聚丙烯/聚烯烃弹性体复合材料物理机械性能及交流电性能

2020-04-22赵洪栗松郑昌佶宋淑伟张文龙

赵洪 栗松 郑昌佶 宋淑伟 张文龙

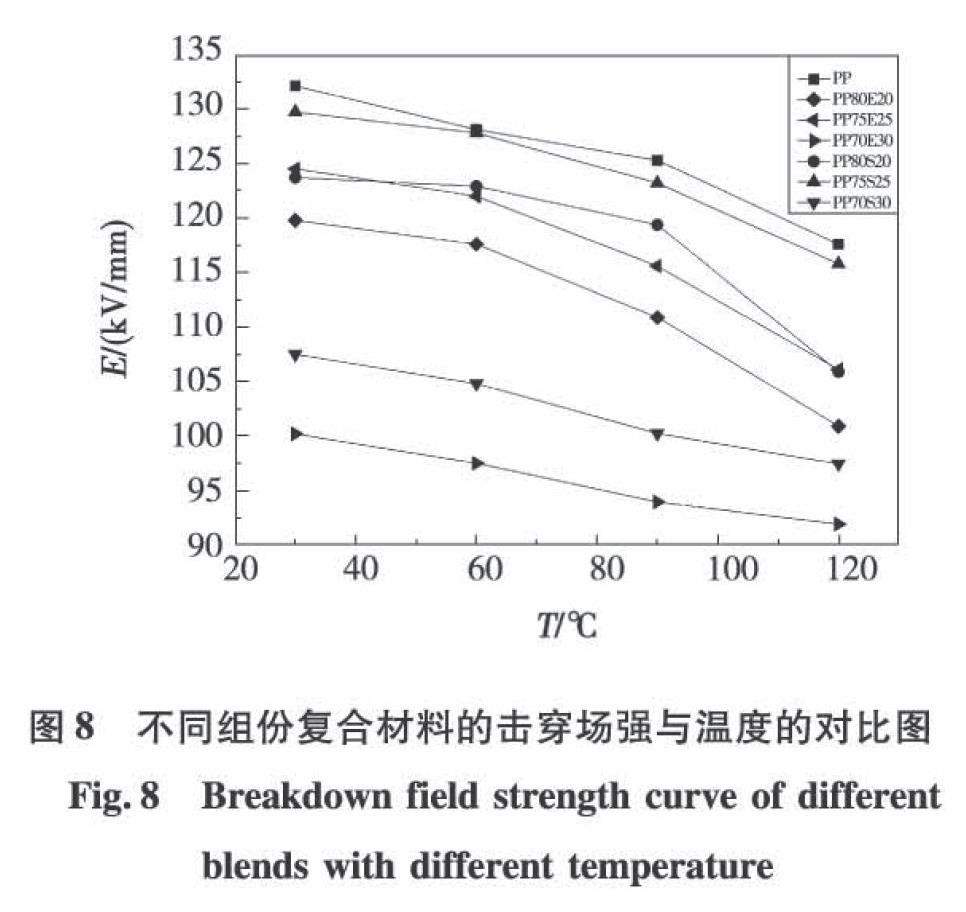

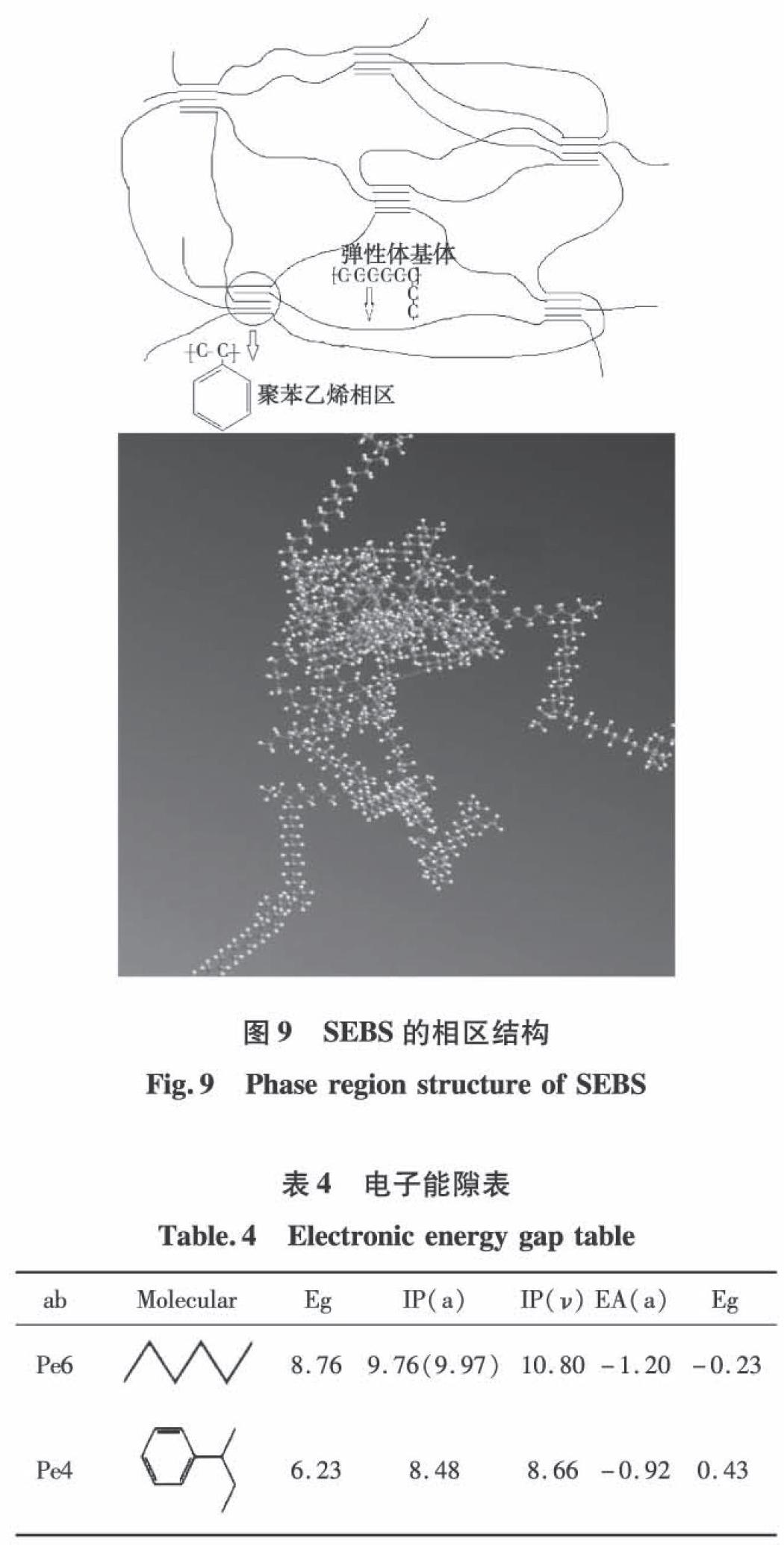

摘 要:聚丙烯(PP)分別与乙烯-辛烯共聚物(POE)弹性体、苯乙烯—乙烯/丁烯—苯乙烯三嵌段共聚物(SEBS)熔融共混,制备出不同质量分数的弹性体/PP复合材料。SEM结果表明复合材料微观形貌呈现弹性体均匀分布在PP中构成的“海岛结构”,随着复合体系中弹性体含量的增加,岛相浓度与尺寸均增大。DSC结果表明当弹性体含量增加时,复合材料结晶度略有下降。力学测试结果表明165 ℃下复合材料的热延伸形变量均大于PP的热延伸形变量,且随弹性体含量增加复合材料热延伸形变量逐渐增加。DMA测试结果表明30%质量分数的POE/PP复合材料的25 ℃弹性模量降低至约750 MPa。交流介电强度测试结果表明不同温度下复合材料交流介电强度均小于PP,其中25%质量分数的SEBS/PP复合材料交流介电强度最接近PP。弹性体/PP复合材料中的“海岛结构”既保留了PP较高温度下的机械强度,又明显降低了PP材料的硬度,增加了韧性和柔顺性。

关键词:聚丙烯;弹性体;微观形态结构;力学性能;交流击穿强度

DOI:10.15938/j.emc.2020.03.004

中图分类号:TM 854文献标志码:A文章编号:1007-449X(2020)03-0028-10

Abstract:Polypropylene/elastomer blend materials with different content (20%,25%,30%) of elastomer are prepared by blending polypropylene and ethylene/octene copolymer elastomers(POE), polypropylene and styreneethylene/ butylenestyrene triblock copolymer (SEBS). The properties of the blends were tested by SEM, polarizing microscope test,DSC,mechanical performance,DMA,and breakdown performance to investigate the micromorphology and crystallization properties, AC breakdown strength and mechanical properties of PP and blends. The results of SEM showed that the elastomer distributed evenly in PP,and formed “island structure”. With the content of elastomer increasing,the concentration and size of island phase increased too. In the same composition,the island phase size of the SEBS/PP composite material is significantly smaller than that of the POE/PP composite material. The results of DSC showed that when the content of elastomer increased,the crystallinity of composite material decreased slightly,but the crystallization temperature (Tc) and crystalline melt temperature (Tm) did not change significantly. Tensile mechanical test results showed that the thermal extension deformation quantity of composite under 165 ℃ were greater than PP,with the content of elastomer increasing,the result increased too. When the content of POE is 30wt%,the deformation quantity rose to 11%,the tensile yield stress of 30wt% SEBS composites decreased to 20.01 MPa. DMA test results show that the elastic modulus decreased to about 750 MPa with the component of 30wt% POE at 25 ℃. Breakdown strength of the composites is generally lower than that of PP,but the composite with 25wt% SEBS almost keeps the breakdown performance of pure PP. The “island structure” in PP/elastomer blends retains the mechanical strength of PP,reduces the hardness of material significantly and increases the toughness and flexibility of PP at the same time.

Keywords:polypropylene; elastomers; microstructure; mechanical properties; AC breakdown strength

2)弹性体的加入,对复合材料力学性能改善明显,降低了屈服应力,提高了断裂伸长率,明显降低了储存模量,进而提高了韧性和柔顺性,适合于高压电缆的应用,复合材料较好的保持了耐热性,165 ℃热延伸值均小于11%。

3)弹性体的加入使复合体系的交流耐电强度降低,归因于岛相结构呈非晶相聚集态,分子间距大,电场下电子加速作用增强。同组分SEBS对PP的耐电强度保留程度优于POE。复合体系的相对介电常数和介质损耗角正切值都保持较低值,不影响材料在工频下的应用。

本文根据对聚丙烯/弹性体复合体系的交流电性能和物理性能的基础性研究认为,SEBS的添加量为25wt%的复合体系对PP高耐电强度特性保留最好,且机械性能表现优良,认为最具备工业化应用的潜力[21]。

参 考 文 献:

[1] 罗潘,任志刚,徐阳,等.退役高压交联聚乙烯电缆老化状态分析[J].电工技术学报,2013,28(10):41.

LUO Pan,REN Zhigang,XU Yang,et al. Aging condition analysis of high voltage XLPE cables out of service[J]. Transactions of China Electrotechnical Society,2013,28(10):41.

[2] 何金良,彭琳,周垚.环保型高压直流电缆绝缘材料研究进展[J].高电压技术,2017,43(2):337.

HE Jinliang,PENG Lin,ZHOU Yao. Research progress of environmentfriendly HVDC power cable insulation materials [J]. High Voltage Engineering,2017,43(2):337.

[3] 刘刚,刘斯亮,金尚儿,等.基于理、化、电特性的110 kV XLPE绝缘电缆剩余寿命的综合评估[J].电工技术学报,2016,31(12): 72.

LIU Gang,LIU Siliang,JIN Shanger,et al. Comprehensive evaluation of remaining life of 110 kV XLPE insulated cable based on physical,chemical and electrical properties[J] Transactions of China Electrotechnical Society,2016,31(12): 72.

[4] 夏向阳,张琦,李明德,等.证据理论与模糊理论集成的 XLPE 电缆绝缘状态评估研究[J].电力系统保护与控制,2014(20):13.

XIA Xiangyang,ZHANG Qi,LI Mingde,et al. Research on insulation assessment of XLPE cables based on evidence and fuzzy theory integrated method [J]. Power System Protection and Control,2014(20):13.

[5] 赵聪.对高压交联聚乙烯电缆的寿命评估及展望[J].电气技术,2014,15(4):60.

ZHAO Cong.For the life of the crosslinked polythene cable for high pressure evaluation and prospects[J]. Electrical Engineering,2014,15(4):60.

[6] HUANG Xingyi,JIANG Pingkai,FAN Yuanyuan. Polypropylene based polypropylene based thermoplastic polymers for potential recyclable HVDC cable insulation applications[J]. IEEE Transactions on Electrical and Electronic Engineering,2017,24(3): 1446.

[7] 陶国良,廖小军,方建波,等.不同弹性体对聚丙烯的协同增韧[J].高分子材料科学与工程,2013,29(3):55.

TAO Guoliang,LIAO Xiaojun,FANG Jianbo,et al.Synergistic toughening effect of different elastomers on Polypropylene [J]. POLYMER MATERIALS SCIENCE AND ENGINEERING. 2013,29(3):55.

[8] QAZVINIHA M R,ABDOUSS M,MUSAVI M,et al. Physical and mechanical properties of SEBS/polypropylene nanocomposites reinforced by nano CaCO3[J]. Materialwissenschaft Und Werkstofftechnik,2016,47(1):101.

[9] 錢微,李颖,王霞,等. 聚丙烯对SEBS弹性体的改性作用与结晶行为[J].高分子材料科学与工程,2014,30(4):50.

QIAN Wei,LI Ying,WANG Xia,et al.Crystallization behaviors of polypropylene in SEBS elastomer compounds[J].Polymer Materials Science and Engineering,2014,30(4):50.

[10] ZHOU Yao,HE Jinliang,HU Jun,et al.Surfacemodified MgO nanoparticle enhances the mechanical and direct current electrical characteristics of polypropylene/polyolefin elastomer nanodielectrics [J].Journal of Applied Polymer Science,2016,133(1): 58.

[11] 江平开,孙小金,黄宇,等.纳米氧化镁聚丙烯复合绝缘材料的制备及其性能[J].高电压技术,2017,43(2):355.

JIANG Pingkai,SUN Xiaojin,HUANG Yu,et al. Preparation of MgO/polypropylene insulation nanocomposites and their properties[J]. High Voltage Engineering,2017,43(2):355.

[12] 周垚,党斌,胡军,等.纳米氧化镁颗粒对聚丙烯的性能调控[J].中国电机工程学报,2016,36(24): 6619.

ZHOU Yao,DANG Bin,HU Jun,et al. Effect of Magnesium Oxide Nanoparticles on Tailoring the Properties of Polypropylene [J]. Proceedings of the CSEE,2016,36(24): 6619.

[13] SHARMA R,MAITI S N.Effects of SEBSgMA copolymer on nonisothermal crystallization kinetics of polypropylene[J]. Journal of Materials Science,2015,50(1):447.

[14] PARAMESWARANPILLAI J,JOSE S,SIENGCHIN S,et al. Phase morphology,mechanical,dynamic mechanical,crystallization,and thermal degradation properties of PP and PP/PS blends modified with SEBS elastomer[J]. International Journal of Plastics Technology,2017:1.

[15] 杨佳明,赵洪,郑昌佶,等.纳米粒子分散性对SiO2/LDPE纳米复合介质直流介电性能的影响[J]. 中国电机工程学报,2015,3(19):87.

YANG Jiaming,ZHAO Hong,ZHENG Changji,et al. Effects of nanoparticles dispersion on the DC dielectric properties of SiO2/LDPE nanocomposite[J]. Proceedings of the CSEE,2015,3(19):87.

[16] 王伟,孙辉,李富平,等.电缆本体中空间电荷的测量与特性[J].电工技术学报,2015,30(1):255.

WANG Wei,SUN Hui,LI Fuping,et al. Space charge measurement and characteristics in the actual cable [J],Transactions of China Electrotechnical Society,2015,30(1):255.

[17] 屠德民,吴力煌,刘文斌,等.国产交联聚乙烯电缆绝缘介电性能的试验研究[J].电线电缆,1983,(4): 14.

[18] 徐航,杜伯学,苏金刚.拉伸状态下聚丙烯/聚烯烃弹性体共混物的空间电荷和陷阱分布特性[J].高电压技术,2017,43(2):453.

XU Hang,DU Boxue,SU Jingang. Space charge behaviors and trap distributions of Polypropylene/ Polyolefin elastomerblend under different elongation ratios [J]. High Voltage Engineering,2017,43(2):453.

[19] HARIPRASAD K,SENTHILKUMAR M. Dynamic mechanical properties of PP/MMT/OMMT nanocomposites[C]//Frontiers in Automobile and Mechanical Engineering.IEEE,2011:16-20.

[20] ZHOU Yao,HE Jinliang. Evaluation of polypropylene/polyolefin elastomer blends for potential recyclable hVDC cable insulatio applications[J]. IEEE Transactions on Dielectrics and ElectricalInsulation,2015,22(2): 673.

[21] HOSIER I L,VAUGHAN A S,SWINGLER S G.An investigation of the potential of polypropylene and its blends for use in recyclable high voltage cable insulation systems[J],Journal of Materials Science,2011: 46(11):4058.

(編辑:贾志超)