青贮添加剂对稻草青贮品质和有氧稳定性的影响

2017-02-28郭海明夏天婵朱雯张勇叶均安

郭海明,夏天婵,朱雯,张勇,叶均安

(浙江大学动物科学学院,浙江 杭州 310058)

青贮添加剂对稻草青贮品质和有氧稳定性的影响

郭海明,夏天婵,朱雯,张勇,叶均安*

(浙江大学动物科学学院,浙江 杭州 310058)

试验旨在探讨不同添加剂对青贮稻草品质和有氧稳定性的影响。稻草青贮时,分别添加乳酸菌(L)、乳酸菌+糖蜜(LM)、乳酸菌+纤维素酶(LC)和乳酸菌+糖蜜+纤维素酶(LMC),乳酸菌、纤维素酶和糖蜜剂量分别为5×105cfu/g、0.6 IU/g、20 mg/g,贮存90 d后开包检测。综合评定青贮稻草的青贮质量,测定常规营养成分,浸提液的pH值、氨态氮和有机酸的含量并测定稻草的有氧稳定性。试验结果:L组、LM组、LC组和LMC组的总综合评分显著高于对照组(P<0.05)。LC、LMC组的酸性洗涤纤维含量显著低于对照组(P<0.05),提高了剩余可溶性碳水化合物的含量。与对照组相比,各处理组均提高了乳酸的含量;LC和LMC组显著提高了乳酸的含量(P<0.05)。对照组的总有机酸含量显著低于LC和LMC组(P<0.05),但是和L、LM组差异不显著(P>0.05)。各组的有氧稳定性和有氧损失均无显著差异(P>0.05)。结果表明:添加乳酸菌,提高了乳酸的含量和综合评分;在乳酸菌的基础上,添加糖蜜或是与纤维素酶的组合,有利于提升发酵品质。

青贮;稻草;乳酸菌;糖蜜;纤维素酶

我国秸秆资源丰富,稻草的年产量达到1.92亿t以上,占秸秆总量的29.93%,是草食家畜的重要粗饲料资源[1]。近年来,每年焚烧秸秆总量在1.3亿t以上,占秸秆总量的20%以上,不仅造成了资源的浪费,也会导致环境的污染[2]。合理开发利用秸秆资源,发展节粮型畜牧生产,已成为发展畜牧业的重要途径。然而稻草适口性差,营养水平低,不易消化的特质限制了其在反刍动物中的应用。同时南方地区多雨,稻草等秸秆不易干燥,将稻草等秸秆进行青贮具有保存饲料,改善适口性等优点,但稻草可溶性碳水化合物含量低,单独青贮不易成功,需要添加青贮添加剂以提高青贮品质。许能祥等[3]在水稻(Oryzasativa)秸秆青贮时,添加乳酸菌提高了乳酸的含量,降低了氨态氮与总氮的比值,提高青贮品质;但侯晓静等[4]在水稻秸秆青贮时,添加乳酸菌提高了丁酸和氨态氮与总氮的比值,降低了发酵品质,在乳酸菌的基础上添加蔗糖,提高了乳酸含量,降低了pH值和丁酸的含量,取得了良好的青贮效果。青贮时,添加纤维素酶可以降解细胞壁的结构,提高可溶性糖的含量,为乳酸菌发酵提供更多的底物。Li等[5]报道,添加乳酸菌提高了稻草发酵品质,在添加乳酸菌的基础上添加木聚糖酶,青贮效果更好。本试验在添加乳酸菌的基础上,再添加糖蜜或(和)纤维素酶,旨在于寻找合理的稻草青贮方案,为开发利用稻草资源提供有效途径。

1 材料与方法

1.1 试验材料

原料采自浙江省海盐县通元镇的鲜稻草(表1)。所需添加剂为乳酸菌(购自台湾亚芯生物科技有限公司,活菌数为1.0×1011cfu/g),糖蜜(海盐丰义牧业有限公司提供),纤维素酶(购自广州溢多利有限公司,酶活为2000 IU/g)。

表1 青贮前鲜稻草营养成分Table 1 Nutrients of fresh rice straw %DM

1.2 试验设计

试验设5个处理组:对照组(control, CK),添加等量的去离子水;在稻草鲜样中,添加乳酸菌5.0×105cfu/g(lactobacillus, L组);添加乳酸菌5.0×105cfu/g+糖蜜20 mg/g(lactobacillus+molasses, LM组);添加乳酸菌5.0×105cfu/g+纤维素酶0.6 IU/g(lactobacillus+cellulose, LC组);添加乳酸菌5.0×105cfu/g+糖蜜20 mg/g+纤维素酶0.6 IU/g(lactobacillus+molasses+cellulose, LMC组)。添加剂的量是以鲜重(FW, fresh weight)为基础。

1.3 青贮的制作

试验于2013年12月5日在浙江大学奶业科学研究所试验牧场进行。将稻草用铡草机切短至2~3 cm,取5 kg稻草鲜样,将添加剂溶解于100 mL的去离子水中,均匀喷洒在稻草上,对照组均匀喷洒等量的去离子水,将拌匀的样品使用尼龙袋制作成圆球状,压实用胶布密封。试验一共5个处理,每个处理3个重复,20~25 ℃避光保存90 d后开包检测。

1.4 测定指标及方法

按常规法[6]测定样品的干物质(dry matter, DM)和粗蛋白(crude protein, CP)的含量,根据青贮前后的质量及干物质含量测定干物质回收率(dry matter recovery, DMR)。采用Van Soest等[7]的方法测定中性洗涤纤维(neutral detergent fiber, NDF)和酸性洗涤纤维(acid detergent fiber, ADF)的含量,半纤维素(hemicellulose)的含量为NDF和ADF含量之差。可溶性碳水化合物(water soluble carbohydrate, WSC)的含量测定使用蒽酮比色法[8]。将准确称取的20 g新鲜样品,加入200 mL去离子水用组织捣碎机匀质30 s之后,4层纱布过滤[9],滤液立即检测pH(pH Meter PB-10,Sartorious)。浸提液样品的氨态氮(NH3-N)浓度采用苯酚-次氯酸钠法测定[10]。乳酸采用对羟基联苯比色法测定[11],采用姜芳等[12]的方法测定乙酸、丙酸和丁酸的含量(GC-2010,Shimadzu);HP-INNOWAX毛细管柱(30 m×0.25 mm×0.25 μm),色谱参数:柱温120 ℃,气化室温度250 ℃,检测室温度270 ℃,载气为氮气,总压力160 kPa。有机酸的含量为乙酸、丙酸、丁酸和乳酸的含量之和。

在青贮后的第90天,打开青贮包,从颜色、气味和质地等指标进行综合评定[13]。参考Conaghan等[14]检测有氧稳定性和有氧损失。操作方法如下:每个样品取3 kg放在塑料箱子(2.5 cm厚,59 cm×39 cm×22 cm)里,在20~23 ℃继续培养15 d,同时在青贮样品旁边放一个装满水的箱子,用作青贮样品温度的对照,每天记录青贮样品的温度。乳酸菌,酵母菌和霉菌分别采用MRS培养基和马丁培养基进行平板培养计数[15]。

1.5 数据处理

数据进行Excel分析和SAS 9.0单因素k水平Duncan多重比较,P<0.05差异显著。

2 结果与分析

2.1 青贮稻草的综合评定

各处理组青贮料中,L、LM、LMC组在气味上的评分值显著高于LC和对照组(P<0.05);同时对照组的气味评分显著低于LC组(P<0.05),酸香味较差。在色泽上,LM、LMC组显著高于对照组(P<0.05),但是和L、LC组的差异不显著(P>0.05),主要是因为糖蜜的添加,提高色泽评分。在质地、pH值和水分的各项评分,各处理组与对照组相比均无显著差异(P>0.05)。在总评分,其他各处理的得分均显著高于对照组(P<0.05),添加剂的使用提高了青贮稻草的综合评分;各组均无霉变的情况,除对照组外,其他各处理的综合评定属于优质青贮料(表2)。

表2 稻草青贮90 d后的综合评分Table 2 The comprehensive evaluation of rice straw after 90 d ensiling

注:SEM:标准误。同一行数据后字母不同者差异显著(P<0.05),下同。

Note:SEM: Standard error of mean. The different small letters in the same row mean significant difference (P<0.05), the same below.

2.2 不同处理对青贮稻草营养成分的影响

青贮后的营养成分见表3。由表3知,添加剂的使用对于DM、DMR、CP等指标均无显著影响(P>0.05)。LC组的NH3-N含量略高于其他各组,但无显著差异(P>0.05)。各组之间的WSC含量差异不显著(P>0.05),从数值上看,添加乳酸菌及乳酸菌与纤维素酶、糖蜜的不同组合,提高了发酵后剩余可溶性碳水化合物的含量,增加了青贮料的能量供应。与对照组相比,添加剂对中性洗涤纤维和半纤维素的含量无显著影响(P>0.05);但是LC、LMC组的酸性洗涤纤维的含量显著低于对照组(P>0.05),降低了青贮稻草的纤维含量,提升了青贮品质。

表3 青贮90 d后各处理组的营养成分Table 3 The nutrients of different groups after 90 d ensiling %DM

2.3 不同处理对青贮有机酸及菌类计数的影响

由表4可知,各处理组的pH值与对照组相比,无显著差异(P>0.05);除对照组外,各处理组pH均低于4.00,青贮效果好。青贮发酵以后,LC组和LMC组的乳酸含量显著高于对照组和L组(P<0.05),但是和LM组差异不显著(P>0.05)。各处理组的乙酸和对照组相比,差异不显著(P>0.05)。LMC、LC组的乳乙比显著高于CK组、L组(P<0.05),但是和LM组差异不显著(P>0.05),同时LM组的乳乙比显著高于对照(P<0.05)。各组均未检测出丙酸和丁酸。

表4 稻草青贮90 d后的有机酸含量及乳酸菌、酵母菌、霉菌计数(干物质基础)Table 4 The organic acid content and lactic acid bacteria acid, yeast, mold counts of rice straw after 90 d ensiling (dry matter basis)

ND:未检测到Not detected.

与对照组相比,LC、LMC组显著提高了总有机酸的含量(P<0.05),LM、L组的总有机酸数值上有升高的趋势,但未达到显著水平(P>0.05)。各组的乳酸菌数量与对照组相比无显著差异(P>0.05),但在数值上都有所提高,在一定程度上印证了各处理组乳酸含量的变化。各组的酵母菌数量无显著差异(P>0.05)。试验各组霉菌均未检出。

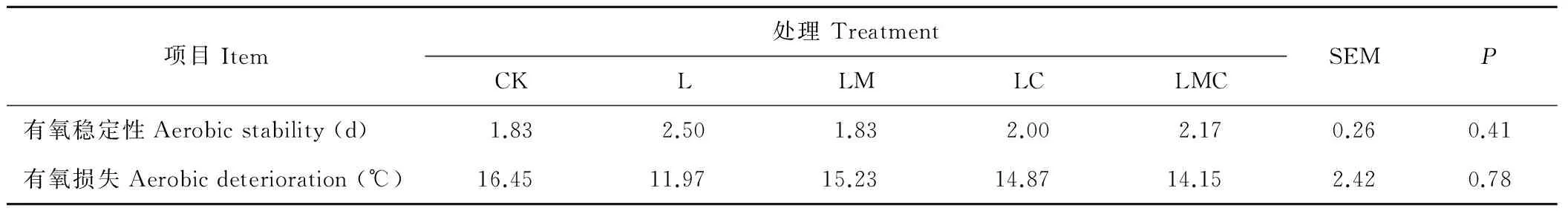

2.4 不同处理对青贮稻草有氧稳定性的影响

由表5知,试验各组有氧稳定性无显著差异(P>0.05),但从数值上来看CK和LM组的有氧稳定性低于其他几组,有氧稳定性较差。CK和LM组的有氧损失要高于L、LC和LMC组,但没有显著差异(P>0.05),这和有氧稳定性的结果相吻合。

表5 稻草青贮90 d后有氧稳定性和有氧损失评价Table 5 The evaluation of aerobic stability and deterioration of rice straw after 90 d ensiling

3 讨论

3.1 乳酸菌对稻草青贮质量的影响

青贮是在厌氧的条件下,附着在青贮料表面的乳酸菌利用糖发酵产生乳酸,进而降低pH值、抑制有害微生物(酵母菌、霉菌和梭状芽孢杆菌等)进而达到保存饲料的目的。青贮的成败,乳酸的含量成为一个关键性的评价指标。与对照组相比,单独添加乳酸菌使乳酸的含量提高了15.23%,降低了pH值,提高了饲料的酸香味,表明乳酸菌的添加提高了青贮稻草的乳酸含量,从总的综合评分这一结果亦可以得到印证。氨态氮与总氮的比值反映了青贮过程中,蛋白质的损失情况,数值越高,损失越多。从本试验结果来看,添加乳酸菌对氨态氮与总氮的比值无显著影响,这与Tabacco等[16]的结果一致。与对照组比,单独添加乳酸菌对NDF、ADF和半纤维素无显著影响,这与许能祥等[3]的结果相一致。

在青贮稻草中,添加乳酸菌,及乳酸菌与糖蜜、纤维素酶的不同组合,除LM组外,其他各组的有氧稳定性略高于对照组,但差异不显著(P>0.05)。乳酸菌利用糖生成乳酸有2种发酵形式:同型发酵乳酸菌,利用1 mol葡萄糖或果糖产生2 mol乳酸;异型发酵乳酸菌,生成等摩尔乳酸、乙酸(或乙醇)和CO2[17]。Tabacco等[18]在玉米(Zeamays)青贮中添加异型发酵乳酸菌制剂,提高了青贮料的有氧稳定性。Conaghan等[14]在萎蔫的黑麦草(Loliumperenne)中添加同型发酵的乳酸菌制剂,降低了有氧稳定性,提高了有氧损失。在本研究中,各处理组的乙酸含量高于对照组而无显著性差异,但均提高了乳酸含量,由此推测在本试验条件下,以同型发酵为主。

3.2 糖蜜对稻草青贮质量的影响

据Nishino等[19]报道,在直接切碎和萎蔫处理的羊草(Leymuschinensis)中添加糖蜜均显著提高了乳酸的含量;在本试验中,LM组的乳酸含量与CK组、L组相比分别提高了61.93%、40.53%,迅速降低了pH值,提高了青贮料的发酵品质。这与Lima等[20]的报道结果一致,主要是因为糖蜜的添加为乳酸菌的发酵提供了更多的发酵底物。LM组的乙酸含量,与CK组相比略有提升,但差异不显著(P>0.05);LM组的有氧稳定性和对照组相比亦无显著差异(P>0.05)。Huisden等[21]报道了在玉米青贮中添加糖蜜,提高了乳酸的含量,但未能提高青贮料的有氧稳定性,与本试验结果相一致,因为乳酸菌的添加并未显著提高乙酸的含量,乙酸含量越高越有助于青贮料的保存,提高有氧稳定性[22]。Arbabi等[23]在狗尾草(Setariaviridis)青贮时,添加2.5%,5.0%,7.5%的糖蜜,随着添加水平的提高,剩余可溶性糖的含量不断提高。在本研究中,添加糖蜜(LM、LMC)组亦提高了剩余可溶性糖的含量,提高了青贮料的营养价值,主要是糖蜜自身的可溶性糖含量较高的原因。

3.3 纤维素酶对稻草青贮质量的影响

Dean等[24]的研究显示,在青贮时添加纤维素酶是通过降低pH值和NDF的含量进而改善青贮的发酵品质,兴丽等[25]在全株玉米青贮发酵时,添加纤维素酶降低了ADF的含量。Guo等[26]认为,与单独添加纤维素酶或乳酸菌相比,同时添加乳酸菌和纤维素酶能进一步提高青贮料的品质。本试验中,LC组的ADF显著低于对照组、乳酸菌组(P<0.05),LC组的乳酸含量显著高于对照组和L组(P<0.05)。吴跃明等[27]在青贮稻草中添加纤维素酶提高了乳酸的含量,本试验结果与其相符合,主要是因为降解了细胞壁的结构,提高了可溶性糖的含量,为发酵提供充足的底物,提高了发酵的品质。在乳酸菌和纤维素酶的基础上,再添加糖蜜,进一步提高了WSC和乳酸的含量,有利于提高发酵品质。

4 结论

在稻草青贮中,添加乳酸菌,提高了乳酸的含量和综合评分;在乳酸菌的基础上,添加糖蜜或是与纤维素酶的组合,有利于提升发酵品质。

References:

[1] Han L J, Yan Q J, Liu X Y,etal. Straw resources and their utilization in China. Transaction of the CSAE, 2002, (3): 87-91. 韩鲁佳, 闫巧娟, 刘向阳, 等. 中国农作物秸秆资源及其利用现状. 农业工程学报, 2002, (3): 87-91.

[2] Feng W, Zhang L Q, Pang Z W,etal. The economic and environmental analysis of crop residues burning and reutilization in China. Chinese Agricultural Science Bulletin, 2011, (6): 350-354. 冯伟, 张利群, 庞中伟, 等. 中国秸秆废弃焚烧与资源化利用的经济与环境分析. 中国农学通报, 2011, (6): 350-354.

[3] Xu N X, Ding C L, Gu H R,etal. Effects of adding lactic acid bacteria and rice bran on the fermentation quality of rice straw silage. Jiangsu Journal of Agricultural Sciences, 2010, (6): 1308-1312. 许能祥, 丁成龙, 顾洪如, 等. 添加乳酸菌和米糠对水稻秸秆青贮品质的影响. 江苏农业学报, 2010, (6): 1308-1312.

[4] Hou X J, Shen Y X, Xu N X,etal. Effects of different additives on the quality and nutrient composition of rice straw. Jiangsu Agricultural Sciences, 2011, (6): 356-360. 侯晓静, 沈益新, 许能祥, 等. 不同添加物对稻草青贮品质及营养组成的影响. 江苏农业科学, 2011, (6): 356-360.

[5] Li J, Shen Y, Cai Y. Improvement of fermentation quality of rice straw silage by application of a bacterial inoculant and glucose. Asian Australian Journal of Animal, 2010, 23(7): 901-906.

[6] Zhang L Y. Feed Analysis and Quality Test Technology (Second Edition)[M]. Beijing: Chinese Agricultural University Press, 2003. 张丽英. 饲料分析及饲料质量检测技术(第2版)[M]. 北京: 中国农业大学出版社, 2003.

[7] Van Soest P J, Robertson J B, Lewis B A. Methods for dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. Journal of Dairy Science, 1991, 74: 3583-3597.

[8] Dubois M, Gilles K A, Hamilton J K,etal. Colorimetric method for determination of sugars and related substances. Analytical Chemistry, 1956, 28(3): 350-356.

[9] Adesogan A T, Krueger N, Salawu M B,etal. The influence of treatment with dual purpose bacterial inoculants or soluble carbohydrates on the fermentation and aerobic stability of bermudagrass. Journal of Dairy Science, 2004, 87(10): 3407-3416.

[10] Broderick G A, Kang J H. Automated simultaneous determination of ammonia and total amino acids in ruminal fluid andinvitromedia. Journal of Dairy Science, 1980, 63(1): 64-75.

[11] Madrid J, Martínez-Teruel A, Hernández F,etal. A comparative study on the determination of lactic acid in silage juice by colorimetric, high-performance liquid chromatography and enzymatic methods. Journal of Science Food Agriculture, 1999, 79(12): 1722-1726.

[12] Jiang F, Wang J K, Liu J X. Study on simultaneous determination of VFAs and lactic acid by using internal standard method. Chinese Journal of Animal Science, 2009, 45(21): 73-76. 姜芳, 王佳堃, 刘建新. 内标法同时测定挥发性脂肪酸和乳酸的方法探究. 中国畜牧杂志, 2009, 45(21): 73-76.

[13] Liu J X, Yang Z H, Ye J A,etal. Reasonable making and evaluation standard of silage (continued). Feed Industry, 1999, 20(4): 3-5. 刘建新, 杨振海, 叶均安, 等. 青贮饲料的合理调制与质量评定标准(续). 饲料工业, 1999, 20(4): 3-5.

[14] Conaghan P, O’Kiely P, O’Mara F P. Conservation characteristics of wilted perennial ryegrass silage made using biological or chemical additives. Jounal of Dairy Science, 2010, 93(2): 628-643.

[15] Fu T. The Effects of Microbial Inoculants on the Fermentation Process and Quality of Corn Silage[D]. Beijing: Chinese Academy of Agricultural Sciences, 2005: 14. 傅彤. 微生物接种剂对玉米青贮饲料发酵进程及其品质的影响[D]. 北京: 中国农业科学院, 2005: 14.

[16] Tabacco E, Piano S, Revello-Chion A,etal. Effect ofLactobacillusbuchneriLN4637 andLactobacillusbuchneriLN40177 on the aerobic stability, fermentation products, and microbial populations of corn silage under farm conditions. Jounal of Dairy Science, 2011, 94(11): 5589-5598.

[17] Zhang T, Cui Z J, Li J P,etal. The effect of different fermentation type of silage inoculants bacteria on the fermentation of silage. Acta Prataculturae Sinica, 2005, 14(3): 67-71. 张涛, 崔宗均, 李建平, 等. 不同发酵类型青贮菌制剂对青贮发酵的影响. 草业学报, 2005, 14(3): 67-71.

[18] Tabacco E, Righi F, Quarantelli A,etal. Dry matter and nutritional losses during aerobic deterioration of corn and sorghum silages as influenced by different lactic acid bacteria inocula. Jounal of Dairy Science, 2011, 94(3): 1409-1419.

[19] Nishino N, Li Y, Wang C,etal. Effects of wilting and molasses addition on fermentation and bacterial community in guinea grass silage. Letter Applied Microbiology, 2012, 54(3): 175-181.

[20] Lima R, Lourenço M, Díaz R F,etal. Effect of combined ensiling of sorghum and soybean with or without molasses and lactobacilli on silage quality and in vitro rumen fermentation. Animal Feed Science Technology, 2010, 155(2-4): 122-131.

[21] Huisden C M, Adesogan A T, Kim S C,etal. Effect of applying molasses or inoculants containing homofermentative or heterofermentative bacteria at two rates on the fermentation and aerobic stability of corn silage. Jounal of Dairy Science, 2009, 92(2): 690-697.

[22] Queiroz O C M, Arriola K G, Daniel J L P,etal. Effects of 8 chemical and bacterial additives on the quality of corn silage. Jounal of Dairy Science, 2013, 96(9): 5836-5843.

[23] Arbabi S, Ghoorchi T. Effect of different levels of molasses as silage additives on fermentation quality of foxtail millet silage. Asian Journal of Animal Sciences, 2008, 2(2): 43-50.

[24] Dean D B, Adesogan A T, Krueger N,etal. Effect of fibrolytic enzymes on the fermentation characteristics, aerobic stability, and digestibility of bermudagrass silage. Jounal of Dairy Science, 2005, 88(3): 994-1003.

[25] Xing L, Han L J, Liu X,etal. Effects of lactobacillus and cellulase on the fermentation characteristics and microorganism of whole-plant corn silage. Journal of China Agricultural University, 2004, (5): 38-41. 兴丽, 韩鲁佳, 刘贤, 等. 乳酸菌和纤维素酶对全株玉米青贮发酵品质和微生物菌落的影响. 中国农业大学学报, 2004, (5): 38-41.

[26] Guo G, Yuan X, Li L,etal. Effects of fibrolytic enzymes, molasses and lactic acid bacteria on fermentation quality of mixed silage of corn and hulless-barely straw in the Tibetan Plateau. Grassland Science, 2014, 60(4): 240-246.

[27] Wu Y M, Liu J X, Liu D,etal. Effects of addition of cellulase-xylanase based enzyme and/or wheat bran on the quality of corn stover and rice straw silages and on their digestibility by sheep. Chinese Journal of Veterinary, 2004, (3): 298-303. 吴跃明, 刘建新, 刘丹, 等. 添加复合酶制剂与麸皮对玉米秸、稻草青贮发酵品质和养分消化率的影响. 中国兽医学报, 2004, (3): 298-303.

Effect of additives on the quality and aerobic stability of rice straw silage

GUO Hai-Ming, XIA Tian-Chan, ZHU Wen, ZHANG Yong, YE Jun-An*

CollegeofAnimalSciences,ZhejiangUniversity,Hangzhou310058,China

The effects of different additives on the fermentation and aerobic stability of rice straw silage were studied under laboratory conditions. The treatments were no additive (CK); Lactobacillus (L); a mixture of Lactobacillus and cellulose (LC); a mixture of Lactobacillus and molasses (LM); and a mixture of Lactobacillus, cellulose, and molasses (LMC). The Lactobacillus, cellulose, and molasses were applied at the rate of 5×105cfu/g, 0.6 IU/g, and 20 mg/g fresh weight, respectively. After 90 days of ensilage, the quality of rice straw silages was assessed and their chemical composition was determined. The pH value, NH3-N, and organic acid contents in fermented juice were determined and the aerobic stability of the silages was evaluated. The comprehensive score was significantly higher for the silages with additives than for the control silage (P<0.05). Compared with the control silage, the LC and LMC silages showed significantly (P<0.05) lower acid detergent fiber content, resulting in higher residual water soluble content. Compared with the control silage, the L, LM, LC and LMC silages showed higher lactic acid concentrations, especially the LC and LMC silages (P<0.05). The total acid content was significantly lower in the control silage than in the LC and LMC silages, but did not differ significantly among the control, L, and LM silages (P>0.05). The aerobic stability and aerobic deterioration did not differ significantly between the control silage and those with additives (P>0.05). In conclusion, the results showed that addition of Lactobacillus increased the lactic acid content and comprehensive evaluation score of silage. Addition of molasses and/or cellulose with Lactobacillus improved the quality of rice straw silage.

silage; rice straw; lactobacillus; molasses; cellulose

10.11686/cyxb2016124

http://cyxb.lzu.edu.cn

2016-03-23;改回日期:2016-05-17

浙江省科技厅反刍动物饲料资源高效利用团队特派员专项资助。

郭海明(1990-),男,安徽阜阳人,在读硕士。E-mail:15067161398@163.com

*通信作者Corresponding author. E-mail: yja@zju.edu.cn

郭海明, 夏天婵, 朱雯, 张勇, 叶均安. 青贮添加剂对稻草青贮品质和有氧稳定性的影响. 草业学报, 2017, 26(2): 190-196.

GUO Hai-Ming, XIA Tian-Chan, ZHU Wen, ZHANG Yong, YE Jun-An. Effect of additives on the quality and aerobic stability of rice straw silage. Acta Prataculturae Sinica, 2017, 26(2): 190-196.