风沙对风力机翼型绕流及其气动性能的影响

2018-08-10李仁年赵振希李德顺李银然于佳鑫

李仁年,赵振希,李德顺,李银然,陈 霞,于佳鑫

风沙对风力机翼型绕流及其气动性能的影响

李仁年1,2,3,赵振希1,李德顺1,2,3,李银然1,2,3,陈 霞1,于佳鑫1

(1. 兰州理工大学能源与动力工程学院,兰州 730050;2. 甘肃省风力机工程技术研究中心,兰州 730050;3. 甘肃省流体机械及系统重点实验室,兰州 730050)

中国西北地区风能资源丰富,然而该地区经常遭受沙尘天气的侵袭。风力机在强风沙环境下运行,其气动性能难免会受到沙尘的影响,并且其叶片会受到比较严重的磨损,导致机组的出力明显下降。翼型作为风力机叶片的基本组成单元,沙尘颗粒对翼型的绕流和气动特性的影响研究显得尤为必要。该文利用雷诺平均Navier-Stokes方程-大涡模拟(large eddy simulation)混合方法中的延迟分离涡模拟方法,模拟了NREL S809翼型在风沙环境下的流动特性,将不同颗粒直径条件下翼型周围的绕流情况和翼型的气动性能进行了对比,研究了空气中的颗粒对风力机翼型绕流及其气动性能的影响规律。结果表明,6.1°攻角时,颗粒对翼型绕流和升力系数的影响较小,但仍会使翼型的升力系数略微降低。随着颗粒直径的增大,翼型的升力系数先减小再增大,其中颗粒直径为20m时达到最小值。当颗粒直径为150m时,其升力系数仍小于洁净空气下的升力系数,但两者已十分接近。8.2°攻角时,不同直径颗粒对翼型绕流具有不同程度的影响,当颗粒直径小于20m时,颗粒的跟随性较好,颗粒紧随气相运动,对翼型绕流的影响较小;当颗粒直径为20m时颗粒对翼型绕流造成了极大的影响,如分离点提前、出现展向流动;当颗粒直径大于20m后,随着颗粒直径的继续增大,颗粒的惯性力变强,颗粒逐渐独立于气相运动,对翼型绕流的影响也逐渐减弱。升力系数随颗粒直径的变化趋势和小攻角时相同,但变化幅度变大,升力系数最小时比洁净空气时减少了7.9%。该文可为不同颗粒直径的风沙环境下颗粒对翼型周围绕流流场及其对翼型升力系数影响等相关研究提供参考。

风力机;风能;计算机仿真;延迟分离涡模拟;翼型;颗粒直径;翼型绕流;流动分离

0 引 言

风力机在工作过程中会受到空气中颗粒的影响,造成气动力和载荷的变化以及磨损。同时,由于固相的加入,改变了翼型周围的绕流流动,对翼型的气动性能造成不可忽视的影响,因此针对风沙环境下翼型流场的研究很有必要。Khalfallah等[1]对赫尔格达风电场内风电机组进行了长期的监测,结果表明,由于沙尘对风力机叶片的冲蚀磨损作用,风力发电机组运行3个月后,其出力出现明显的下降,下降率近15%,且随着运行时间的增长,下降幅度加剧;Khakpour[2]研究了风沙环境下翼型的气动性能;李德顺等[3-4]研究了DU96-W-180翼型前缘不同磨损阶段下的气动性能,结果表明前缘发生脱层后翼型的气动性能显著降低;采用可实现湍流模型和离散相模型(discrete phase model, DPM)研究了风力机翼型的升阻力系数和静压随沙尘质量浓度变化的规律,以及不同风沙环境下风轮的转矩特性。但是这些研究都是以二维翼型为研究对象并且采用定常的方法计算,而颗粒对翼型周围流动结构的影响是十分复杂的并且具有很强的非定常特性,特别是在攻角较大的情况下。

目前针对风力机翼型的气固两相流研究较少,但是针对圆柱绕流的相关研究已初具规模。罗坤等[5]利用PIV技术研究了气固两相圆柱绕流的近场特性;樊建人等[6]利用直接数值模拟研究了气固两相圆柱绕流中颗粒的扩散运动;刘洪涛等[7]研究了圆柱绕流背风区不同直径颗粒的运动特性;李文春等[8]针对三维气固两相圆柱绕流进行了数值模拟,分析了不同Stokes数的颗粒在涡作用下的扩散;嵇峰等[9]进行了三维数值模拟,发现颗粒在圆柱展向上的扩散也和颗粒的Stokes数有关,相同雷诺数下,颗粒Stokes数越小,展向扩散越大,流动越不稳定;黄远东等[10]针对液固两相圆柱绕流研究了颗粒的扩散。结合针对圆柱绕流的相关研究,说明了针对翼型的两相流研究也应该采用三维、非定常的方法。

当前经常使用的湍流模型是求解雷诺平均Navier- Stokes(reynolds average navier-stokes, RANS)方程,该方法可以准确预测附着流和小分离时的气动特性。但该方法对颗粒引入后的翼型流场其预测精度急剧下降,预测结果不真实。大涡模拟(large eddy simulation, LES)通过模化小尺度涡,直接计算大涡,在非定常及分离流动问题上体现出明显的优势,然而该方法对网格的要求十分苛刻,且尚不成熟的近壁面模型制约了LES方法的应用。近年来兴起的RANS-LES混合方法,结合了RANS和LES2种方法的优点。其中包括Spalart等[11-13]提出的分离涡方法(detached eddy simulation,DES),采用RANS方法高效准确地模拟近壁区域的高频小尺度运动,同时采用LES方法模拟低频大尺度占主导的非定常分离流动区域。Strelets[14]结合SST湍流模型发展了SST-DES模型。Menter等[15]改进了SST-DES模型并提出了给出了一种延迟分离涡模拟(delay detached eddy simulation,DDES),此方法解决了近壁面网格较密时,LES方法提前启动的问题,以保证边界层内完全使用RANS方法。

胡偶等[16]将SST-DDES混合模型应用在大分离流动的分析中。刘周等[17]研究了翼型大攻角非定常分离流动。刘健等[18]基于iDDES模型研究了双三角翼大攻角的涡破特征。赵伟文等[19]利用DES模型研究了串列双圆柱绕流的问题。夏明等[20]采用DDES模型模拟了Gurney襟翼的分离流动,得到满意的效果。白俊强等[21]模拟了钝前缘三角翼在大攻角下的流动。王翔宇等[22]基于SST-DES模型在小分离流动中的表现,提出了改进方法,以减小RANS区对LES区的影响。靳瑶等[23]针对=3 900的圆柱绕流进行了数值模拟并与试验结果对比,发现DDES模拟可捕捉丰富的流场结构。刘若阳等[24-26]利用DDES模型对叶栅以及翼型绕流问题进行了大量研究。

本文选用基于SST湍流模型的DDES方法,对美国风力机翼型NREL S809[27]在风沙环境下进行数值模拟,研究不同直径颗粒对翼型绕流流场及其气动性能的影响。

1 数值方法

1.1 数学模型及计算网格

本文以NREL S809三维直叶片为研究对象,其相对厚度21%,弦长1 m,展向拉伸0.5倍弦长。采用C型计算域。以翼型前缘点为原点建立坐标系,尾缘方向为方向;翼型展向为方向,表示翼型弦长。在方向,从翼型前缘拓展到弦长的16倍,从翼型尾缘拓展到弦长的20倍;在方向,正负两方向拓展到弦长的16倍。

本文采用欧拉-拉格朗日方法,空气作为连续相基于欧拉框架通过SST-DDES湍流模型进行求解;固相颗粒作为离散相基于拉格朗日框架通过离散相模型求解。颗粒喷射入口采用surface类型,喷射入口距叶片前缘5倍弦长,面积0.5 m×6 m,颗粒轨道数为960×80,共76 800。

采用结构化网格,首层网格厚度取0.012 mm,其无量纲高度+小于1,翼型表面有250个点,展向布置50个点,使得D≈D。颗粒入射方向和速度与气相一致,时间步长取0.000 4 s。计算域和近壁面网格如图1所示。

1.2 计算条件与可靠性验证

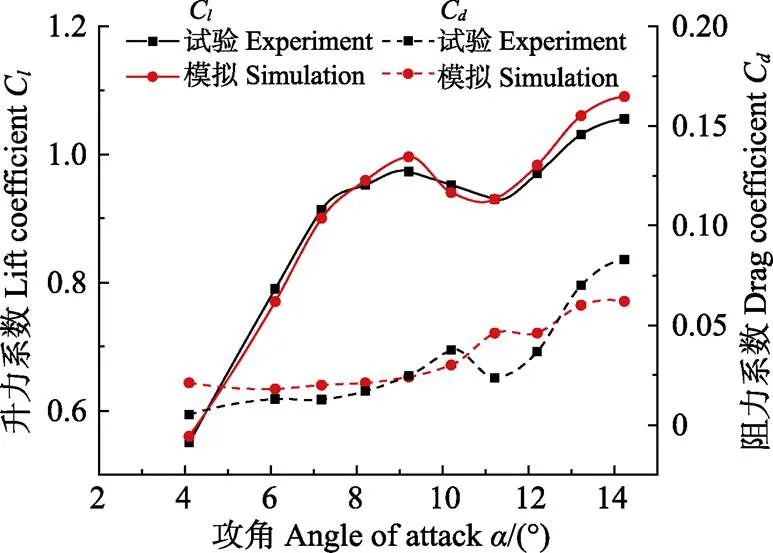

进口采用速度进口边界,出口采用压力出口边界,翼型展向两侧边界设置为对称边界。雷诺数为=106,风速为14.61 m/s。颗粒密度为1 550 kg/m3,颗粒入射质量流率取为空气质量流率的0.01,为0.537 kg/s。换算成颗粒质量浓度为6.13´106g/m3,对应体积浓度为3.95´10-6(属于强沙尘暴)[28]。计算采用SIMPLEC算法,动量和湍动能均采用二阶迎风格式。根据文献[29-30]中的方法修正模型系数1和*,提高近壁面RANS区的模拟精度。图2为洁净空气条件下不同攻角下的升力系数与文献[31]中DUT大学(Delft University of Technology)利用低速低湍流度风洞得到的试验数据进行对比,模拟结果与试验数据吻合度较好,14.2°攻角时升力系数误差达到最大,为3.3%。

注:c为弦长;x方向为横坐标正方向。

图2 洁净空气条件下升力、阻力系数模拟数据与试验数据对比图

对于DPM模型,通过对气固两相流条件下的圆柱绕流进行数值模拟,通过分析颗粒的运动轨迹,并与罗坤等[5]的图像测速(particle image velocimetry)试验进行比较。工况设置与试验条件相同,质量浓度比为10%,颗粒Stokes数为0.98,圆柱直径d为0.01 m。结果如图3所示,离散相模型可以模拟出沙尘颗粒随空气圆柱绕流时的运动特性,但是对比真实情况,数值模拟的耗散较快,导致颗粒运动到圆柱后较远时模拟结果与试验结果差异较大。图4为距离圆柱后x/d=2截面上的颗粒平均速度试验结果和模拟结果对比,可以看出在近尾流区域模拟结果与试验结果吻合度较高[32]。因此,认为本文的模拟方法可靠。

图3 模拟颗粒运动轨迹与试验PIV图像对比

注:U0为来流速度;U为颗粒速度;y/dc表示纵向位置;dc为圆柱直径。

2 结果及分析

2.1 颗粒对翼型绕流的影响

图5是6.1°攻角时,洁净空气和不同直径颗粒条件下的翼型吸力面极限流线图,可以看出在此攻角时,颗粒对翼型表面的绕流情况没有明显的影响,翼型表面没有发生流动分离,流动状态稳定且可以简化为二维流动。

注:d为颗粒直径。

当攻角增大到8.2°时,从洁净空气下翼型表面极限流线,翼型吸力面从前缘起0.607处将发生流动分离,并在分离点后产生了分离泡,流动状态稳定,依然可以视为二维流动,如图6所示。

图7为在不同直径颗粒条件下,翼型吸力面的极限流线图,从图中可以看出8.2°攻角时,颗粒对翼型表面绕流的影响非常大。当加载10m直径的颗粒时,流动开始发生变化,沿展向每个截面上分离点的位置均不同,平均分离位置略微朝翼型前缘移动了0.049,即分离点在0.558处,并且分离涡出现了微小的展向流动,流动状态已从简单的二维流动变成了三维流动;颗粒直径增大到20m,可以看出翼型表面的流动状态发生了非常大的变化,分离点大幅度前移,平均分离位置大幅度向翼型前缘移动了0.094,即分离点在0.512处,并且沿展向每个截面上分离的位置均不同,气流经过分离点后的流动状态为复杂的三维流动;当颗粒直径为30m时,翼型表面的绕流状态趋于稳定,分离点后移,三维流动现象减弱。随着颗粒直径的继续增大,翼型表面的流动状态愈发趋于稳定,三维流动现象减弱。当颗粒直径为50m时三维流动现象基本消失;当颗粒直径为100m时分离点位置向洁净空气时的分离位置移动。当颗粒直径为150m时,分离点基本与洁净空气状态下的分离点重合,相较洁净空气下的分离点仍向前缘移动了0.01。

图6 8.2°攻角时洁净空气下极限流线和中间截面处流线

图7 8.2°攻角时不同直径颗粒条件下翼型吸力面极限流线

为了更好地揭示颗粒对翼型周围绕流流场的影响,在翼型尾缘和翼型尾缘后0.5处分别建立截面,图8为洁净空气和不同直径颗粒条件下翼型周围三维流线和截面上的展向速度云图。图9是各工况下翼型展向0.5倍截面处颗粒质量分布图和三维流线图。

由图8可知,洁净空气时,在翼型尾流区存在微小的展向流动,速度较小可忽略;当加载10m颗粒时,翼型周围的流线出现了小幅度的扰动,从翼型尾缘处的展向速度云图可知,气流在尾流区有微弱的展向速度,在气流经过翼型之后展向速度逐渐减弱,在尾缘后0.5处基本消失;加载20m直径颗粒时,翼型周围流线出现了大幅度的扰动,气流在尾流区具有较大的展向速度,且在翼型尾缘后0.5处依然较大;随着颗粒直径的增大,流动趋于稳定,展向速度减弱。当颗粒直径为150m时,流动状态基本与洁净空气时无异,但展向速度仍大于洁净空气时的展向速度。

当气相流经翼型表面时,在翼型的前驻点分为两股,沿着上、下翼面流向翼型尾缘。此时的流动状态明显区别于来流的流动状态[33]。同时,空气中的沙尘颗粒响应气相流动状态改变的时间称为颗粒的松弛时间,过程中伴随着颗粒与气相之间的动量交换。颗粒的松弛时间为τ=ρd2/18,为气相流动的特征时间,其中ρ和d分别为颗粒的密度和直径;和为翼型的弦长和来流风速,颗粒的Stokes数=τ/可以用来衡量颗粒的惯性[34]。越大,颗粒的惯性力越强,颗粒需要更长的时间来响应流场的变化;越小,颗粒的跟随性越好,颗粒响应流场变化所需的时间越短。综上,颗粒对翼型绕流流场的影响非常大。这是颗粒与气相之间的动量交换引起的。

图8 8.2°攻角时不同直径颗粒条件下翼型周围三维流线和截面上的展向速度云图

图9 8.2°攻角时不同直径颗粒条件下翼型中间截面上颗粒质量浓度分布图和三维流线

由图9可知,当颗粒直径为10m时,较小。颗粒主要分布在分离区边缘,表现出较强的跟随性。惯性力的作用很小,气流挟颗粒绕过翼型时发生了微弱的动量交换,导致出现了微弱的三维流动现象并且分离点略微前移,但这并不足以对整个流场产生剧烈的影响;当颗粒直径为20m时,颗粒不再紧随气相运动,大量颗粒进入了尾流区,并改变了翼型附近的流场,说明此时气流与颗粒之间发生了很强的动量交换。这是因为对比10m直径的颗粒,20m直径颗粒的数较大,惯性力的作用较强,因此气流挟颗粒绕流过翼型时与颗粒发生了剧烈的动量交换,从而导致了整个流场的变化,表现出三维流动现象并且分离点大幅度前移。

颗粒直径为30m时,可以看出此时流场情况已经开始逐渐恢复;当颗粒直径增大到50m,流动状态开始趋于稳定,观察颗粒质量分布和翼型周围流线可以发现此时颗粒的流动基本独立于气流,这是因为颗粒直径增大惯性力已经开始占主导作用,气流对于颗粒的作用力基本可以忽略;颗粒直径为150m时,由于惯性力作用,此时颗粒已经完全独立于气相运动,从此工况下的三维流线中,可知气流紧贴翼型表面流动,与洁净空气状态下的流动状态几乎一致。对比不同时刻不同截面的三维流线图和颗粒质量分布图,发现当颗粒大于50m时和洁净空气条件时流动没有体现出非定常现象。

2.2 颗粒对翼型气动性能的影响

颗粒对翼型绕流的影响反映到对翼型气动性能的影响上。图10是洁净空气和不同直径颗粒条件下翼型表面压力系数图。

由图10可知,在流动发生分离之前,风沙环境下翼型压力面的压力系数均小于洁净空气下压力面的压力系数,同时吸力面的压力系数颗粒也均小于洁净空气下的压力系数;流动发生分离之后,风沙环境下压力面的压力系数仍小于洁净空气下压力面的压力系数,当流动发生分离后,风沙环境下吸力面的压力系数明显大于洁净空气时吸力面的压力系数,并且在20m直径颗粒条件下达到最大值,这与流动尚未发生分离时的规律恰好相反,这说明在翼型吸力面的分离区,颗粒的加入反而会提高压力系数。通过对比不同条件下翼型表面的压力系数,可以发现随着颗粒直径的增大,压力面和吸力面的压力系数变小,当颗粒直径为20m时达到最小值,随后随着颗粒直径的增大逐渐朝洁净空气时的圧力曲线靠拢,当颗粒直径为150m时,其压力系数曲线基本与洁净空气时无异。

注: x/c表示横向位置,见图1a。

图11是S809翼型的升力系数随颗粒直径变化曲线。可以看出当洁净空气中加入小直径颗粒,翼型升力系数变小,颗粒直径为20m时升力系数达到最小值。6.1°攻角时减小了3.9%,随后随着颗粒直径的增大,翼型升力系数将逐渐增大,但还是比洁净空气时小,颗粒直径为150m时的升力系数比洁净空气时减小了1.3%。当攻角为8.2°时,总体趋势跟6.1°攻角时一样,在20m直径颗粒条件下升力系数达到最小值,比洁净空气时减小了7.9%,颗粒直径为150m时的升力系数比洁净空气时减小了0.77%。相较没有发生流动分离的6.1°攻角,8.2°攻角时升力系数的变化幅度更大。

图11 升力系数随颗粒直径变化

3 结论与讨论

本文基于RANS-LES混合方法中的SST-DDES方法,研究了风力机翼型在不同颗粒直径的风沙环境下颗粒对翼型周围绕流流场及其对翼型升力系数的影响,结论如下:

1)颗粒对翼型绕流流场有不可忽视的影响。当攻角较小时,颗粒对流场的影响较小,但仍使翼型的升力系数发生微小的变化;当攻角较大时(8.2°),颗粒对翼型绕流流场的影响较大,体现在分离点提前、出现展向流动、尾涡变大。当颗粒直径不同时,翼型绕流情况也不同。当颗粒直径小于20m时,随着颗粒直径的增大,翼型吸力面分离点提前,三维流动现象出现并逐渐加剧;当颗粒直径大于20m后,随着颗粒直径的增大,翼型绕流情况逐渐恢复,三维流动现象减弱、分离点后移。当颗粒直径为150m时,其绕流情况基本与洁净空气时相同。

2)当颗粒直径小于20m时,翼型的升力系数随着颗粒直径的增大而减小。当颗粒直径为20m时,翼型的升力系数达到最小值:6.1°攻角时相对于洁净空气条件下的升力系数减小了3.9%;而8.2°攻角时则下降了7.9%。当颗粒直径大于20m后,翼型的升力系数随着颗粒直径的增大而增大,但当颗粒直径增大到150m时仍比洁净空气时的升力系数小。

3)当颗粒直径小于20m时,颗粒的惯性力较弱,颗粒紧随着气相运动,表现出良好的跟随性,对翼型绕流流场的影响较小。随着颗粒直径的增大,颗粒对翼型绕流流场的影响越来越大;当颗粒直径为20m时,此时颗粒的惯性力较强,颗粒与气相之间存在剧烈的动量交换,颗粒对翼型绕流流场的影响最为严重;当颗粒直径大于20m后,随着颗粒直径的增大,颗粒的惯性力越来越强,固相几乎独立于气相运动,对翼型绕流流场的影响逐渐减弱。

本文在同一颗粒质量浓度下,研究了不同直径颗粒对翼型绕流及其气动性能的影响,后续将进一步研究系统颗粒数翼型绕流及其气动性能随攻角和颗粒质量浓度的变化规律。

[1] Khalfallah M G, and Koliub A M. Effect of dust on the performance of wind turbines[J]. Desalination, 2007, 209(1): 209-222.

[2] Khakpour Y. Aerodynamic Performance of Wind Turbine Blades in Dusty Environments[D]. Chicago: Illinois Institute of Technology, 2007.

[3] 李德顺,王成泽,李银然,等. 叶片前缘磨损形貌特征对风力机翼型气动性能的影响[J]. 农业工程学报,2017,33(22):269-275. Li Deshun, Wang Chengze, Li Yinran, et al. Influence of blade leading edge erosion features on aerodynamics characteristics of wind turbine airfoil[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(22): 269-275. (in Chinese with English abstract)

[4] 李德顺,董麟,刘宜,等. 风沙环境对NACA-0012翼型气动性能的影响[J]. 兰州理工大学学报,2015,41(6):54-59. Li Deshun, Dong Lin, Liu Yi, et al. Effect of sand-laden wind environment on aerodynamic characteristics of airfoil NACA-0012 [J]. Journal of Lanzhou University of Technology, 2015, 41(6): 54-59. (in Chinese with English abstract)

[5] 罗坤,陈松,蔡丹云,等. 气固两相圆柱绕流近场特性的实验研究[J]. 中国电机工程学报,2006,26(24):116-120. Luo Kun, Chen Song, Cai Danyun, et al. Experimental study of flow characteristics in the near field of gas-solid two-phase circular cylinder wakes[J]. Proceedings of the CSEE, 2006, 26(24): 116-120. (in Chinese with English abstract)

[6] 樊建人,胡桂林,姚军,等. 气固两相圆柱绕流的直接数值模拟[J]. 工程热物理学报,2003(3):433-436. Fan Jianren, Hu Guilin, Yao Jun, et al. Direct numerical simulation of particle dispersion in the temporal wake of a circular cylinde[J]. Journal of Engineering Thermophysics, 2003(3): 433-436. (in Chinese with English abstract)

[7] 刘洪涛,张力,陈艳容. 气固两相圆柱绕流背风区颗粒的运动特性[J]. 重庆大学学报,2010,33(4):54-59. Liu Hongtao, Zhang Li, Chen Yanrong. Investigations of the particle motion characteristics in the gas-solid two-phase wake of leeward side circular cylinder[J]. Journal of Chongqing University, 2010, 33(4): 54-59. (in Chinese with English abstract)

[8] 李文春,金晗辉,任安禄,等. 气固两相三维圆柱绕流的直接数值模拟[J]. 工程热物理学报,2006,27(5):808-810. Li Wenchun, Jin Hanhui, Ren Anlu, et al. Direct numerical simulation of gas-solid two-phase 3d wake of a circular cylinder[J]. Journal of Engineering Thermophysics, 2006, 27(5): 808-810. (in Chinese with English abstract)

[9] 嵇峰,樊建人,任安禄,等. 气固两相圆柱绕流转捩两种模式的三维直接数值模拟[J]. 中国电机工程学报,2006,26(23):55-60. Ji Feng, Fan Jianren, Ren Anlu, et al. Three-dimensional direct numerical simulation of circular cylinder wake transition in gas particle flow[J]. Proceedings of the CSEE, 2006, 26(23): 55-60. (in Chinese with English abstract)

[10] 黄远东,吴文权. 液固两相圆柱绕流尾迹内颗粒扩散分布的离散涡数值研究[J]. 应用数学和力学,2006,27(4): 477-483. Huang Yuandong, Wu Wenquan. Numerical study of particle distribution in wake of liquid-particle flows past a circular cylinder using discrete vortex method[J]. Applied Mathematics and Mechanics, 2006, 27(4): 477-483. (in Chinese with English abstract)

[11] Spalart P. Detached-eddy simulation[J]. Annual Review of Fluid Mechanics, 2008, 41(41): 203-229.

[12] Shur M, Strelets M, Zajkov L, et al. Comparative numerical testing of one- and two-equation turbulence models for flows with separation and Reattachment[R]. Reno, NV: AIAA 1995-0863.

[13] Shur M, Spalart P, Strelets M, et al. A hybrid RANS-LES approach with delayed-DES and wall-modelled LES capabilities[J]. International Journal of Heat and Fluid Flow, 2008, 29: 1638-1649.

[14] Strelets M. Detached eddy simulation of massively separated flows[R]. Reno, NV: AIAA 2001-0879.

[15] Menter F, Kuntz M. Development and application of a zonal DES turbulence model for CFX-5[R]. CFX-VAL17/0703, 2003.

[16] 胡偶,赵宁,沈志伟. SST-DDES模型在大分离流动问题中的应用[J].南京航空航天大学学报,2017,49(2):206-211. Hu Ou, Zhao Ning, Shen Zhiwei. Simulation of large separated flow with SST-DDES model[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2017, 49(2): 206-211. (in Chinese with English abstract)

[17] 刘周,杨云军,周伟江,等. 基于RANS-LES混合方法的翼型大迎角非定常分离流动研究[J]. 航空学报,2014,35(2):372-380. Liu Zhou, Yang Yunjun, Zhou Weijiang, et al. Study of unsteady separation flow around airfoil at high angle of attack using hybrid RANS-LES method[J]. Acta Aeronautica ET Astronautica Sinica, 2014, 35(2): 372-380. (in Chinese with English abstract)

[18] 刘健,蒋永,吴金华. 基于iDDES的双三角翼大迎角非定常涡破裂特征分析[J]. 工程力学,2016,33(4):241-249. Liu Jian, Jiang Yun, Wu Jinhua. Analysis on characteristics of unsteady vortex breakdown flows around a double-delta wings at high incidence based on iddes method[J]. Engineering Mechanics, 2016, 33(4): 241-249. (in Chinese with English abstract)

[19] 赵伟文,万德成. 用DES分离涡方法数值模拟串列双圆柱绕流问题[J]. 应用数学和力学,2016,37(12):1272-1281. Zhao Weiwen, Wan Decheng. Detached-Eddy Simulation of flow past tandem cylinders[J]. Applied Mathematics and Mechanics, 2016, 37(12): 1272-1281. (in Chinese with English abstract)

[20] 夏明,张晓东,钟伯文. 基于延迟脱体涡模拟方法对Gurney襟翼分离流动的数值模拟[J]. 航空制造技术,2014,460(16):114-117. Xia Ming, Zhang Xiaodong, Zhong Bowen. Numerical simulation of separated flow over gurney flap based on DDES[J]. Aeronautical Manufacturing Technology, 2014, 460(16): 114-117. (in Chinese with English abstract)

[21] 白俊强,王波,孙智伟. 使用RANS/LES混合方法对钝前缘三角翼进行数值模拟[J]. 空气动力学学报,2012,30(3):373-379. Bai Junqiang, Wang Bo, Sun Zhiwei. The application of numerical simulation of delta wing with blunt leading edge using RANS/LES hybrid method[J]. Acta Aerodynamica Sinica, 2012, 30(3): 373-379. (in Chinese with English abstract)

[22] 王翔宇,李栋. SST-DES在小分离流动数值模拟中的改进[J]. 北京航空航天大学学报,2014,40(9):1245-1249. Wang Xiangyu, Li Dong. Improved SST-DES in numerical simulation of mild separation[J]. Journal of Beijing University of Aeronautics & Astronautics, 2014, 40(9): 1245-1249. (in Chinese with English abstract)

[23] 靳瑶,蔡晋生,廖飞. Re=3900的圆柱绕流湍流模拟对比研究[J]. 应用数学和力学,2016,37(12):1282-1295. Jin Yao, Cai Jinsheng, Liao Fei. Comparative numerical studies of flow past a cylinder at Reynolds number 3900[J]. Applied Mathematics and Mechanics, 2016, 37(12): 1282-1295. (in Chinese with English abstract)

[24] 刘若阳,侯安平,单树军,等. 基于DDES方法的叶栅分离旋涡的非定常流动数值研究[J]. 推进技术,2017,38(1):16-26. Liu Ruoyang, Hou Anping, Shan Shujun, et al. Unsteady numerical investigation on cascade separation vortex flow based on delayed detached-eddy simulation [J]. Journal of Propulsion Technology, 2017, 38(1): 16-26. (in Chinese with English abstract)

[25] 杜若凡,阎超,韩政,等. DDES延迟函数在超声速底部流动中的性能分析[J]. 北京航空航天大学学报,2017,43(8):1585-1593. Du Ruofan, Yan Chao, Han Zheng, et al. Performance of delayed functions in DDES for supersonic base flow[J]. Journal of Beijing University of Aeronautics & Astronautics, 2017, 43(8): 1585-1593. (in Chinese with English abstract)

[26] 唐雨萌,柳阳威,陆利蓬. 高升力翼型复杂流动模拟中湍流模型性能评估[J]. 航空动力学报,2016,31(12):2859-2869. Tang Yumeng, Liu Yangwei, Lu Lipeng, et al. Evaluation on turbulence models in simulating complex flows around high-lift airfoil[J]. Journal of Aerospace Power, 2016, 31(12): 2859-2869. (in Chinese with English abstract)

[27] Somers D M. Design and experimental results for the S809 airfoil[J]. Office of Scientific & Technical Information Technical Reports, 1997, 25(3): 555-562.

[28] 顾兆林. 风扬粉尘[M]. 北京:科学出版社,2010.

[29] 文晓庆,柳阳威,方乐,等. 提高k-ω SST模型对翼型失速特性的模拟能力[J]. 北京航空航天大学学报,2013,39(8):1127-1132. Wen Xiaoqing, Liu Yangwei, Fang Le, et al. Improving the capability of k-ω SST turbulence model for predicting stall characteristics of airfoil[J]. Journal of Beijing University of Aeronautics & Astronautics, 2013, 39(8): 1127-1132. (in Chinese with English abstract)

[30] 钟伟,王同光. 湍流模型封闭常数对S系列翼型CFD模拟的影响[J]. 太阳能学报,2013,34(10):1690-1696. Zhong Wei, Wang Tongguang. Influence of closure coefficient of turbulence model on CFD simulations of S series airfoils[J]. Acta Energiae Solaris Sinica, 2013, 34(10): 1690-1696. (in Chinese with English abstract)

[31] Hand M M, Simms D A, Fingersh L J, et al. Unsteady aerodynamics experiment phase VI: Wind tunnel test configurations and available data campaigns[R]. Colorado: National Renewable Energy Laboratory, 2001.

[32] Li D S, Zhao Z X, Li Y R, et al. Effects of the particle Stokes number on wind turbine airfoil erosion[J]. Applied Mathematics and Mechanics: English Edition, 2018, 39(5): 639-652.

[33] 吴双群,赵丹平. 风力机空气动力学[M]. 北京:北京大学出版社,2011.

[34] 袁竹林. 气固两相流动与数值模拟[M]. 南京:东南大学出版社,2013.

Effect of wind sand on flow around airfoil of wind turbine and its aerodynamic performance

Li Rennian1,2,3, Zhao Zhenxi1, Li Deshun1,2,3, Li Yinran1,2,3, Chen Xia1, Yu Jiaxin1

(1.,,730050,; 2.,730050,; 3.,730050,)

As a kind of clean and environment-friendly energy, wind power has been developed rapidly in recent years. With top wind power capacity, Northwest region is also a region with frequent dust storm incidents. Obviously, when wind turbine works under sand-wind conditions, its aerodynamics performance will be affected severely, and the flow structure around airfoil will be affected by the function of particles in the air. Wind turbine blades will even be eroded due to the impact of particles. Therefore, it is urgent to study the effect of sand-wind flow on wind turbine. The effect of particles on the flow structure around airfoil and its aerodynamic performance has been studied in this paper. In order to capture the detail of the flow structure around airfoil in various dusty environments with different particle diameters, a delayed detached eddy simulation (DDES) method, which is a hybrid Reynolds average Navier-Stokes equation and large eddy simulation (RANS-LES), and the discrete phase model were used for the simulation of the flow around NREL S809 airfoil. The flow structure around airfoil, mass distribution of particles and its aerodynamic performance in each dusty environment were compared. Both aerodynamic performance and flow structure were affected by particle, and the influences would be different when the angle of attack or particle diameter was different. When the angle of attack was small (6.1°, there was no flow detachment), the particles did not affect the flow around airfoil obviously, but the lift coefficient was decreased. With the increasing of particle diameter, lift coefficient of S809 decreased first and then went up, and turning point was 20m (3.9% lower than the lift coefficient obtained in clear air). Butthe lift coefficient could not be completely recovered, and it was still smaller than the lift coefficient in clear air when the particle diameter was 150m. When the angle of attack became larger (8.2°, flow detachment occurred), particles had a great influence on the flow structure around airfoil, such as the advancing of the flow separation point and the appearing of the flow along spanwise direction, and these influences were also affected by particle diameter. With particle diameter increasing, the flow structure became chaotic first and then gradually recovered. When the particle diameter was 20m, particles had the most effects on the aerodynamics performance of airfoil and the flow around it. This was due to the dramatic momentum exchange between particle and gas, that was, a large number of particles were rolled into wake area and broke the flow structure around airfoil, which affected the lift coefficient greatly. When the particle diameter was smaller than 20m, the particles would flow closely with air due to its weak inertia force. On the contrary, the particles would move independently of air flow, because of its strong inertia force when the particle diameter was larger than 50m. The flow structure recovered gradually with the increasing of particle diameter when particles diameter was larger than 20m. However, the aerodynamic performance of airfoil could not recover completely, only close to the lift coefficient in clear air, and the minimum value of lift coefficient was also obtained when the particle diameter was 20m (7.9% lower than thelift coefficient in clear air). In summary, the particles in the air will have a great influence on both the flow around airfoil and the aerodynamic performance of airfoil, especially in the area where the flow separates. When the particle diameter is smaller than 20m, the particle diameter increase will strengthen the effect, which reaches the climax when the particle diameter is 20m. Under this condition, if there is no flow detachment in clear air (the attack angle is small), the influence of particles would be weak, which can be ignored. If there exists flow separation phenomenon in clear air (the attack angle is large), then the influence would be strong, and it would aggravate the flow separation, causing the flow to transform into three-dimensional flow. After that, further increase of the particle diameter would weaken the effects of the particles, and when the particle diameter is 150m, both the flow structure and the lift coefficient are very close to that in clear air.

wind turbines; wind energy; computer simulation; delayed eddy simulation; airfoil; particle diameter; flow around airfoil; flow separation

10.11975/j.issn.1002-6819.2018.14.026

TK83

A

1002-6819(2018)-14-0205-07

2018-01-05

2018-05-20

国家重点基础研究发展计划(973计划)(2014CB046201);国家自然科学基金(51766009,51566011)

李仁年,教授,博导,主要从事流体机械理论及工程技术的研究。Email:lrn@lut.cn

李仁年,赵振希,李德顺,李银然,陈 霞,于佳鑫. 风沙对风力机翼型绕流及其气动性能的影响[J]. 农业工程学报,2018,34(14):205-211. doi:10.11975/j.issn.1002-6819.2018.14.026 http://www.tcsae.org

Li Rennian, Zhao Zhenxi, Li Deshun, Li Yinran, Chen Xia, Yu Jiaxin. Effect of wind sand on flow around airfoil of wind turbine and its aerodynamic performance[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(14): 205-211. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.14.026 http://www.tcsae.org