RES:定制材料成形

2015-03-02AndreFelipeEscudero,DimitrijeMiletic,GiovanniParodi等

RES:定制材料成形

学生组:Dres ( Andre Felipe Escudero, Dimitrije Miletic, Giovanni Parodi, Dimitar Pouchnikovl)

导师: Robert Stuart-Smith

工作室技术顾问:Tyson Hosmer

该研究策略性地执行了场外和现场施工流程,从而创造出一种能够将浪费最小化的设计和施工方法,无需在现场使用大量脚手架,并能带来成形生产工艺所固有的新的设计潜力。该项目设计了一座采用轻型纤维复合材料的宜居桥梁。桥梁预制件切自工厂的平面纤维材料,然后将其裁剪组合成三维构件,这种方式类似于对大块布料的操作方式。这些材料预先用树脂浸透,并以平面的方式运至现场,这样能大大的减少所需的运输的体量。现场使用一种普通脚手架来悬吊桥梁预制件,并将其拉伸成一种预设的特定形状,这个过程无需采用昂贵而又浪费的模板。一旦处于适当形态,树脂就会激发活性,以加固形成轻型复合部件。桥梁的每个部分均采用自承重设计,无需使用脚手架就能够安置在现场。由纤维布局组成的优化结构以及对自支撑部件的结构分析结果都与设计相符,其设计范畴包括制造和装配过程。从理论上说,这座桥梁大大的节省了材料、运输量、现场脚手架的搭建以及施工时间。

-- PREFABRICATION --RES: TAILORED MATERIAL FORMATION

STUDENTS: DRES: ANDRE FELIPE ESCUDERO, DIMITRIjE MILETIC, GIOVANNI PARODI, DIMITAR POUCHNIKOVL

SUPERVISOR: ROBERT STUART-SMITH

STUDIO TECHNICAL CONSULTANT: TYSON HOSMER

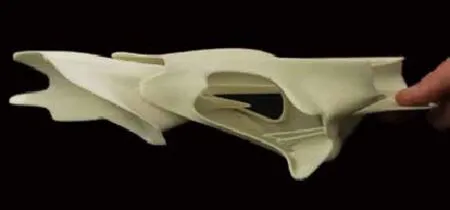

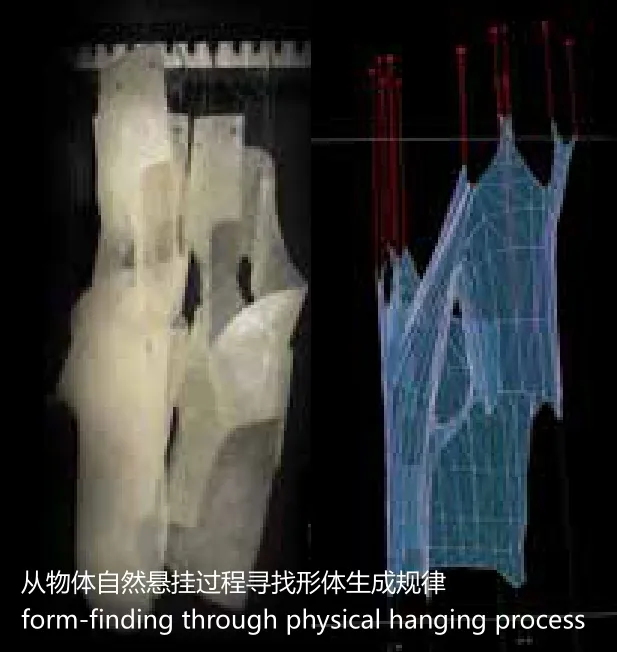

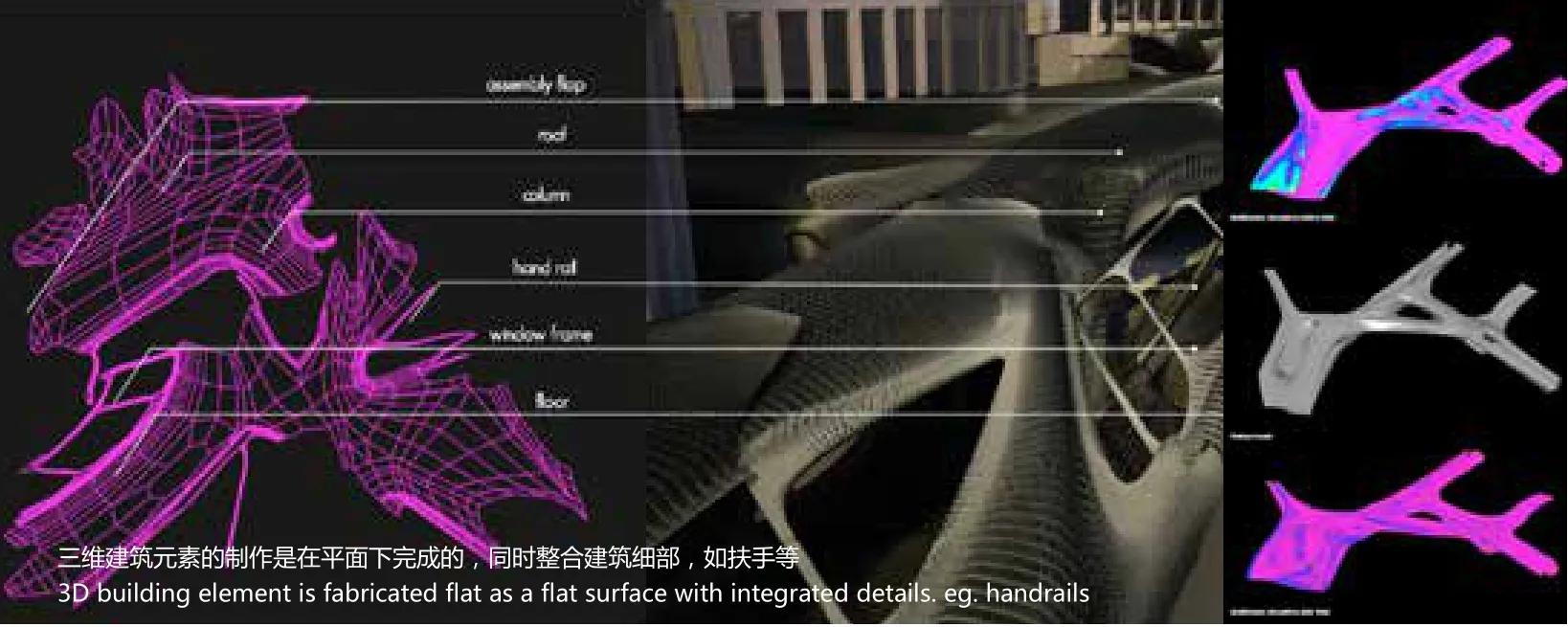

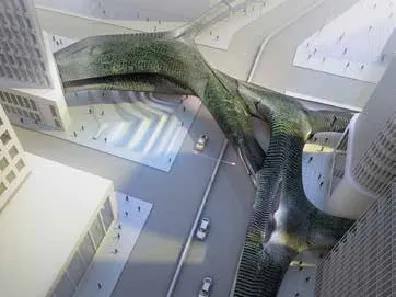

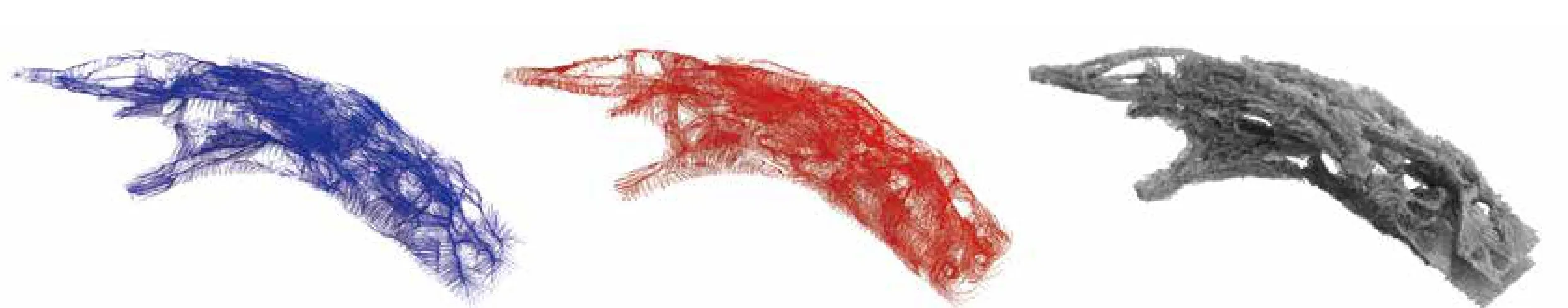

This research strategically implements off-site and on-site processes in order to create a design and construction methodology that minimises waste, removes the need for substantial on-site scaffolding and enables new design potentials that are intrinsic to its formative production processes. A habitable bridge is developed that is constructed from light-weight fibre-composite construction. Prefabricated sections of the bridge are cut from flat fibre matts in the factory and tailored into 3-dimensional patterns similar to large items of clothing. These would be preimpregnated with resin and transported to site flat, requiring little transportation volume. Onsite a generic scaffold-frame is used to hang each bridge section and stretch its material into a specific form without the need for costly and wasteful formwork. Once in the appropriate form, the resin is activated in order to create lightweight composite components. Each segment of bridge is designed to be self-supporting and able to be positioned on-site without the need for scaffolding. Structural optimisation of the fibre placement and the structural analysis of the self-supporting components inform the design, which embodies the fabrication and assembly process within its design expression. The bridge theoretically reduces material waste, transportation volumes, on-site scaffolding and construction time.

各构件在现场施工时再形成立体individual parts are formed into 3d on-site

大尺度构件的快速装配rapid assembly of large parts

每部分构件的安装均无需脚手架即能装配成型each part is designed to be assembled without scaffolding

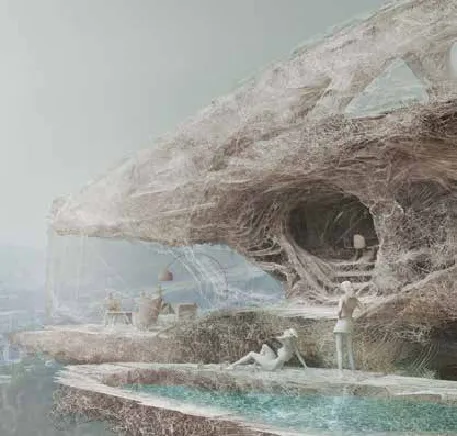

宜居桥体在首层架空以方便交通,在街道上层连接周边建筑the habitable bridge connects a number of buildings above street level while leaving the majority of ground-level free for circulation

最终宜居桥形态final habitable bridge

最终形态展示着用于装配过程的建筑节点building joints expressed in the geometry as a result of the assembly process

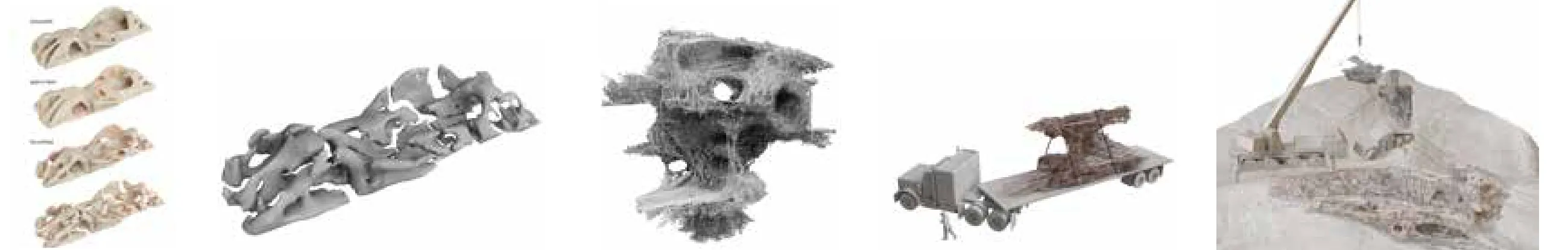

组装过程被整合在设计中一并考虑,设计要求装配过程不使用脚手架的支撑,因此必须确定所预制的大型构件能够自承重the assembly process is integral to the design which requires no scaffolding to assemble by ensuring large prefabricated parts are self-supporting

3D打印出结构主要受力区域,形成多孔结构 material is printed only where principle stress appears within the structure, creating a porous structure

建筑各部分先预制后在基地装配 the building is prefabricated in parts and assembled on-site

三维打印原型1:33模型 3d printed prototype model scale 1:33

多孔性三维打印房屋的三维可视化视图 3D visualisation of the porous 3d printed house

三维打印的分部原型模型包含直径小于1mm的材料杆件3d printed prototype part consists of elements less than 1mm in diameter

三维打印原型1:33模 3d printed prototype model scale 1:33