基于组合磁极的无轴承永磁同步电机转子优化设计

2020-04-22朱熀秋程一峰

朱熀秋 程一峰

摘 要:无轴承永磁同步电机是一种正弦波驱动的电机,气隙磁场的正弦性影响着电机的性能,为了获得较小的转矩脉动和悬浮力脉动,提出了永磁体采用组合磁极的特殊结构。首先阐述了该结构对改善气隙磁场正弦性的作用,推导出了新的数学模型。其次,基于有限元分析,利用田口法正交试验,以电机的电磁转矩脉动与转矩平均值的比值和悬浮力脉动与悬浮力平均值作为评价标准,优化设计了磁极参数。最后将优化后的组合磁极式BPMSM与传统的单一磁极的BPMSM对比分析,结果显示,优化后的电机空载气隙磁密波形得到了明显改善,在保证转矩和悬浮力大小的基础上,转矩脉动和悬浮力脉动显著减小。

关键词:无轴承永磁同步电机;组合磁极;田口法;转矩脉动;悬浮力脉动

DOI:10.15938/j.emc.2020.03.015

中图分类号:TM 303文献标志码:A文章编号:1007-449X(2020)03-0123-08

Abstract:The bearingless permanent magnet synchronous motor(BPMSM)is driven by sinusoidal wave, so the performance of motor is affected by sinusoidal shape of the airgap magnetic flux distribution. To reduce the torque ripples and suspension force ripples, a special structure called modular permanent magnet poles is proposed. Firstly, the effect of the structure to improve sinusoidal shape of the airgap magnetic flux distribution was described. Then, a mathematical model is deduced. Secondly, taguchi method was employed to optimize magnetic pole parameters where the ratio of torque ripples to average torque and the ratio of suspension force ripples to average suspension force were chosen as an objective function. Finally, conventional BPMSM with common pole and the BPMSM with modular pole were compared. The results show that the optimized noload airgap flux density waveform is significantly improved and lower torque ripples and suspension force ripples are produced based on almost the same average torque and suspension force.

Keywords:bearingless permanent magnet synchronous motor; modular poles; taguchi method; torque ripples; suspension force ripples

0 引 言

無轴承永磁同步电机(bearingless permanent magnet synchronous motor,BPMSM)继承了磁悬浮轴承没有机械磨损、噪声小和寿命长等优点,于此同时具有永磁同步电机的优良运行特性,受到了人们越来越多的关注。BPMSM在定子中同时嵌入极对数相差为1的转矩绕组和悬浮力绕组,转矩绕组和永磁体产生的气隙磁链作用生成转矩,转矩绕组与永磁体产生的合成气隙磁链与悬浮绕组产生的气隙磁链作用生成悬浮力。对于正弦波驱动的无轴承永磁同步电机,永磁体的气隙磁密分布影响着BPMSM的性能,当气隙磁密分布为正弦波时性能最佳,永磁体磁密分布的形状主要取决于永磁体的材料和磁极参数。

目前出现了许多永磁体磁极的设计方法,文献[1]中提出正弦磁极调制式的永磁电机,小磁块阵列构成转子的永磁体磁极,调整阵列中磁块的宽度、高度和磁块间的间隔,使其产生的气隙磁场波形更加接近于正弦波,提升电机的输出性能,但是增加了电机加工的复杂度。文献[2]也提出使用永磁体阵列的方法,每个永磁体和相邻阵列的磁化方向相差90o,这种方法需要不同尺寸的永磁体块,同样增加了永磁电机制造的复杂度和成本。文献[3]针对开关磁阻永磁电机提出使用钕铁硼和铁氧体材料的组合磁极方案,从整体来看,电机的制造成本被减少了,但是采用这样的组合磁极方案,因为两种磁极材料之间性能相差较大,结合起来形成组合磁极不仅加工困难,而且造成的转矩波动较大,同时如果需要保证和只使用高性能磁极材料相同的输出能力,就需要增加电机的轴向长度。

针对以上的问题,本文提出采用组合磁极改善气隙磁密正弦性的方法,其中组合磁极所用的材料为不同型号的钕铁硼。通过将这些磁极材料作为永磁体段的方式进行组合,形成厚度相同,宽度不同的组合磁极,可以改善气隙磁密的波形,进而提高电机的性能。本文分析了组合磁极改善气隙磁密的原理,推出了采用组合磁极的表贴式无轴承永磁同步电机的数学模型,基于有限元分析,采用Taguchi方法进行正交试验,以转矩脉动和悬浮力脉动为评价标准,优化设计了该电机转子磁极的结构参数。

1 组合磁极的磁密分布

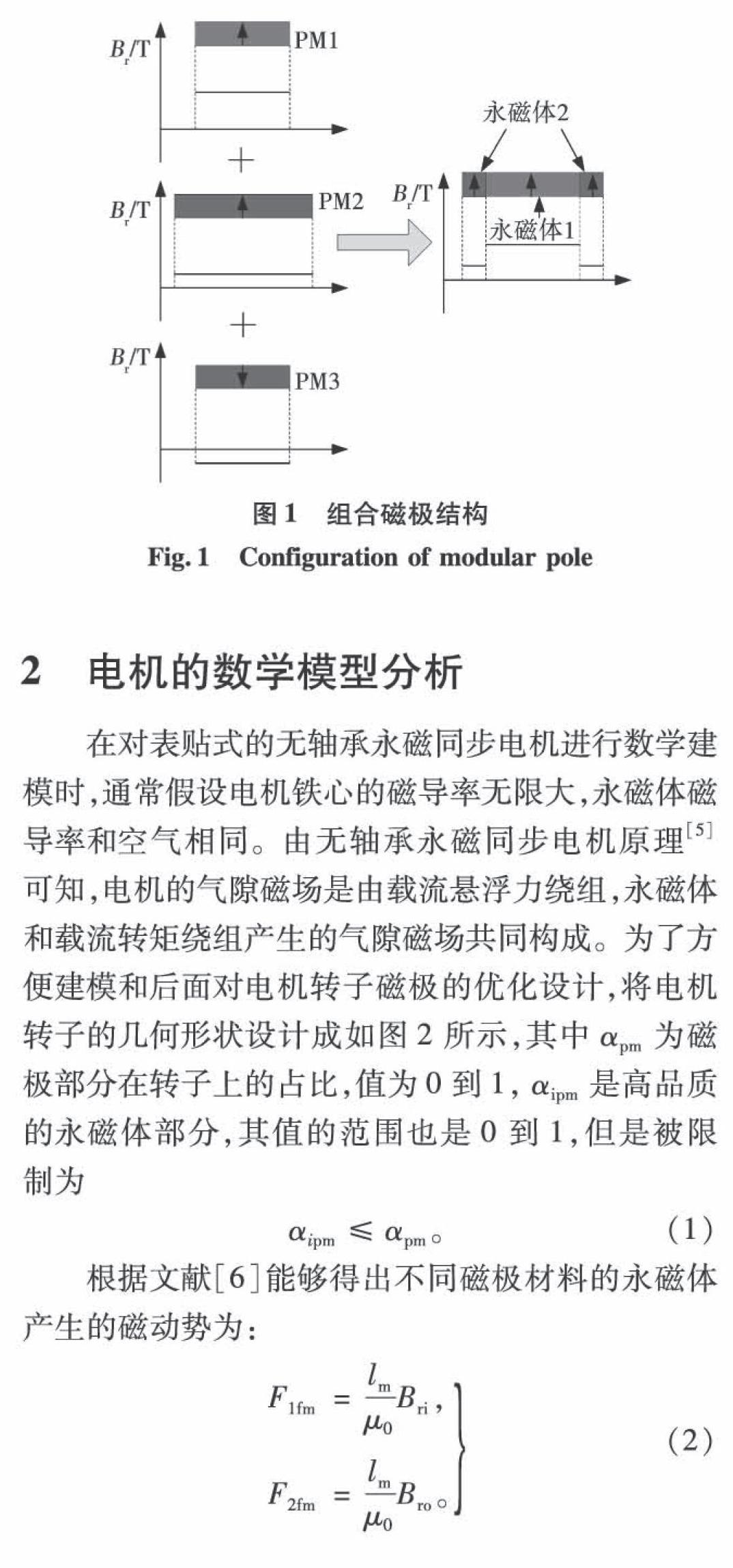

组合磁极由两种磁极材料组成,每块永磁体的剩余磁通密度如图1所示,两种材料的永磁体剩余磁通密度通过线性叠加后的剩余磁通密度提高了正弦度。因此,在永磁体厚度一定的条件下,可以通过合理配置两种磁极材料的宽度比获得正弦度较高的气隙磁密分布。

组合磁极中的磁极材料都是采用径向充磁的方式,其中中间部分的磁极材料性能优于两边的磁极材料,磁极两边的磁极材料相同。为了便于后面数学建模的建立与转子磁极的优化设计,将组合磁极在气隙中产生的磁密当作三块材料单一的磁极在气隙中产生磁密的线性叠加,通过分别计算每块磁极材料的气隙磁密可以获得组合磁极的气隙磁密。

4 结 论

本文对组合磁极的磁密分布进行了分析,建立了采用组合磁极的无轴承永磁同步电机的数学模型,基于有限元分析,以转矩脉动和悬浮力脉动为评价标准,采用Taguchi方法优化设计了采用组合磁极的无轴承永磁同步电机的磁极参数,有效提高了气隙磁密的正弦度,有效减少了电机的转矩脉动和悬浮力脉动,提升了电机的运行性能。

参 考 文 献:

[1] 安跃军, 温宏亮, 安辉, 等. 正弦极宽调制式永磁电机的磁场分析与实验[J]. 电机与控制学报, 2011, 15(11):61.

AN Yuejun, WEN Hongliang, AN Hui,et al. Magnetic field analysis and experiment of sinusoidal pole width modulation permanent magnet motor[J]. Electric Machines and Control, 2011, 15(11): 61.

[2] LEE M G, LEE S Q, GWEON D G. Analysis of halbach magnet array and its application to linear motor[J]. Mechatronics, 2004, 14(1): 115.

[3] AFINOWI I A A, ZHU Z Q, GUAN Y,et al. Performance analysis of switchedflux machines with hybrid NdFeB and ferrite magnets[C]//Proceedings of 2014 17th International Conference on Electrical Machines and Systems, October 22-25, 2014, Hangzhou, China. New York: Institute of Electrical and Electronics Engineers Inc. 2015: 3110-3116.

[4] ISFAHANI A H, VAEZZADEH S, RAHMAN M A. Performance improvement of permanent magnet machines by modular poles[J]. IET Electric Power Applications, 2009, 3(4): 343.

[5] 李慧. 无轴承永磁同步电机悬浮力模型及运行控制研究[D]. 镇江:江苏大学,2016.

[6] OOSHIMA M, CHIBA A, FUKAO T, et al. Design andanalysis of permanent magnettype bearingless Motor[J]. IEEE Transactions on Industrial Electronics, 1996, 43(2): 292.

[7] KASHA ANDREW E, SUDHOFF SCOTT D. Multiobjective design optimization of a surfacemounted modular permanentmagnet pole machine[C]//Proceedings of the 2016 IEEE Power and Energy Conference at Illinois, February 19-20, 2016, Urbana, IL, United states. New York: Institute of Electrical and Electronics Engineers Inc. 2016.

[8] ISFAHANI A H,VAEZZADEH S, RAHMAN M A. Using modular poles for shape optimization of flux density distribution in permanentmagnet machines[J]. IEEE Transactions on Magnetics, 2008, 44(8): 2009.

[9] 杨玉波,王秀和,朱长青. 组合磁极削弱永磁同步电动机转矩脉动方法研究[J]. 电机与控制学报,2013,17(2):34.

YANG Yubo, WANG Xiuhe, ZHU Changqing. Research of modular pole on the reduction of torque ripple of permanent magnet synchronous motor[J]. Electric Machines and Control, 2013, 17(2):34.

[10] OMEKANDA A M. Robust torque and torqueperinertia optimization of a switched reluctance motor using the taguchi methods[J]. IEEE Transaction on Industry Applications, 2006, 42(2):473.

[11] 曹永娟,黄允凯,金龙,等. 磁极组合型轴向磁场无铁心永磁电机的设计与分析[J]. 中国电机工程学报,2014,34(6):903.

CAO Yongjuan, HUANG Yunkai, JIN Long, et al.Design and analysis of a stator coreless axialflux permanent magnet machine with module poles[J]. Proceedings of the CSEE, 2014,34(6):903.

[12] 王明杰,程志平,焦留成. 组合磁极无槽PMLSM正弦磁场分析[J]. 电机与控制学报,2015,19(4):34.

WANG Mingjie, CHENG Zhiping, JIAO Liucheng.Analysis on the sinusoidal magnetic field of slotless PMLSM using modular poles[J]. Electric Machines and Control,2015,19(4):34.

[13] LI Guangjun ZHU Ziqiang. Demagnetization of modular surface mounted permanent magnet machines[C]// Proceedings of the 2016 22nd International Conference on Electrical Machines, September 4-7,2016, Lausanne, Switzerland. New York: Institute of Electrical and Electronics Engineers Inc. 2016: 702-708.

[14] 林展汐. 基于組合磁极的一字型内置式永磁同步电机的研究[D]. 哈尔滨:哈尔滨工业大学,2015.

(编辑:贾志超)