Network topology optimization of supply chain information systems

2015-04-22XUNa许娜PENGSuping彭苏萍

XU Na(许娜), PENG Su-ping(彭苏萍)

(1.State Key Laboratory of Coal Resources and Safe Mining, China University of Mining and Technology, Beijing 100083, China; 2.School of Business, Shandong Jianzhu University, Jinan 250101, China)

Network topology optimization of supply chain information systems

XU Na(许娜)1,2, PENG Su-ping(彭苏萍)1

(1.State Key Laboratory of Coal Resources and Safe Mining, China University of Mining and Technology, Beijing 100083, China; 2.School of Business, Shandong Jianzhu University, Jinan 250101, China)

Network topology optimization has been widely researched. Since market competition has gradually developed into competition among the supply chain information systems, the network topology optimization of supply chain information systems has been in urgent need. However, the network topology optimization of supply chain information systems is still in its early stages and still has some challenges. So a description of typical seven network topologies for various supply chain information systems has been given. The generic characteristics of each network topology can be summarized. To analyze the optimization of network topology optimization of supply chain information systems, a numeric model has been established based on these general characteristics. A genetic algorithm is applied in the network topology optimization of supply chain information systems model to achieve the minimum cost and shortest path. Finally, our experiment results are provided to demonstrate the robustness and effectiveness of the proposed model.

supply chain; network topology; optimization; genetic algorithm

Supply chain information systems consist of hardware, software, network, resources, and users and handle supply chain information flow. Market competition has gradually developed into competition among the supply chain information systems. However, the network topology optimization of supply chain information systems has not been widely researched.

The robustness of network topology has been widely researched, and optimizing supply chain information system models using computer network topology has begun to be adopted[1-2]. Liu et al.[2]proposed an opportunity-based topology control method, which employs a distributed algorithm based on the reliability theory to ensure the performance of the network. Zhu et al.[3]proposed an energy-efficient topology control method with cooperative communication. Zhu[4]proposed a recursive scalable topology for NoC. Fulya et al.[5]proposed a method based on a genetic algorithm for the multi-objective optimization of supply chain networks. Pathak et al.[6]developed a theory-based framework that combines the adaptive systems theory, industrial growth theory, network theory, market structure theory, and game theory. There is also research on network topology, such as the analysis of the supply chain information networks[7], truthful topology control in wireless ad hoc networks with selfish nodes, a geometric approach of network topology knowledge[8], and discrete event simulation[9].

As the network topology of supply chain information systems changes with the dynamic variation of the nodes, the network topology should be built for different industries based on specific requirements[10]to avoid uncertainties in the supply chain information system. Many robust optimization methods have been developed[11-15]to solve these uncertainties, such as dynamic key management schemes for wireless sensor networks and dynamic peer-to-peer overlay hierarchy for network-warning models. Meade et al.[16]summarized two driving forces which affect the interests and investment in the reverse supply chain information system, specifically environmental and business factors.

Min[17]proposed a mixed-integer, nonlinear programming model and a genetic algorithm that can solve the reverse logistics of both the spatial and temporal consolidation of returned products.

Qin et al.[18]employed a fuzzy programming tool to design a product recovery network to manage uncertainty and a hybrid intelligent algorithm to integrate the fuzzy simulation and genetic algorithm for optimization. Pishvaee et al.[19]proposed a model for integrated logistics networks to minimize total costs and maximize responsiveness.

Predominantly, extant work only covers reverse supply chain information systems, reverse logistics, and returned products. Few researchers have tackled the whole supply chain information system. Thus, we propose a method to optimize the network topology of the whole supply chain information system.

The rest of the paper is organized as follows. Section 1 discusses different network topologies of supply chain information systems. Section 2 presents the optimization model for the network topology. Finally, Section 3 concludes the paper.

1 Different network topologies of supply chain information system

Different industries have different network topologies that require unique network topology optimization models. We summarize seven network topologies in Fig.1 that include the automobile, hotel, theater, workshop, e-commerce, material, and pet industries.

Fig.1 Network topologies of supply chain information system for different industries

1.1 Network topology for the automobile supply chain

The automobile supply chainspans from the suppliers to the customers. The suppliers’ suppliers, suppliers, manufacturers, distributors or retailers and customers are included in the whole supply chain process[20]. The logistics flow, information flow, and capital flow are included in the whole supply chain network flow among the nodes of the supply chain. Internally, all nodes cooperate in the automobile supply chain, which is based on the principle of benefit maximization. The structure of the automobile supply chain[21]is shown in Fig.2.

Fig.2 Structure of the automobile supply chain

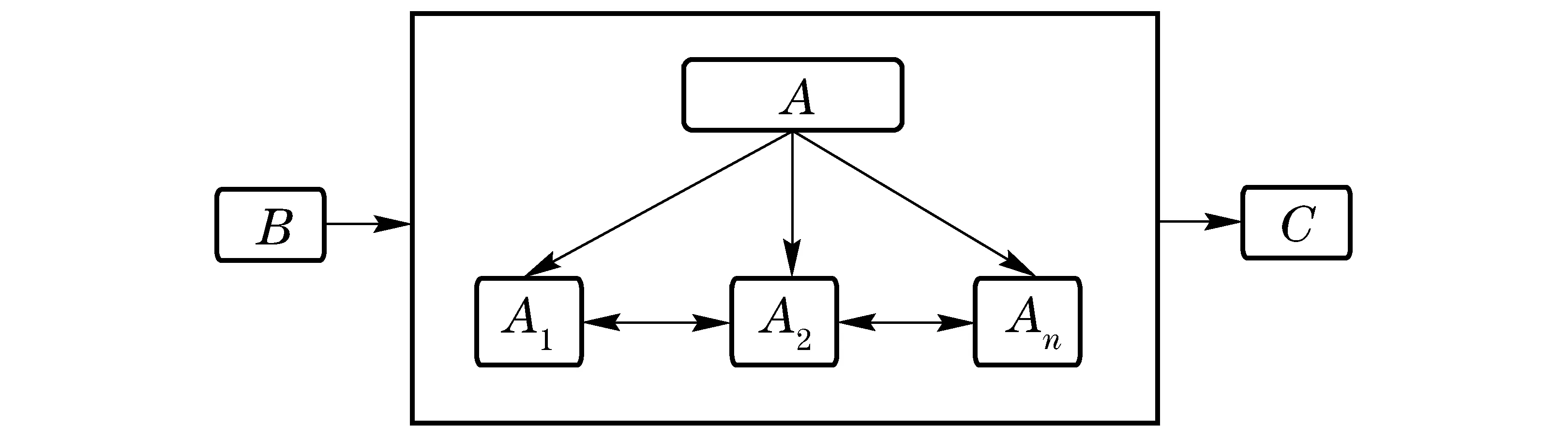

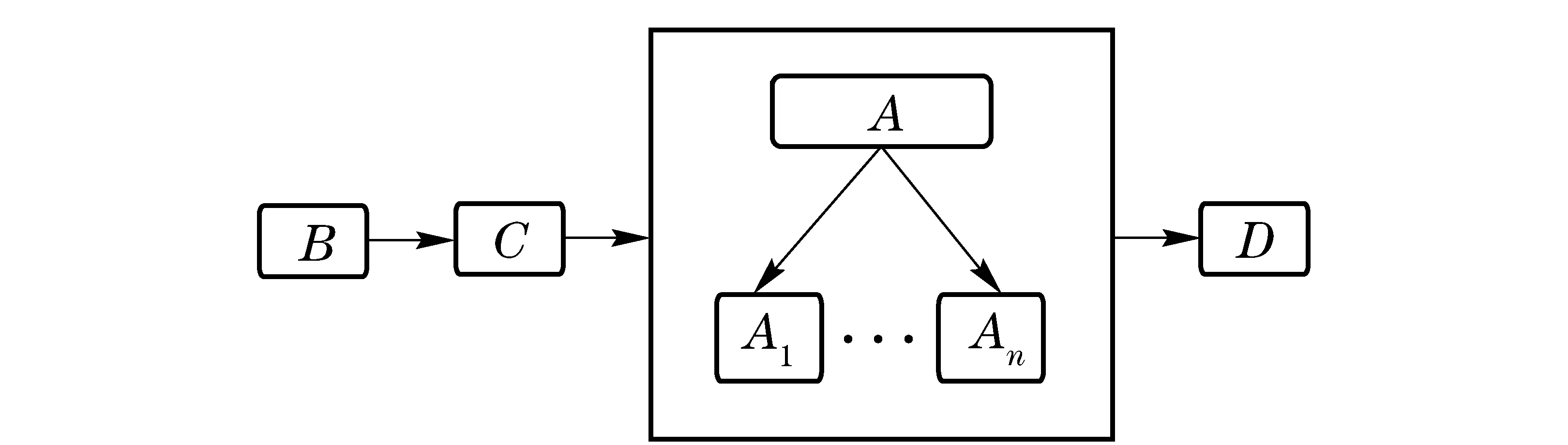

The automobile manufacturer purchases materials through orders, creates a production plan, coordinates distribution or retail arrangements, and ensures the logistics flow, information flow, and capital flow throughout the whole process. Sharing information and developing a cooperative supply chain information system effectively is a major consideration. The information in the supply chain includes the storage, product, order, and requirement information of the distributors; the sales, product, and requirement information of the retailers; the requirements of the customers; the product, material, storage, order, and supply information of the manufacturers; and, the material, supply-demand, product, and order information of the suppliers. All information should be coordinated in the supply chain system to maximize profits and minimize costs. The structure of the automobile supply chain information system is shown in Fig.3. The network topology of the automobile supply chain information system is shown in Fig.4.

Fig.3 Structure of the automobile supply chain information system

Fig.4 Network topology for automobile supply chain system information

Fig.5 Structure of the hotel supply chain information system

1.2 Network topology for the hotel industry supply chain

Occupancy rates and the hotel scale and reputation contribute to the success of hotels. The scale and reputation typically interact such that chain hotels and hotel supply chains are established. The theories integrated in the hotel supply chain include the resource-limited theory, scale economy theory, management efficiency theory, searching cost theory, and risk theory[22].

The hotel supply chainis based on how hotels cooperate on the basis of benefit and risk sharing to achieve maximum total profits and achieve strategic objectives. The model of the hotel supply chain connects hotels with suppliers and customers through the management information system. Chain hotels share the same management information system. As shown in Fig.5, the management information system includes the online procurement, reservations, checkout, query, finance, personnel, and database management. The major modules of the hotel supply chain information system are shown in Fig.6.

Fig.6 Major modules of the hotel supply chain information system

Lodging and catering are the two basic functions of hotels, and catering has become a major source of revenue. Hotels provide not only conference and banquet spaces, but also facilities services, such as commercial centers[22].

Hotels are part of the service industry and have many management departments[22], such as guestroom management, catering management, sales management, administrative management, and other additional service departments.

The network topology of a hotel supply chain information system is shown in Fig.7.

Fig.7 Network topology for hotel supply chain information system

1.3 Network topology for the theatre industry supply chain

The theatre chain system coordinates with other theatres to share profits and risks. The theatre chain is responsible for the operation and management of all the theaters, and is supported by the theatre group[23].

The structure of the theatre chain isshaped like a star, or a centralized structure, and the theatre chain can invest more in the superior theatres and reconstruct the inferior theatres. The competition of the theatre chain can be improved by resource integration. The mode of the theatre chain is the theatre plus the shopping mall or supermarket that attract potential consumers.

The structure of the theatre chain supply chain is shown in Fig.8.

Information flows and is shared throughout the theatre chain supply chain process. All the information in the theatre chain supply chain process is managed by a different management information system. The network topology of the theatre chain supply chain information system is shown in Fig.9.

Fig.8 Structure of the theatre chain supply chain

Fig.9 Network topology for theatre chain supply chain information system

1.4 Network topology for the workshop supply chain

The structure ofthe workshop supply chain with self-reliance has just one node, known as a one node topology.

1.5 Network topology for the E-commerce supply chain

The E-commerce supply chain includes the purchaser, supplier, payment authority, certificate authority, logistics center, and E-commerce service provider. All activities of the customers, suppliers, and other companies in the E-commerce supply chain are conducted online. The purpose of the E-commerce supply chain is to maximize profits and competitiveness.

The structure of the E-commerce supply chain is shown in Fig.10. The network topology of the E-commerce supply chain information system is shown in Fig.11.

Fig.10 Structure of E-commerce supply chain

Fig.11 Network topology of E-commerce supply chain information system

1.6 Network topology for the material supply chain

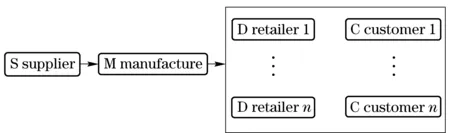

The structure of the material supply chain includes the supplier, manufacturer, retailer, and customer. This is known as a linear topology.

1.7 Network topology for the pet profession supply chain

The pet profession supply chain information system includes the pet service management center, service terminal, and the professional institutions for pets, and can provide services for pets, such as breeding, behavior, dealing, food, utensils, medical care, education, insurance, and internment. The structure of the pet profession supply chain is shown in Fig.12. The network topology of the pet profession supply chain information system is shown in Fig.13.

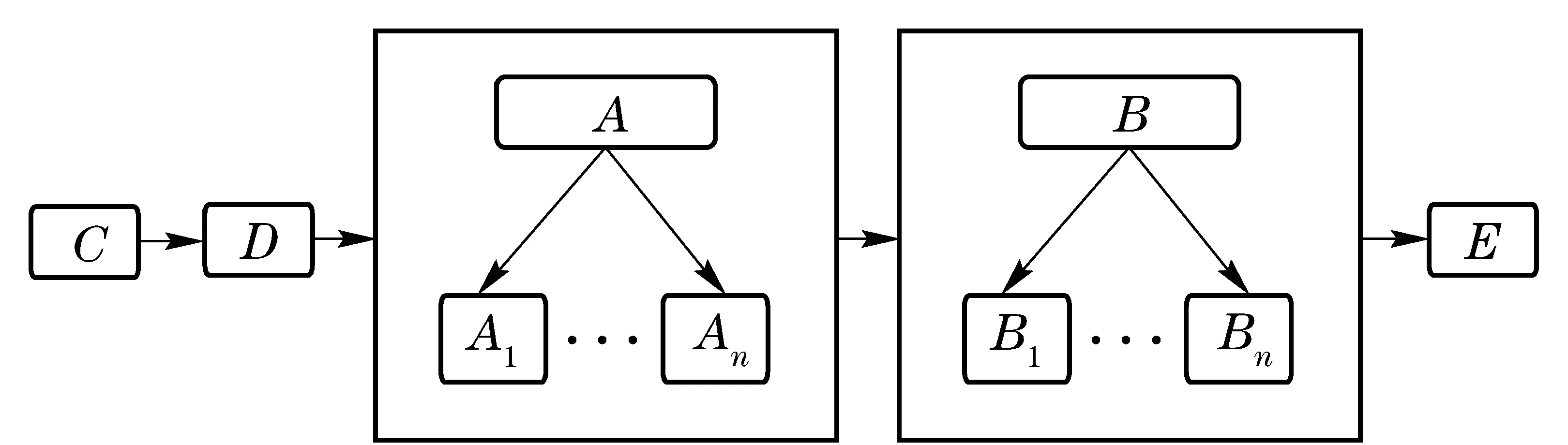

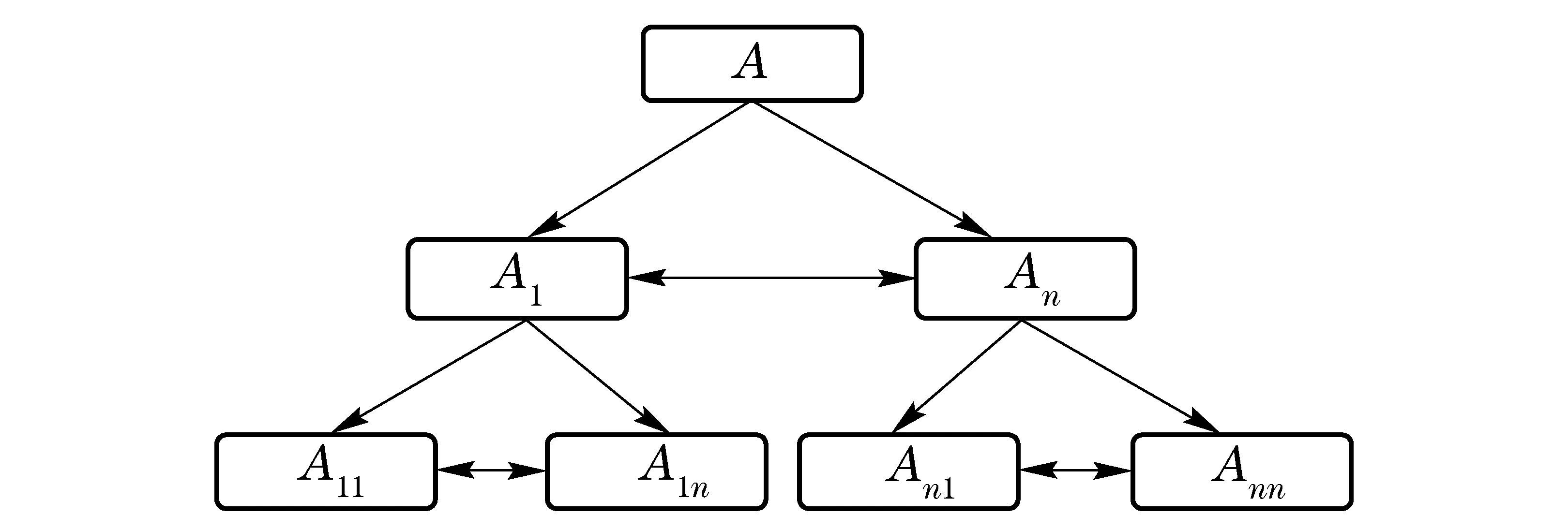

Based on the characteristics of these different industry networks, we generate a general network topology, as shown in Fig.14.

Fig.12 Structure of the pet profession supply chain

Fig.13 Network topology for pet supply chain information system

Fig.14 Elements of the general network topology

2 Network topology optimization of the supply chain information system

2.1 Network topology optimization model

Based on the characteristics and optimization requirements of the supply chain network topology, we propose a network topology optimization model that can achieve the lowest cost and shortest path. When a new node joins the supply chain network, the proposed model optimizes the topology of the whole network.

The hypotheses for the network topology optimization model are as follows:

① When new nodes are added to the supply chain network topology, the basic supply chain network will be steady, including suppliers, manufactures, and customers.

② The supplier is the only material provider that does not have its requirements considered; the manufacturer is both the material provider and the requirements node; and the customer is the requirements node.

③ The flow of the transportation fee in the supply chain network is unidirectional.

④ The loss in the manufacturing and delivering processes is ignored.

At the beginning, the distance between the existing nodes and the newly joined node is the shortest. The objective of the model is to minimize the total cost of the network topology of the supply chain. All parameters are constrained, as shown in Tab.1.

Tab.1 Parameters of the model

The shortest path method is shown as follows:

IfBmnandAijis connected

Compare the elements ofBmnwith the elements ofAij;

Find the shortest path betweenBmnandAij;

Else,

find the node connected withAij;

End.

After finding the right node and establishing the supply chain network, the optimization model is as follows:

2.2 Analysis of the network topology optimization of the supply chain information system

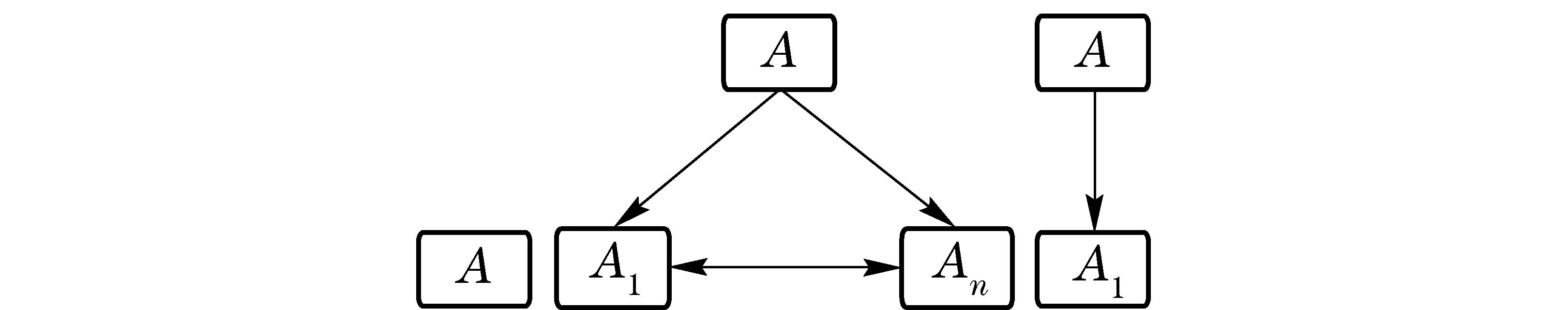

The supply chain unites the suppliers, manufacturers, retailers, distributors, and customers as a chain. Throughout the process, the activities, including the manufacture, distribution, delivery, consumption, information flow, capital flow, and logistics flow, are produced. The typical network topology of the supply chain system is shown in Fig.15.

When suppliers′ joins the typical supply chain network, the new network topology is shown as Fig.16. The solid lines are the relationships between the nodes, while the dashed lines are the relationships between the nodes in the network considering the shortest path but not the lowest cost.

Fig.15 Typical network topology of a supply chain

Fig.16 New network topology of a supply chain

First, the right nodes′ is determined based on the shortest path method.

If the newly joined node is a supplier node, the new optimization network model is as follows:

Ageneticalgorithmwasusedtooptimizethemodelwith164iterationsin30s.Throughthismethod,thelowestcostcanbeobtainedandtherobustnessofthenetworktopologycanbeenhanced.TheresultsareshowninFig.17.

Fig.17 Experiment results

Thenetworktopologycanbeoptimizedsimilarlywhenothernodesjointhesupplychainnetwork.

3 Conclusions

Inthispaper,weanalyzethesupplychaininformationsystemnetworkandproposesevennetworktopologies.Weproposeanetworktopologyoptimizationmodelforsupplychaininformationsystemstominimizecost.Whennewnodesjointhesupplychainnetwork,theproposedmodelcanbeusedtooptimizethenetworktopology.Wealsopresentacasestudytoshowtheeffectivenessoftheproposedmethod.

Onelimitationofthisstudyisthattheoptimizationprocessoftheoptimizationmodelmustbeimprovedtomakethemodelmoregeneric.Thisstudypresentsopportunitiesforfutureresearch,includingdevelopinganewsupplychainnetworktopologytodescribemoreindustries.

[1] Yu Min, Nagurney Anna. Competitive food supply chain networks with application to fresh produce[J]. European Journal of Operational Research, 2013, 224(2): 273-282.

[2] Liu Y H, Zhang Q, Lionel M Ni. Opportunity-based topology control in wireless sensor networks[C]∥Proceedings of the 28th International Conference on Distributed Computing Systems (ICDCS), Beijing, China, 2008.

[3] Zhu Y, Huang M S, Chen S Y, et al. Cooperative energy spanners: energy-efficient topology control in cooperative ad hoc networks[C]∥Proceedings of IEEE International Conference on Computer Communications (INFOCOM), Shanghai, China, 2011.

[4] Zhu Xiaojing. A recursive scalable topology for network on chip [J]. Chinese Journal of Computers, 2011, 34(5): 924-930.(in Chinese)

[5] Fulya A, Mitsuo G, Lin L, et al. A genetic algorithm approach for multi-objective optimization of supply chain networks [J]. Computers and Industrial Engineering, 2006, 51(1): 196-215.

[6] Pathak S D, Dilts D M, Biswas G. On the evolutionary dynamics of supply network topologies [J]. IEEE Transactions on Engineering Management. 2007, 54(4): 662-672.

[7] Bernstein F, Federgruen A. Decentralized supply chains with competing retailers under demand uncertainty [J]. Management Science, 2005, 51(1): 18-29.

[8] Kao D, Sabharwal A. Impact of network topology knowledge on fairness: a geometric approach[C]∥Proceedings of IEEE International Conference on Computer Communications (INFOCOM), Rio de Janeiro, 2009.

[9] Morrice D J, Valdez R A, Jack J, et al.. Discrete event simulation in supply chain planning and inventory control at free scale semiconductor[C]∥Proceedings of the Winter Simulation Conference, 2005: 1718-1724.

[10] Harland C M, Lamming R C, Zheng J, et al.. A taxonomy of supply networks [J]. Journal of Supply Chain Management, 2001, 37(4): 21-28.

[11] Kong Fanrui, Li Chunwen. Dynamic key management scheme for wireless sensor network [J]. Journal of Software, 2010, 21(7): 1679-1691.

[12] Salvatore S, Ilias L, Cecilia M, et al.. Understanding robustness of mobile networks through temporal network measures[C]∥Proceedings of IEEE International Conference on Computer Communications (INFOCOM), Shanghai, China, 2011.

[13] Xu Jia, Feng Dengguo, Su Purui. Research on network-warning model based on dynamic peer-to-peer overlay hierarchy [J]. Journal o f Computer Research and Development, 2010, 47(9): 1574-1586.

[14] Feng Tao, Li Hongtao, Yuan Zhanting, et al. Analysis method of robustness for topology of Bernoulli node model [J]. Acta Electronica Sinica, 2011, 39(7): 1673-1678.

[15] Gilvan C Souza. Closed-loop supply chains: a critical review, and future research [J]. Decision Sciences, 2013, 44(1): 7-38.

[16] Meade L, Sarkis J, Presley A. The theory and practice of Reverse Logistics [J]. International Journal of Logical System Management, 2007, 3: 56-84.

[17] Min H, Ko C S, Ko H J. The spatial and temporal consolidation of returned products in a closed-loop supply chain network [J]. Computers & Industrial Engineering, 2006, 51(2): 309-320.

[18] Qin Z F, Ji X Y. Logistics network design for product recovery in fuzzy environment [J]. European Journal of Operational Research, 2010, 202(2): 479-490.

[19] Pishvaee M S, Farahani R Z, Dullaert W. A memetic algorithm for bi-objective integrated forward/reverse logistics network design [J]. Computer & Operations Research, 2010, 37(6): 1100-1112.

[20] Lin Yun, Research on Construction and application of logistics service supply chain based automobile industry [D]. Chongqing: Chongqing University, 2011. (in Chinese)

[21] Huang Ru. Study on automotive industry supply chain net collaborative model based on value net [D]. Shandong: Shandong University, 2009. (in Chinese)

[22] Hu Ming. Research on the relationship of knowledge ambiguity, organizational absorptive capacity and knowledge transfer performance among hotel chain enterprises: knowledge transferred media as moderator variable[D]. Nanjing: Southeast University, 2009. (in Chinese)

[23] Fang Na. Study on reorganization of cinema line system [D].Beijing: Beijing Jiaotong University,2009. (in Chinese)

(Edited by Wang Yuxia)

10.15918/j.jbit1004-0579.201524.0415

TP 39 Document code: A Article ID: 1004- 0579(2015)04- 0526- 08

Received 2014- 05- 08

Supported by the National Natural Science Foundation of China (61202363, U1261203)

E-mail: xuna_1011@student.cumtb.edu.cn

杂志排行

Journal of Beijing Institute of Technology的其它文章

- Influence of shear sensitivities of steel projectiles on their ballistic performances

- Triaxial high-g accelerometer of microelectro mechanical systems

- Dynamic modeling and simulation for the rigid flexible coupling system with a non-tip mass

- Multi-constrained model predictive control for autonomous ground vehicle trajectory tracking

- Estimating the clutch transmitting torque during HEV mode-switch based on the Kalman filter

- Optimal tracking control for automatic transmission shift process