Viscoelastic Characteristics of Asphalt Binders at Softening Point Temperature

2014-07-25FanLiangLinJianWeiJianmingZhangYuzhenWangLin

Fan Liang; Lin Jian; Wei Jianming; Zhang Yuzhen; Wang Lin

(1. State Key Laboratory of Heavy Oil Processing, China University of Petroleum (East China), Qingdao 266580; 2. Highway Maintenance Technology Key Laboratory for Transportation Industry, Jinan 250031; 3. CPECC East-China Design Branch, Qingdao 266071)

Viscoelastic Characteristics of Asphalt Binders at Softening Point Temperature

Fan Liang1,2; Lin Jian3; Wei Jianming1; Zhang Yuzhen1; Wang Lin2

(1. State Key Laboratory of Heavy Oil Processing, China University of Petroleum (East China), Qingdao 266580; 2. Highway Maintenance Technology Key Laboratory for Transportation Industry, Jinan 250031; 3. CPECC East-China Design Branch, Qingdao 266071)

In this paper, in order to investigate the viscoelasticity of asphalt binder at the softening point temperature, more than 30 different asphalt binders were selected and tested by dynamic rheological scan method using a dynamic shear rheometer (DSR). The softening points and the rheological parameters of the asphalt samples were measured and analyzed. The results indicated that at the softening point temperature the neat asphalt and the SBS modified asphalt showed two different rheological states. The neat asphalt binders had a majority of viscous components in viscoelastic composition, with the phase angles being mostly higher than 80°. The SBS modified binders had lower phase angles, with their elasticity still retained. Meanwhile, the Shapiro-Wilk normality test showed that at a confidence level of 0.05, at whatever aging state, the neat asphalt had a stable complex modulus corresponding to the softening point, which was 13.034 kPa at a standard deviation of 2.105 kPa under the same test condition. The softening point of neat asphalt binder can be calculated via the equivalent modulus rule. It is found out that there is a good relationship between the calculated and the measured softening points. And it is suggested that more data are needed to validate this finding.

asphalt binder; softening point; viscoelasticity; equivalent modulus temperature

1 Introduction

Asphalt binder is a mixture of hydrocarbons coming from the distillation of crude oil. It is known that the asphalt binder belongs to an amorphous material without a def inite melting point. And the softening point, which characterizes the high temperature performance of asphalt binder, only reflects the hardness degree of one binder under certain experimental conditions. According to the current specifications[1], the softening point is measured under the specified experimental conditions, such as the heating rate (5±0.5 ℃/min) and the loading (under a ball mass of 3.5±0.05 g). Hence, the softening point is actually the combination effect of temperature softening and stress softening. Unfortunately, the softening point is only characterized by a temperature. And it cannot reflect the loading influence, which leads to its existence only as an empirical indicator.

The softening point cannot show any basic mechanical properties. Accordingly it is very important and necessary to convert it from experience to theory, especially mechanical properties. In the previous studies[2], the classical nomograph was established to calculate the stiffness modulus of asphalt binder in terms of penetration and softening point values, through which the empirical data were converted to mechanical performance of asphalt binder. Although this nomograph has been used widely, it has some shortcomings, such as poor data precision and operator dependant, which would limit its application[3]. In regard to the softening point theory, studies showed that the softening point is an equivalent viscosity temperature, at which the viscosity is about 2 100 Pa·s. However, the viscosities of asphalt binders range from 800 Pa·s to 3 000 Pa·s at softening point temperatures[4]. Hence, this equivalent rule has some errors and is only valid under certain conditions[2,4]. Similarly, the equivalent softening point (T800) was proposed because many asphalt penetration values at softening point vary from 600 to 1 000, most of which are close to 800(0.1 mm)[4]. Still, this equivalent method is actually a penetration in-dex which is influenced by many test factors[4-5]. Thus, it cannot be equivalent to the real softening point. In addition, It has been reported that when the softening point is less than 68.2 ℃, the equivalent zero shear viscosity is about 7 380 Pa·s[4]. Whereby, the zero shear viscosity can be influenced by the calculation models[6], indicating that this index is not practical yet. A report delivered on the Forum of European National Highway Research Laboratories (FEHRL) investigated the relationship between the softening point and the stiffness modulus at 10 ℃ and 20 ℃, but the results showed that the correlation was very weak[5].

In general, many people have noticed the changes in mechanical properties of asphalt binder at the softening point, and some equivalent indexes for the softening point were proposed. However, these indicators have been proved that they were not perfect for evaluating the asphalt performance in practicality[5]. It is known that the asphalt binder is a kind of viscoelastic material, the mechanical property of which is affected by temperature, loading, and time[3]. And the dynamic shear rheometer (DSR) has been applied widely to characterize the viscoelastic properties of the asphalt binder, including the modulus and phase angle. Hence, the objective of this study was to investigate the rheological properties of asphalt binders at the softening point, through which an indicator more close to the nature of material could be obtained.

2 Experimental

2.1 Materials

In order to cover more asphalt samples and assure the universality, more than 30 asphalt binders were studied, including 30 neat asphalt binders (coded as 1—30) and 2 styrene butadiene styrene (SBS) modified asphalt binders (coded as 31 and 32). The neat binders have penetration grades of 50, 70, 90, and 200. The SBS modi fied binders meet the I-D technical requirements in China road speci fication[7].

The softening points for the asphalt samples were determined with the ring-and-ball method according to the standard test method T0606 in JTG E20-2011[1], with the results shown in Table 1. It should be noted that the specification requires the softening point to be recorded at the temperature with an accuracy of 0.5 ℃[1]. However, in order to reflect the real condition, this study used the true softening points instead of the rounded values of asphalt samples. Additionally, the influence of aging was investigated as well. A 70 graded neat binder was subjected to the thin film oven (TFO) test and the pressure aging vessel (PAV) test, respectively. At the TFO test, aging was conducted at 163 ℃ for 5, 10, 15, and 30 h, respectively. At the PAV test, aging was performed at 100 ℃ and 2.1 kPa for 5 h, 10 h, and 20 h, respectively. And the aged samples were stored for further tests.

2.2 DSR measurement

A TA-AR 2000ex dynamic shear rheometer (DSR) was used to evaluate the rheological properties of asphalt samples using the temperature scanning program. And the data of complex modulus (G*) and phase angle (δ) were collected. Then for each asphalt binder, the changes in curves ofG* andδversus temperature (T) were obtained. Afterwards, theG* andδvalues at the softening point temperature could be calculated through the two curves using the Origin software, respectively. During the measurements, the stress control mode was applied, and the stress was equal to 100 Pa. For the plate, 25 mm in diameter, a gap of 1 mm was used. The frequency was set at 10 rad/s. The starting temperature was higher than the softening point of the asphalt binder. When the termination temperature was higher than 10℃, the cooling rate was equal to 1 ℃/min.

3 Results and Discussion

3.1 Softening points and corresponding rheological properties

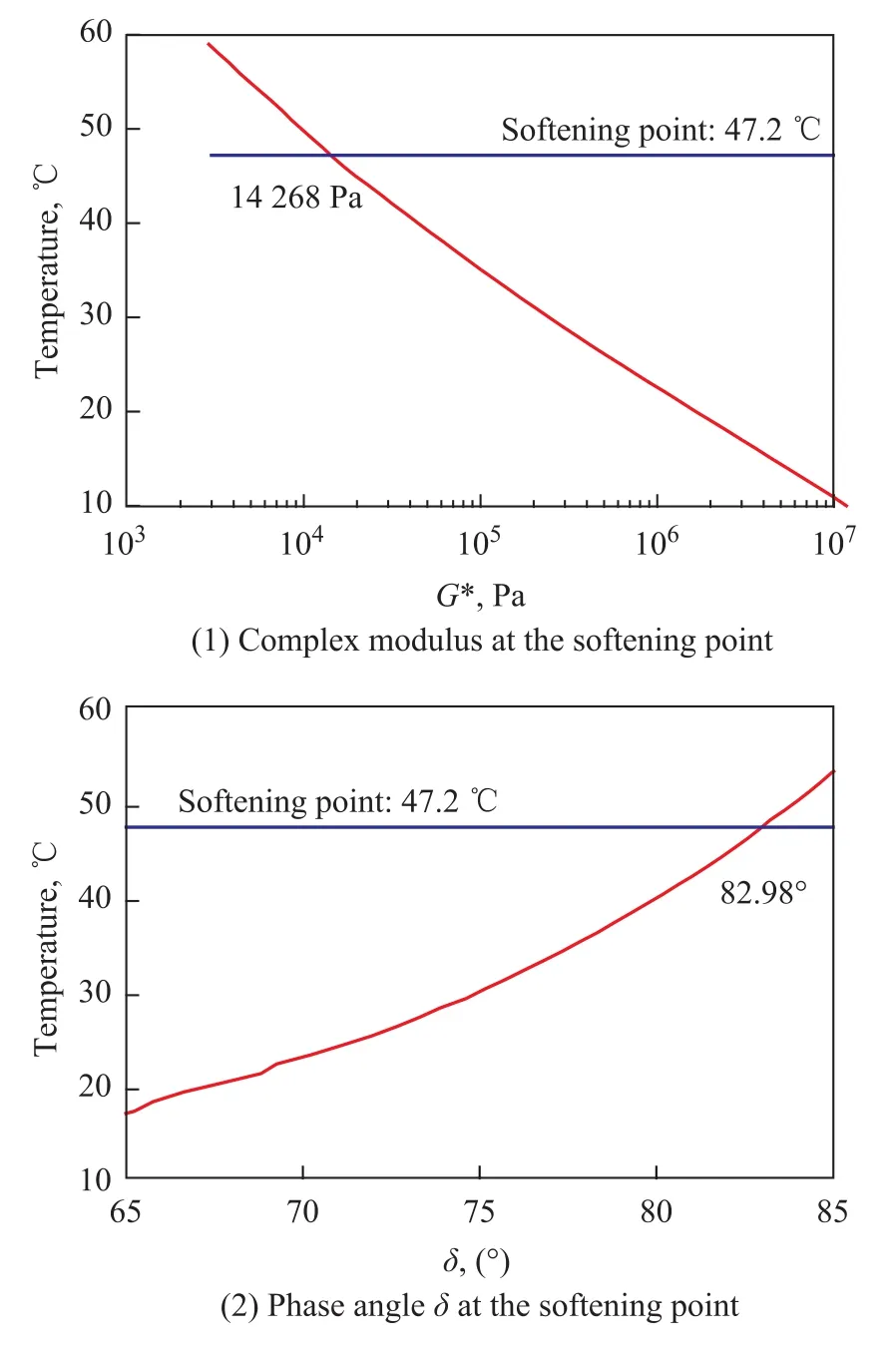

Figure 1 shows the typical rheological curve of asphalt with a penetration grade of 70. It is convenient to determine theG* andδat the softening point for each asphalt binder using the curves in Figure 1. The softening points and corresponding viscoelastic parameters of 32 asphalt binders are given in Table 1.

It can be seen from Table 1 that the softening points of neat asphalt binders are lower than those of the SBS modified binders. And the corresponding viscoelastic parameters at the softening point temperatures also show great difference between these two kinds of asphalt binders.

Figure 1 Determination of viscoelastic parameters in rheological curve

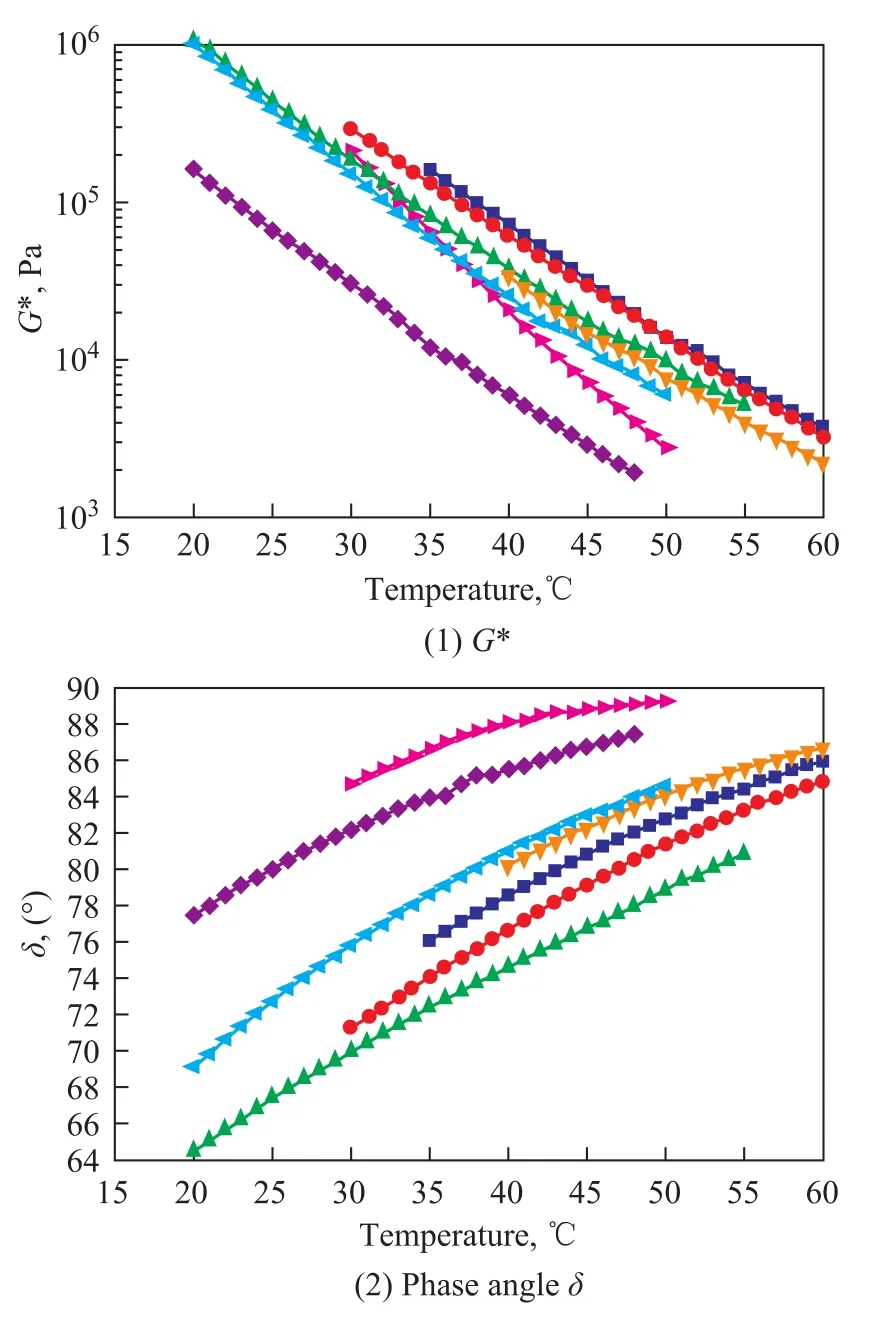

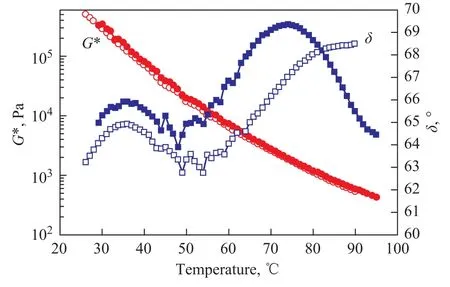

TheG* values for the neat binders are about 10 kPa, and the largest one is still less than 20 kPa. And mostδvalues are around 82°; only twoδvalues are less than 80°. Upon considering the experimental error of the softening point temperature, the difference inδvalues is not significant. With respect to the SBS modified binders, it is found out that theG* values at the softening points are much lower than those of neat binders, and theδvalues are also less than 70°. And two SBS modified asphalts show difference in terms of softening point temperatures andG* values. It can be seen from Table 1 that at softening point temperatures, viscous components are dominant in viscoelasticity composition of neat asphalt samples. But in the SBS modified asphalt samples, there is still sufficient elasticity because of their lowδvalues. According to the NCHRP 648 report[8]and other related literature information[9], a phase angle ranging from 85° to 90° represents an asphalt transition process from viscoelastic state to fluid state. Hence, the neat asphalt binder is close to the fluid state at its softening point temperature, but the SBS modified asphalt still retains the elastic property. Figure 2 and Figure 3 present the difference between the neat asphalt and the modified asphalt clearly. Figure 2 is a rheological curve for the neat asphalt having a penetration grade of 70 with a softening point of 47.5 ℃, with its corresponding phase angle equating to 82°. The phase angle increases monotonically with an increasing temperature after 47.5 ℃, and the other neat asphalts also show the same characteristics. However, in Figure 3 the SBS modified asphalt displays a different phase angle development feature, even though it has the similarG* change curve as the neat asphalt, and its phase angle change is not monotonically and always stays at less than 70° in a temperature range from 25 ℃ to90 ℃. This phenomenon indicates that the high elasticity of the SBS modified asphalt is directly resulted from the SBS polymer, which displays its application advantage in road construction.

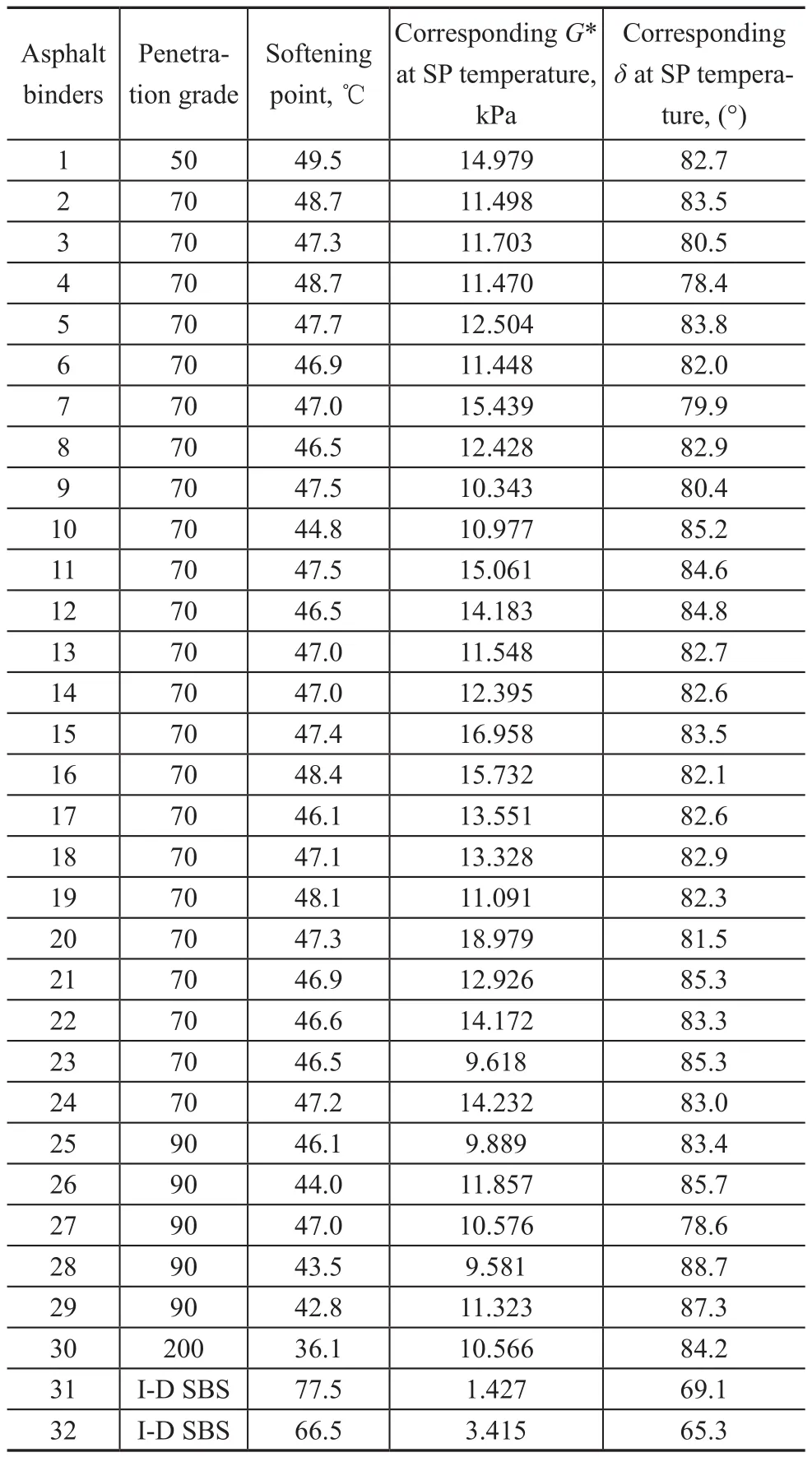

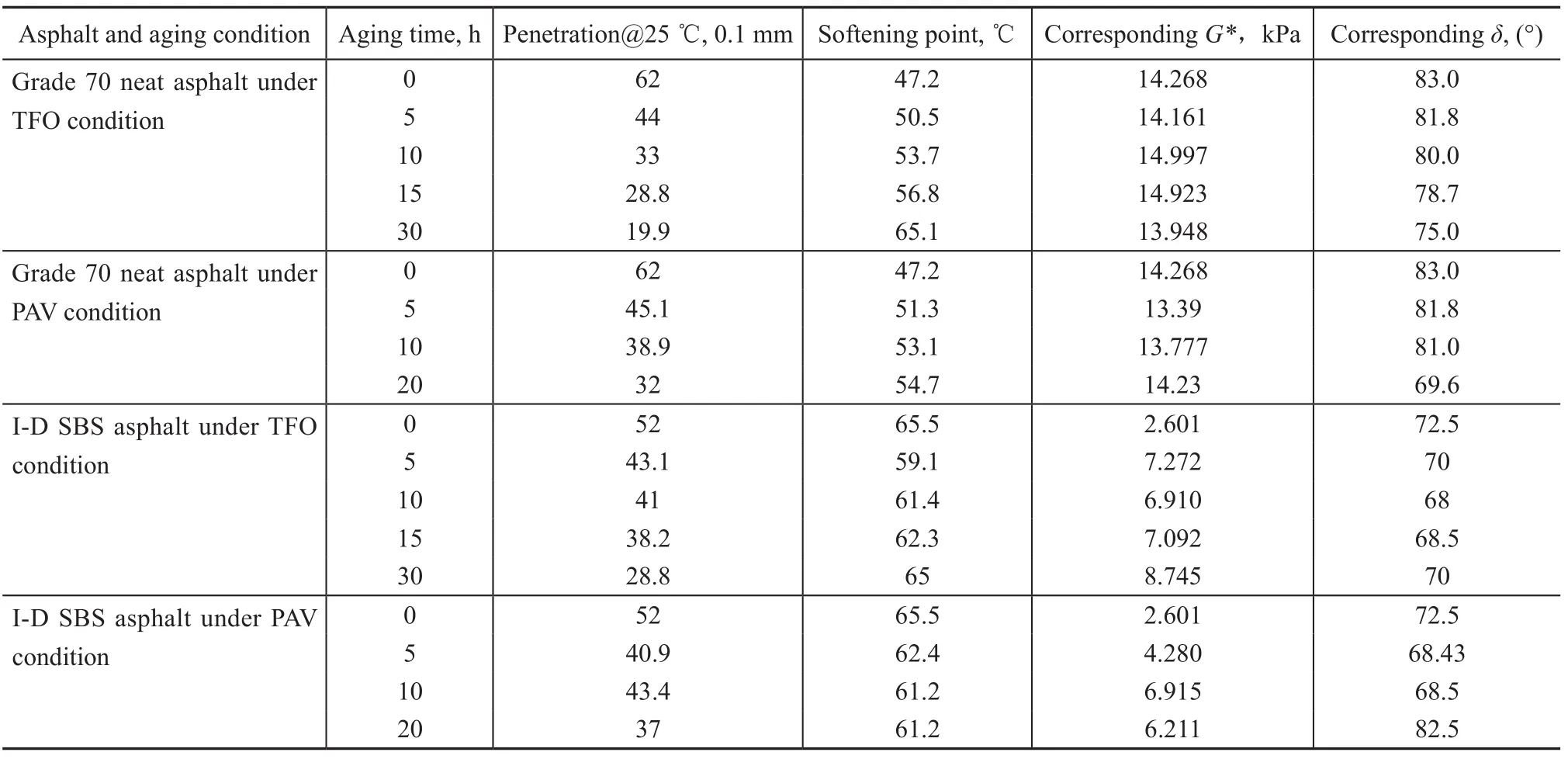

Table 1 Softening points and corresponding viscoelastic parameters of asphalt binders

Figure 2 Rheological curves of neat asphalt with penetration grade of 50, 70, 90 and 200

Figure 3 Rheological curves of SBS modified asphalts (with softening points of 77.5 ℃ and 66.5 ℃)

3.2 Statistical relations between softening point, complex modulus and phase angle

It is can be known from the aforementioned analysis that the neat asphalt and the SBS modified asphalt show different rheological performance at the softening point temperatures. And it is noticed that all neat binders have the similar situation. Besides, the neat binders with different penetration grades have close complex modulus and phase angles at each softening point temperature. Hence, it is necessary to do a statistical analysis between the softening point and the complex modulus plus phase angle for neat asphalt samples. Scatter matrixes[10]of softening points, complex modulus, and phase angles for neat binders were drawn using the Origin mathematical software, as shown in Figure 4. It is found out that there is no apparent relationship between softening point,G* andδ. However, the data ofG* andδare distributed within a 95%confidence degree, which means that there possibly exists a relative concentration ofG* andδcorresponding to softening point for the neat asphalt binder.

Figure 4 Correlation between softening point, G* and δ

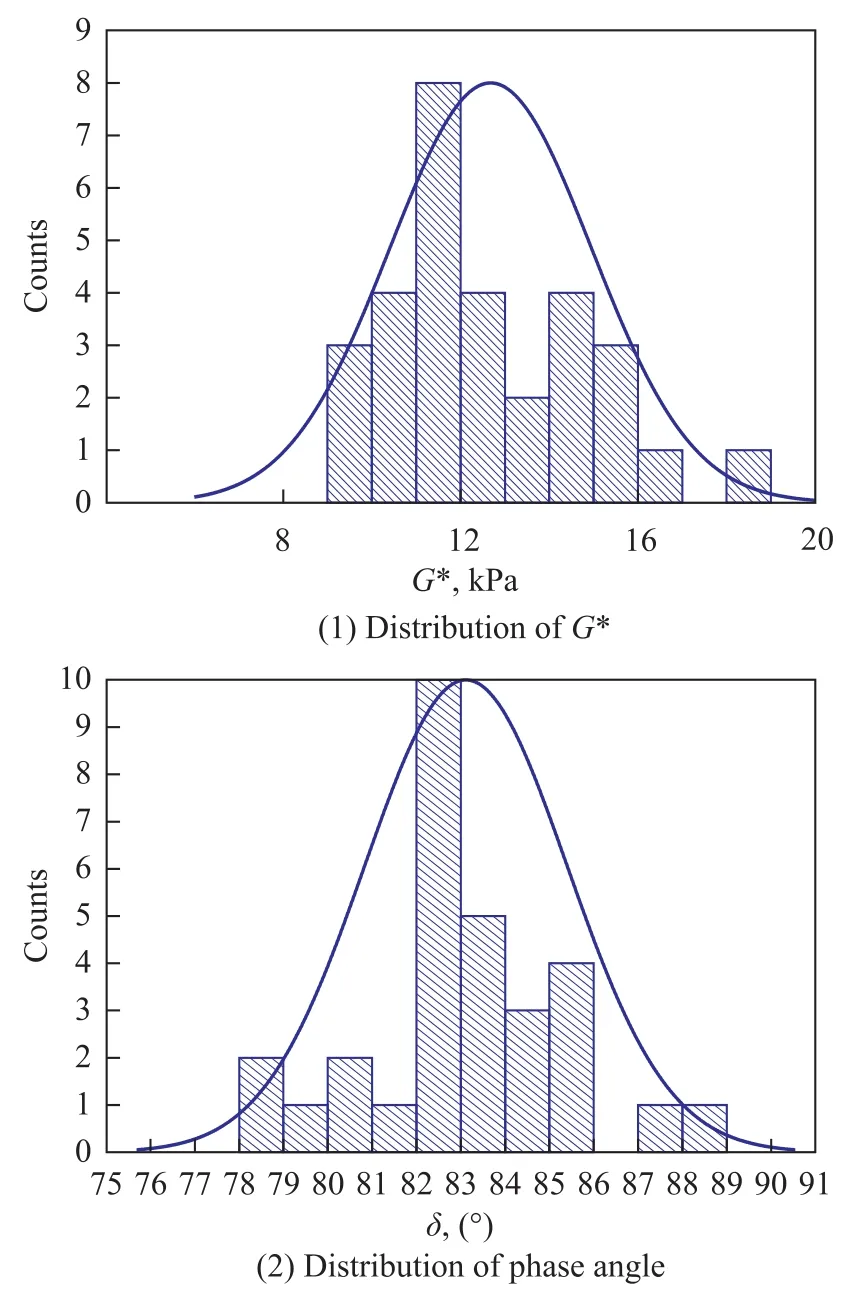

Since the number of asphalt samples was not sufficient, the Shapiro-Wilk test (W test) was used to conduct the normality test for theG* andδ, which was suitable for the samples ranging from 3 to 50[10]. Table 2 gives the descriptive statistics and normality test results, and Figure 5 shows the column diagram. It is seen that at a confidence level of 0.05, theG* figures andδfigures show normal distribution and the averageG* corresponding to softening point is 12.679 kPa with a standard deviation of 2.273 kPa, while the correspondingδis 83.1° with a standard deviation of 2.3°. Hence, it is concluded that for the neat asphalt binder, whatever the penetration grade is, the softening point is approximately equivalent to the temperature, at which theG* is equal to 12.679 kPa. This has the same meaning to the equivalent softening point (T800) and the equivalent viscosity temperature. However, it also includes the mechanical information, such as loading (100 Pa) and frequency (10 rad/s).

Table 2 The descriptive statistics and normality test forG* andδat softening point

Figure 5 Normality distribution test for G* and phase angle at the softening point temperature

3.3 Aging in fluence and equivalent modulus correction

Generally speaking, aging can reduce the penetration and ductility of asphalt, and increase the softening point and viscosity at the same time[11]. Table 3 shows the softening points change of grade 70 asphalt binders and SBS modified asphalt samples under different conditions. As for the grade 70 asphalt binders, it is found out that the above rules could apply to the changes in evaluation indexes. Meanwhile it is observed that the extent of softening point increase under TFO and PAV conditions is different. At an aging time of 20 hr, the PAV aged binder still has higher penetration value, and the rate of softening point increase is less than that of the TFO aged binder, which is related with the aging conditions. Although the PAV aging needs a certain air pressure, the aging temperature is lower (100 ℃), which leads to less signi ficant aging effects in comparison with the TFO aging. But for the SBS modified asphalts, after being aged at different conditions, penetration values and softening point values would change irregularly and are not similar to those of neat asphalt binders. This occurs mainly because the SBS microstructure is destroyed during the aging process[12-13], through which theG* andδat the softening point can not keep a constant value, and this issue will not be discussed in this study.

Figure 6 presents theG* andδat the softening point for the TFO and PAV aged neat binders. It is noticed that as far as the TFO or PAV aged binders are concerned, it seems that the softening points still correspond to oneG* value in the temperature scan range, which does notchange much with the aging time. However, theδas a reflection of viscoelasticity structure information would decrease monotonically with an increasing aging time under both aging conditions, as shown in Figure 6. This also indicates that PAV aging has more significant influence on the asphalt structure than TFO aging, making the ratio of viscosity and elasticity change greatly.

Table 3 Softening points and corresponding viscoelasticity parameters under different ageing conditions

Figure 6 Softening points and corresponding viscoelasticity parameters of neat asphalt binder

All complex modulus values and phase angles of neat asphalt binders corresponding to softening points after aging tests were added to Table 1, and the Shapiro-Wilk normality test was performed again. Table 3 shows the final results and it is found out thatG* passes normality test at a confidence level of 0.05. The average modulus value for the 39 asphalt binders is 13.034 kPa with a standard deviation of 2.105 kPa. However, theδdoes not pass the W test, as shown in Table 4. This illustrates that despite the aging conditions, and the neat asphalt binder has an equivalent modulus temperature corresponding to the softening point. Thus, upon considering the aging influence under the current experimental conditions (a loading of 100 Pa, and a frequency of 10 rad/s), the modulus value is corrected to 13.034 kPa with a standard deviation of 2.105 kPa.

Table 4 Shapiro-Wilk normality test forG* and phase angle

3.4 EquivalentG* temperature

Base on the above analysis, the equivalent modulus temperatures were calculated. Figure 7 demonstrates the relationship between the equivalentG* temperatures and the measured softening points of the asphalt samples. It can be seen that there is a good relationship between the two parameters, and the coefficient of determination (R2) is higher than 0.9.

Thus, this is an interesting and meaningful performanceindicator for neat asphalt binder. By means of the method of equivalentG* temperatures, the softening point can be easily obtained and this method is more convenient and accurate than the ring and ball test method.

Figure 7 Relationship between the softening point and equivalent modulus temperature

4 Conclusions

(1) At the softening point temperature, the neat asphalt and SBS modified asphalt show different rheological states. With respect to the neat asphalt binder, viscous component is a dominant part in viscoelasticity composition, and the SBS modified asphalt still retains sufficient elasticity.

(2) Through the Shapiro-Wilk test it is found out that no matter what the aging condition is, the neat asphalt binder has an equivalent modulusG* temperature at the softening point at a confidence level of 0.05, in which the modulus is 13.034 kPa with a standard deviation of 2.105 kPa.

(3) Based on the equivalent modulus rule, the softening point of neat asphalt can be calculated easily, and this method is more convenient and accurate than the ring and ball test method. But in practical applications, more neat asphalt samples are suggested to be used to verify this finding.

Acknowledgements:This work was financially supported by the Shandong Natural Science Foundation (ZR2009FL020) and the Shandong Transportation Innovation Foundation (2010Y20).

[1] Industry standard of the People’s Republic of China. Standard test methods of bitumen and bituminous mixtures for highway engineering (JTG E20-2011) [S]. Beijing: China Communications Press, 2011 (in Chinese)

[2] David W. The Shell Bitumen Handbook [M]. Shell Bitumen UK, 1995

[3] Zeng M L, Li J, Huang B, et al. A general formulation for stiffness modulus of asphalt binders using routine test data [J]. Journal of Central South Highway Engineering, 2004, 29(1): 45-58 (in Chinese)

[4] Shen J A. Asphalt and Asphalt Mixture Pavement Performance [M]. Beijing: China Communications Press, 2009 (in Chinese)

[5] Cliff N. Report on phase 1 of the BiTVal Project: Analysis of available date for validation of bitumen tests[R], FEHRL, 2006

[6] Fan L, Fan X Z, Song X J, et al. Comparison of calculation model and methods for asphalt zero shear viscosity [J]. New Building Materials, 2012, 39(5): 20-23 (in Chinese)

[7] Industry standard of the People’s Republic of China. Technical specifications for construction of highway asphalt pavement (JTG F40-2004) [S]. Beijing: China Communications Press, 2005 (in Chinese)

[8] Randy C W, Donald E W, Pamela A, et al. Mixing and compaction temperatures of asphalt binders in hot-mix asphalt[R]. Transportation Research Board, 2010

[9] Zhang X N. Viscoelasticity of Asphalt Binder and HMA Mixture [M]. Beijing: China Communications Press, 2006

[10] Xiao X. Origin 8.0 Handbook: Scientific Plot and Data Analysis [M]. Beijing: China Electric Power Press, 2009 (in Chinese)

[11] Ji X P, Hou Y Q, Xu H, et al. Comparative study on antiaging performance of asphalt based on dynamic aging equation [J]. Journal of Building Materials, 2013, 16(2): 365-369 (in Chinese)

[12] Zhao Y L, Gu F, Huang X M. Analysis on SBS modified asphalt aging characterization based on Fourier transform infrared spectroscopy [J]. Journal of Building Materials, 2011, 14(5): 620-623 (in Chinese)

[13] Chen S M, Chen X, Chen W S. Analysis of correlation for aging effect on RTFOT and TFOT to SBS modified asphalt[J]. Guangdong Chemical Engineering, 2011, 36(24): 55-65 (in Chinese)

Received date: 2014-01-24; Accepted date: 2014-05-18.

Dr. Wei Jianming, Telephone: +86-13954666229; E-mail: jianming_wei@yahoo.com.

杂志排行

中国炼油与石油化工的其它文章

- Spray Characteristics Study of Combined Trapezoid Spray Tray

- Effect of Stirring on Oil-Water Separation in Rare Earth Mixer-Settler

- Synergetic Effect of Y Zeolite and ZSM-5 Zeolite Ratios on Cracking, Oligomerization and Hydrogen Transfer Reactions

- Preparation of Tungsten Film and Its Tribological Properties under Boundary Lubrication Conditions

- Solvothermal Synthesis of V2O3Catalysts for Oxidative Desulfurization of Dibenzothiophene

- Preparation of Spherical MgCl2/SiO2/THF-Supported Late-Transition Metal Catalysts for Ethylene Polymerization