渔船拖网绞车张力自动控制系统设计及试验

2017-01-17王志勇汤涛林徐志强倪汉华

王志勇,汤涛林,徐志强,倪汉华

(1. 农业部渔业装备与工程重点开放实验室,上海 200092;2. 中国水产科学研究院渔业机械仪器研究所,上海 200092)

渔船拖网绞车张力自动控制系统设计及试验

王志勇1,2,汤涛林2,徐志强2,倪汉华2

(1. 农业部渔业装备与工程重点开放实验室,上海 200092;2. 中国水产科学研究院渔业机械仪器研究所,上海 200092)

为了补偿拖网渔船作业过程中绞车纲绳张力波动或渔船转向造成的负载不对称性,保持网具良好的开口形状,基于电液控制技术设计了拖网张力自动控制系统。对拖网曳纲张力采集方法进行了研究,采用油压力传感器间接测量拖网左右曳纲张力数据作为输入信号,传输到控制器进行逻辑运算,控制先导溢流阀调整马达溢流压力,改变绞车输出扭矩,从而驱动拖网绞车收、放来控制左右曳纲张力,达到系统动态平衡。并基于实验室虚拟仪器工程平台(laboratory virtual instrument engineering workbench,LabVIEW)对系统软件进行了设计,实现绞车张力控制系统的参数设置与控制管理。为了验证系统的张力控制特性和实用性,对系统进行了海上应用试验,在张力自动控制模式下,拖网绞车根据渔船航速和水流自动调节收放网速度,减少作业过程中曳纲张力波动。拖曳过程中拖网曳纲长度范围为350~490 m,绞车曳纲张力范围为118~148 kN,对应系统压力为2.3~2.7 MPa,渔船平均拖速为5.6节。试验结果表明,左右曳纲张力差在合理范围内,系统能很好调节曳纲张力大小,为渔船安全生产提供了保障;启用张力控制系统后网口面积比未使用张力控制系统前增大了9.5%,有效调整了网口扩张,提高了捕捞效率。

渔业;渔船;控制系统;拖网绞车;曳纲张力;电液控制;张力平衡

0 引 言

拖网捕捞是中国捕捞产量最高的捕捞方式,拖网绞车作为拖网渔船捕捞作业中最为重要的设备,其性能好坏至关重要[1-2]。拖网渔船上一般配置2台拖网绞车,分别牵引网具的左、右曳纲,拖曳网具在渔场前行。拖网渔船上拖网过程中由于风浪、底质、转向变化以及海底障碍物等影响都会引起拖网曳纲上的张力波动,对拖网绞车的性能和寿命具有很大的影响,另外,曳纲张力波动过大也会影响拖网网口扩张,引起网口形状变形,导致捕捞效率低下[3-8]。国外从20世纪80年代开始起就对拖网曳纲张力自动控制技术开展了研究[9-14],研制了恒张力绞车控制系统,目前,其大型的拖网加工船一般都配套曳纲张力控制设备,系统自动根据设定的曳纲长度值调节绞车张力,用于补偿曳纲长度变化以及渔获数量变化而引起的负载拖力变化,能够及时有效的补偿船体受海浪引起的附加运动[15-18]。国内的研究学者也对拖网渔船波浪补偿[19-21]、海洋恒张力绞车液压控制等技术分别进行了研究[22-24],但相关研究的应用相对较少。

本文基于电液控制技术,采用阀控液压马达恒压力方式实现拖网曳纲张力恒定,详细介绍了系统控制过程,重点分析了拖网作业不同阶段控制特性和效果,旨在提高中国渔船捕捞装备自动化水平,为渔船安全生产提供技术保障。

1 材料及方法

1.1 原理设计

控制原理见图1所示,通过在液压油路中油压力传感器测量马达输出压力,根据马达压力与输出扭矩的关系,将采集的绞车液压油路高压端油液压力值通过压力与张力换算模块转算为张力值信号,换算公式为

式中T为拖网曳纲张力,N;P为液压马达高压口压力,MPa;Q为马达流量,L/min;D为绞车滚筒直径,m;η为机械效率,取值0.95。

图1 电液控制技术框图Fig.1 Block diagram of electro hydraulic control technology

以曳纲张力为反馈信号,张力值信号通过数据通讯线传输给可编程逻辑控制器(programmable logic controller,PLC)控制先导阀调整溢流阀压力,实现控制左、右绞机马达高压端溢流压力[25-27]。绞车放纲长度通过脉冲编码器来测量,编码器信号通过PLC高速计数模块进行处理,在操作界面上可以转换成曳纲放绳长度,作为曳纲张力控制的反馈信号。

液压控制系统如图2所示,拖网过程中,绞车大部分时间处于收纲微动平衡状态,绞车收纲拉力与网具受力平衡,油泵一直开启供油从而溢流阀长期处于开启状态,保证马达高压端油压。由于波浪引起船舶上下升沉运动导致拖网曳纲张力大小随机变化,当渔船转向或波浪引起曳纲张力变小时,PLC通过先导阀5提高溢流阀4溢流压力,液压控制系统驱动左、右绞车收纲,调整左右曳纲张力与位置,如果需要放纲则降低溢流阀压力网具将在水流带动下放出,使左右曳纲达到动态平衡。

图2 液压控制原理图Fig.2 Hydraulic control schematic diagram

1.2 控制功能

拖网过程中曳纲张力主要通过控制溢流阀压力变化来实现,溢流阀先导口控制器通过端口输出0~20 mA电流信号,通过比例放大器转换为0~5 V电压信号控制先导阀0~1 MPa输出,从而保证0~4 MPa油压溢流。

整个拖网作业过程主要包括放网、拖曳和起网阶段,系统控制流程如图3所示。当渔船达到指定渔场后,操作人员将网囊从艉滑道抛入海中,依靠水的阻力将网身、手纲、网板拖入水中。操作人员手动操纵绞车松放曳纲,当曳纲放出50 m后转入自动放网阶段,连通阀7得电,此时系统根据设定张力值自动对称的将两边曳纲放出,保证左右绞车受力平衡,放网速度稳定。因为放网速度过慢会导致作业效率低下,而放网速度过快会导致曳纲松弛引起网板倾覆,网具变形,导致放网过程失败。放网长度达到设定长度时,系统由放网转换为自动拖曳工作,此时,控制器自动采集左右绞车油路压力信号,经过换算转换成绞车曳纲张力,通过比例积分微分(proportion in tegration differentiation,PID)运算控制保证此张力差为一个定值,通过调整左右绞车工作压力差值,使拖网曳纲在一定长度变化范围内保持张力恒定,左右曳纲绞车的最大绳长差设为30 m。系统最小、最大拖曳压力可随时调整,最大拖曳压力设定线性溢流阀的压力,具体对应关系为0~4 M Pa线性对应0~5 V。当拖曳结束后,拖网绞车开始起网,此时网具在水中的拖曳速度为渔船航速与绞车起网速度之和,拖网曳纲张力最大。起网压力可通过人机界面调整,设定值线性对应溢流阀的设定压力输出。

图3 系统控制流程图Fig.3 Control flow chart of system

1.3 软件设计

基于实验室虚拟仪器工程平台(laboratory vi rtual Instrument engineering workbench,LabVIEW)进行了张力平衡控制系统人机界面设计,LabVIEW具有强大的计算机图形环境,采用可视化的图形编程语言和平台,能与整个硬件系统无缝连接。系统软件设计主要由参数设置、信息管理、系统监控、历史数据查询等子系统组成,主界面如图4所示,分别实现系统设置、张力平衡系统信息设置与管理、液压动力系统自动化操作与监视、历史信息查询等功能。软件使用操作系统:windows xp,windows7操作系统;软件数据库:基于微软Access数据库开发;

图4 系统软件设计界面Fig.4 Design interface of system software

2 系统试验与分析

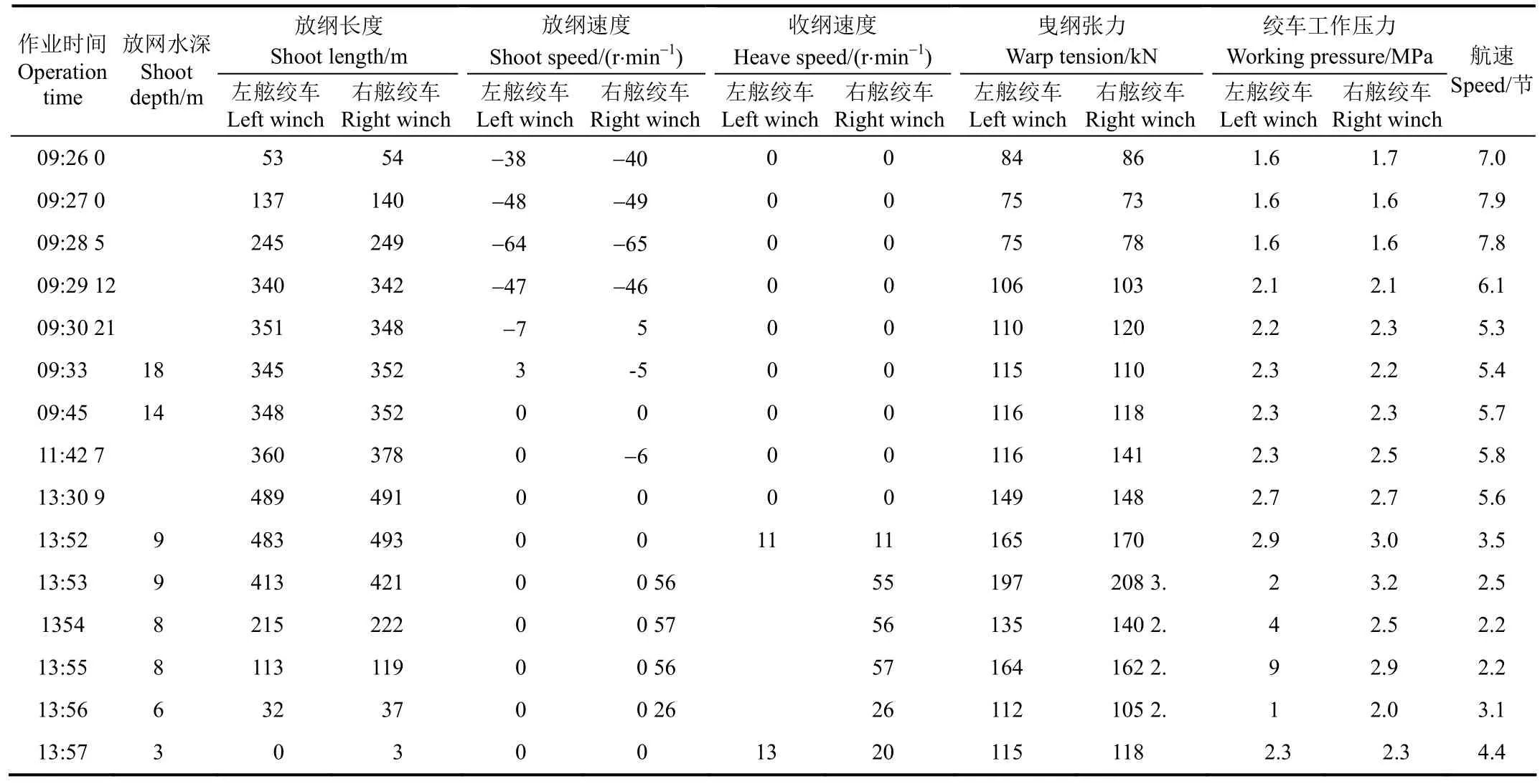

为了验证系统的实用性,2015年3月在中国东海海域对拖网张力自动控制系统进行了海上试验,试验渔船为上海开创渔业公司“开裕号”渔船,气控拖网绞车主液压额定工作压力4 MPa,钢丝绳直径32 mm,测量了一个网次拖网左右曳纲作业数据,如表1所示。

表1 系统试验结果Table 1 System experiment result

由表1中数据分析,放网开始时船速为5.4~7.9节,张力自动控制系统自动调节左右绞车放网速度基本一致,随着放纲长度增加,拖网绞车曳纲张力也逐渐增大,但左右曳纲张力始终处于平衡状态,使得网具具有稳定的对地速度进而保证网具具有稳定的下沉速度以及理想的网口扩张。

拖曳过程是拖网作业最重要也是持续时间最长的步骤,曳纲长度范围:350~490 m;绞车工作压力:2.3~2.7 MPa;绞车拉力118~148 kN;拖速范围:5.3~5.8节,平均拖速为5.6节。渔船匀速拖曳,当放纲长度和水深不变时,拖网曳纲处于平衡状态,主要受到水动力、曳纲自重和水中渔具的阻力作用。拖网绞车大部分时间处于恒张力状态,曳纲张力始终在一定范围内波动。当曳纲张力差超过设定范围时,张力自动控制系统控制拖网绞车放出纲绳达到左右曳纲张力平衡。

起网时由于网具相对水流速度增加,拖网曳纲张力开始增大,为了防止曳纲过度绞收,损坏曳纲和网具,此时船舶航速减半,航速2~4节,同时绞收曳纲。单拖渔船拖网绞车曳纲的最大负荷出现于网板即将露出水面时,网板的水阻力和重量以及网具的阻力完全由拖网绞车承担,曳纲收绞完毕后,网板固结于网板架上,由于网具对水速度减小,拖网绞车拉力骤减[28-30],测量数据与拖网作业实际情况比较吻合。

借助船上网位仪采集了应用拖网张力控制系统前后的网口形状图,如图5a和图5b所示。对网形测试结果进行了分析,图5a为未使用张力平衡控制系统时网形,图5b为使用曳纲张力控制系统网形,对比2个图形,图5a中网口变形较为严重,左右两端出现明显的锐角;图5b中网形张开形状较好,呈流畅的椭圆形网口,网形变形量显著减小。对测量网形图进行计算,由图中可知每格为20 m,对应网形数据如表2所示,在网口周长基本一致的情况下,启用张力控制系统后网口高度增大明显,改善了网口扩张,网口面积增大了9.5%,有效提高了捕捞效率。

图5 拖网作业网口形状Fig.5 Shape of net mouth

表2 网形测试数据Table 2 Test data of net shape

3 讨 论

张力控制过程中,通过在不同作业模式下设定溢流阀开口压力,根据需要调整拖网曳纲最大张力。当左右曳纲张力差值最大为25 kN时,右舷绞车能够实时放出纲绳,张力控制系统对曳纲张力随波浪变化的动态响应性能较好。试验过程中,左、右舷绞车工作压力值从1.6 MPa变化至3.2 MPa,无论在放网、起网阶段还是拖曳阶段,左舷绞车和右舷绞车马达进油阀口压差始终保持恒定,减少了绞车速度受负载变化的干扰。

该张力自动控制系统采用溢流阀控制系统相对恒定的压力,由于该张力控制采用马达高压口压力恒定来实现拖网曳纲张力平衡,所以液压泵一直供应液压油,液压系统会产生热量,有一定的功率损失,一般适用于中小功率的绞车[31]。但该拖网绞车液压系统为低压系统,所以功耗与散热并不是很大,另外,该系统设计简单、适应性强、可靠性高、成本较低,因此相对于渔船应用更为经济、实用。

4 结 论

1)在放网初始阶段及收网的最后阶段,由于网板及网具距离渔船较近,拖网绞车一般为人工操作,采用速度控制。当曳纲长度不变,而拖网船加速或减速运动时,曳纲张力、位置和形状受惯性力的影响有较大的不同。渔船加速运动时拖网曳纲张力增大,而渔船减速运动时则拖网曳纲张力减小。该试验中起网时曳纲张力达到最大值208 kN,为了拖网绞车安全,此时,渔船减速航行。

2)由试验测试结果显示,采用张力自动控制系统稳定可靠,控制拖网绞车大部分时间处于恒张力状态,即曳纲张力一定张力范围波动,保证了拖网渔船安全生产。网口面积可以增大9.5%,有效改善了网口扩张,对于提高渔船作业效率具有实际意义。

[1] 贺波.世界渔业捕捞装备技术现状及发展趋势[J].中国水产,2012,(5):43-45.

[2] 谌志新.我国渔船捕捞装备的发展方向与重点[J].渔业现代化,2005,(4):3-4.

[3] 欧阳弋.曳纲张力监测及其监测仪的研制[J].渔业现代化,1992,19(4):27-29.

[4] 佘显炜.拖网曳纲动力学问题的研究[J].浙江水产学院学报,1993,12(1):1-13.She Xianwei. A study on dynamic forces acting upon a trawl warp [J]. Journ al of Zhejia ng College of Fish eries,1993,12(1):1-13.(in Chinese with English abstract)

[5] Lee C W,Lee J H. M odeling of a m idwinter trawl system with r espect to the vert ical m oment [J]. Fisher ies Sci ence,2000,66(5):851-857.

[6] Sun Xiaofeng,Yin Yong,Jin Yicheng,et al. The modeling of single-boat,mid-water trawl systems for f ishing simulation [J]. Fisheries Science. 2011,109(1):7-15.

[7] Lee C W,Zhang C I,Shin H O. Sim plified tr awl system modeling and d esign of a d epth control s ystem using fuzzy logic [J]. Fisheries Research,2001,53(1):83-94.

[8] Weinberg K L,Somerton D A. Variation in trawl geometr y due to unequal warp length [J]. Fisher y Bulletin,2006,104(1):21-34.

[9] Murphy H M,Bungay T,Stern E W P,et al. Measurement of warp loads of bongo plankton samplers [J]. Fisheries Research,2015,162:43-46.

[10] Johan R K,Vegar J. Control struc ture for tra wl systems[C]. Lisbon,Portug al:7th Conf erence on Man euvering and Control of Marine Craft,IFAC,2006.

[11] Lee C W,Lee J H,Kim I J. Application of a fuzzy controller to depth control of a mid water trawl net [J]. Fisheries Science,2000,66(5):858-862.

[12] Trout G C. A deep-trawling w inch for can adian f isheries research [J]. Ocean Engineering,1972,2(3):117-122.

[13] Carral J,Carral L,Lamas M,et al. Fishing grounds’ influence on trawler winch design [J]. Ocean Engineering,2015,102:136-145.

[14] Wang Y D,Pan H. Stud yon constant tension winch with PDF controller applications in ocean engineering [J]. Advanced Materials Research,2013,830(8):101-107.

[15] Holmes P G,S mithson J G. Development of an improved electric trawl-winch control for stern trawlers [J]. Proceedings of the Institution of Electrical Engin eers-London,1968,115(7):1045-1055.

[16] Hystad P H. Device and a meth od for autotrawl operation:U.S. Patents 5351430[P]. 1994-10-4.

[17] Fuwa S,Ebata K,Kinoshita H,et al. New tr awling system equipped in Nansei Maru of Kagoshima U niversity [J],Fisheries Engineering,2005,42(1):29-38.

[18] Mitchell M R,Dessureault J G. A constant tension winch:design and t est of a s imple pas sive s ystem[J]. Ocean Engineering,1992,19(5):489-496.

[19] 徐志强,羊衍贵,王志勇,等.大型远洋拖网渔船拖网被动补偿系统的研究[J].船舶工程,2013,35(4):51-54.Xu Zhiqiang,Yang Yangui,Wang Zhiy ong,et al. Research on passive compensation system for trawlnet used in large ocean trawlers[J]. Ship Enginee ring,2013,35(4):51-54.(in Chinese with English abstract)

[20] 谢安桓,宋金威,喻峰,等.曳纲绞车液压系统的设计及控制研究[J].液压与气动,2014,(10):11-16.Xie Anhuan,Song Jinwei,Yu Feng,et al. Design and control of th e h ydraulic s ystem of trawl win ches [J]. Chinese Hydraulics &Pneumatics,2014,(10):11-16.(in Chinese with English abstract)

[21] 宋金威.拖网渔船液压系统研究[D].杭州:浙江大学,2014.Song Jinwei. Research on the Hydraulic System of Trawler [D]. Hangzhou:Zhejiang University,2014.(in Chinese with English abstract)

[22] 魏素芬,杨文林,张竺英.液压绞车主动升沉补偿控制研究[J].液压与气动,2009(7):27-28.Wei Sufen,Yang Wenlin,Zhang Zhuying. Research on the active h eave control of h ydraulic winch [J]. Chines e Hydraulics &Pneumatics,2009(7):27-28.(in Chinese with English abstract)

[23] 张超.海洋拖曳绞车液压调速及张力波动抑制研究[D].杭州:浙江大学,2011.Zhang Ch ao. Research on Speed Control and Tension Fluctuation Sup pression of the Oceanog raphic H ydraulic Towing Win ch [D]. Hangzhou:Zh ejiang Univ ersity,2011.(in Chinese with English abstract)

[24] 王福山,王克文,周然,等. 液压绞车复合控制技术[J].液压与气动,2012(6):43-45.Wang Fushan,Wang Kewen,Zhou Ran,et al. The technology of composite control for hydraulic winch [J]. Chinese Hydraulics &Pneumatics,2012(6):43-45.(in Chinese with English abstract)

[25] 毛建忠,朱康武,钱怡,等.基于工控机的钢绳绞车张力速度控制系统[J]. 机械设计与制造,2008(5):91-92.Mao Jianzhong,Zhu Kangwu,Qian Yi,et al. Tension and velocity control s ystem for steel wire winch based on industrial computer [J]. Machinery Design &Manufacture,2008(5):91-92.(in Chinese with English abstract)

[26] 鄢华林,宋林. 恒张力绞车的应用研究[J].液压与气动,2011(7):80-82.Yan Hualin,So ng Lin. Applica tion research of winch with constant tension [J]. Chinese Hydraulics &Pneumatics,2011(7):80-82.(in Chinese with English abstract)

[27] 常晴晴,孙斌,高世阳.基于AMESim与SIMULINK的双绞车恒张力控制研究[J].液压与气动,2011(10):107-110. Chang Qingq ing,Sun Bin,Gao Shiy ang. Con stant tension control of do uble winch es based on A MESim and SIMULINK [J]. Chinese Hydraulics &Pneumatics,2011(10):107-110.(in Chinese with English abstract)

[28] Kotwicki S,Weinberg K L,Somerton D A. The effect of auto trawl s ystems o n the P erformance of a s urvey trawl [J]. Fishery Bulletin,2006,104(1):35-45.

[29] 汪锦源.拖网绞车拉力分析探讨[J].水产学报,1964,1(1):99-118.Wang Jinyuan. An analysis for the pull loads of trawl winch [J]. Journal of Fisheries of China,1964,1(1):99-118.(in Chinese with English abstract)

[30] Fujimori Y,Ch iba K,Oshim a T. Th e influence of warp length on trawl dimension and catch of walleye pollock theragra cha lcogramma in a bot tom tr awl s urvey [J]. Fisheries Science,2005,71(4):738-747.

[31] 江峰,陈恺恺.浅析船用被动式恒张力控制液压绞车[J].液压气动与密封,2013(11):38-40.Jiang Feng,Chen Kaikai. Analysis of marine passive constant tension winch [J]. Hydraulics Pneumatics &Seals,2013(11):38-40.(in Chinese with English abstract)

Design and experiment of automatic tension control system for trawl winch on fishing boat

Wang Zhiyong1,2,Tang Taolin2,Xu Zhiqiang2,Ni Hanhua2

(1. Key Laboratory of Fishery Equipment and Engineering,Ministry of Agriculture,Shanghai 200092,China;2. Fishery Machinery and Instrument Research Institute,Chinese Academy of Fishery Science,Shanghai 200092,China)

Trawl winch is the most important equipment of t rawler fishing. In order to ensure safe dragging operations of fishing vessel equipment under the complex sea conditions as well as to realize the quick response and precise control of trawl winch,an d keep net sh ape goo d,in th is stud y,th e t rawl ten sion automatic co ntrol system was designed based on electro-hydraulic control technology. The systemmainly consisted of proportional directional valve,balance valve,overflow valve,pilot valve,oil pressure sensor,and electric control system. Through measured input and output pressure of motor,we calculated warp tension as the fee dback signal and usedPLC(programmable logic controller) to control the pressure of pilot relief valve,whichwas used to adjust the left and right warp tension and position,to maintain the dynamic balance of system as well as to keep the net s hape good. T he m an-machine interface and ope ration m ode of a utomatic tension c ontrol was developed bas ed on La bVIEW,of which i ts main f unction co nsisted of parameter set,in formation m anagement,syste m monitor an d data inqu ire. The system facilitated o perator m onitoring t he running state of th e various eq uipment,and management equipment operation. In order to verify the characteristic and practicability of tension control of th e system,application test w as carried on the East C hina Sea ar ea in 2015. The experiment continued about 4.5 hours,including three stages:shooting net,dragging net,and heaving net,which tested speed control and tension control performance of the system under the corresponding operating conditions,and measured relevant data su ch as sho ot depth,shoot length,shoot speed,heave speed,warp tension and winch working pressure. The test resultshowed that dragging stage was the longest,and in this process,the left warp and right warp were kept balance,warp tension was mainly affected by hydrodynamic,warp weight,and water resistance of fishing gear. Warp shoot length range was 350-490 m,warp tension range was 118 -148 kN,corresponding to the system pressure of 2.3-2.7 MPa,and the average trawling speed of fishing vessel was 5.6 kN. Although warp tension various with the shoot length and shoot depth change,the winch was in constant tension state at the most. Data showed that the system could adjust the warp tension well to en sure trawl warp tension maintained in a certain rang e through adjusting the speed of receiving or releasing net,which suppressed effectively the interference of the warp tension variation on the nets. In addition,experiment also recorded the chart of net shape by netsonde,calculated the net expansion parameter. It could be known that net mouth perimeter was equal before and after using the tension automatic control system by comparison data. The net mouth height and net mouth roundness increased and the net mouth area was expanded by 9.5% after using tension control system,which effectively adjusted the net mouth expansion and improving the fishing efficiency. During the different stage of experiment,the set pressure of overflow valve should be different correspondingly. At the beginning of shooting,the pressure value was small,which can maintain good net mouth shape and position. Due to net speed increased relative to water flow,warp tension was increased and the maximum value reached 208 kN. The set pressure of overflow valve should be large so that it could be used to effectively protect warp and net safety,provided a guarantee for the safe production of fishing vessel. The experiment process was basically consistent with the actual fishing conditions. We concluded that in the tension automatic control mode,the trawl winch can automatically adjust speed of heave and shoot according to the fishing vessel speed and water flow. Though the system could generate heat and result in power loss during uses,the warp tension control system still cab meet the requirements of warp speed and tension control in the different trawl condition.

fisheries;fishing vessels;control systems;trawl winch;warp tension;electro-hydraulic control;tension balance

10.11975/j.issn.1002-6819.2017.01.012

S981.9

A

1002-6819(2017)-01-0090-05

王志勇,汤涛林,徐志强,倪汉华. 渔船拖网绞车张力自动控制系统设计及试验[J]. 农业工程学报,2017,33(1):90-94.doi:10.11975/j.issn.1002-6819.2017.01.012 http://www.tcsae.org

Wang Zhiyong,Tang Taolin,Xu Zhiqiang,Ni Hanhua. Design and experiment of automatic tension control system for trawl winch on fishing boat[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2017,33(1):90-94.(in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2017.01.012 http://www .tcsae.org

2016-06-28

2016-10-31

国家科技支撑计划资助(2013BAD13B02)

王志勇,男,河南汝南人,副研究员,主要从事海洋渔业装备研究。上海 中国水产科学研究院渔业机械仪器研究所,200092。Email:wzy279@sina.com