巨菌草种茎辊式排种器结构优化及排种动力学仿真与试验

2017-11-17郑书河林长山叶大鹏

郑书河,林长山,叶大鹏,刘 斌

巨菌草种茎辊式排种器结构优化及排种动力学仿真与试验

郑书河1,林长山1,叶大鹏1,刘 斌2

(1. 福建农林大学机电工程学院,福州 350002;2. 国家菌草工程研究中心,福州 350002)

针对目前巨菌草种植机普遍存在的重、漏播率高、人工劳动强度大、种茎易破损等问题,该文设计了一种槽型辊式排种器。先分析排种过程中的种茎受力状态,推导出种茎的受力角为目标值的函数,确定送种辊入种槽长宽尺寸为20 mm´20 mm;其次,采用弹性垫料改善送种辊排种进程,基于受力角为目标的函数,优化求解得到垫料侧边垫料厚4 mm、底部垫料厚8 mm;最后采用虚拟样机软件ADAMS建立了种茎排种动力学模型,对其排种过程进行仿真,并在此基础上进行了实验室台架试验和田间排种试验。台架试验表明,排种器实现种茎有序地排种,垫料有效地提高排种流畅度;田间试验过程中排种作业稳定,排种合格率均值为93.33%,排种间距变异指数均值为13.63%,平均漏排和重排指数均值为4.1%和2.5%,各项指标均符合巨菌草种植要求。该研究可为同类排种器和巨菌草种植机的研制提供参考。

农业机械;设计;优化;巨菌草;槽型辊式排种器;动力学仿真;试验

0 引 言

巨菌草作为人工栽培的高产优质菌草之一,其用途广泛,可用于食药用菌培养基料、鱼畜类饲料、植保作物、生物质燃料、造纸和工业纤维原料等,具有极强的综合经济价值[1-5]。巨菌草种植是巨菌草生产的重要环节,亦是巨菌草生产过程中劳动强度较大,作业流程较繁杂的一环[6-7]。排种器作为播种机的核心部件,其性能直接影响播种机的作业质量与效能,设计高效、可靠的巨菌草种茎排种器有利于提高巨菌草播种的机械化水平[8-12]。

当前,巨菌草种植以人工扦插植栽为主,作业强度大、效率低。国内相关根培种植设备如甘蔗种植机,采用实时切种式方式,能够实现开沟、切段、播种、覆土、培土和镇压一体化作业,极大程度上减轻了工人的作业强度,但其排种器需人工喂种,在实现种植自动化、精准化方面略显不足。而采用预切种式排种器具有机械化程度高,排种均匀等优势[13-16]。漏种率高、劳动强度大、种茎易损是实现巨菌草机械化精确播种的关键问题。本文设计一款采用种茎排序喂入的预切种式巨菌草排种器,利用ADAMS虚拟样机技术,创建排种器排种过程动力学仿真模型,优化排种器结构尺寸,实现种茎依次有序排种,并试制样机进行试验,为巨菌草机械化精确种植提供参考。

1 排种器整体结构及工作原理

巨菌草种茎辊式排种器主要结构如图1a所示,种茎放置于储种箱1中,通过储种箱正下方的下种箱2进入送种辊的入种槽5中。减速器9与动力轴相连,在同步带8带动下,送种辊4转动,在脱离护罩7后,种茎在重力作用下通过落种板6排出排种器。目前排种器为单行排种,单辊作业时,其转速为1~2 r/s,作业速度为1.8~3.6 km/h,播种间距300~700 mm,依照密播或稀播的要求进行调整。

排种原理如图1b,下种箱起着种茎进入送种辊的过渡作用。三根送种辊上的入种槽表面内附垫料,在送种辊的转动下入种槽口依序正对着入种槽,三个送种辊的初始入种槽角度依次相差60°。在送种辊转动过程中,种茎在入种槽的限位作用下成排堆积,在其自身重力作用下沿辊表面落入入种槽中,最终随辊转动依序抛离送种辊。

1. 储种箱 2. 下种箱 3. 垫料 4. 送种辊 5. 入种槽 6. 落种板 7. 护罩 8. 同步带轮 9. 减速器

2 送种辊结构设计

送种辊是实现种茎由下种箱向落种板过渡的核心部件,其结构设计是影响排种流畅度的重要因素[17-20]。由于种茎的形状存在一定差异,为便于分析,将种茎简化为质量均布的圆柱体,并假定种茎在下种箱中平行排放,对此进行受力分析。

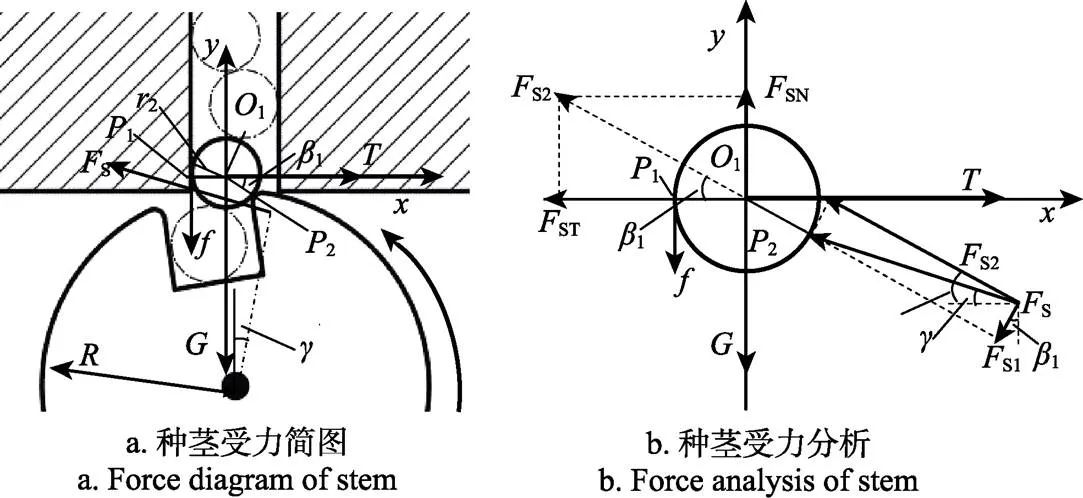

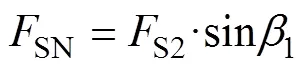

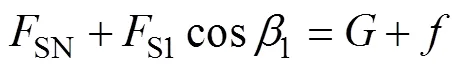

2.1 种茎受力

当底层种茎滑入入种槽后,与入种槽右壁2点相接触,并在已落入入种槽内种茎的相互作用下被顶起,受力分析如图2a所示。当排种辊入种槽对种茎支持力S作用在种茎径向时,此时种茎不受切向力作用,1为12与水平方向夹角亦即S2与水平方向的夹角,简称受力角,显然1大于,即1。如图2b,建立种茎受力模型。

注:FS为送种辊对种茎支持力,N;FS1、FS2为FS在切向和径向的分力,N;FST、FSN为FS2在水平和铅垂方向上的分力,N;T为种茎受外壁支持力,N;γ为FS与水平方向的夹角,rad;G为下种箱中种茎重力总和,N;P1为下种箱左壁与种茎的接触点;P2为入种槽与种茎的接触点;O1为次底层种茎的质心;β1为P2 O1和水平方向的夹角(0≪β1≪π/2),rad;f为种茎与下种箱间的摩擦力,N;R为送种辊半径,mm;r2为次底层种茎半径,mm。

式中为种茎与下种箱间的摩擦系数。

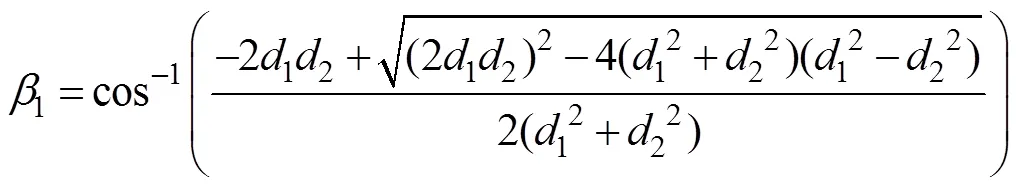

联立式(1)~(6),求得种茎受力模型如下

由式7可知,β1、γ值对FS值影响较大,其中γ值由种茎和送种辊的半径决定,由图2b可知0≪γ≪r/R,假定γ=0.1π、G=10 N、μ=0.26[21]。压缩试验求得巨菌草顺纹压缩最大抗压强度均值为10.1 MPa[22]。因送种辊入种槽直角处倒角半径约为1 mm,菌草种茎长度在300 mm以内,假定辊对种茎的接触面近似为长300 mm、宽2 mm的矩形面,则种茎所能承受的支持力为606 N。如图3可知,FS随β1取值的增大先减小后增大,当β1=0.291时,种茎受力处于其抗压能力的极限,即当β1取值范围为0.291~π/2时,排种过程中种茎受力满足其抗压强度要求,当β1=0.942 5时,种茎受力值极小值为13.285 1 N。

2.2 入种槽尺寸

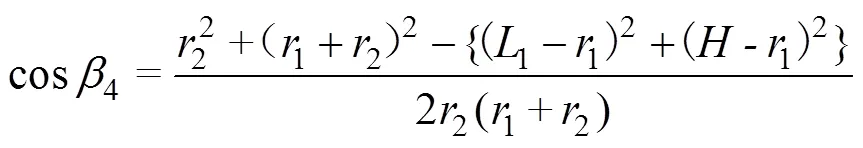

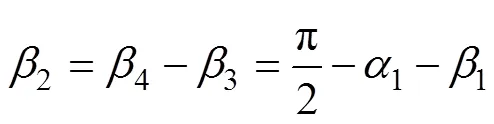

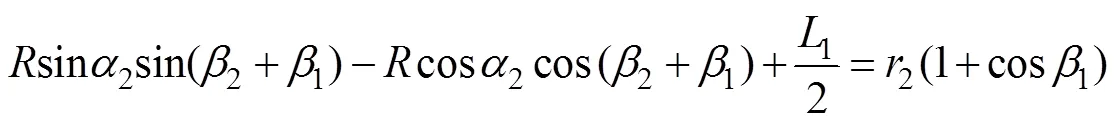

假定辊转动1时,次层种茎在入种槽作用下恰好脱离底层种茎,如图4所示,以点为坐标原点建立直角坐标系,可求得

注:O为送种辊轴心;O0为底层种茎质心;O0O0v、O1O1V与NM垂直;O1I与NM平行;O1J为水平线;KO为铅垂线;α1、α2分别为O0vO、P2O与OK的夹角,rad;β2为O1vO1与O1P2的夹角,rad;β3、β4为O1vO1、P2O1与O0O1的夹角,rad;L1为入种槽及下种箱宽,mm;H为入种槽深,mm;r1为底层种茎半径,mm。

又可求得2坐标为(sin,cos),可求得2与1的距离为

联立式(8)、式(9)、式(10)得

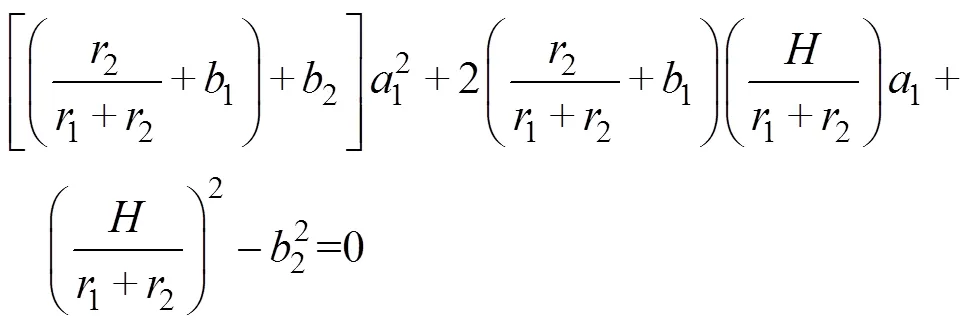

设cos2=1、sin2=2、cos4=1、sin4=2,可化简求得关于1的等式

联立式(10)、式(11)、式(12)可求得关于1的等式

设cos2=1、sin2=2,化简求得:

可最终化简求得1的值为

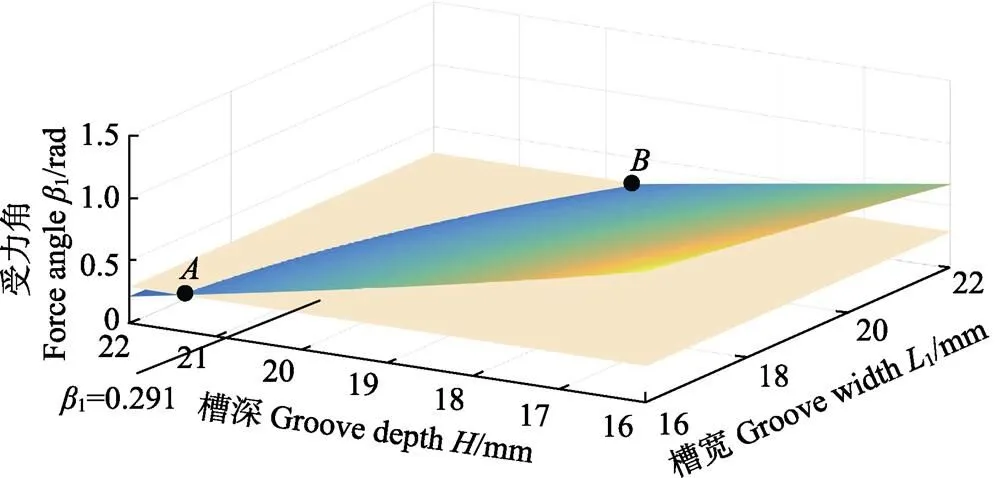

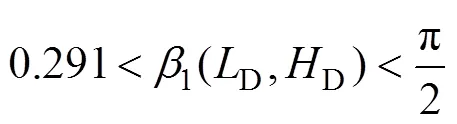

结合巨菌草种植实际需求,以16~20 mm直径的种茎作为宜栽苗,由节2.1分析可知,当1值在0.291~π/2时,种茎受力在可承受范围内。求解得1值随入种槽宽、深变化的曲面图[23-24],如图5所示。

图5 不同入种槽尺寸下种茎受力角

由图5可知,1值与槽的宽、深呈明显的负相关关系,其中曲线为曲线与1边界值的交线,由2.1节可知,当1=0.942 5时,种茎受力值最小,可求得当槽深取16~16.7 mm、槽宽取16~17.8 mm时,种茎受力最小。当选用直径为16~20 mm的种茎时,为保证直径为20 mm的种茎能够顺利排出,确定入种槽的高、宽均取20 mm,此时1值为0.348 7,满足排种要求。

2.3 入种槽垫料尺寸

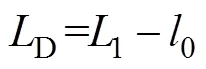

巨菌草种茎形态差异是排种堵卡问题的主要因素,同时极易造成芽节破损。通过在入种槽中加设弹性垫料可有效消除种茎径宽差带来的排种问题,同时对种茎芽节起到保护作用。如图6a、图6c,通过垫料的缓冲作用,当底层种茎过小的时候,垫料可垫高种茎在入种槽中的高度;如图6b、图6d,当种茎过大时,通过垫料的弹性形变,种茎嵌入入种槽中。可见借助垫料的缓冲作用,能够提高排种的流畅度。考虑到垫料对入种槽空间大小的影响,将入种槽的宽、深值扩大20%,即1与均取值24 mm。基于式(13),建立带垫料的1值模型。

式中D为加垫料后的槽宽,mm;D为加垫料后槽深,mm;0为侧边垫厚,mm;0为底部垫料厚,mm。

图6 有无垫料送种辊的排种示意图

由2.1节可知,当1=0.942 5时,种茎受力值最小。当种茎尺寸较小时,设种茎直径为16 mm,如图7a所示,曲线为垫料可取值的边界,在边界内的取值均满足1取值要求,当底部垫料厚度取7.5~12 mm、侧边垫料厚度取6.73~12 mm时,取值最佳;当种茎尺寸较大时,设种茎直径为20 mm,如图7b所示,曲线为垫料可取值的边界,在边界内的取值均满足1取值要求,当底部垫料厚度取4.28~8 mm、侧边垫料厚度取4~8 mm时,取值最佳。考虑到侧边垫料过厚时,将增大种茎进入入种槽的摩擦力,在满足1取值要求前提下,取侧边垫料厚4 mm;底部垫料取上述2种情况下其最佳取值的均值,即8 mm。

图7 种茎受力角随垫料尺寸变化

3 种茎排种过程的动态仿真与分析

3.1 柔性种茎建模

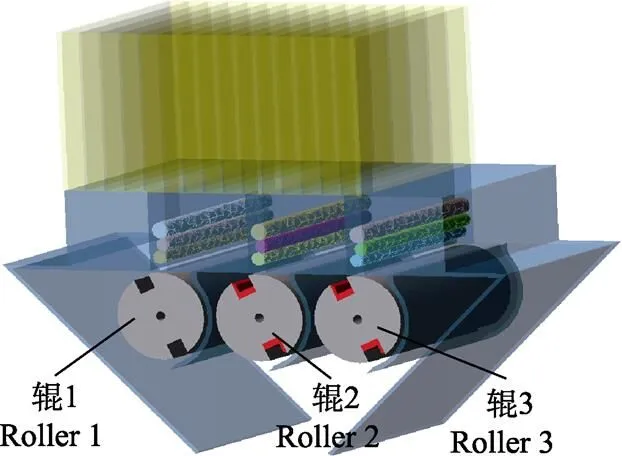

为简化虚拟样机仿真模型,考虑到种茎芽节微小凸起与种茎轴向直径差异较小,将种茎近似为光滑圆柱体,建立ADAMS柔性种茎模型[25],无垫料入种槽尺寸为20 mm×20 mm,带垫料入种槽尺寸为24 mm×24 mm,侧边垫料取4 mm,底部垫料取8 mm,送种辊直径为120 mm。对种茎模型进行柔性化处理,设置种茎的弹性模量593.8 MPa,压缩模量126.4 MPa,弯曲模量610.5 MPa[22],泊松比为0.3[26],导入ADAMS中进行仿真分析[27-29]。图8为在ADAMS中创建的排种器模型及柔性种茎。其中辊1采用无垫料的入种槽,辊2、辊3采用添加垫料的入种槽。

图8 ADAMS排种器运动仿真模型

3.2 垫料对大小直径种茎的排种影响

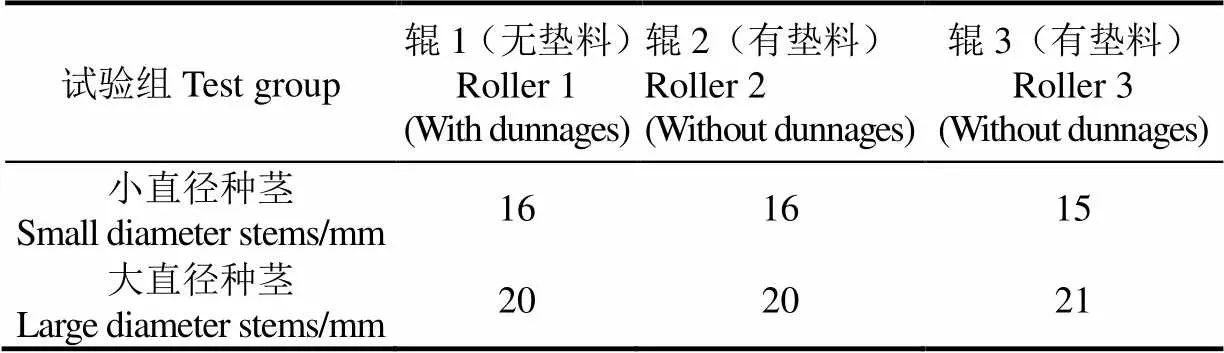

宜栽种茎直径主要集中在16~20 mm之间,当直径较小的种茎同时排放时,其1值较小,受到的挤压力较大,容易导致种茎伤损。而对于直径较大的种茎而言,添加弹性垫料后由于排种种腔空间变小,无疑会增大送种辊对种茎的压力,分别进行大、小直径种茎的连续排种仿真,对比添加垫料前后的排种效果。而在实际种植作业中,往往存在排出的种茎直径径宽超出选定宜栽范围(16~20 mm)的情况。选定辊3作为超出选定宜栽范围种茎的排种仿真,仿真过程中采用的种茎直径如表1。

如图9a、图9b所示,大小种茎落入入种槽时,无垫料送种辊中的种茎受力较大,而带垫料送种辊中的种茎则受力相应较小,可以看出其垫料受力形变减轻了种茎受力。如图9c、图9d所示,小种茎移出入种槽时,垫料能够增加小种茎的受力角,减小入种槽与送种辊对它的挤压力;而大种茎移出入种槽时,通过垫料形变实现大直径种茎的排出,而垫料的形变在一定程度上会增加种茎的受力,通过垫料的颜色变化可以看出垫料形变受力并不大。

表1 仿真试验方案

a. 小种茎落入入种槽a. Small stems fall into the grooveb. 大种茎落入入种槽 b. Large stems fall into the groove c. 小种茎移出入种槽 c.Small stems shift from seeding grooved. 大种茎移出入种槽 d. Large stems shift from seeding groove

注:垫料与种茎的颜色随随受力值的增大,由深蓝变化至深红。

Note: Color of dunnage and stems changes from dark blue to deep red along with increases of the suffered force value.

图9 有无垫料下大小种茎排种过程仿真

Fig.9 Seeding simulation of small &large stems with dunnages or not

由上述分析可知,在种茎移出入种槽过程中大小种茎存在一定的差异,如图10所示,为排种过程中,与下种箱相接触的种茎在重力方向上的位移、速度曲线图。由图10a、图10b可知,在添加垫料前后,小种茎在重力方向上的运动轨迹大致相同,而大种茎则存在一定的波动,这是由于垫料增大了小种茎的受力角,但不会改变种茎的位移轨迹;而大种茎移出入种槽时,通过挤压垫料形变实现排种,因此添加垫料的大种茎的位移曲线存在一定的波动。如图10c、图10d所示,为种茎排种过程中的速度曲线图,在排种过程中,种茎的速度值呈递减趋势,其中无垫料的种茎速度变化更为平缓,这是由于在排种过程中,种茎所受作用力直接作用在垫料上,并随着垫料的弹性形变出现速度波动,一方面也证明了垫料在排种过程中对种茎起着缓冲作用。同时,从图10可看出,辊3的仿真结果与辊2相近,表明通过垫料不仅能够有效减轻种茎在排种过程中受力,同时能够增强对小种茎的适应范围,对于偶然出现的尺寸小于给定范围的种茎依然具有较强的适应性。

表2为排种过程中,种茎落入入种槽与移出入种槽时,种茎模型受力值的最大应力、应变值。可知,添加垫料后,大小种茎落入入种槽时所受的应力、应变值均有所减小,这进一步说明了垫料在种茎落入入种槽时起到了缓冲保护作用。同时可知,小种茎移出入种槽时所受的应力、应变值有所减小,而大种茎所受的应力、应变值有所增大,这说明了采用垫料能够减小入种槽与送种辊对它的挤压力;而当种茎的直径值较大时,而垫料的形变在一定程度上会增大种茎的受力。

表2 排种过程中种茎最大应力、应变值

图10 种茎的垂直位移、速度曲线

4 试 验

4.1 排种器排种台架试验

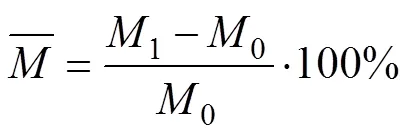

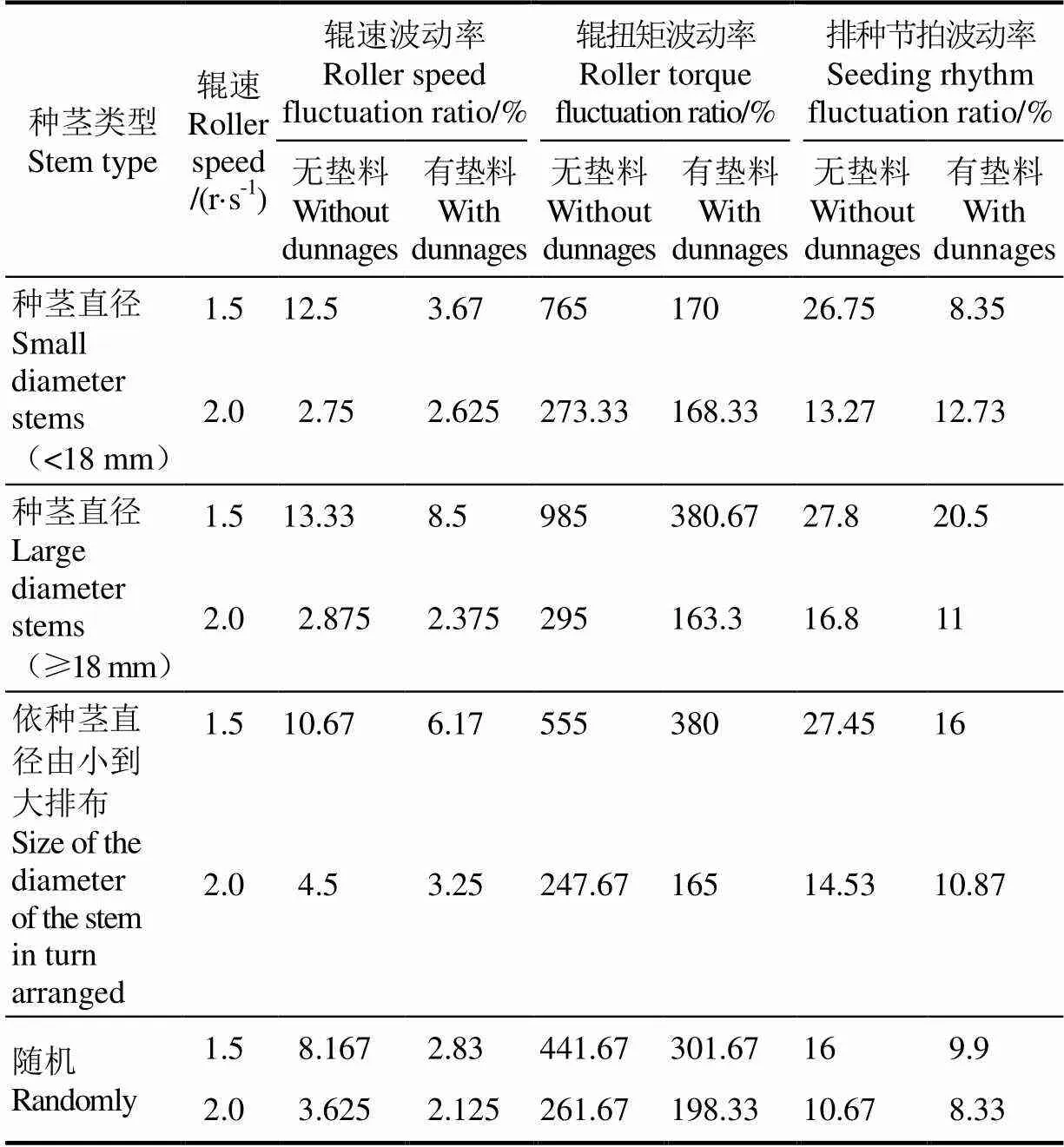

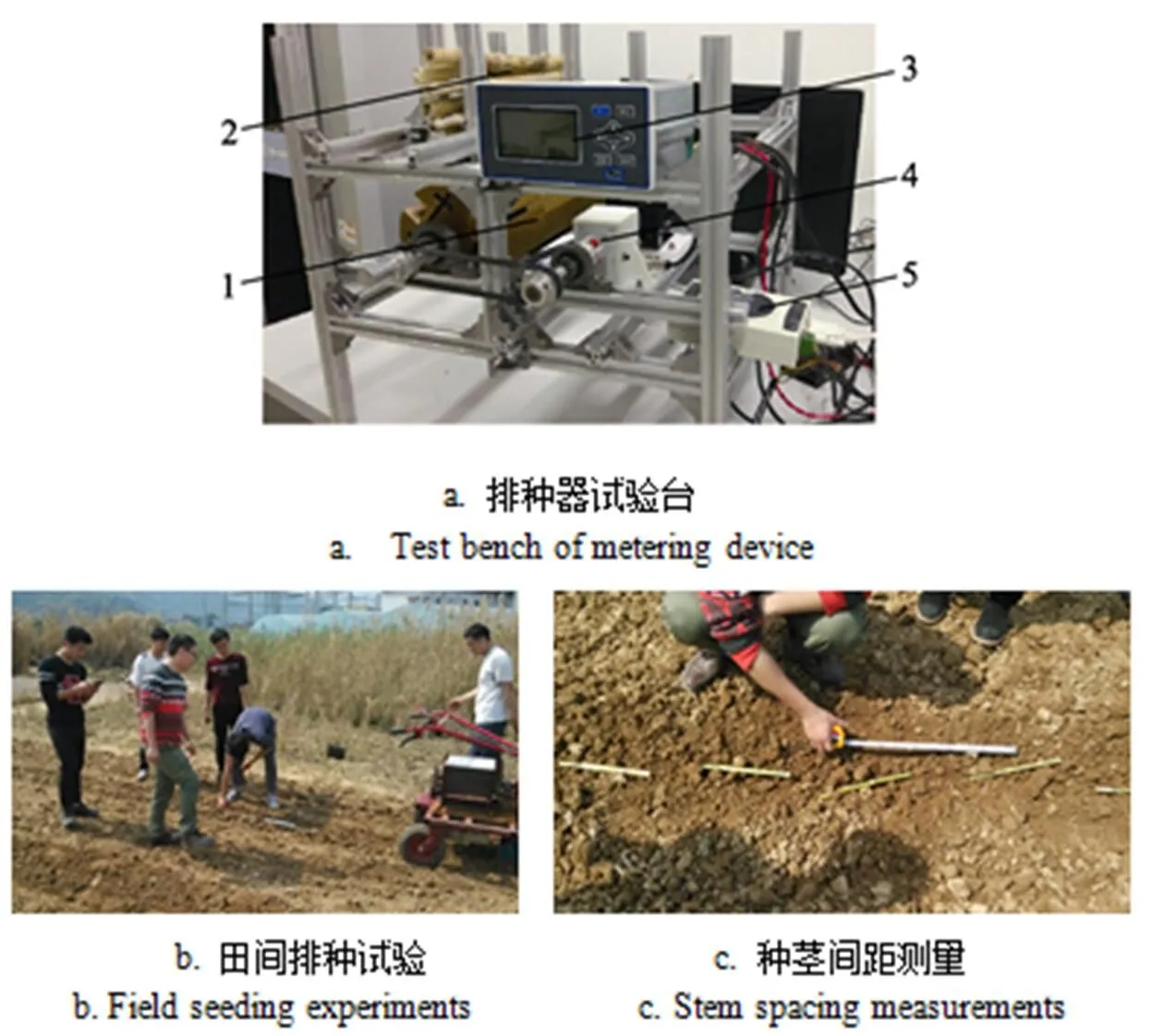

为了验证仿真结果的有效性,检验排种器的工作性能,制备巨菌草槽型辊式排种器试验台进行台架试验,如图11a,采用南京冉控科技有限公司生产的GGSNJT- 100型精密扭矩传感器(测量范围0.01~10 N·m)采集试验数据。试验种茎选取本校试验田栽植的半年生巨菌草,其直径范围为16~20 mm,长度在290 mm左右,且保证至少含有2个芽节。

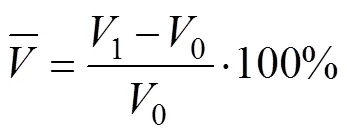

表3 送种辊台架试验数据

台架试验结果表明,所设计排种器能够满足巨菌草种植的密播和稀播需要。由对比试验可知,垫料能在一定程度上提高排种的流程度,其中辊速波动率小于10%、辊扭矩波动率小于400%、排种节拍波动率在20%左右,均优于无添加垫料的排种结果。同时,在一定范围内送种辊转速并不影响排种效果,且在一定程度上提高了排种流畅度,这是由于当转速较高时,种茎进入槽内的时间较短,位于其上层的种茎进入槽中的体积较少,因此减少了排种堵卡现象,但当转速过快时会加剧排种堵卡。

4.2 田间排种性能试验

田间排种试验于2016年12月于福建农林大学菌草试验田进行如图11b。试验过程主要考核排种器在田间的排种合格率,为此田间排种试验样机仅实现开沟排种功能,不做覆土处理,可较为直观地考察排种作业后进入种床的试验结果,如图11c。

按密播(排种转速2 r/s)与稀播(排种转速1.5 r/s)要求分2组进行,每组包含4种种茎排布方式,各进行2次重复试验,试验参数如表4。

根据巨菌草种植的农艺要求[14],参考中国国家标准《单粒(精密)播种机试验方法》(GB-T 6973-2005)[30]中的相关规定进行排种性能试验,试验结果如表4。试验结果表明,该排种样机排种合格率均值为93.33%,排种间距变异指数均值为13.63%,说明该排种装置的具有较好的排种均匀性,作业过程稳定;其中整机的平均漏排和重排指数均值为4.1%和2.5%,说明该排种结构能较好的适应巨菌草种茎的形态特征,方案设计较为合理,具有良好的排种连续性;综上所述,该排种装置的田间作业排种效果良好,适用于巨菌草机械化种植作业,可为今后巨菌草排种器的设计提供参考。

1.送种辊 2. 下种箱 3. 数据显示仪 4. 扭矩传感器 5.232转485转换器

注:行进速度为1 m·s–1;投种高度为20 mm。

Note: The travel speed is 1 m·s–1and the projection height is 20 mm.

5 结 论

本文设计一款预切种式巨菌草种茎辊式排种器,利用ADAMS虚拟样机技术,创建排种器排种过程动力学仿真模型,优化排种器入种槽和垫料的结构尺寸,通过台架试验和田间试验验证优化模型,实现种茎依次有序、顺畅和稳定地排种。

1)基于排种过程中巨菌草种茎受力模型,推导出以受力角为目标值的排种顺畅函数,确定无垫料送种辊槽型长宽尺寸为20 mm´20 mm;采用弹性垫料优化入种槽结构设计,求得垫料侧边垫料厚4 mm、底部垫料厚8 mm。

2)创建种茎三维柔性模型,利用ADAMS对排种过程进行动力学仿真分析,分析结果表明,槽型辊式排种器能够实现种茎的依次有序排放,通过垫料的缓冲作用能够减小排种过程中种茎的应力、应变值,增强排种的流畅性和稳定性。

3)台架试验结果表明,排种器能够实现巨菌草种茎排种作业,垫料能够有效提高排种流畅度;田间试验过程中排种作业稳定,排种间距合格率变异指数均值为13.63%,平均漏排和重排指数为4.1%和2.5%,合格率为93.33%,各项指标均符合巨菌草种植要求。

[1] 林兴生,林占熺,林冬梅,等. 菌草作为生物质燃料的初步研究[J]. 森林与环境学报,2013,33(1):82-86. Lin Xingsheng,Lin Zhanxi,Lin Dongmei,et al. Preliminary study on Juncao as biomass fuel [J]. Journal of Forest and Environment, 2013, 33(1): 82-86. (in Chinese with English abstract)

[2] Takara D, Khanal S K. Characterizing compositional changes of Napier grass at different stages of growth for biofuel and biobased products potential[J]. Bioresource Technology, 2015, 188(7): 103-108.

[3] 张毅,孔晓英,李连华,等. 能源草厌氧发酵产气性能与动力学分析[J]. 农业机械学报,2016,47(5):191-196. Zhang Yi, Kong Xiaoying, Li Lianhua, et al. Biogas production performance and dynamics of anaerobic digestion of different energy grasses[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 191-196. (in Chinese with English abstract)

[4] 罗艳,郑正,杨世关,等. 皇竹草厌氧发酵产沼气特性[J]. 环境化学,2010,29(2):258-261. Luo Yan, Zheng Zheng, Yang Shiguan, et al. Study on the fermentation character istics of herba andrographitis [J]. Environmental Chemistry, 2010, 29(2): 258-261. (in Chinese with English abstract)

[5] 张全国,张丙学,蒋丹萍,等. 能源草酶解光合生物制氢实验研究[J]. 农业机械学报,2014,45(12):224-228,261. Zhang Quanguo, Zhang Bingxue, Jiang Danping, et al. Photo-hydrogen production of energy grasses pretreated by enzymatic hydrolysis[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(12): 224-228, 261.(in Chinese with English abstract)

[6] 张秀平,杨志杰,张亚振,等. 巨菌草在冀中南地区的引种试验[J]. 安徽农业科学,2015,43(36):78-80. Zhang Xiuping, Yang Zhijie, Zhang Yazhen, et al. Introduction experiment of pennisetum sp. in central and southern regions of hebei[J]. Journal of Anhui Agricultural Sciences, 2015, 43(36): 78-80. (in Chinese with English abstract)

[7] 宋福超,权金鹏,甘辉林,等. 河西冷凉区巨菌草引进种植适宜性研究[J]. 中国牛业科学,2016,42(6):41-44. Song Fuchao, Quan Jinpeng, Gan Huilin, et al. The Study of the planting suitability of Jujun grass introduction in Hexi Cold District. [J]. China Cattle Science, 2016, 42(6): 41-44. (in Chinese with English abstract)

[8] 高筱钧,周金华,赖庆辉.中草药三七气吸滚筒式精密排种器的设计与试验[J]. 农业工程学报,2016,32(2):20-28. Gao Xiaojun, Zhou Jinhua, Lai Qinghui. Design and experiment of pneumatic cylinder precision seed-metering device for panax notoginseng [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(2): 20-28. (in Chinese with English abstract)

[9] 吕金庆,杨颖,李紫辉,等. 舀勺式马铃薯播种机排种器的设计与试验[J]. 农业工程学报,2016,32(16):17-25. Lü Jinqing, Yang Ying, Li Zihui, et al. Design and experiment of cup-belt type potato seed-metering device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(16): 17-25. (in Chinese with English abstract)

[10] 翟改霞,包德胜,王志军,等. 牧草播种机排种装置关键部件设计[J]. 农业机械学报,2014,45(增刊):47-51. Zhai Gaixia, Bao Desheng, Wang Zhijun, et al. Design for metering device key parts of pneumatic grass seeder [J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(Supp): 47-51. (in Chinese with English abstract)

[11] 史嵩,张东兴,杨丽,等. 气压组合孔式玉米精量排种器设计与实验[J]. 农业工程学报,2014,30(5):10-18. Shi Song, Zhang Dongxing, Yang Li, et al. Design and experiment of pneumatic maize precision seed-metering device with combined holes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(5): 10-18. (in Chinese with English abstract)

[12] Yang S, Zhang S M. Design and parameter optimization of flexible comb-type grass seed metering device [J]. International Journal of Agricultural & Biological Engineering, 2015, 8(1): 9-16.

[13] Dhaloemthoi C, Saengprachatanarug K, Wongpichet S, et al. Development and evaluation of metering devices for sugarcane billet planter [C]//Tsae International Conference. 2015.

[14] 赵芳伟,童向亚,郑书河,等. 2CJQ-1型预切种式巨菌草种植机的设计与试验[J]. 甘肃农业大学学报,2015,50(5):150-156. Zhao Fangwei, Tong Xiangya, Zheng Shuhe, et al. Design and experiment of 2CJQ-1.sp precutting type planter[J]. Journal of Gansu Agricultural University, 2015, 50(5): 150-156. (in Chinese with English abstract)

[15] Jia H, Wang W, Luo X, et al. Effects of profiling elastic press roller on seedbed properties and soybean emergence under double row ridge cultivation [J]. Soil & Tillage Research, 2016, 162: 34-40.

[16] 郑书河,童向亚,林长山,等. 巨菌草辊式排种器及排种方法:201510396570.1 [P]. 2015-09-23.

[17] 张静,李志伟,刘皞春,等. 气力滚筒式排种器种子吸附边界模型及验证[J]. 农业工程学报,2016,32(23):12-20. Zhang Jing, Li Zhiwei, Liu Haochun, et al. Mathematical modeling and validation of seeder's suction-boundary on pneumatic-roller type metering [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(23): 12-20. (in Chinese with English abstract)

[18] Singh R C, Singh G, Sarawat D C. Optimisation of design and operational parameters of a pneumatic seed metering device for planting cottonseeds[J]. Biosystems Engineering, 2006, 92(4): 429-438.

[19] Biala T A, Jator S N. Block implicit Adams methods for fractional differential equations[J]. Chaos Solitons & Fractals the Interdisciplinary Journal of Nonlinear Science & Nonequilibrium & Complex Phenomena, 2015(81): 365-377.

[20] 杨然兵,张翔,李建东,等. 锥体帆布带式排种器参数优化与试验[J]. 农业工程学报,2016,32(3):6-13. Yang Ranbing, Zhang Xiang, Li Jiandong, et al. Parameter optimization and experiment on cone canvas belt type seed-metering device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(3): 6-13. (in Chinese with English abstract)

[21] 成大先.机械设计手册(第五版):单行本. 常用设计资料[M]. 北京:化学工业出版社,2010:8-9.

[22] 陈文滔,方兵,梁晓,等. 成熟期巨菌草底部茎秆力学特性试验[J]. 湖北农业科学,2016,55(8):2031-2034. Chen Wentao, Fang Bing, Liang Xiao, et al. Experimental research on the mechanical properties of bottom stalk of thesinese in mature period[J]. Hubei Agricultural Sciences, 2016, 55(8): 2031-2034. (in Chinese with English abstract)

[23] 田立权,王金武,唐汉,等. 螺旋槽式水稻穴直播排种器设计与性能试验[J]. 农业机械学报,2016,47(5):46-52. Tian Liquan, Wang Jinwu,Tang Han, et al. Design and performance experiment of helix grooved rice seeding device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 46-52. (in Chinese with English abstract)

[24] 刘宏新,刘俊孝,唐师法,等. 对置斜盘高速精密大豆排种器设计与充种机理分析[J]. 农业工程学报,2016,32(20):24-31. Liu Hongxin, Liu Junxiao, Tang Shifa, et al. Design on opposed inclined-plate high-speed precision seed-metering device and its working mechanism analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(20): 24-31. (in Chinese with English abstract)

[25] 崔涛,刘佳,张东兴,等. 基于ANSYS和ADAMS的玉米茎秆柔性体仿真[J]. 农业机械学报,2012,43(增刊1):112-115. Cui Tao, Liu Jia, Zhang Dongxing, et al. Flexible body simulation for corn stem based on ANSYS and ADAMS[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Supp1): 112-115. (in Chinese with English abstract)

[26] 刘声春. 玉米植株生物力学特性试验研究[J]. 中国农机化学报,2016,37(3):58-61. Liu Shengchun. Experimental research on the biomechanical characteristics of maize plants[J]. Journal of Chinese Agricultural Mechanization, 2016, 37(3): 58-61. (in Chinese with English abstract)

[27] Lei X, Liao Y, Liao Q. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat[J]. Computers & Electronics in Agriculture, 2016(131): 29-39.

[28] 李尚平,邓雄,钟家勤,等. 甘蔗收获机喂入系统结构改进与仿真试验[J]. 农业机械学报,2016,47(5):91-98. Li Shangping, Deng Xiong, Zhong Jiaqin, et al. Structure improvement and simulation test of sugarcane harvester feeding system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 91-98. (in Chinese with English abstract)

[29] 施印炎,陈满,汪小旵,等. 芦蒿有序收获机切割器动力学仿真与试验[J]. 农业机械学报,2017,48(2):110-116. Shi Yinyan,Chen Man, Wang Xiaochan, et al. Dynamic simulation and experiments on artemisia selengensis orderly harvester cutter [J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(2): 110-116. (in Chinese with English abstract)

[30] GB/T 6973-2005,单粒(精密)播种机试验方法[S].

郑书河,林长山,叶大鹏,刘 斌. 巨菌草种茎辊式排种器结构优化及排种动力学仿真与试验[J]. 农业工程学报,2017,33(21):36-43. doi:10.11975/j.issn.1002-6819.2017.21.004 http://www.tcsae.org

Zheng Shuhe, Lin Changshan, Ye Dapeng, Liu Bin. Structural optimization of grooved-roller seed metering device forand simulation and experiment of seed metering dynamics[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(21): 36-43. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.21.004 http://www.tcsae.org

Structural optimization of grooved-roller seed metering device forand simulation and experiment of seed metering dynamics

Zheng Shuhe1, Lin Changshan1, Ye Dapeng1, Liu Bin2

(1.350002;2.350002)

A new grooved-roller seed metering device is developed to overcome the breakage of seedling, obtain high sowing rate and raise seeding efficiency in present, and exercise the optimal design. Firstly, this paper introduces the main structure, the working principle and the related structural parameters of the device in detail. Seed metering device is a key component to realize mechanized cultivation of Pennisetum, which is divided into 2 types according to its working principle. One type is real-time cutting seed metering device and the other type is pre-cut seed metering device. Compared with real-time cutting metering device, pre-cut seed metering device has the advantages of high automation, no damage to seed and lower labor intensity, so it shows a good market prospect and is the main trend of the future development of the metering device. The grooved-roller seed metering device is one of pre-cut seed metering devices. In terms of the stem stress state of seeding process, the evaluation function of seeding smoothness with force angle of the stem as the target was derived. According to the function, opening width of the seed groove and depth of the seed groove were the main impact factors of the improved device’s seeding performance. Based on the compressive strength of the stem, the best size of seeding slot was deduced as 20 mm × 20 mm finally. The different morphology and difference of seed diameters are the main influence factors of the problem, and those are easy to cause the bud break. The smoothness and accuracy of seeding were improved by adding the elastic dunnages on the groove of the seeding drum. According to the evaluation function of seeding smoothness, the structure size of the dunnages was optimized as the side gasket thickness of 4 mm and the bottom gasket thickness of 8 mm. In order to study the effect of dunnages on the fluency, the model of grooved-roller seed metering device of the Pennisetum was established by using the dynamic simulation software ADAMS (automatic dynamic analysis of mechanical systems). The effect regularities of structural parameters and motion parameters on seed groove and dunnages were studied. The simulations showed that the new seed metering device could realize the orderly discharge of seeds, and obviously reduce the stress of small-diameter seed by using the plastic dunnages, ensuring the seed row stability and the adaptability of seed diameter. Then the real tests in the laboratory and field were undertaken to verify the conclusions of virtual tests. Bench test results showed that the gasket could improve the flow degree of the seed row to a certain extent, in which the roller speed fluctuation ratio was less than 10%, the roller torque fluctuation ratio was less than 400%, and the seeding rhythm fluctuation ratio was about 20%. The research further indicated that the quality of the seeding was not affected by the roller speed, and sometimes the faster speed would slightly improve the fluidity of the seeding. Because when the roller speed was faster, the time the stem entered the entry took shorter, which reduced the resistance of the seed row to a certain extent. The results indicated that the seed metering device can realize the seeding operation and the dunnages can effectively improve the seeding fluency. Field experiment indicated that the seeder was stable, and the qualified index was greater than 93.33%, the missing index was less than 4.1%, the multiple index was less than 2.5%, and the variance coefficient was13.63%. The indicators were in line with the planting requirements of giant grass. The research provides a theoretical reference for the design of grooved-roller seed metering device of Pennisetum and the technical reference for the related design of planting machine.

agricultural machinery; design; optimization;; grooved-roller seed metering device; dynamic simulation; experiments

10.11975/j.issn.1002-6819.2017.21.004

S223.2

A

1002-6819(2017)-21-0036-08

2017-04-11

2017-09-07

国家科技支撑项目(2014BAD15B00);福建省自然科学基金资助项目(2016J01209)

郑书河,福建尤溪,副教授,博士,美国俄亥俄州立大学大学研修,主要从事农业机械装备、机械系统动力学及植物力学研究。Email:zshld1998@163.com