Ecological Dyeing of Polyamide 6, 6(PA66) Fabrics with Monascus Pigments in Decamethylcyclopentasiloxane(D5) Solvent

2021-11-02FENGLili冯丽丽RENLimin任丽敏ZHAOYanDONGChunmin董春敏QIUYiping邱夷平ZHANGHongjie张宏杰

FENG Lili(冯丽丽), REN Limin(任丽敏), ZHAO Yan(赵 研), DONG Chunmin(董春敏), QIU Yiping(邱夷平), 3, ZHANG Hongjie(张宏杰)*

1 College of Textiles and Apparel, Quanzhou Normal University, Quanzhou 362000, China

2 Shishi Institute for Ecological & Smart Textile, Quanzhou Normal University, Quanzhou 362000, China

3 College of Textiles, Donghua University, Shanghai 201620, China

Abstract: Synthetic dyes in the aqueous media have been commonly used for textile dyeing, resulting in resource and environmental pressure arising from consumption of water and environmentally unfriendly chemicals. In this study, an eco-friendly process of dyeing polyamide 6, 6(PA66) fabrics with natural Monascus pigments in decamethylcyclopentasiloxane(D5) solvent has been developed to minimize water consumption and effluent generation. The influence of processing parameters including dyeing temperature, dyebath pH and dyeing time on dyeing effects was explored. It was shown that color strength and color fastness of the samples dyed in D5 media were higher than those of the samples dyed in the aqueous media. Moreover, PA66 fabrics exhibited the highest color strength, good color fastness and a bacteriostatic rate of 53.6% against Staphylococcus aureus when it was dyed at pH of 3.5 and temperature of 80 ℃ for 30 min.

Key words: Monascus pigments; decamethylcyclopentasiloxane(D5); polyamide 6, 6(PA66) fabric; ecological dyeing; antibacterial property

Introduction

Synthetic dyestuffs derived from nonrenewable petrochemical source play a very dominant role in textile industry. However, owing to their toxicity and non-degradability, the application of synthetic dyestuffs exert highly negative impact on environment[1]. Natural pigments with good environmental compatibility and biodegradability have attracted increasing attention in recent years. Among them, microbial pigments present a potential industrial interest for textile industries because they are abundant in nature and have short product life cycles[2-3]. Moreover, the production of microbial pigments is independent of season, climate and geography[4-5].

Monascuspigments are secondary metabolites ofMonascusfungi. They are a polyketone mixture composed of red, orange and yellow pigments with different chemical structures and similar properties[6]. Rubropunctamine and monascorubramine(red pigments), rubropunctatin and monascorubrin(orange pigments), and monascin and ankaflavin(yellow pigments) are well-knownMonascuspigments[7]. Due to their excellent safety and biodegradability, many researchers have begun to explore the application ofMonascuspigments in textile dyeing industry, such as dyeing wool[8]and silk[9]. However, in the aqueous solution,Monascuspigments exhibit poor affinity for textile substrate, and mordant is often needed to obtain better color depth and color fastness, which not only increases the dyeing cost, but also produces a large amount of waste effluent.

Decamethylcyclopentasiloxane(D5), a colorless and odorless liquid with benign nature, has been widely used in cosmetics and body care products[10-11]. Meanwhile, it is easy for silicone to penetrate the fiber interior because of low surface tension, making it a good candidate for dyeing media to minimize the consumption of water and to reduce waste effluent[12-13]. In this study, a sustainable approach has been adopted for dyeing polyamide 6, 6(PA66) fabrics withMonascuspigments in D5 media. The effect of processing parameters on dyeing and color fastness properties of PA66 fabrics dyed in this system is studied.

1 Experiments

1.1 Materials

PA66 woven fabrics(40D/34F×30) were used as the substrate material andMonascusrice powder was purchased from Beijing Weishenglong Food Co., Ltd., Beijing, China. D5 was provided by GE Toshiba Silicones Co., Ltd., Tokyo, Japan. Biological reagent and other chemical reagents were supplied by Sangon Biotech Co., Ltd., Shanghai, China.Staphylococcusaureus(S.aureus) ATCC 6538 andEscherichiacoli(E.coli) ATCC 29522 were obtained from American Type Culture Collection, USA.

1.2 Methods

1.2.1DyeingPA66fabricswithMonascuspigments

Monascusrice powder was firstly dissolved in distilled water, and then 1 g PA66 fabrics with 2 mL dissolved dye were mixed in 20 mL D5 media. The dyeing process was carried out on an infrared dyeing machine(Mebon Company, Quanzhou, China). The dyeing temperature was controlled following a specific heating curve as shown in Fig. 1. After the dyeing process, PA66 fabrics were rinsed repeatedly with running water and dried at room temperature.

1.2.2Colorcharacteristics

The color characteristics of dyed PA66 fabrics were tested using a Datacolor 800 spectrophotometer(Datacolor Company, USA) under illuminant D65. The test result was the average of observed values from five different locations.

1.2.3Breakingload

The breaking load of PA66 fabrics was tested on a YG026HB electronic fabric load tester(Mebon Company, Quanzhou, China) according to the standard GB/T 3923.1—2013. The result was the average of three specimens for each sample.

1.2.4Colorfastness

The rubbing fastness of dyed PA66 fabrics was tested by a Y571 rubbing fastness tester(Electron Instrument Co., Ltd., Laizhou, China ) according to the standard GB/T 29865—2013.

1.2.5Coloruniformity

The color uniformity of dyed samples was evaluated by calculating the standard deviation ofK/Svalues on 20 random spots from each sample. Lower standard deviation represents higher color uniformity of dyed samples[14].

1.2.6Antibacterialtests

Antibacterial tests for the samples againstS.aureusandE.coliwere carried out according to the antibacterial standard for textiles(GB/T 20944.3—2008), and the reduction of bacteria was calculated according to

(1)

whereRis the bacteriostatic rate,Ais the number of bacterial colonies from undyed PA66 fabrics, andBis the number of bacterial colonies from dyed PA66 fabrics.

2 Results and Discussion

2.1 Dyeing mechanism in D5 media

AsMonascuspigments are insoluble in D5 media at room temperature, dye molecules aggregate and suspend in the D5 media.Monascuspigment particles gradually dissolve to form dye molecules because they can be protonated at high temperature and under the acid condition. Meanwhile, the PA66 fabric is swollen due to the increasing dyeing temperature and the presence of cationic groups under the acid condition. Therefore, the dye molecules can migrate readily from the outer surface and diffuse into the fiber structure until equilibrium dyeing is attained.

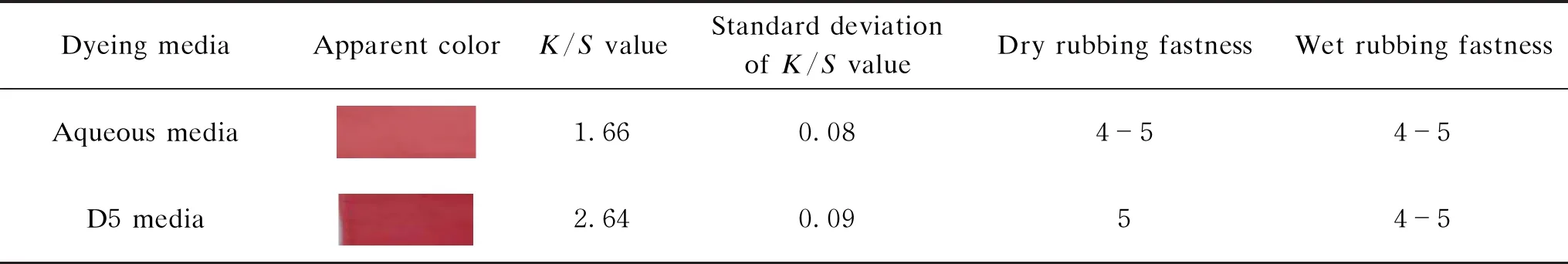

Table 1 shows the dyeing effects of PA66 fabrics usingMonascuspigments in aqueous and D5 media at pH of 3.0. PA66 fabrics dyed withMonascuspigments in D5 media presented a darker apparent color and higherK/Svalue than the sample dyed in the aqueous media. It is because that dissolvedMonascuspigments cannot mix with D5 media, thus forming a tiny dyeing bath at a low bath ratio, which is effective in increasing dyeing performance. Standard deviation ofK/Svalue in Table 1 clearly indicated that equivalent color uniformity was obtained for PA66 fabrics dyed in D5 media as well as aqueous media. Additionally, PA66 fabrics dyed withMonascuspigments in D5 media met the quality requirements of dyed fabrics, while wet rubbing fastness was 4-5 and dry rubbing fastness could reach 5.

Table 1 Influence of dyeing media on dyeing effect

2.2 Effect of dyebath pH

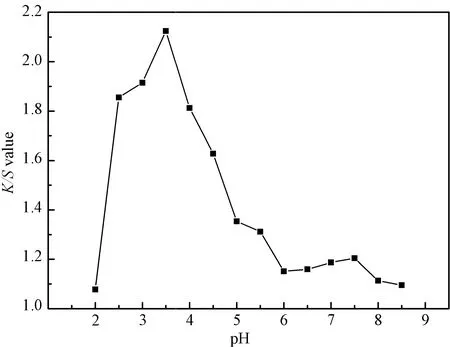

The influence of dyebath pH values on color strength of PA66 fabrics dyed at 100 ℃ for 60 min is shown in Fig. 2. PA66 fabrics andMonascusred pigment carried positive charge because —NH— group and —NHCO— group on PA66 as well as —NH— group onMonascusred pigment could be protonated at pH of 2.0, and thusK/Svalue was extremely low due to presence of electrostatic repulsion.K/Svalue of dyed PA66 fabrics increased significantly along with the enhancement of dyebath pH as a result of the decreased electrostatic repulsion, and the maximumK/Svalue was observed when pH reached 3.5. Futher increasing dyebath pH not only reduced the electrostatic repulsion between PA66 fabrics andMonascuspigments but also caused a significant decrease in the solubility of theMonascuspigments, which was not effective in dyeing PA66 fabrics withMonascuspigments.

Fig. 2 K/S value of dyed PA66 fabrics at different pH values

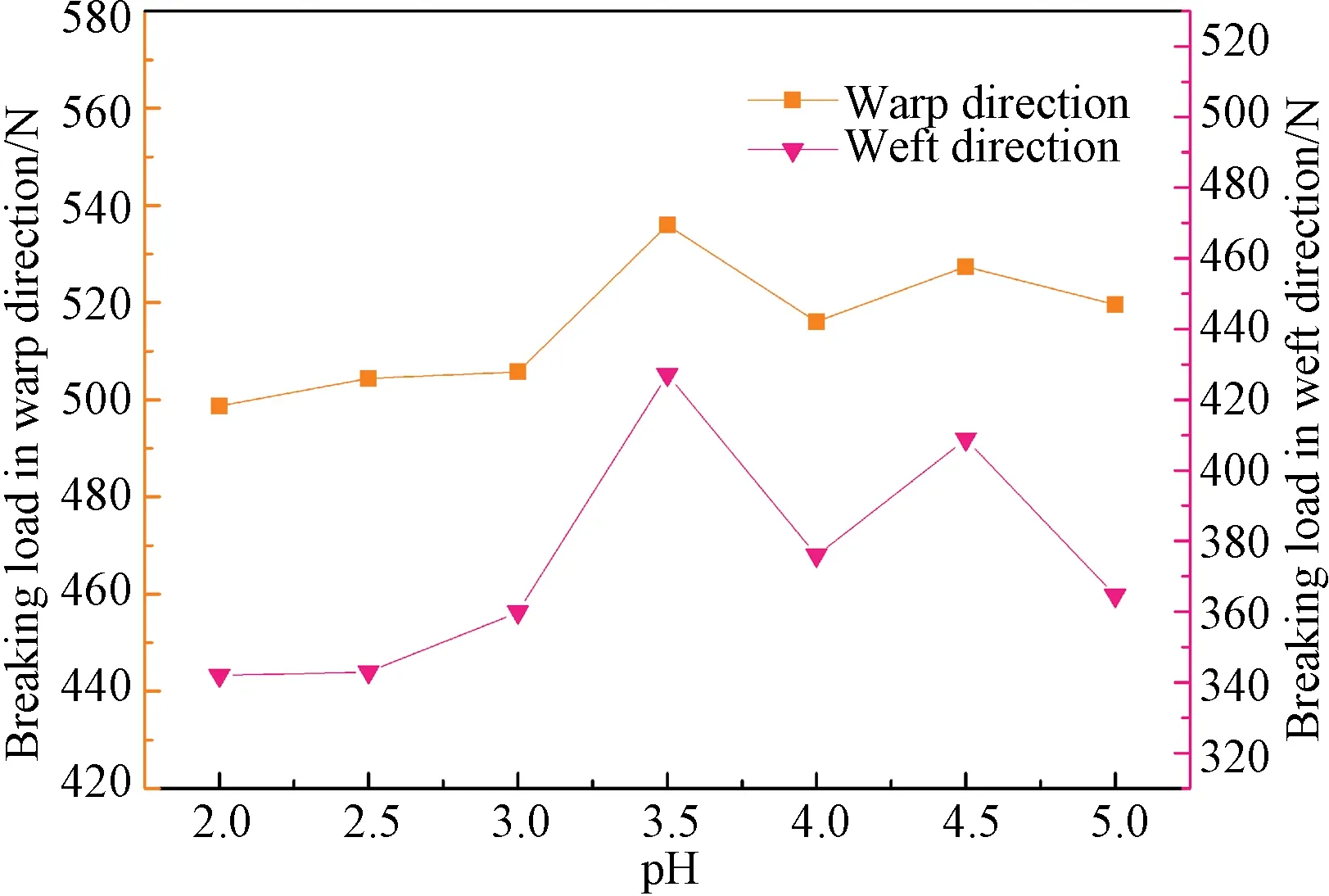

Fig. 3 Breaking load of dyed PA66 fabrics at different pH values

It is acknowledged that the PA66 fabric can be hydrolyzed and consequently lose its load when it is dyed at high temperature and under the acid condition for a long time. Figure 3 presents the load changes of PA66 fabrics dyed withMonascuspigments at different pH values. When the maximumK/Svalue was obtained at pH of 3.5, the highest breaking loads in both warp direction and weft direction were also observed, and more acid or more alkaline dyebath resulted in substantial loss of load.

2.3 Effect of dyeing temperature

Color loss may happen during dyeing process owing to a low stability of natural pigments compared to synthetic colorants at high temperature[15]. Therefore, careful selection of dyeing temperature is critical to obtain an optimal dyeing effect. The dyeing process was uniformly maintained for 60 min, and pH of the dyebath was adjusted to 3.5.

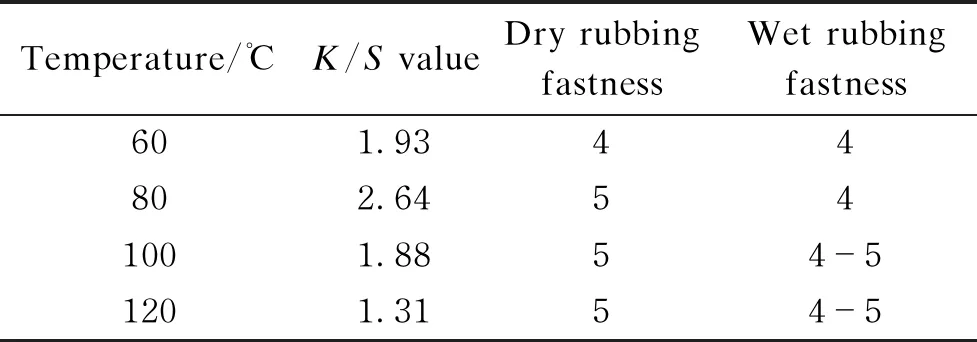

It was evident in Table 2 that theK/Svalue of dyed PA66 fabrics increased significantly as the dyeing temperature raised and the maximum value was obtained at 80 ℃. That was because the PA66 fabric was relatively swollen and solubility ofMonascuspigments increased at high temperature, resulting in faster diffusion of the pigments into PA66 fibers. Moreover, a higher temperature also eliminated the aggregation tendency of dye molecules and reduced the size of dye particle. However, further increase in temperature, for example above 80 ℃, accelerated degradation ofMonascuspigments, leading to the decrease of color strength.

Table 2 Effect of dyeing temperature on K/S value and rubbing fastness

2.4 Effect of dyeing time

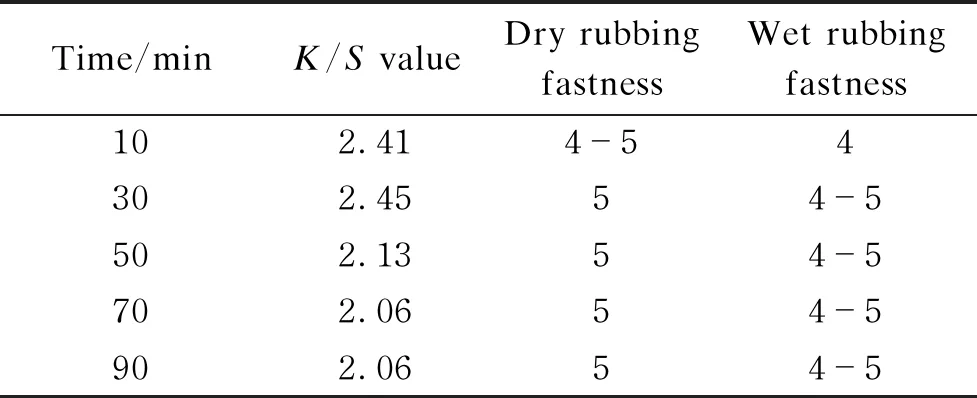

Table 3 displays the effect of dyeing time onK/Svalue and rubbing fastness of PA66 fabris dyed at pH of 3.5 and temperature of 80 ℃. It was found that the optimumK/Svalue was obtained when dyeing time was 30 min, and further increasing dyeing time resulted in decreasedK/Svalues due to heat degradation ofMonascuspigments. Dyeing time has a limited effect on dry rubbing fastness and wet rubbing fastness of dyed fabrics. Considering the effect of dyeing time onK/Svalue and color fastness of the fabric, an optimum dyeing time was 30 min for subsequent experiments.

Table 3 Effect of dyeing time on K/S value and rubbing fastness

2.5 Antibacterial properties

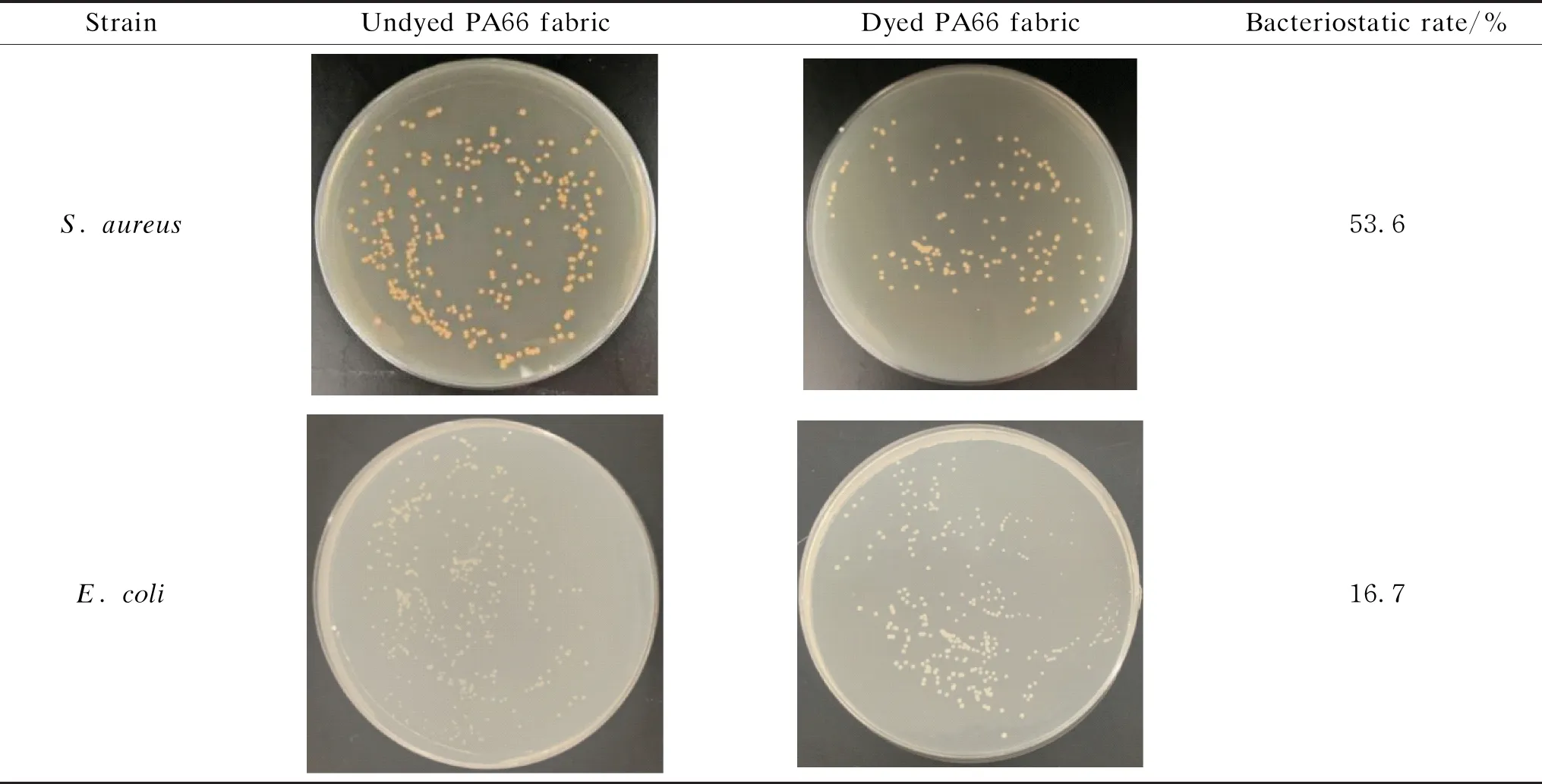

Monascuspigments are natural pigments with antibacterial activity[16-17]. Table 4 shows the antibacterial properties of PA66 fabrics dyed at pH of 3.5 and temperature of 80 ℃ for 30 min. It was clear that the number ofS.aureuscolonies on the dyed fabric was much lower than that on the undyed PA66 fabric, and the bacteriostatic rate was 53.6%. However, the reduction ofE.colicolonies was inconspicuous, and the bacteriostatic rate was only 16.7%. Antibacterial effects againstS.aureusmay be explained as thatMonascuspigments can interact with the membrane proteins, thereby resulting in membrane disruption and further induction of cell lysis[18].

Table 4 Antibacterial activity of PA66 fabrics

3 Conclusions

In this study, a sustainable dyeing approach was explored to minimize the consumption of water and environmentally unfriendly chemicals by dyeing PA66 fabrics withMonascuspigments in D5 media.K/Svalue was much higher for fabrics dyed in D5 media without any process auxiliaries compared to the aqueous dyebath. In addition, dyebath pH and dyeing temperature could greatly influence the dyeing results, while dyeing time had a limited effect. The PA66 fabric exhibited a good color strength and color fastness when it was dyed at pH of 3.5 and temperature of 80 ℃ for 30 min. Meanwhile, the sustainable technique forMonascuspigments endowed the PA66 fabric with antibacterial activity to a certain degree.

猜你喜欢

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Axial Compression Properties of 3D Woven Special-Shaped Square Tubular Composites with Basalt Filament Yarns

- Structural Color Modified Fabrics with Excellent Antibacterial Property

- Parametric Effects on Length of Stable Section of Electrospinning Jet

- Preparation and Performance of Fluorescein Isothiocyanate-Labeled Fluorescent Starch and Polyvinyl Alcohol for Warp Sizing

- Effects of Magnolia denudata Leaf Litter on Growth and Photosynthesis of Microcystis aeruginosa

- Order Allocation in Industrial Internet Platform for Textile and Clothing