Integrated management system of agro-fishery products based on QR-code*

2013-11-01NamjinBaeYongyunChoJongsunChoiJaeyoungChoi

Namjin Bae, Yongyun Cho, Jongsun Choi, Jaeyoung Choi

(1. Deptartment of Information and Communication Engineering, Sunchon National University, Sunchon 540-950, Korea;2. School of Computer Science and Engineering, Soongsil University, Seoul 156-743, Korea)

Integrated management system of agro-fishery products based on QR-code*

Namjin Bae1, Yongyun Cho1, Jongsun Choi2, Jaeyoung Choi2

(1. Deptartment of Information and Communication Engineering, Sunchon National University, Sunchon 540-950, Korea;2. School of Computer Science and Engineering, Soongsil University, Seoul 156-743, Korea)

Recently, both the importance and awareness relating to food safety relating to agrochemicals, chemical fertilizers, the pollution of ecosystem and unwholesome foods are growing rapidly. For the same reason, the purchaser’s curiosity increases to know about the production process which can be accomplished by production traceability system. The traceability system can store and superintend the specific attribute information about products regarding the productive centre, producer and production finish data. The products undergo various circulation processes and they are being managed by individually constructed traceability system. Thus, it is difficult for the producer and the consumer to guarantee the safety from transpirable issues about the falsification of production traceability because the traceability information can be re-produced by forging through various ways. So in this paper, we proposed a system for integrated management of agro-fishery products based on quick response code (QR-code) for forgery prevention which may help to solve these issues. The proposed system makes QR-code using production information provided by producer. And then it is provided to the distributor and the consumer through integrated service model using the QR-code. Therefore, this system make sure to provide the same production traceability about the products to the distributor and the consumer and always keeps both updated with the same information.

quick response code (QR-code); production traceability; traceability system

The formatter needs to create some components, incorporating the applicable criteria that follows. Recently, many agro-fishery products are distributed to the market due to the opening of agro-fishery products importation. Consequently, the faulty agro-fishery products and the unidentified ones also flood into the market[1]. And the need for safety of agro-fishery products from the consumer is increasing because of agro-fishery products' complex distribution structure[2]. Thus, the government established Korea Agro-Fisheries and Food Trade Corporation. After that the government is building distribution system through distribution of agro-fishery products for direct dealing between the producer and the consumer.

Production traceability of the present agro-fishery is created directly by handwriting on the box or the sticker. Therefore, production traceability created by handwriting has many problems, where the biggest problem is the loss of information on delivery as the created production traceability is being exposed. Also, the reliability of agro-fishery products is causing a negative impact due to either the producer omission or the seller changing it[3]. Thus, the previous studies tried to use one-dimension barcode to solve this problem. But it has failed because of some reasons such as the need of a bar code reader, the limitation of the data storage capacity and the damage of the barcode.

In this paper, a system for integrated management is proposed to avoid the forgery or the damage during the distribution process using quick response code (QR-code). The QR-code has increased data storage capacity and can restore damaged data using restoring function in comparison with the barcode[4-10]. Also, QR-code is utilized on almost every way of sale such as advertisement flyer, TV home shopping, internet shopping mall and offline store, because it is very easy to use through smartphone which is used widely recently. Therefore, the sellers do not need to make separate production traceability information by the promotion or the distribution structure.

The integrated service uses QR-code for prevention of forged production traceability that is based on the integrated management system, which manages information technology (IT) resource of database and the web service of heterogeneous environment dispersed by a single system[5,6]. The producer can register directly the production traceability using this service model. The registered production traceability can connect automatically to the shopping mall or the system of distributor through the application program interface (API) provided in the integrated service model. The existing production traceability system is costly in both construction and the management of system because each distributor makes individual construction and management. Application of service model can improve efficiency of management, reliability and economics because the production traceability can forge during distribution process.

In this paper, we proposed a new service model to manage and supplement the existing production traceability system efficiently. The following body explains the system architecture.

1 Integrated management system based on QR-code

1.1 System architecture

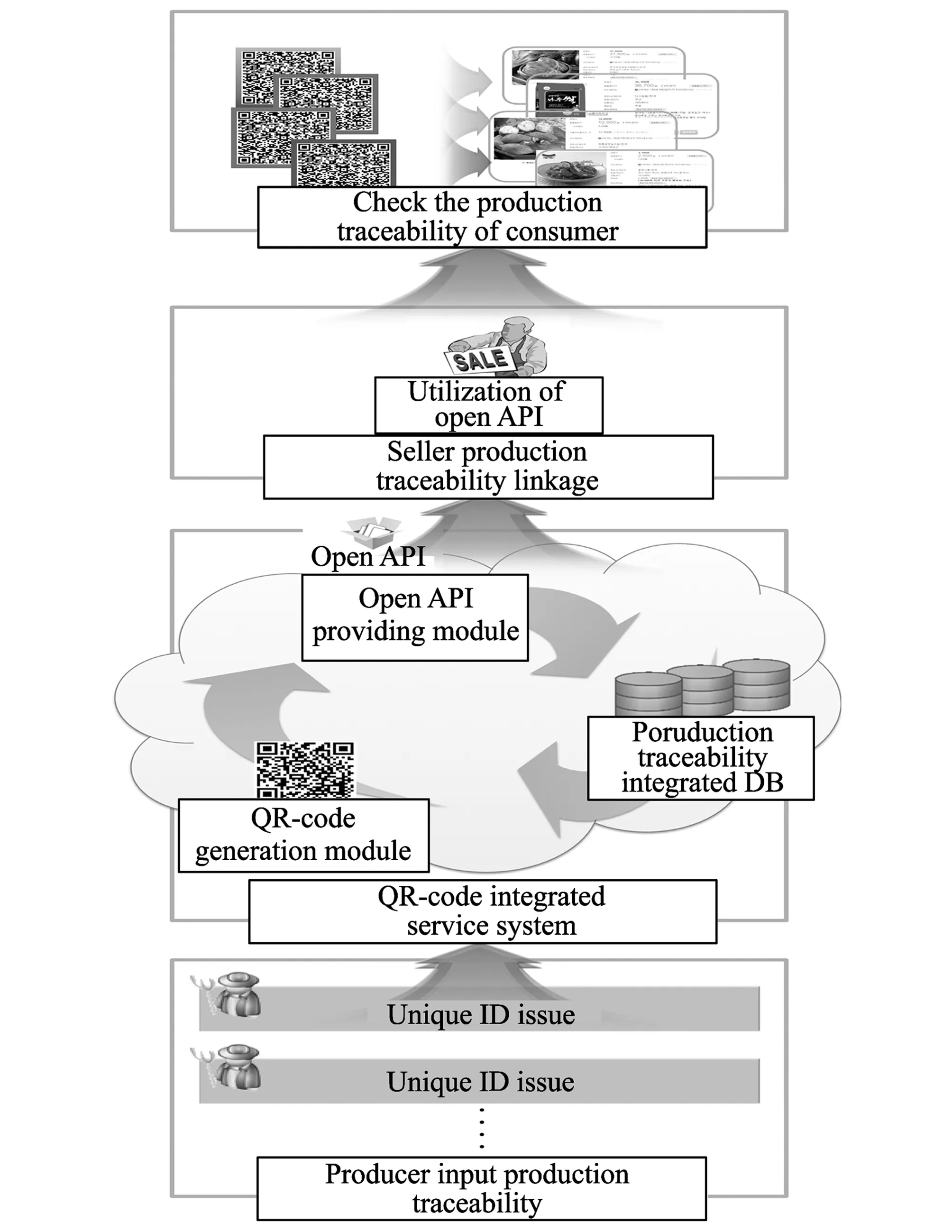

Fig.1 is architecture of the system for the integrated management based on QR-code.

Fig.1 System architecture

Integrated management is built to manage the production traceability between the producer and the sellers. The consumer can be provided with the same production traceability for the same products using the service. Integrated service model proposed is managed only by issuing a unique ID to the producer. The producer, who issue ID, is provided with an identification number of the products and a registration page of production traceability. After registering the production traceability, the production traceability can confirm about all products registered through the integrated service model. The production traceability information created using QR-code conversion module is stored into the data base for management. The sellers have to know an identification number stored in service model to sell it by distributing the products of the producer. If you know identification number, the products information can be provided through the QR-code, also the production traceability is stored because the OpenAPI makes public the production traceability. For example, in case the seller sells the products through shopping mall, the seller needs to input the OpenAPI-code into the production information page of Internet shopping mall, and then the seller can use the QR-code of the production traceability called from integrated service model based on QR-code.

1.2 Conditions of traceability system[7]

1.2.1 Record and management

Operators of each step must record and manage the information such as the purchase-place and purchase-amount to institute traceability system.

1.2.2 Identification

The information needs to be recorded and stored by distinguishing the products, the purchase-place and the sale-place to institute the traceability system. Also, it should be a unique ID that is given to each of the products and operators.

1.2.3 Inspection

The inspection is divided into internal inspection and external inspection, which amis to confirm whether the traceability system is effective or not.

1.2.4 Information providing

Information used in the traceability system is required to be recorded and managed. The information is divided into obligatory information and voluntary information that are personally recorded and managed by user to improve the information added value.

1.3 Service process

The proposed service model can not be utilized online and in various parts. The buyer is provided with an identification number of the products from the seller when the seller sells the products using general store or advertisement-flyer. Because the service can use QR-code received from service model which is attached to wrapper or advertisement-flyer, the consumer using the smart phone is able to confirm the same production traceability entered by the producer for the same products.

In this paper, the reason for using the QR-code is high popularity of smart phone and well-made infrastructure of service model. And QR-code has self-error-restoration function about damage possibilities of identification code.

The following conditions must be satisfied to improve the reliability of the service model.

1) The producer must receive ID through strict judicial scrutiny from a management agency of integrated service model and should be managed.

2) The producer must be able to make inquiries about the production traceability at any time.

3) After the registration of production traceability, the modification must be approved by the management agency.

4) The safety management and quality management of the production process should be made by formal government branch.

1.4 Service implementation and test

Fig.2 shows the producer registration page. The functions of the integrated service include producer registration, QR-code creation and traceability registration, which are materialized through the web for testing.

It can be seen from Fig.2, firstly we make the producer ID and register production traceability. And then we materialize shopping mall. Finally registered products are sold.

Fig.3 shows purchase page about products and it provide simple information with QR-code.

The screen of the service is shown in Fig.4 when the QR-code of Fig.3 are taken picture using smart phone.

Fig.3 Products purchase page

Fig.4 Products traceability page

In Fig.4, the purchaser can know related information of the products such as producer, contact information of the producer and the production traceability.

2 Conclusion and future work

In this paper, the proposed service model can provide the same production traceability during the distribution process from the producer to the consumer. The reliable production traceability information can prevent the forgery of the production traceability. The service model can solve the problems of the existing production traceability system such as difficulty about direct management of the producer and inconvenience about direct input of each information into the sales page.

The information records and manages to solve the transpirable problems ranging from production to distribution, processing, sale through the integrated management system. Therefore, the consumer injury and economic loss can be minimized efficiently. And the clarity of the distribution channel and the justice of the deal can be enhanced.

In the future, the producer allows confirming the consumers’ tastes and the regional’s sales volume by adding storage function of the consumer date. We will be able to minimize such situations as upheaval of the cabbage by predicting production and production day of the products through this function. And we will develop service that can be easily used by anyone , which can do direct dealing and self-publication relation between the producer and the consumer.

Later, the system can be used in various public relations through design process using QR-code. And it is expected to provide production traceability information with high reliability and accuracy in the distribution phase.

[1] Hur W, Seo J M, Lee S M. A modeling of temporal database for farm products traceability system. Journal of Korean Multimedia Society, 2007: 500-503.

[2] Paek M H, Ko S S. A study on RFID code system for Traceability of agro-livestock products. Journal of Society for e-Business Studies. 2007, 12(2 ): 95-110.

[3] Kim M H, Son B R, Kim D K, et al. Agricultural products traceability management system based on RFID/USN. Journal of Korea Institute of Information Scientists and Engineers. 2009, 15(5): 331-343.

[4] Lee K Y, Kim E H. Characteristics of QR code ad and its effects on usage satisfaction and consumers' behavior as a commercial communication tool. Korean Journal of Advertising, 2011, 22(3): 103-124.

[5] Jin J H, Park J M, Lee and M J. SNS integrated management API and its application. Journal of Korea Institute of Information and Communication Engineering, 2012, 16(3): 499-510.

[6] Lee S W, Youn J K, Kim H S, et al. Development of a user interface of the integrated management system for heterogeneous distributed systems. Korea Computer Congress, 2010, 37(2B): 348-353.

[7] Lee B S. Agricultural & fishery trading information. Korea Agricultural Trade Information, 2003, 178: 4-12.

[8] WANG Lung-chuang. Enhancing construction quality inspection and management using RFID technology. Automation in Construction, 2008, 17(4): 467-479.

[9] Park S M, Lim T K, Lee D E. A study of construction quality management system using QR code. Journal of Korea Institute of Building Construction, 2012, 12(2): 137-139

[10] Densowave. QR-Code. [2013-03-25].www.qrcode.com.

date: 2013-04-11

The MSIP(Ministry of Science, ICT & Future Planning), Korea, under the ITRC(Information Technology Research Center) support program (NIPA-2013-H0301-13-2006) supervised by the NIPA(National IT Industry Promotion Agency)

Jaeyoung Choi (choi@ssu.ac.kr)

CLD number: TP391.44 Document code: A

1674-8042(2013)03-0252-04

10.3969/j.issn.1674-8042.2013.03.011

杂志排行

Journal of Measurement Science and Instrumentation的其它文章

- Impact of low temperature on smartphone battery consumption*

- Roll angle measurement system based oni triaxial magneto-resistive sensor*

- Dynamic test methods for natural frequency of footbridge*

- High-speed broadband data acquisition system based on FPGA*

- Method of military software security and vulnerability testing based on process mutation*

- Study on denoising filter of underwater vehicle using DWT*