Efficiently enhanced energy storage performance of Ba2Bi4Ti5O18 film by co-doping Fe3+and Ta5+ion with larger radius

2022-09-24QiongWu吴琼LeiZhao赵雷XinghaoChen陈兴豪andShifengZhao赵世峰

Qiong Wu(吴琼), Lei Zhao(赵雷), Xinghao Chen(陈兴豪), and Shifeng Zhao(赵世峰)

Inner Mongolia Key Laboratory of Nanoscience and Nanotechnology,&School of Physical Science and Technology,Inner Mongolia University,Hohhot 010021,China

Keywords: Ba2Bi4Ti5O18 film,ferroelectrics,energy storage,co-doped,radius

1. Introduction

Electric dipoles within ferroelectrics can respond to external electrical stimuli,which allows ferroelectrics to store electrical energy.[1-4]When an electric field is applied through the two measured electrodes, the ferroelectric film capacitors are charged. After removing the external electric field,the stored electric energy is released in the scale of milliseconds.[5,6]For practical applications,ferroelectric film capacitors are always expected to have high energy density, efficiency, power density,excellent frequency stability,temperature stability and so on.[7]However, for most ferroelectrics, they are not suitable for energy storage because of their low polarizability, breakdown strength and high dielectric loss. So far,the energy density released by ferroelectric film system in a charge-discharge process has been improved to more than 150 J/cm3.[8]

Many innovative approaches have been proposed to improve energy storage performance. In terms of the final effect, these approaches can be basically divided into two categories. According to the formula for the recoverable energy densityWrec=EdP, wherePrandPmare the remnant and maximum polarizations of ferroelectric film under the external electric fieldE, it can be seen that high external electric field and large difference betweenPmandPrcan obtain large recoverable energy density.[9]Therefore,the first strategy is to improve the breakdown strength so that ferroelectric film capacitors can operate in a high external electric field. The second strategy is to improve the polarizability of ferroelectric films so that they can achieve higher polarization under the same external electric field. Meanwhile,the remnant polarization should be reduced as much as possible. For the former, there are many ways to increase the breakdown strength. For example,Panet al. introduced paraelectric SrTiO3in conventional ferroelectric BiFeO3to transform macroscopic electric domains into highly-dynamic polar nano-regions.[10]As the content of SrTiO3gradually increased from 30% to 75%, the maximum external electric field (Em)increased from 2750 kV/cm to 4460 kV/cm. And energy storage performance had also been greatly improved. However,thePmunder the same external electric field (1500 kV/cm)gradually decreases as the proportion of SrTiO3increases.ThePmdecreases by nearly 20µC/cm2as the proportion of SrTiO3increases from 30% to 75%. This decrease is significant, especially for the fact that thePmof the 0.7BiFeO3-0.3SrTiO3film is just over 40 µC/cm2under external electric field of 1500 kV/cm. Finally, the discharged energy density of the 0.25BiFeO3-0.75SrTiO3film (70 J/cm3) is lower than that of the 0.4BiFeO3-0.6SrTiO3film (70.3 J/cm3), although the maximum external electric field of the former(4460 kV/cm)is higher than that of the latter(3850 kV/cm). In conclusion,the high breakdown strength of paraelectric SrTiO3has a positive contribution to the energy storage performance of the system,while the ultra-low polarization has a negative effect. What is more, Zhanget al. select PbZr0.52Ti0.48O3and linear dielectric Al2O3to form composite film with sandwich structure.[11]Although the maximum electric field of the composite film reaches 5711 kV/cm, thePmis still less than 30 µC/cm2. In practical application, such a high external electric field can easily lead to the occurrence of electrode injection behavior,which increases the probability of thermal breakdown.[12,13]And it is also increases the probability of danger. If the film operates at a relatively low external electric field, such low polarization is not conducive to a good energy storage performance. For the second type, ferroelectrics with large lattice distortion,such as BiFeO3,are usually introduced into the original system in order to obtain higher polarization.[14-17]Songet al.prepared(1-x)Bi0.2Sr0.7TiO3-xBiFeO3films,and the results showed that as the proportion of BiFeO3increases,the maximum polarization under the same external electric field (2000 kV/cm) increased by about 30 µC/cm2.[18]However,BiFeO3,as a typical conventional ferroelectric,can promote the transformation of the original domains into macroscopic domains. This leads to a significant reduction in efficiency. Therefore,the increase in discharged energy density is very low,and the increase is less than 10 J/cm3at an external electric field of 2000 kV/cm.

According to the current research status and practical application requirements of ferroelectric film capacitor, it should have a suitable and moderate working electric field(2000 kV/cm-4000 kV/cm), an appropriatePm(50 µC/cm2-150µC/cm2)in the range of working electric field,so as to ensure that it is possible to obtain an ideal energy storage density,and finally,a high efficiency(>80%). Ignoring the improvement of polarization in pursuit of very high working electric field is not conducive to the comprehensive improvement of energy storage performance. Similarly, it is not satisfactory to ignore the improvement of efficiency in order to pursue high polarization. Based on this, Ba2Bi4Ti5O18(BBT) was selected as the object. BBT is a typical relaxor ferroelectric with the Aurivillius structure consisting of oxygen octahedral(perovskite-like)blocks interleaved with(Bi2O2)2+layers.[19]The strong relaxor properties of BBT are thought to be due to the random electric fields created by the compositional and chemical disorder of the A-site cations, which is beneficial to induce a weak polarization hysteresis behavior.[19]What is more, the (Bi2O2)2+layer has the effect of inhibiting the diffusion of space charges and defects.[20]This gives BBT unparalleled fatigue resistance. These features make BBT a candidate for energy storage applications. Previous studies have shown that BBT film has high efficiency, moderate operating electric field, but lowPm.[21,22]This makes the energy storage density of BBT films low. At present, the highest energy storage density of BBT film is 41.2 J/cm3with the efficiency of 79.1%.[23]According to previous studies, the replacement of Ti4+by ions with larger radius, such as Fe3+,will produce tensile chemical stress, which reduces free energy and improves polarization.[18,20]Based on this, a series of Ba2Bi4Ti5-xFexO18films were prepared withx=0,0.03, 0.06, 0.09, 0.12 (dubbed as BBT, F3, F6, F9, F12).As the content of Fe3+increases,Pmunder same external electric field are greatly improved, but efficiency and breakdown strength are gradually reduced. And then, a series of Ba2Bi4Ti5-x(Fe0.5Ta0.5)xO18films were prepared with samexvalue(dubbed as BBT,FT3,FT6,FT9,FT12). The radius of Ta5+and Fe3+are both larger than that of Ti4+, which helps to maintain a high polarization. The charge balance is realized by introducing Ta5+and Fe3+together,so that the breakdown strength does not decrease. What is more, The introduced Fe3+and Ta5+also induce compositional and chemical disorders in the BBT films. This helps to improve the relaxor properties of BBT films. So that efficiency is not decreased,but slightly improved.Finally,the energy storage performance of all co-doped films have been all-side improved. This results show that Ta5+and Fe3+with larger radius together replace Ti4+is an effective way to improve energy storage performance of BBT film.

2. Experimental details

2.1. Fabrication of films

All the processes of preparation of sol were performed at room temperature. The solvents mentioned below were mixtures of glycol and glycol methyl ether with a volume ratio of one to one. For Ba2Bi4Ti5-xFexO18sols, (CH3COO)2Ba,Bi(NO3)3·5H2O and Fe(NO3)3·9H2O were added to a beaker sequentially. The weight of Bi(NO3)3·5H2O required an excess of 10% to compensate for its volatilization during annealing process. After all solutes are completely dissolved,C16H36O4Ti was slowly dropped into the beaker. Then, by adding solvent, the concentration of the solutions was adjusted to 0.03 mol/L. For Ba2Bi4Ti5-x(Fe0.5Ta0.5)xO18sols,the previous steps are the same. In addition,quickly dropped C10H25O5Ta into another beaker containing 5 ml acetic acid.After the substances in the two beakers were completely dissolved, they were mixed together. The concentration of the solutions was adjusted to 0.03 mol/L by adding solvents. After the sols had aged for 120 h,it could be crystallized on the Pt(111)/Ti/SiO2/Si substrate. First,the sol was dropped on the substrate holding for 15 s at 500 r/min and then for 35 s at 7000 r/min. Then the films were dried at 320°C for 3 min and crystallized at 725°C for 3 min using rapid thermal annealing system. The steps above were repeated until the films reached a certain thickness and finally annealing at 725°C for 15 min.

2.2. Characterization

X-ray diffraction (XRD, Kratos Amicus, UK) with CuKa radiation was used for structural characterization. Scanning electron microscopy(SEM,Hitachi SU4800)was used to measure the thickness of films. TheP-Ehysteresis loops and leakage properties of the film were characterized by multiferroic tester system(Multi Ferroric,RT,USA).And temperature control system(Instec mK2000)was used to achieve temperature changes.

3. Results and discussion

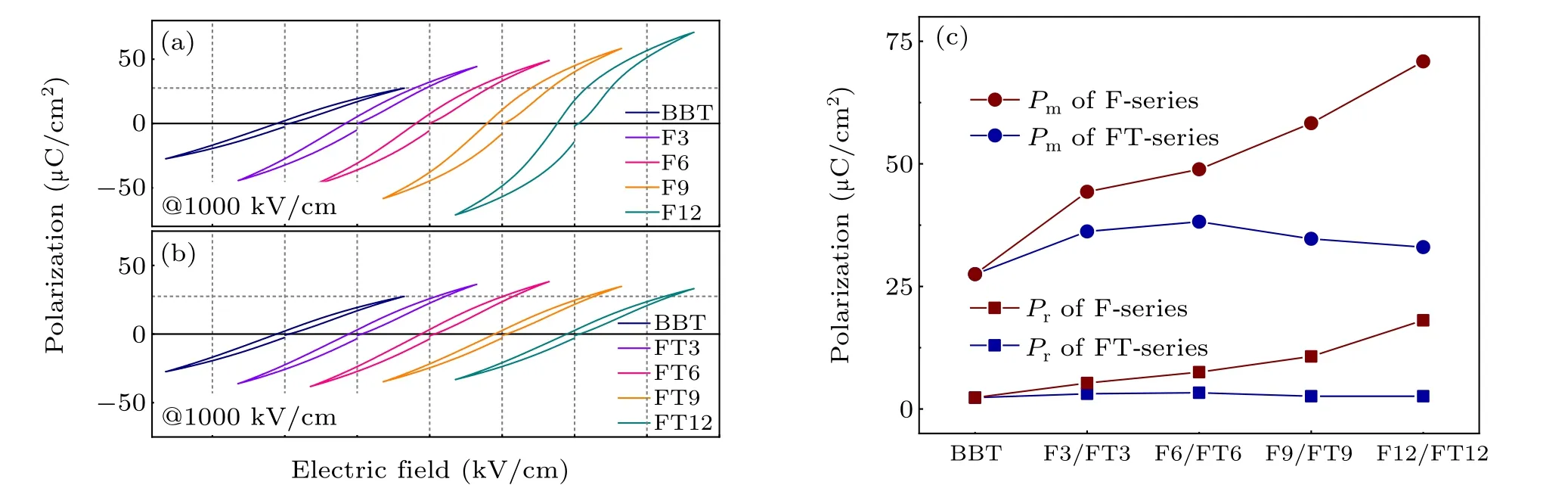

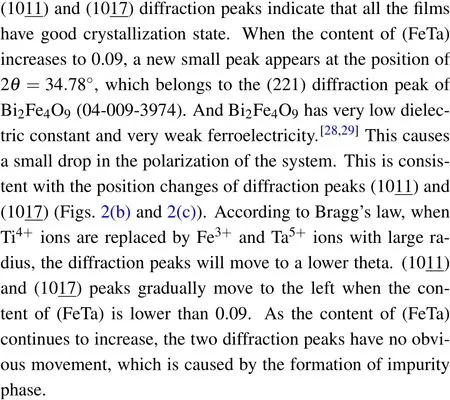

Fig.1. The P-E hysteresis loops under the external electric feild of 1000 kV/cm of(a)F-series and(b)FT-series flims with the same scale of ordinates. (c)Pr and Pm (1000 kV/cm)of F-series and FT-series.

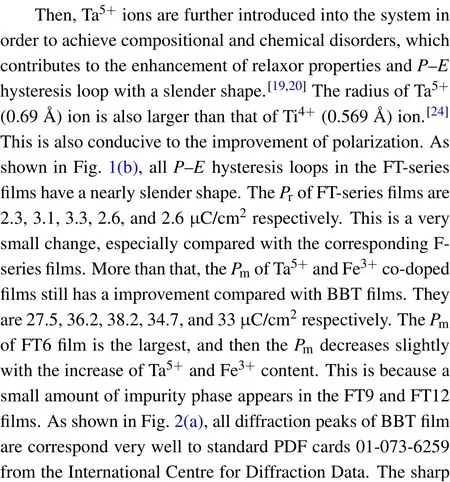

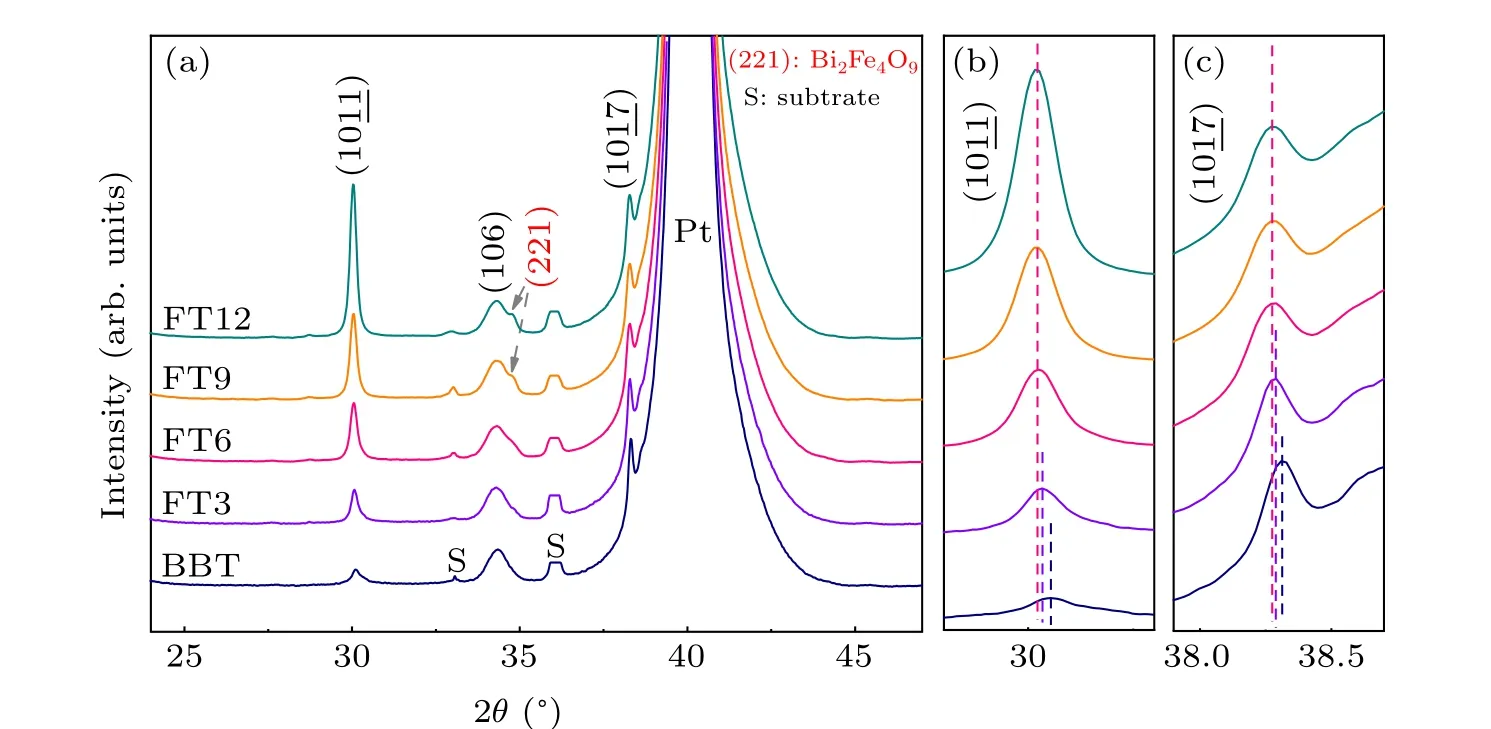

The thickness of BBT film is about 200 nm(Fig.S2(a)).For all doped films, their thicknesses are also considered to be 200 nm due to the very low doping amount. Figure 1(a)shows theP-Ehysteresis loops of Ba2Bi4Ti5-xFexO18films under external electric field of 1000 kV/cm. It can be seen that BBT film has a very slim shape ofP-Ehysteresis loop due to its strong relaxor properties,which contributes to a high energy storage efficiency.[20]Nevertheless,a high energy storage density cannot be obtained because of very low polarization.With the gradual increase of Fe3+content, there is a significant increase inPm(Fig.1(c)). They are 27.5,44.3,48.9,58.3,and 70.9µC/cm2respectively. ThePmof F12 film is 2.5 times higher than that of BBT film. Such a huge increase is due to the fact that the radius of Fe3+(0.609 ˚A)ion is larger than that of Ti4+(0.569 ˚A)ion,which can create tensile chemical pressure in the lattice.[24]This tensile chemical pressure reduces the fourth and sixth Landau coefficientsα11andα111in the Landau energy density(fLand=α1P2+α11P4+α111P6-EP)and further increase polarization.[20,25,26]However, the introduction of Fe3+ions can not only enhance the polarization,but also stabilize the long-range ferroelectric order.[27]This is conducive to the formation of macro domains and increasePr.And eventually,the shape of theP-Ehysteresis loops change significantly. TheProf F-series films are 2.3, 5.3, 7.5, 10.7,and 18.1 µC/cm2respectively. TheProf F12 is almost eight times that of BBT. These changes increase energy loss during charge-discharge process, which is detrimental to energy storage performance.

TheI-Eloops of F-series and FT-series flims under external electric feild of 1000 kV/cm are shown in Fig.S1. For BBT flims, a typical relaxor ferroelectric, the current peaks caused by domain switching are very diffuse. With the increase of Fe3+content,current peaks gradually become sharp and move to both ends. This shows that the relaxor properties of the system decreases significantly. And the films tend to conventional ferroelectrics.This is because Fe3+ion stabilizes the long-range ferroelectric order. For films co-doped with Fe3+and Ta5+ions,the position of the phase transition peaks move slightly to the center and the current intensity decreases slightly,which is the characteristics of enhanced relaxor properties. Compositional and chemical disorders contribute to slightly enhanced relaxor properties. And this phenomenon is consistent with the variation ofP-Ehysteresis loops.

Fig.2. (a)XRD patterns of BBT,FT3,FT6,FT9,and FT12 flims. (b)and(c)Enlarged images of(1011)and(1017)peaks,respectively.

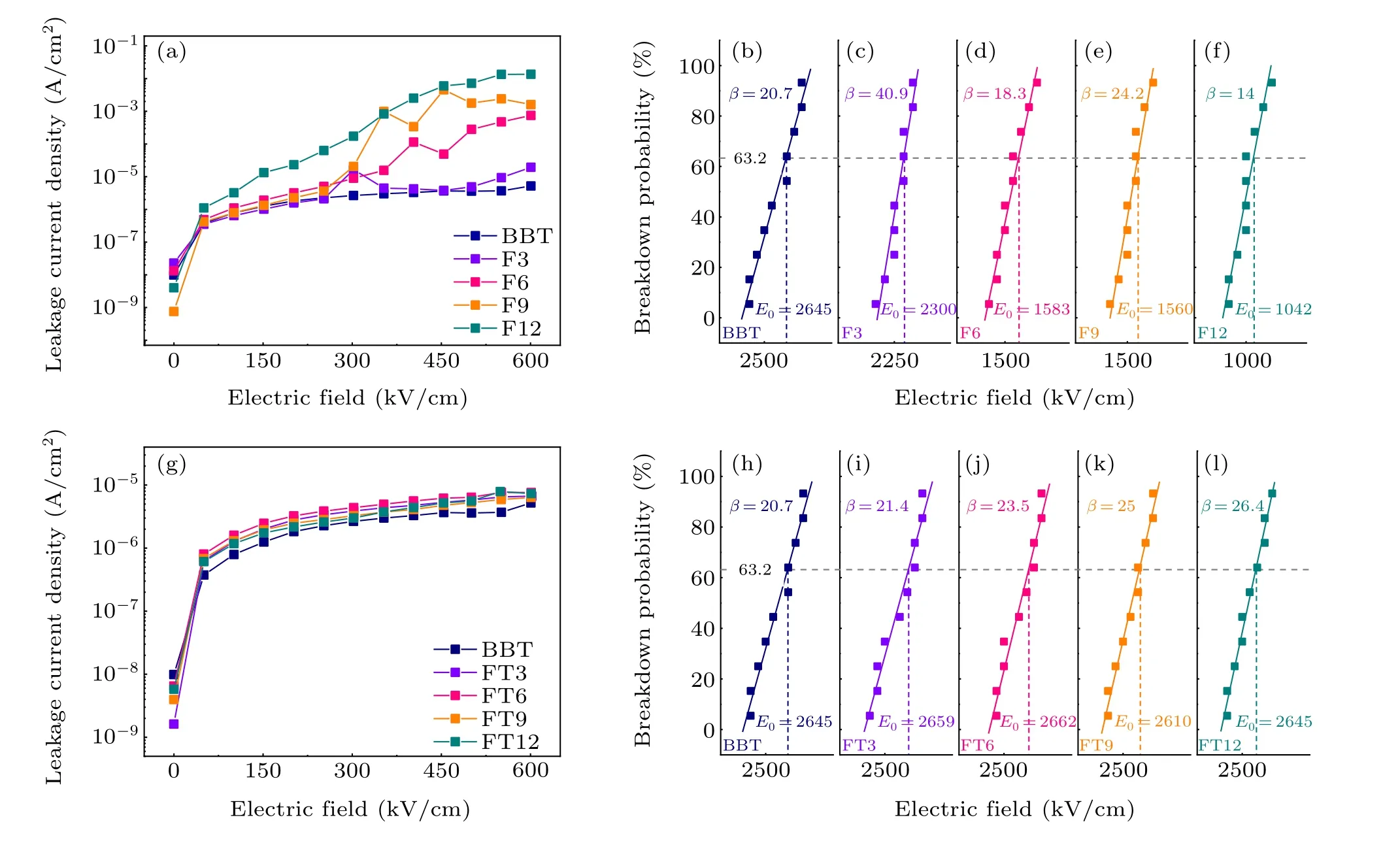

Fig.3. Leakage current densities of(a)F-series and(g)FT-series films as a function of external electric field. (f)Two-parameter Weibull distribution analysis of the breakdown strengths of(b)-(f)F-series and(h)-(l)FT-series films. E0 is the characteristic breakdown strength.

As is known to all,the doping of Fe3+ions is easy to introduce oxygen vacancies in the film because of the valence state of Fe3+ion is smaller than that of Ti4+ion.[20,30]On the one hand,the defect dipoles formed by Fe3+ions and oxygen vacancies contribute to the improvement of polarization.[20,27]However, on the other hand, the oxygen vacancy itself is a defect with net charge, which easily leads to an increase in leakage current. What is more, the oxygen vacancies also affect the height of potential barrier between the electrode and film, which makes the electrode injection behavior easier to occur.[31]As is shown in Fig. 3(a), BBT film has a good leakage properties. The leakage current density is about 10-6A/cm2when the external electric field is 600 kV/cm.With the increase of Fe3+content, the leakage current density gradually increases to~10-1A/cm2. Such a significant increase in leakage current density is detrimental to the breakdown strength of the films.The characteristic breakdown electric fieldE0derived from Weibull distribution is a parameter that can be used to evaluate the breakdown strength of a film(Figs.3(b)-3(f)).[32]TheE0of F-series are 2645,2300,1583,1560, and 1042 kV/cm. After Ta5+ion continues to be introduced into the system, the leakage performance is greatly improved compared with the Fe-doped films due to the charge balance (Fig. 3(g)). The leakage current densities of all FTseries films are very similar. And theE0of FT-series films are stable at about 2600 kV/cm. What is more, Allβvalues of F-series and FT-series films show that the film has a good uniformity.

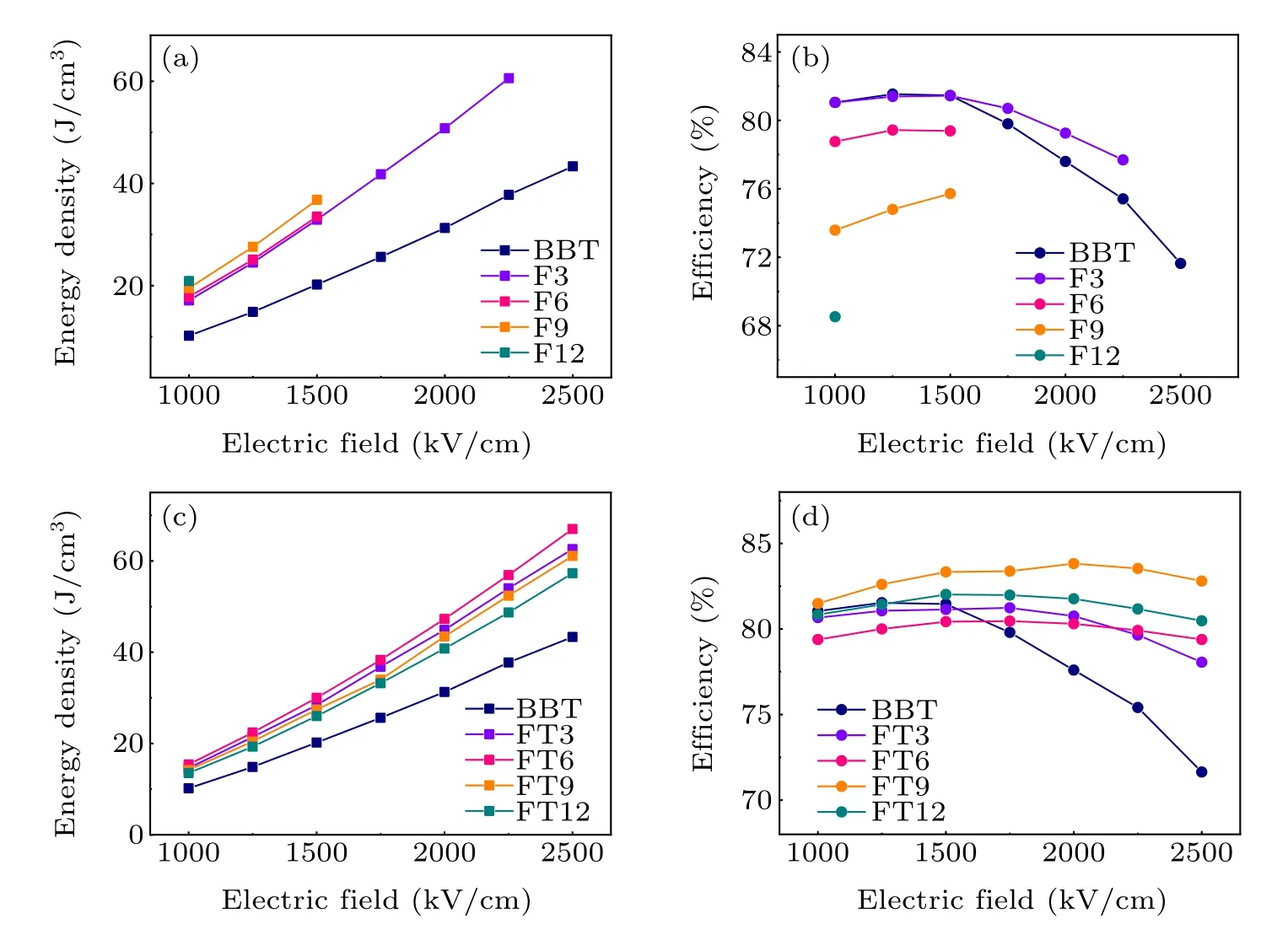

Fig.4. Energy storage performance of(a),(b)F-series and(c),(d)FT-series films.

TheP-Ehysteresis loops of F-series and FT-series films under different external electric fields including the highest external electric field are shown in Fig. S2. TheEmof F-series films are significantly reduced, they are 2500, 2250, 1500,1500, and 1000 kV/cm. However, for FT-series films, they both have aEmof 2500 kV/cm. ThePmof all (FeTa)-doped films is improved relative to BBT film. And the shape of hysteresis loops has become thinner. Their energy storage performance is shown in Fig. 4. The energy density represents the energy density that can be recovered and is labeledWrec.The optimalWrecof F-series films are 43.3, 60.6, 33.5, 36.8,and 20.9 J/cm3with the efficiency of 71.6%, 77.7%, 79.4%,75.7%,and 68.5%,respectively,under theEmof 2500,2250,1500, 1500, and 1000 kV/cm. Only the energy storage performance of F3 film has been improved due to the greatly improved polarization, which mask the negative effects of the reduced breakdown strength. For films with more Fe3+ions doping, the significantly reduced breakdown strength makes the energy storage performance almost lost. However,for FTseries films,the energy storage performance of all doped films have been all-side improved. The optimalWrecare 43.3,62.6,67,61.1,and 57.3 J/cm3with the efficiency of 71.6%,78.1%,79.5%, 82.8%, and 80.5%, respectively, under the sameEmof 2500 kV/cm. TheWrecof FT6 (67 J/cm3) is increased by 54.7% compared with BBT (43.3 J/cm3) film. The BBT film prepared by Yanget al.achieved aWrecof 41.2 J/cm3with an efficiency of 79.1%. They further prepared a composite films composed of BBT and BiFe0.93Mn0.07O3with high polarization. However, theWrecstill does not exceed 53 J/cm3.[23]The energy storage performance of BBT film co-doped with Fe3+and Ta5+ion has been significantly improved. Such an obvious improvement can be attributed to two aspects. On the one hand, Fe3+ion and Ta5+ion have larger radius than Ti4+ion leading to an increase in polarization. On the other hand, Fe3+ion and Ta5+ion co-doping leads to the increase of relaxor properties caused by compositional and chemical disorder. In previous studies, La3+and Pr3+ions are usually chosen as dopants. The relaxor properties of doped systems are improved, but thePmunder the same external electric field is significantly reduced.The improved energy storage performance is due to the enhanced breakdown strength. However, the excessively high applied electric field easily leads to the occurrence of electrode injection behavior and reduces the safety. For example,Yanget al.prepared La-doped Pb1-xLax(Zr0.52Ti0.48)O3films with dopant concentrations of up to 12%.[33]As the concentration of La3+increases from 0 to 12%, the relaxor properties of the films are improved. However, thePmat an external electric field of 1000 kV/cm decreases from 47 µC/cm2to 30 µC/cm2. Finally, the reason why theWrecof the Pb0.92La0.08(Zr0.52Ti0.48)O3film (27.5 J/cm3) is higher than that of the Pb(Zr0.52Ti0.48)O3(10.4 J/cm3)film is because theEmof the former(1200 kV/cm)is significantly higher than that of the latter (2200 kV/cm). In fact, the vast majority of previous studies have shown that it is difficult to achieve simultaneous enhancement of relaxor properties andPmunder the same external electric field, whether in doped systems, composite systems,or solid solution systems. Based on the results of this work,a strategy of co-substituting the B-site ions with multiple ions with larger radius may give better results.

Frequency stability and temperature stability are important indexes of dielectric film capacitors in practical application. Good stability allows the capacitor to operate at wide range of frequencies and temperatures. Stability tests of FTseries films were performed at an external electric fields of 2000 kV/cm.P-Ehysteresis loops of FT-series films at frequency of 200, 500, 1000, 1500, and 2000 Hz are shown in Fig. S3. TheWrecof all films hardly changed with the increase of frequency. The efficiency of BBT film responds slightly to frequency changes. This response becomes smaller and smaller with the increase of (FeTa) content. This should be attributed to the slightly increased relaxor properties.P-Ehysteresis loops of FT-series films at different temperatures are shown in Fig.S4.The hysteresis loops of BBT film change obviously when the temperature rises from 20°C to 80°C.This result in the efficiency drops from 75.1%to 60.7%. This may be related to the increase in leakage current density at high temperatures. For co-doped films, their energy storage density and efficiency change slightly in the temperature range of 20°C to 120°C,which shows an excellent temperature stability.

4. Conclusion

In summary, we compare the effects of Fe3+ion doping and Fe3+and Ta5+ions co-doping on the energy storage performance of Ba2Bi4Ti5O18films. The results show that the polarization of the Fe-doped films under same external electric fields increases dramatically because the radius of Fe3+is larger than that of Ti4+. The leakage current density increases significantly with the increase of Fe3+content resulting in a significant decrease in breakdown strength. What is more, Fe3+doping stabilizes the long-range ferroelectric order, which greatly reduces the efficiency under the same external electric field. However, the co-doping of Fe3+and Ta5+ions not only improves the polarization of BBT film,but also enhances the relaxor properties. These lead to an overall improvement in the energy storage performance of codoped film. TheWrecof Ba2Bi4Ti4.94(FeTa)0.06O18film is 67 J/cm3with efficiency of 79.5%under external electric field of 2500 kV/cm,which is a significant increase compared with theWrec(43.3 J/cm3)and efficiency(71.6%)of Ba2Bi4Ti5O18film under same external electric field. Moreover, all films co-doped with Fe3+and Ta5+ions show stable energy storage performance in the frequency range of 200 Hz to 2000 Hz and temperature range of 20°C to 120°C.This results show that Ta5+and Fe3+with larger radius together replace Ti4+is an effective way to enhance energy storage performance of BBT film.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 12074204,11864028, and 11904054) and the Natural Science Foundation of Inner Mongolia,China(Grant No.2022ZD06).

猜你喜欢

杂志排行

Chinese Physics B的其它文章

- Characterizing entanglement in non-Hermitian chaotic systems via out-of-time ordered correlators

- Steering quantum nonlocalities of quantum dot system suffering from decoherence

- Probabilistic quantum teleportation of shared quantum secret

- Spin–orbit coupling adjusting topological superfluid of mass-imbalanced Fermi gas

- Improvement of a continuous-variable measurement-device-independent quantum key distribution system via quantum scissors

- An overview of quantum error mitigation formulas