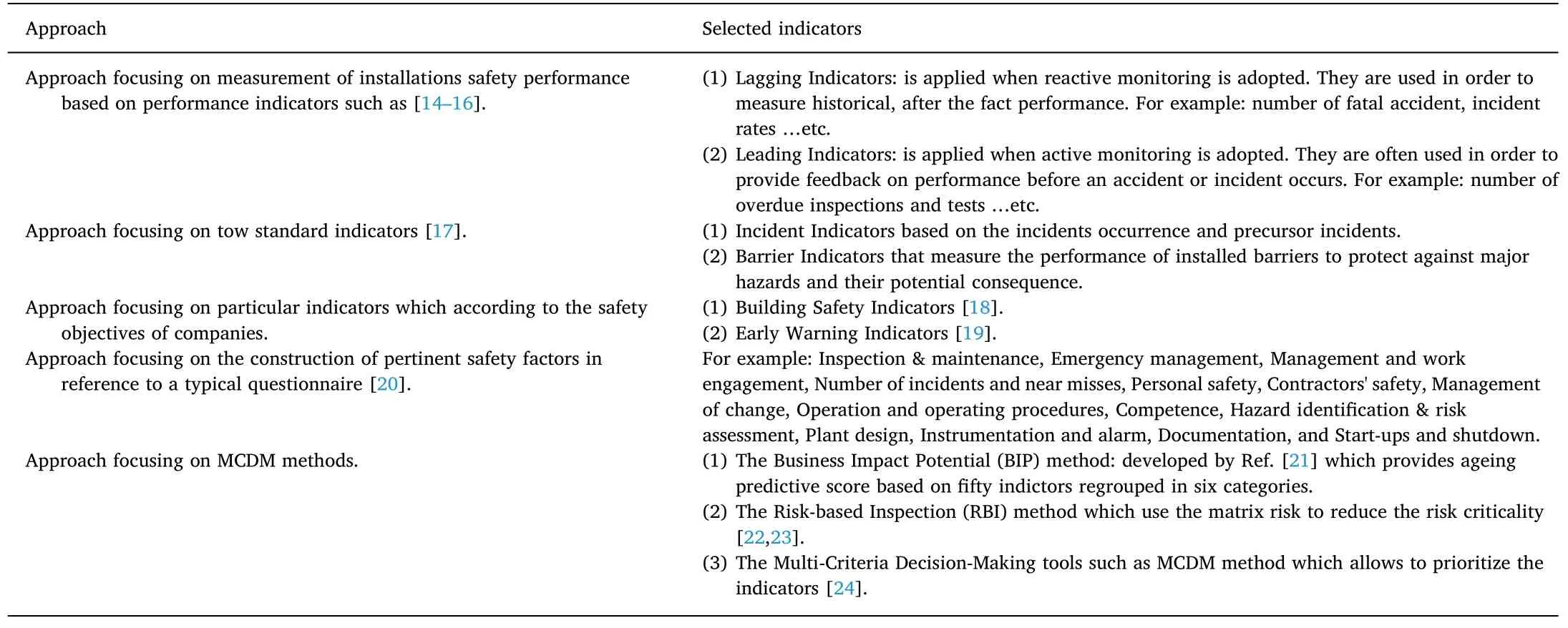

Many researchers have addressed the problem of industrial ageing to the point where several approaches have been developed (Table 2).

The discussion of approaches covering industrial ageing indicators raises three points:

(1)Some approaches (case of the first three approaches in Table 2)focus on particular indicators that do not systematically frame the O&G sector.Therefore,these indicators are classified as particular.

(2)These particular indicators are often aggregated by specific tools such as the “Probability-Consequence (P-C)matrix” used in the RBI method.However,some authors as [25-27]point out that the "(P-C)matrix” method suffers from many limitations such as: (i)low resolution which restores,in a certain number of cases,identical risk levels to different risk levels on the quantitative plan,(ii)errors due to assignment of high qualitative scores to low quantitative risks,(iii)allocation of under-optimal resources,because the risk treatment cannot be based on the categories provided by the “P-C matrix”,and (iv)ambiguous inputs-outputs because they are requiring subjective interpretations and users may reach different classifications based on the same risk classification.

(3)The use of questionnaire for indicators construction is considered as an interesting approach because it helps to retain as many indicators that allows bettering to frame the questionnaire thematic(industrial ageing in our case).However,indicators derived from the Questionnaire-based Approach (QBA)must be processed by classification methods such as the Principal Component Analysis(PCA)method [26,27]or to prioritize those using MCDM methods in which TOPSIS is the most recommended tool [28].

This paper deals with such context and aims to initially determine,the ageing indicators of Algerian onshore O&G installations and secondly,to prioritize such indicators based on MCDM method to reach better control of ageing problem.

3.Developed approach

The proposed approach for ageing control of Algerian O&G installations consists of two stages as detailed below.

3.1.Proposition of industrial ageing indicators

To solve the ageing problem of Algerian O&G installations,it is imperative as first step,to focus on ageing phenomenon analysis.Such phenomenon appears over time through gradual degradation process due to the use of installations equipment's.In other words,ageing analysis consists in identifying and/or monitoring potential factors.Recent studies as [7,29]recommend focusing on factors such as: environmental conditions,conditions of use (or operating regime),operating time of equipment's,equipment properties … etc.

Such factors may be formalized by ageing indicators that must be defined,assessed and prioritized.

The benefits to use of ageing industrial indicators are various like[30]: risks communication associated with industrial installations because of ageing problem,helping in decision making allowances on control of ageing and assessing the achieved progress either in ageing control or in installations’ modernization in order to address ageing problem.

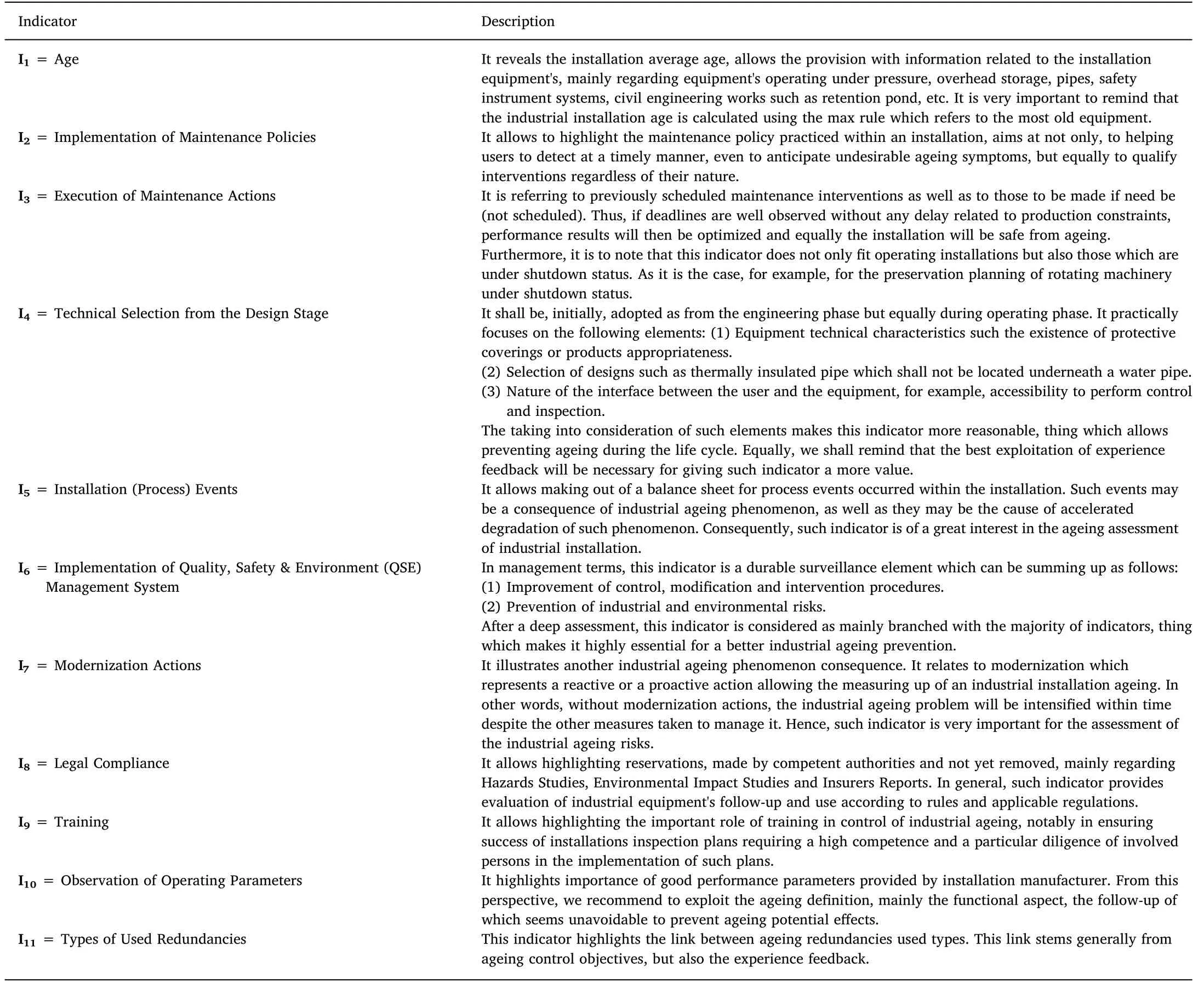

Due to the importance of industrial ageing indicators,it is imperative when proposing them to take into consideration some criteriasuch as [31]: stakeholders consultation,experience feedback (EF),quality and relevance of proposed indicators.Such criteria are taken into consideration when creating the following indicators (Table 3).

Table 1 Summary of modernization actions (SH Group).

Table 2 Different approaches to industrial ageing.

These indicators have been audited in order to examine their quality and usability.This audit,conducted among the HSE (Health,safety &environment)managers of SH Group fields,showed that these eleven indicators: (i)fit perfectly with the SH Group objective,which is to control the ageing of installations,(ii)perfectly complement each other without being duplicated and (iii)that they align with applicable standards and regulations.

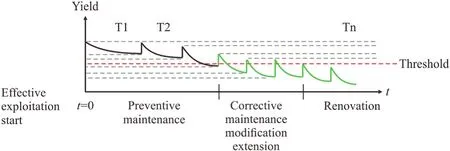

A general assessment regarding all adopted indicators is that such indicators are independent (Fig.1)in a proportional or an inversely proportional manner.In fact,we confirm that an advanced age of a given industrial installation will have effects in terms of maintenance strengthening and its execution on time,observation of operating parameters,as well as appropriate technical selection which is in most cases,materialized by: modifications,used redundancies types,events data availability,QSE Management System requirements,potential implementation of modernization actions,and mainly of an objective evaluation of its legal compliance,in addition to an action plan dedicated to training.

It should be noted that other indicators may be added such as the organization.However,for the sake of indicators' standardization of all SH Group facilities,on one hand,and in view of the fact that organization is implicit,taken into account through its distribution over the proposed indicators,it's considered useful to limit ourselves to the eleven proposed indicators resulting from reviewing of industrial field's managers which selected in this study.Likewise,it's used if the proposed indicators are incorporated in life cycle management (LCM).

The final observation is that industrial ageing problems are not limited to outcome indicators (highlighting industrial ageing problem which may be represented by I1& I5),but are also,concerned with context indicators (ageing analysis represented by I2,I3,I8,I9& I10),as well as output indicators (ageing control by I4,I6& I11and of modernization by I7).

3.2.Proposed indicators’ prioritization

The objective of the second stage is prioritization of the proposed indicators of all industrial fields within the same sector (our case is related to O&G industry).

Indicators’ prioritization requires the use of Multi-Criteria method such as TOPSIS method which is developed for MCDM [32].This method is used in many research areas due to its flexibility [28,33].In this respect,many fields are closed to industrial ageing such as:

(1)Risk assessment [34]: has evoked the contribution of this method resulting from its application in a case of Gas Refinery.

(2)Environmental analysis [35]: has studied the impact of environmental releases by Iranian Cement Plants.The application of TOPSIS method has highlighted the importance of ISO 14000 (Environmental Management System)in preventing environmental risks in connection with Cement Plants.

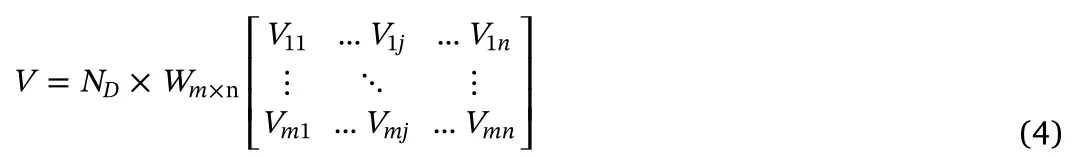

The basic concept of such method consists in elaborating a decision matrix “D'',in which,columns will be corresponding to fields and lines to indicators (Eq.(1)):

Each ''rij'' element of the decision matrix ''D'' may be calculated as follows:

where ''ii'' is the indicator's relative importance,''k'' being the indicator's value and ''s'' is the standard value.

The handling of the decision matrix ''D'' in prioritization of ageing indicators will be made in succession of the following stages:

(1)Performance normalization by the Eq.(3):

where ''nij'' is the normalized value of ''rij''.It is an important stage to measure different units' indicators and consequently,the ''D'' matrix scores are transformed to normalized values.

Table 3 List of proposed indicators.

Fig.1.Industrial installation life-cycle modernization (IILM).

where ''ND″ is normalized decision matrix and ''Wm×n'' is the weight matrix,which equivalent for all fieldsV=ND.

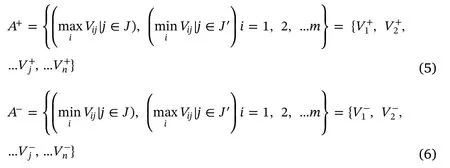

(3)Determine the positive and negative ideal solutions (profiles)(Eq.(5)and (6)):

where ''J'' is associated with advantage indicator and ''J‴ is associated with cost indicator.Hence,the ideal positive alternative is characterized by extreme performances on each indicator and the ideal negative alternative is characterized by inverse extreme performances on each indicator.

(4)Calculation of Euclidean distance compared with profiles: the positive ideal solution and the negative ideal solution (Eq.(7)and(8)):

(5)Calculation of reconciliation measurement coefficient with ideal profile (Eq.(9)):

Finally,the last stage consists in indicators’ classification by descending order of C+i.

3.3.Results

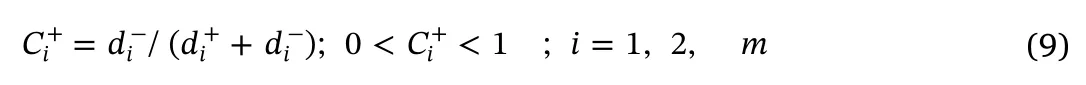

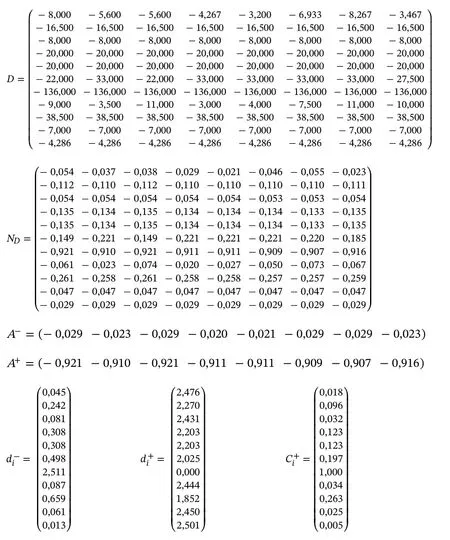

To assess relevance of the selected method,such method will be applied to industrial fields of SH Group O&G facilities.It concerns eight onshore oil and gas fields located at South of Algeria which are: Hassi R'Mel (HRM),Haoud Berkoui (HBK),Hassi Messaoud (HMD),Gassi Touil (GTL),TFT (Tin Fouye Tabankort),Ohanet (OHNT),In Amenas(INAS)& Stah (STH).

The Table 4 provides data related to the selected fields,it shows that such fields are of great importance for SH Group owing to: large areas of each field,personnel number and production capacity.The selected fields are considered as 1st Category Facilities; hence,they are submitted to Ministerial Authorization.

除反刍动物自身和饲料原料差异的影响外,如何使饲料利用达到最大效率对反刍动物至关重要。饲料加工的目的就是为了充分发挥饲料的营养价值潜力,从而提高饲料产品的质量和饲养效果。目前,对饲料的加工处理方法很多,主要包括物理加工、化学加工和生物学加工等方法。

The application of ageing indicators’ prioritization method to O&G fields that are selected in the Table 3 starts through the quantification of these indicators (Table 5).

It should be highlighted that Table 5 values are representing nonefficiency percentage of each indicator derived from Company Annual Report (HSE,Maintenance and Technical Support)of each field,except that the first directly represents the age of each field.Therefore,relative importance values are inspired from the field (appreciations provided by managers of selected fields).However,standard values are set with regard to Global Management of such selected fields.Consequently,from the data in Table 5 and according to equation (1)- (9),the following results are obtained:

Table 5 Ageing indicators’ quantification.

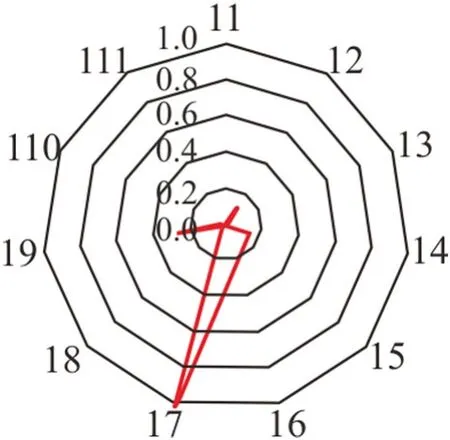

Hence,proposed indicators’ prioritization (Fig.2):

Table 4 Data drawn from selected fields.

4.Discussion

The obtained results through indicators’ prioritization,prompt us to refer to three significant points:

(1)Confirmation of studied fields ageing.Therefore,modernization schemes are an absolute necessity.

(2)Necessity of supervising modernization schemes through strategic action plan (AP)governed by QSE Management System.

(3)The importance of training in this action plan.

In our point of view,this action plan must focus essentially on two aspects: diagnosis of the studied fields and the launch of fields’ compliance program in accordance with the Executive Decree N° 14-349.

As regards compliance program,it is imperative to focus on integrity and fire proofing of technical equipment's,different studies such as: (Hazardous Area,Safety Integrity Level,Occupational Hazards Assessment,Hazards Study and Environmental Impact Study),civil infrastructures integrity,modification management and operating procedures updating.

In fact,the success of the action plan which tackles the ageing problems depends on SH Group ability to develop its human resources(HR)and mobilizing them towards the action plan which integrates its strategic priorities.In addition to this,it is necessary within the framework of such plan to take into consideration the diagnosis effect of SH Group onshore O&G fields when launching HSE-MS (Health,Safety and Environment- Management System)and consequently,an appropriate action plan.

The results of ageing indicators' prioritization confirm also,the interest of the first principle of industrial prevention [36]by controlling risks at the source (I4).In this regard,an Industrial Modernization Reference is approved by SH Group allowing the modification of necessary equipment's.Likewise,the instruction number 224/2017(February 16th,2017)issued by the Group for identifying installations and equipment's subject to regulation and legislation,confirms the importance of the fifth indicator (I5).

Concerning the three indicators (I2,I8& I3)which indicate successively,the importance of the adopted maintenance policy,reservations to applicable regulatory,execution of interventions and their prioritization shows that is necessary to give serious consideration to such indicators,notably in terms of quality,costs and time limits of actions taking into account such indicators.In this regard,managers of SH Group are aware of efforts that must be made in this context,thing which justifies the development strategy adopted by this Group for 2030 timeline (SH Project 2030).

A particular attention should be given to the benefit of operating parameters observation (I10)(static and dynamics equipment's,etc.),because they represent a selective place.Prioritization of the indicator(I1)in next-to last position confirms the obligation to strengthen the selected fields' modernization efforts while moving further apart,the idea that ageing can be only measured by life cycle duration.Lastly,redundancies types are in the last position due to the benefit of experience feedback mainly starting from the design phase.For example,the fire and gas system redundancies to avoid frequent triggering and consequently,the fatigue of attached installations.

Fig.2.Prioritization of selected fields ageing indicators.

Finally,one merit of the developed approach in this paper is the possibility of its use in other O&G sectors (offshore,for example).This is possible by adding other specific indicators to this sector because the MCDM-based approach aims to expand the list of indicators in order to better frame the O&G sector to be study.As a result,the selected method can be used in other O&G fields in other O&G-producing countries that have older installations such as those in Algeria.However,the indicators' prioritization differs from one country to another because the data used in the industrial ageing indicators’ prioritization are specific to each industry Group.This is an advantage in that the selected method in this paper compares ageing control policies between different O&G-producing countries.

5.Conclusions

On the practical side of the industrial ageing problematic,this paper presents the contribution of the TOPSIS method to prioritize onshore O&G fields ageing indicators.The purpose of this prioritization is to promote the selection of priority actions (axes of progress)to control the ageing of these fields,and consequently,the proper conduct of the modernization plan of these fields that the SH Group intends to launch in the near future.Likewise,the selected method is perfectly in line with the industrialists' practice related to industrial ageing where it focuses on “equipment deemed important” to establish an adequate industrial ageing control policy.In fact,the industrial ageing indicators’prioritization ensures adequate and optimal monitoring of this policy.

Methodically speaking,the selected method enables to overcome the limits commonly encountered with different approaches related to industrial ageing assessment by expanding the list of indicators to include different aspects of ageing while facilitating decision-making based on the proposed indicators’ prioritization.

The deployed method also remains flexible since the relative importance of the proposed indicators can be modified by including the results taken from the Questionnaire-based Approach (QBA).Finally,this method can be integrated into the QBA,which makes it possible to strengthen the regrouping of the items by prioritizing their obtained groups by the data classification methods.This is one of the possible perspectives of this paper.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.petlm.2019.11.006.

猜你喜欢

杂志排行

Petroleum的其它文章

- Wax deposition mechanisms and the effect of emulsions and carbon dioxide injection on wax deposition: Critical review

- Review of intelligent well technology

- Research about distal-basin shallow-river fluvial-dominated delta mode of Xiaoheba formation of Silurian of Southeastern Sichuan Basin and thinking about oil and gas exploration

- Wellbore stability analysis of layered shale based on the modified Mogi-Coulomb criterion

- Effectiveness and sensitivity analysis of solution gas re-injection in Baikouquan tight formation,Mahu sag for enhanced oil recovery

- Polymeric microsphere injection in large pore-size porous media