Parametric Effects on Length of Stable Section of Electrospinning Jet

2021-11-02QUANZhenzhen权震震ZUYaoLEISailing雷赛玲QINXiaohong覃小红YUJianyong俞建勇

QUAN Zhenzhen(权震震), ZU Yao(祖 遥), LEI Sailing(雷赛玲), QIN Xiaohong(覃小红)*, YU Jianyong(俞建勇)

1 Key Laboratory of Textile Science & Technology, Ministry of Education, College of Textiles, Donghua University, Shanghai 201620, China

2 Innovation Center for Textile Science & Technology, Donghua University, Shanghai 201620, China

Abstract: While electrospinning is an effective method for fabricating nanofibers with good application prospects, controlling the length of stable section of electrospinning jet is critical and remains challenging. In the paper, the effects of electrospinning parameters on the length of stable section have been investigated experimentally using polyacrylonitrile(PAN). The results based on single factor experiments and orthogonal experiments showed that the stable-jet length increased with the increase of solution concentration, receiving distance, voltage and solution flow rate, and decreased with the enhanced concentration of salt which was commonly utilized as additive to facilitate the spinning. Furthermore, experimental results based on polyethylene oxide(PEO) and polyvinyl alcohol(PVA) showed that the length of stable section changed with increasing salt concentration, and due to the parametric interaction, the change was distinct under different driving voltages or solution concentration conditions.

Key words: electrospinning; stable section; nanofiber; jet; orthogonal experiment

Introduction

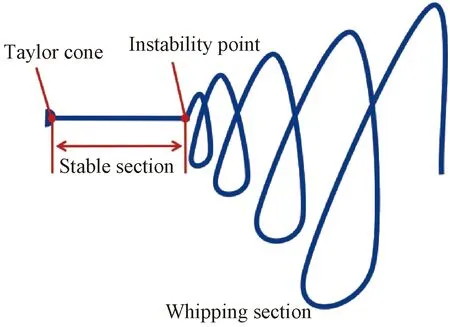

With the wide applications of nanofibers in various fields such as filtration[1-2], catalysis[3], energy[4], tissue engineering[5], and cancer detection[6], electrospinning, as an effective preparation method of nanofibers, has attracted widespread attentions. During electrospinning, a polymer solution or melt is loaded and stimulated with a voltage of high level to overcome its surface tension and eject from the Taylor cone. The charged jet is then stretched enormously by electrostatic force with the solvent evaporation, solidifies into nanofibers being collected by the receiver[7-8]. The spatial trajectory of the electrospinning jet from the Taylor cone to the receiver can be divided into two sections[9], as shown in Fig. 1, the stable section where the jet is stretched stably and in the straight shape, and the whipping section where the jet begins to spirally bend and whip. The turning point is called instability point.

Fig. 1 Sections of electrospinning jet

The diameter of electrospun fiber plays an important role in the application of fiber membrane in various fields, and the stable section affects the final fiber radius in the electrospinning process, as the length of the stable section of spinning jet could impact the jet stretching, solvent evaporation, fiber morphology and diameter uniformity[10-11]. Researchers[12-13]used allometric scaling to establish the relationship between jet radiusrand axial passage distancezfrom nozzle,r~zb, where the scaling exponentbfor the stable section was -1/2, and concluded that the jet conductivity and current influenced the stable section of the jet most. Theronetal.[14]analyzed the effects of applied voltage, the solution flow rate, and polymer solution mass fraction on the shape of spinning jets experimentally. Qinetal.[15]added LiCl into the polyacrylonitrile(PAN) spinning solution to study the effect of salt content on the length of the stable section. Lietal.[16]analyzed the influence of the solution mass fraction, conductivity and the applied voltage on the vertex angle of the conical envelope trajectory formed by the jet motion, the deposition area of the nanofibers and the diameter of the nanofibers. Leietal.[17]adopted polymethyl methacrylate(PMMA) for electrospinning experiments and discussed the relationship between the steady jet length and the terminal fiber radius. Most of the existing theoretical researches on electrospinning are focused on the fiber properties[18-20].

So far, systematic analysis on the factors affecting the length of stable section of electrospinning jet still keeps insufficient and lacks experimental support. In this work, the effects of five parameters(voltage, receiving distance, solution flow rate, solution concentration and salt concentration) on the length of stable section of electrospinning jet have been discussed.

1 Experiments

1.1 Materials

PAN was purchased from Shanghai Sinopharm Group Reagent Co., Ltd., China. Polyvinyl alcohol(PVA)(alcoholysis degree at a range from 87.0% to 89.0%), polyethylene oxide(PEO,Mw=700 000 g/mol) and LiCl were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., China.N,N-Dimethylformamide(DMF) was purchased from Shanghai Lingfeng Chemical Reagent Co., Ltd., China. These reagents were used without further purification.

1.2 Solution preparation

To prepare the spinning solution, PAN was dissolved in DMF at mass fraction between 8% and 12%. Different mass fractions of LiCl(0.2%, 0.5% and 0.8%) were prepared to study the effect of salt concentration on the length of stable section. PEO was dissolved in deionized water with a mass concentration of 4%, and LiCl was added at mass fractions of 0.2%, 0.6% and 1.0%. Similarly, PVA was dissolved in deionized water with a mass fraction of 10%, and LiCl was added as mass fractions of 0.2%, 0.6% and 1.0%, respectively. All the solution was stirred magnetically for hours until the solute was completely dissolved to obtain a homogeneous solution. All electrospinning experiments were performed at room temperature and 55% humidity.

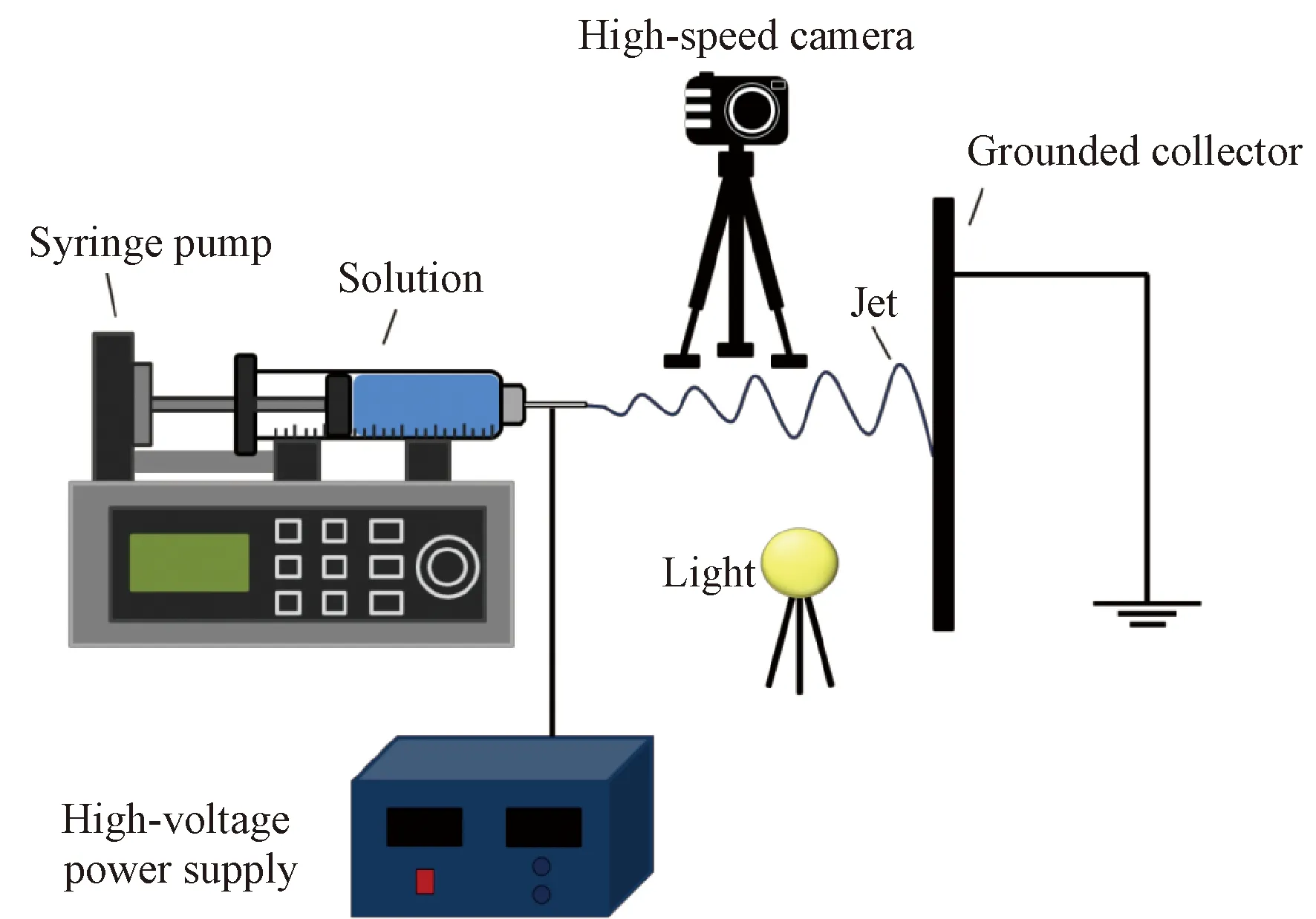

1.3 Experimental setups

The single-needle high-voltage electrostatic spinning device built in the laboratory was shown in Fig. 2. It included a laboratory microinjector pump(LSP01-3A, longer pump, England). The spinning solution was stored in a stainless steel needle syringe. The high-voltage generator provided positive high voltage at the tip of the needle. A grounded collector with aluminum foil was placed at a distance to collect the fibers.

Fig. 2 Electrospinning device

A high-speed video camera(i-SPEED716, Nikon, Japan) was used to capture the jet image at the speed of 2 000 frame/s, and the shutter speed was 499 461 ns. A 1 000 W quartz lamp with continuous light source was used to irradiate the electrospinning nozzle. After the jet was stabilized, it was photographed by the high-speed camera. Three images were randomly selected from the obtained jet images and image-pro Plus software(Media Cybernetics, America) was used for image processing and jet stable segment length measurement. The average stable section lengthLrefers to the average of the stable section length measured in three pictures.

2 Results and Discussion

2.1 Single factor experiments

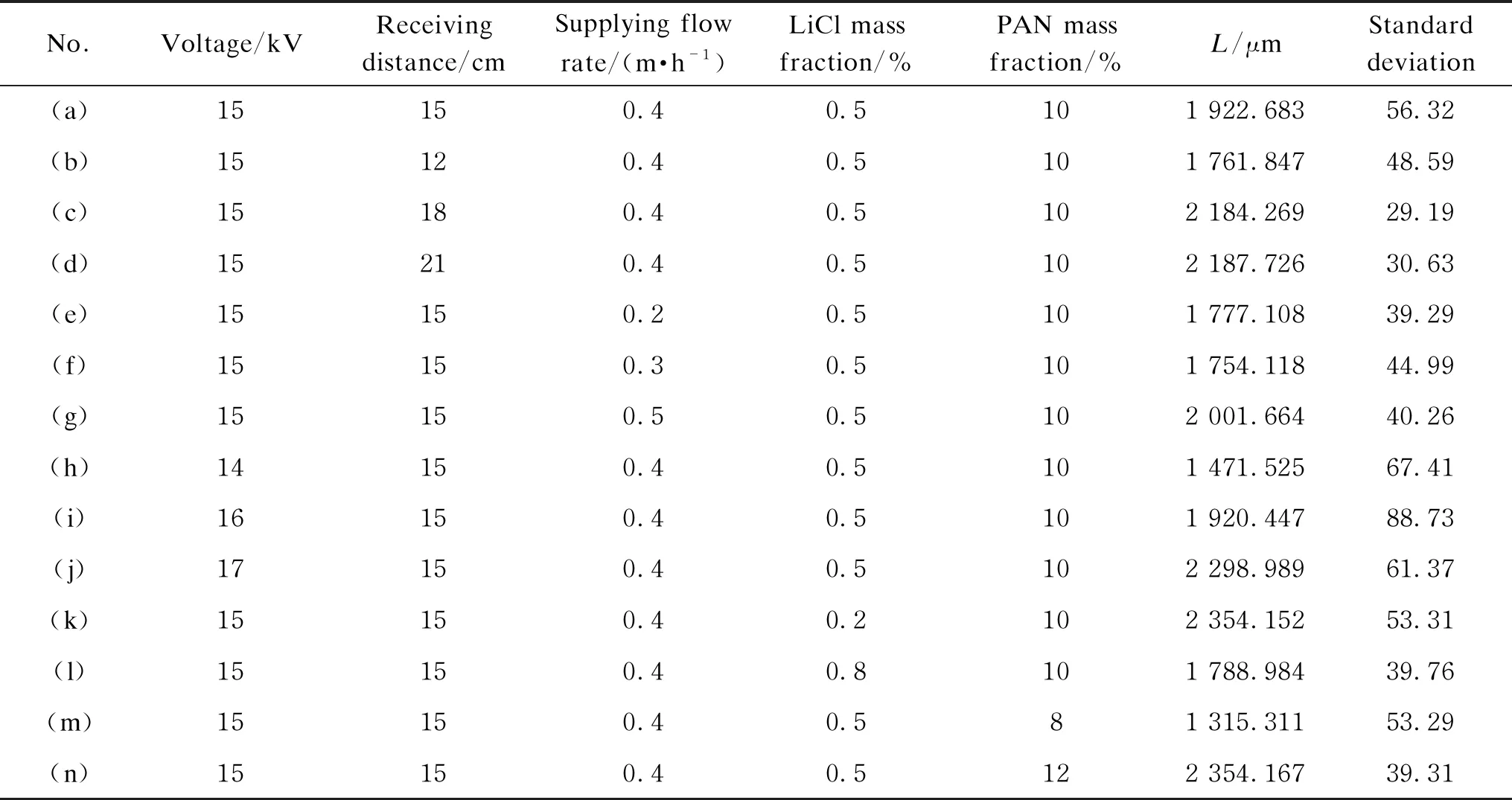

The images of PAN solution jets captured by the high-speed camera during the single factor experiments were shown in Fig. 3, of whichLwas given in Table 1.

Table 1 Average stable-jet lengths under different electrospinning parameters

Fig. 3 High-speed camera captured images of PAN solution jets during the single factor experiments(the inserted characters corresponding to experiment No. in Table 1)

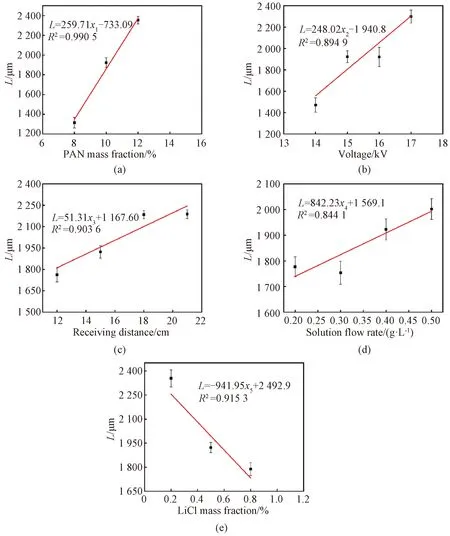

As shown in Fig. 4, the length of the stable section increased with the increase of solution concentration, receiving distance, voltage and spinning solution flow rate and the decrease of the mass fraction of the salt. The influence caused by the increase of PAN mass fraction could be divided into two aspects. (1) The increase of PAN mass concentration effectively increased the conductivity, which was conducive to the jet drafting, thus increased the length of the stable section. (2) The solution viscosity was raised with the increase of PAN mass concentration, which made the jet difficult to bend and stir, and increased the length of the stable section.

Fig. 4 Variation of stable-jet length against: (a) PAN mass fraction x1; (b) voltage x2; (c) receiving distance x3; (d) solution flow rate x4; (e) salt LiCl mass fraction x5

As shown in Fig. 4(b), with the increase of voltage, the electric force acting on the jet direction increased. That was, the traction force increased and the draft length of the stable section increased. In Fig. 4(c), along with the receiving distance raising, the electric field intensity was reduced, and the disturbance of the electric field force on the jet decreased, resulting in the delay of the jet entering the whipping section, and the length of the stable section increased accordingly. Figure 4(d) showed that increasing the flow rate of the solution increased the initial diameter of the jet, which led to a longer distance of refinement under the action of electric field force, which made the jet not easy to bend, and the length of the stable section would increase. As shown in Fig. 4(e), the length of the stable section of the jet decreased with the higher mass fraction of the salt. The underlying cause was that the higher mass of the salt increased the conductivity of the solution, resulting in an increase in the total number of charges in the jet, with the increase of repulsion force between charges. The jet was more prone to bending and whipping, and entered the unstable section, resulting in a decrease in the length of the stable section of the jet[21].

Comparing with the size of the parameterR2of the one-element linear regression equation of five factors in Fig. 4, as 0.990 5> 0.915 3> 0.903 6> 0.894 9> 0.844 1, a preliminary conclusion was 1ed to: the receiving distance, the salt LiCl mass fraction, and the PAN mass fraction were the main influencing factors. Furthermore, the orthogonal experiments were performed using these three factors.

2.2 Orthogonal experiments

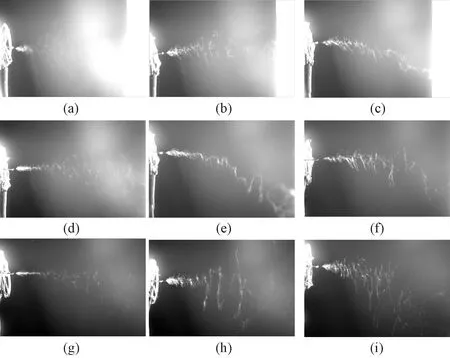

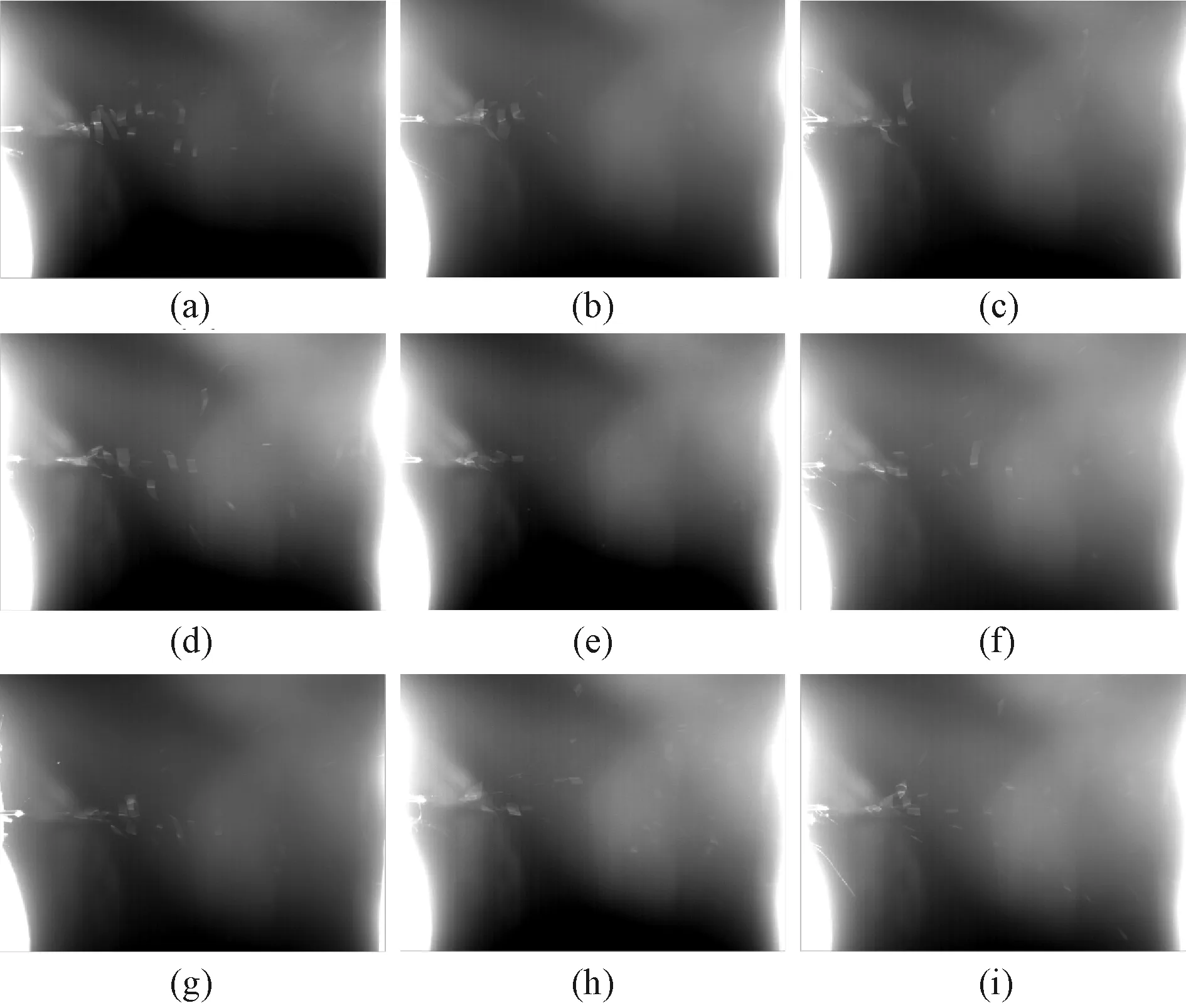

Based on the results of the single-factor experiment, the receiving distance, the salt LiCl mass fraction, and the PAN mass fraction were the important factors affecting the length of the stable section. These three factor were used to conduct the three-factor three-level orthogonal experiment to further study their influence. Since the independent variables are linearly correlated, three levels were selected for each factor and the experiment was arranged according to the L9(34) orthogonal array(shown in Table 2). The images of the orthogonal test results were shown in Fig. 5.

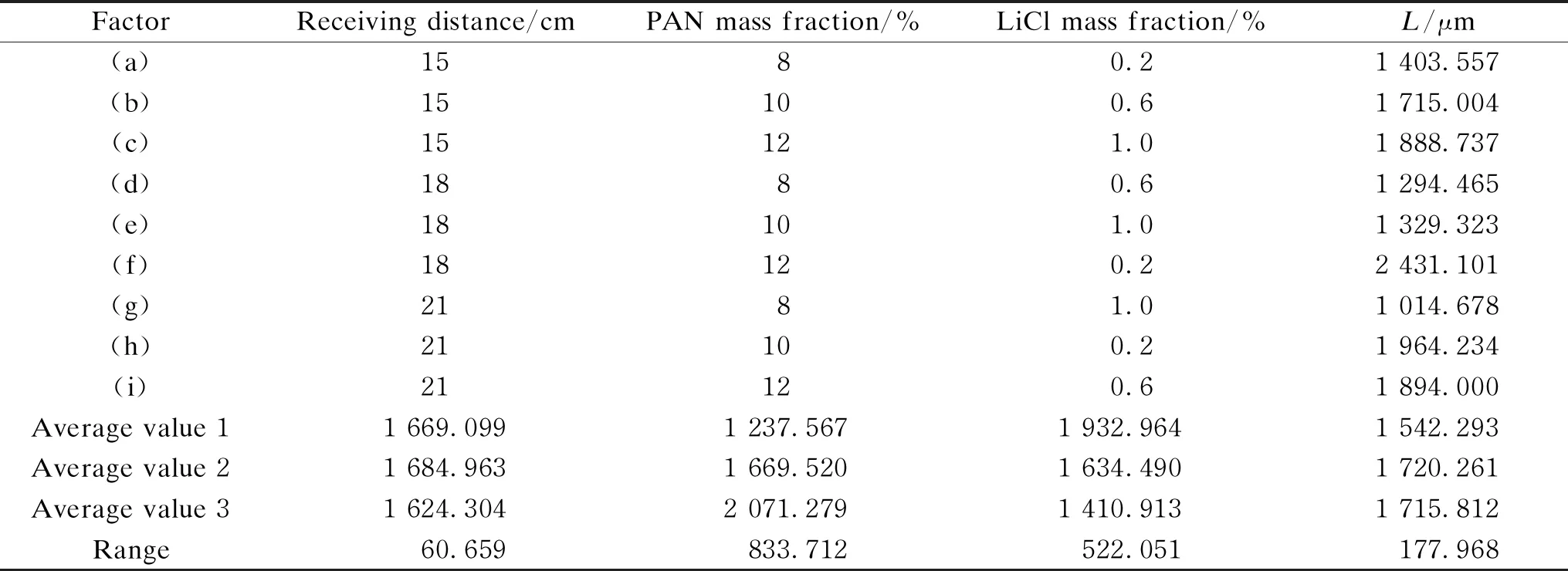

Table 2 Orthogonal experimental design and analysis of range

Fig. 5 High-speed camera captured images of PAN solution jets during orthogonal tests(the characters corresponding to experiment No. in Table 2)

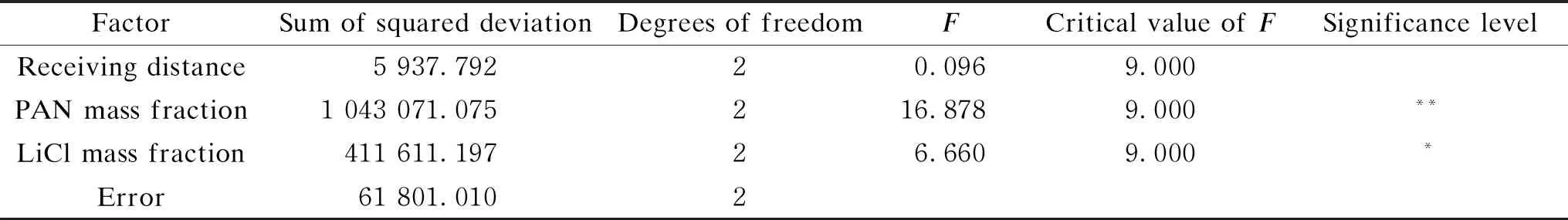

The results of orthogonal experiment and analysis of range are displayed in Table 2. By calculating the difference between the maximum and the minimum mean values of each factor(range), the influence of factors on the experimental results can be judged. The larger the range was, the more important the corresponding factor was. The analysis of variance(shown in Table 3) was used to distinguish whether the differences of test results were caused by changes in levels or by test errors, so as to verify which factors had an impact on the results(on the basis of analysis of range) and which ones had no impact. From the analysis of range and variance(shown in Tables 2-3), PAN mass fraction was the most significant, while receiving distance was not significant.

Table 3 Analysis of variance for three factors(receiving distance, PAN mass fraction and LiCl mass fraction)

2.3 Effect of salt concentration on the stable-jet length used PVA and PEO

As PEO and PVA were commonly used electrospinning materials. The effect of salt concentration on the stable-jet length of PVA and PEO was further investigated during different voltage levels.

The images of PEO solution jets captured by the high-speed camera were shown in Fig. 6. Pre-experiment results found that the jets with the PEO mass fraction of 5% and 6% vibrated violently intermittently at the nozzle after adding LiCl. As it was impossible to obtain a continuous and stable jet, 4%(mass fraction) PEO solution was used in the experiment.

As shown in Fig. 7, the length of PEO stable section increased first and then decreased with the increase of salt concentration, and increased with the increase of voltageV, which was different from the trend of PAN electrospinning. The possible explanation could be that the viscosity of the solution was low as PEO mass fraction was small, and the viscosity of the solution increased due to the increase of salt concentration. As a result, the jet was hard to stretch and the length of stable section increased. In this case, the effect of viscosity changed on the length of the stable section was higher than that of the conductivity, so that the length of the stable section had a positive relationship with the salt concentration. When the mass fraction of salt was 0.6% compared with 1.0%, the length of stable section of 1.0% salt concentration decreased obviously. The reason was that the influence of conductivity on the jet was greater than that of viscosity. When the mass fraction of salt increased, the charge repulsion caused by the conductivity of the jet increased. Therefore, the length of PEO stable section decreased with the increase of salt concentration.

Fig. 6 Images of 4%(mass fraction) PEO solution jets captured by high-speed camera(the inserted characters corresponding to experiment No. in Table 4)

Fig. 7 Relationship between salt LiCl mass fraction and stable-jet length of 4%(mass fraction) PEO solution(receiving distance is 15 cm and solution flow rate is 0.4 mL/h)

Fig. 8 Images of 10%(mass fraction) PVA solution jets captured by high-speed camera(the characters corresponding to experiment No. in Table 5)

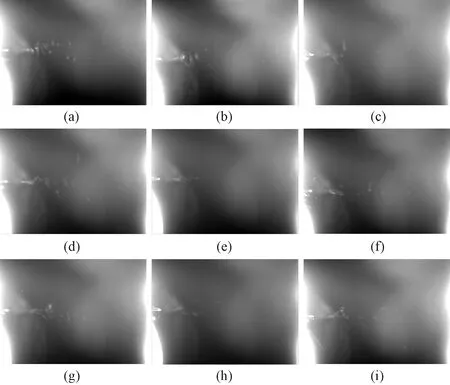

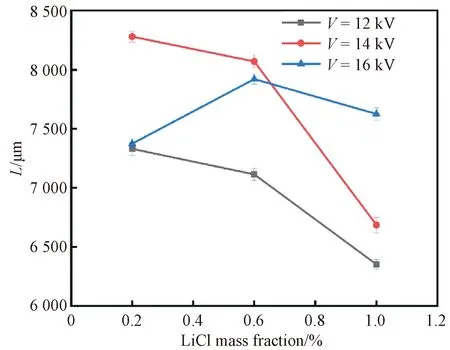

Similarly, the images of PVA solution jets captured by the high-speed camera were shown in Fig. 8. It was shown that the stable-jet length decreased with the increase of salt concentration and increased with the increase of the voltage when the voltage was 12 kV and 14 kV(shown in Fig. 9). This was due to the fact that the mass fraction of the salt made the total charge number in the jet increased, which increased the repulsion of the same kind of charge in the charged jet. The jet was easier to bend, swing and enter the whipping section, so the length of the stable section was shortened. On the contrary, the increase of electric charge made the electric field force increased and the jet refined more quickly, which was one of the reasons for the increase of the length of the stable section. In the electrospinning of PVA at 12 kV and 14 kV, the former had more influence on the stable section, which resulted in the decrease of the length of the stable section with the increase of the mass fraction of salt. When the voltage was 16 kV, the influence of salt content on the length of the stable section was no longer obvious. This was because the electric field force made the jet refining speed fast, and the whip caused by the charge density was no longer the main factor.

Fig. 9 Relationship between salt LiCl mass fraction and stable-jet length of 10%(mass fraction) PVA solution(receiving distance is 15 cm and solution flow rate is 0.4 mL/h)

3 Conclusions

Parametric effects on the length of stable section of electrospinning jet were studied using single factor experiments as well as orthogonal experiments. It is shown that the salt concentration plays a significant role in regulating the length of stable section. Moreover, the change of the length with increasing salt concentration is distinct under different spinning conditions.

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Axial Compression Properties of 3D Woven Special-Shaped Square Tubular Composites with Basalt Filament Yarns

- Structural Color Modified Fabrics with Excellent Antibacterial Property

- Preparation and Performance of Fluorescein Isothiocyanate-Labeled Fluorescent Starch and Polyvinyl Alcohol for Warp Sizing

- Effects of Magnolia denudata Leaf Litter on Growth and Photosynthesis of Microcystis aeruginosa

- Order Allocation in Industrial Internet Platform for Textile and Clothing

- Blockchain-Based Log Verification System for Cloud Forensics