An investigation on improving the homogeneity of plasma generated by linear microwave plasma source with a length of 1550 mm

2021-02-27JichengZHOU周继承WeiXU徐伟andTechaoCHEN陈特超

Jicheng ZHOU (周继承), Wei XU (徐伟) and Techao CHEN (陈特超)

1 School of Energy Science and Engineering, Central South University, Changsha 410083, People’s Republic of China

2 Hunan Red Solar Photoelectricity Science and Technology Co.,Ltd,Changsha 410083,People’s Republic of China

Abstract To develop a larger in-line plasma enhanced chemical vapor deposition (PECVD) device, the length of the linear microwave plasma source needs to be increased to 1550 mm.This paper proposes a solution to the problem of plasma inhomogeneity caused by increasing device length.Based on the COMSOL Multiphysics, a multi-physics field coupling model for in-line PECVD device is developed and validated.The effects of microwave power, chamber pressure, and magnetic flux density on the plasma distribution are investigated, respectively, and their corresponding optimized values are obtained.This paper also presents a new strategy to optimize the wafer position to achieve the balance between deposition rate and film quality.Numerical results have indicated that increasing microwave power and magnetic flux density or decreasing chamber pressure all play positive roles in improving plasma homogeneity,and among them,the microwave power is the most decisive influencing factor.It is found that the plasma homogeneity is optimal under the condition of microwave power at 2000 W,chamber pressure at 15 Pa, and magnetic field strength at 45 mT.The relative deviation is within −3.7% to 3.9%,which fully satisfies the process requirements of the equipment.The best position for the wafer is 88 mm from the copper antenna.The results are very valuable for improving the quality of the in-line PECVD device.

Keywords: in-line PECVD, linear microwave plasma source, multi-physics field, COMSOL simulation, homogeneity

1.Introduction

As a mature technology, plasma enhanced chemical vapor deposition (PECVD) is widely used for the fabrication of various thin-film materials for photovoltaics.At present,there are three main types of PECVD equipment used in solar cell production lines: the planar RF-PECVD, the tubular RFPECVD, and the in-line MW-PECVD [1–3].Owing to its outstanding features such as high deposition rate, large area uniformity, high safety, and excellent controllability [4], the in-line PECVD device is developed for the deposition of various thin films, like antireflection layers of silicon nitride,back passivation layers of AlOxand amorphous silicon layers for heterojunction cells [5–8].

The linear microwave plasma source is the kernel of the in-line PECVD device.Petaschet al[9]studied on the coaxial line-coupled cavities,and developed a plasma generator called Duo-Plasmaline.Liehret al[10]optimized the Duo-Plasmaline by spirally winding a copper tube around the inner conductor surface to facilitate the transfer of microwave energy and increase the plasma density.Kaiseret al[11] redesigned the outer cavity of the linear plasma source to improve the uniformity and electron density of the linear microwave plasma source.Katoet al[12]suggested that an external magnetic field could effectively increase plasma density.This was because the magnetic field could increase the confinement and the efficient collision frequency of the charged particles under Lorenz force.Based on this, Schlemmet al[13] developed the linear microwave plasma source used in the in-line PECVD device for silicon nitride deposition of solar cells, and realized its application in industry.The uniform plasma with large area can be generated easily from multiple linear microwave plasma sources that are aligned in parallel.To keep pace with the development of the PV (Photovoltaic) industry, the linear plasma sources need to be evolved towards better performance(>5% uniformity over large areas) and higher productivity in order to reduce production costs and match new cell concepts and technologies.

It is known that higher productivity can be achieved by improving deposition rate or enlarging equipment size.There have been a few comprehensive works focusing on improving deposition rate, including optimization of the structure and process parameters [14–16].In fact, enlarging the size of the device is supposed to be a more efficient approach.In recent years,the length of linear microwave plasma source in in-line PECVD device has increased from 1100 mm to 1340 mm(with a 4×6 graphite frame),which has been widely applied in the industry.It is aimed to develop the next generation linear microwave plasma source with a length of 1550 mm(with a 4×7 graphite frame).That means the production capacity would be increased by 17%.However, the most prominent problem is the decrease in plasma uniformity,causing inhomogeneity of the target film, which cannot meet the PECVD process requirement.

As indicated by Hübneret aland Ganesanet al[17,18],the uniformity of plasma generated from linear microwave source is mainly influenced by the device structure, microwave power,chamber pressure,and the magnetic flux density.However,previous studies have mainly focused on laboratory equipment, and both the size and process conditions are dramatically different from linear microwave plasma sources in the in-line PECVD device.This will result in different or even opposite effects on plasma uniformity influenced by certain parameters, such as chamber pressure.Besides, the ultimate difference from smaller devices is that the linear microwave plasma source with a length of 1550 mm is difficult to optimize by adjusting a single parameter, but requiring adjustment of multiple parameters simultaneously.Therefore, this paper aims to study the influence of microwave power,chamber pressure,and magnetic flux density on plasma uniformity and to obtain an optimal parameter recipe by adjusting the parameters mentioned above.

In the industry, obtaining the optimal parameter recipe mainly relies on extensive trial and experience work, which would cost much time and money.Therefore, numerous numerical studies have been adopted to explore the performance of linear microwave plasma sources.Rahimiet al[19]presented a two-dimensional(2D)model of a linear coaxial plasma source and investigated the propagation of electromagnetic wave.Chenet al[20] developed a selfconsistent 2D models based on the COMSOL Multiphysics.Their work unveiled the characteristics and available propagation mechanism of linear coaxial microwave plasma.Besides, Obrusníket al[21] proposed a mixed 2D/3D fluid model and demonstrated the influence of the microwave shielding on the plasma and particles.In this paper, a multiphysics field coupling model for in-line PECVD device is developed based on the simulation software, COMSOL Multiphysics.It is robust in multi-field coupling with specialized plasma module.More information about COMSOL Multiphysics can be found in [22].

This paper is generally formed as below.The numerical model and simulation conditions are presented in section 2,with verifying the validity of this model.The section 3 explores the plasma distribution by increasing the length of the linear microwave plasma source to 1550 mm.Then the effects of microwave power,chamber pressure,and magnetic flux density on plasma homogeneity are investigated,obtaining an optimal parameter recipe.The summary is given in section 4.

2.Numerical simulation and verification

2.1.Model simplification

Figure 1(a) presents a schematic diagram of the in-line PECVD.The microwave at 2.45 GHz, generated by two microwave magnetrons, passes the microwave mode converter which is designed to change the microwave from TE10mode to TEM mode into the chamber.The working gas (e.g.argon)enters the chamber through the gas shower,then being excited into plasma around the quartz tube.The magnetic field,generated by the external magnet,increases the collision frequency of charged particles, contributing to improve the plasma density and uniformity [23].The working gas, under the action of high-energy electrons in the plasma, forms a large number of highly reactive surface reaction precursors,which eventually form a film on the wafer surface by chemisorption.The wafers are placed on the graphite frame.The heating plate is used to regulate the surface temperature of the wafer to ensure the quality of the film [24], and the vacuum pump is used to maintain chamber pressure.

The model needs to be simplified while keeping it feasible to investigate the effect of relevant parameters on plasma homogeneity.First of all,it is assumed that microwave is fed directly from the ports on both sides of the quartz tube in TEM mode[20],and the microwave power used in the model refers to average microwave power.After that, due to the subtle influence of the gas velocity field on the plasma discharge characteristics, the flow field and the region under the heating plate are not calculated in this model [21].Finally,argon is employed instead of the complex process gas.Ultimately a 2D simplified model is developed, as presented in figure 1(b).

Figure 1.(a) Schematic configuration of in-line PECVD.(b) Schematic diagram of the simplified model.

2.2.Mathematical model formulas

The 2D self-consistent argon plasma model is developed based on COMSOL Multiphysics.The whole model containing microwave, plasma, magnetic, and heat field are solved self-consistently in a frequency-transient study.The electromagnetic waves are solved in the frequency domain,and all plasma variables are solved in the time domain.

The electric field satisfies the following wave equation[25]:

whereErepresents the amplitude of electric field and ω represents the angular frequency of the microwave.k0means the wavenumber in free space,andσare permeability, permittivity, and conductivity of the material, respectively.μ0andε0represent permeability,permittivity in vacuum.μrandεrare relative permeability and relative permittivity.Equation (1) is solved in air, quartz, and plasma.Both air and quartz are non-conductive (σ= 0) and non-magnetic (μr= 1).The relative permittivities areandrespectively, and the electromagnetic properties of the plasma are calculated from the plasma and magnetic field module.

For magnetized high-frequency plasma, the plasma conductivity σ needs to be expressed in full tensor form.The inverse of the plasma conductivity is denoted as follows:

whereνenand j represent the frequency of electron–neutral particle collisions and the imaginary symbol, respectively;Bsx,Bsy,Bszare three external magnetic field components in thex,y,andzdirections, respectively.The relative permittivity and permeability of plasma are given in equations (4) and (5) [26]

In the plasma modules, the drift-diffusion equations describing electron density and electron energy density are given as follows:

Table 1.Reactions scheme for the argon plasma.

and

whereRedenotes the electron rate expression.Esrepresents the electric field,which is given by equation(1),umeans the neutral fluid velocity vector anduis set to zero in this model.Qdescribes heating of the electrons.μeandDeare the electron mobility and diffusivity, respectively.μεandεDare the electron energy mobility and diffusivity, respectively.μeshould represent in full tensor form:

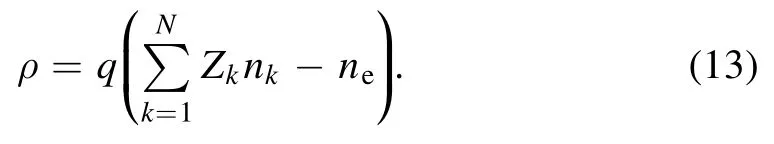

Plasma potential calculation by Poisson’s equation:

Here,V,ρare potential and space charge density, respectively.The space charge density is calculated from the number density of electrons and other charged particles:

In the relation above, the indexkruns over all species that enter the reactions.

Figure 2.Comparisons between the numerical results calculated from the model and the experimental results in the literature [9].

The mass fraction of heavy species is derived by solving the mixed-average diffusion formula:represent the mass fraction of heavy species, diffusive flux vector, rate expression for speciesk, respectively.ρrepresents the density of the mixture.

The gas temperature distributionTgis obtained from the heat equation in the form:

whereλis the thermal conductivity, andQhis the heat sources from neutrals.

All the reactions that are considered in the model are presented in table 1.To simplify the model, assuming that only four species exist in the argon plasma, i.e.electrons (e),ground state atoms (Ar), metastable particles (Ars), and ions(Ar+).The rate constant is computed from cross-section data by the following equation:

Figure 3.Under the standard parametric recipe, linear microwave plasma source length increased to 1550 mm.(a) Plasma density,(b) electron temperature, (c) gas temperature distribution.

whereσkis the collision cross-section, which can be obtained from database [31].frepresents the EEDF with Maxwellian distribution.

2.3.Model validation

In this paper,the model accuracy is validated by comparing with the extensive and detailed experimental results from literature[9].In order to verify the accuracy of the model,the simulation conditions need to be kept consistent with literature[9].It means that the linear microwave plasma source length is set to 600 mm,the microwave power is 210 W and the chamber pressure is 50 Pa.Figure 2 shows the comparison between the simulation results and the experimental results.By comparing the scale and distribution of electron density along the axial direction at distances of 10,20,and 30 mm from the quartz tube,it is found that the simulation results are in good agreement with the experimental results.Moreover, the simulation results show that the radial electron density attenuates with increasing radial distance,which is also in accordance with the experimental results in literature [17].The results above demonstrate that the model is valuable for improving the chamber design and process parameter of linear microwave plasma source.

3.Results and discussion

Figure 4.Plasma density distribution and relative deviation at the monitoring line (r = 40 mm).

After validating the accuracy of the model, we simulate the plasma distribution by increasing the length of the linear microwave plasma source to 1550 mm with a standard parametric recipe.For example, microwave power is set at 1800 W, chamber pressure at 25 Pa, and magnetic flux density at 30 mT(For existing 1340 mm length linear microwave plasma sources).The results of plasma density, electron temperature, and gas temperature distribution are shown in figure 3.From figure 3(a),it can be seen that the plasma density decreases axially after the length of the linear microwave plasma source being increased up to 1550 mm under the standard parametric recipe.Particularly in the intermediate regions of the device, the plasma is significantly insufficient.That is because the microwave is emitted from the magnetron at both ends of the device, then being fed from both ends of the quartz tube after passing the waveguide.Subsequently,the microwave interacts with the gas in the chamber, causing the ionization of gas.As microwave propagates to the intermediate region of the device, the microwave energy is consumed and gradually decays under the interaction between microwave and plasma.Thus, the probability of ionization of the neutral particles is reduced by direct absorption of the microwave energy.On the other hand,due to the lower energy of the electrons,the probability of ionization of the neutral particles by collision with the electrons is greatly reduced.Comparing figures 3(a) and (b), it is known that a high plasma density corresponds to a high electron temperature,which indicates that the increase in electron temperature is mainly due to inelastic collisions between electrons and heavy particles.In addition,it can be seen that both electron density and electron temperature decay along the radial direction, but the attenuation amplitude of electron temperature is much larger than that of electron density.Its deeper physical mechanism can be explained as follows: as the gas around the quartz tube discharges by absorbing microwave energy, the microwave energy decays exponentially owing to being absorbed and consumed along the normal direction.Therefore, when the gas molecules are close to the quartz tube,they will absorb more microwave energy, so that the ionization degree, the electron energy, as well as the probability of secondary ionization through electron collision are high, thus resulting in higher electron density and temperature.On the contrary,when the gas molecules are away from the quartz tube,they will maintain the discharge mainly by ionization through collision with the electrons.Therefore, the ionization degree of electrons with less energy will be relatively low, resulting in lower electron density and temperature.Figure 3(c) shows the temperature distribution of gas inside the chamber.Such distribution in the chamber is far more uniform than the electron temperature, with a maximum value of about 650 K, which is consistent with the actual PECVD process temperature range.

To quantify the variation of plasma homogeneity, the monitoring line is selected asr= 40 mm, introducing the relative deviation:

nedenotes the plasma density at the point of measurement,andis the average plasma density on the monitoring line.Figure 4 presents the corresponding results, and it can be seen that the relative deviation of the plasma density ranges from−90%to 13.8%,which is unacceptable for the PECVD process.

3.1.Limitations on microwave power

The relationship between microwave power and plasma homogeneity is shown in figure 5.As shown in figures 5(a)and(b), along with the increase in microwave power, the plasma keeps extending from the two sides of the device to the intermediate region, and the density and uniformity of the plasma also keep increasing.It means that increasing microwave power is beneficial for plasma homogeneity, which is consistent with our experience.According to the work of Chenet al[32], the generation and propagation of the plasma in linear microwave plasma source mainly depend on the interaction of the penetration part,transmission part and absorption part of the microwave electromagnetic field.Therefore,higher microwave power generates higher electron density, making the reflectivity of the electromagnetic field of plasma higher.That is to say,the plasma behaves more like a metal,allowing greater fractions of the microwave energy to propagate along the quartz tube surface.Consequently, increasing the microwave power can significantly improve the plasma uniformity.Figure 5(c) presents the average density of the plasma and relative deviation at different microwave powers.It is evident that with the increase in microwave power,the average plasma density is almost proportional to the microwave power,and the range of relative deviation of the plasma is also significantly narrowed.Plasma homogeneity is optimal when the microwave power increases to 2200 W, with a relative deviation of−10.2% to 6.1%.However, due to the limitations of the microwave generator, the microwave power can only be increased to 2000 W at most.In this case,the relative deviation of plasma density is −23.1% to 11.9%, which is unable to satisfy the process requirements of the in-line PECVD device.

3.2.Influence of chamber pressure

Figures 6(a)and(b)illustrate the plasma distribution both in the chamber and at the monitoring line under different chamber pressures, respectively.The simulation results for a chamber pressure of 25 Pa have been shown in figure 3(a), so they are omitted in figure 6(a)to avoid repetition.It can be found that as the chamber pressure reduces from 25 to 15 Pa, the plasma becomes more uniform in the axial direction while becoming more concentrated in the radial direction.When the chamber pressure is increased to 30 Pa, the plasma homogeneity will decrease.Thus,reducing the chamber pressure helps to generate a more uniform plasma,but results in a lower plasma density.It can be explained by the fact that due to the decrease in pressure,the collision frequency between electron–neutral particles decreases.On one hand,the loss of energy caused by collisions also decreases, which is beneficial for electron diffusion, leading to excellent uniformity.On the other hand, the number of emerging electrons caused by collisions decreases,resulting in a lower plasma density.Due to the limitations of the vacuum pump, the chamber pressure could not be reduced less than 15 Pa.Corresponding relative deviation of the plasma density is calculated to be within −11.3% to 8.2%.

Figure 5.Plasma density distribution (a) in the chamber and (b) at the monitoring line, (c) average plasma density and relative deviation under different microwave powers.

Figure 6.Plasma density distribution (a) in the chamber and (b) at the monitoring line under different pressures.

3.3.Effects of magnetic flux density

Figure 7.Plasma density distribution (a) in the chamber and (b) at the monitoring line at different magnetic field strengths.

Table 2.Average plasma density and relative deviation for different conditions.

In this section,we turn our attention to the effect of magnetic flux density on the uniformity of the plasma generated by the linear microwave plasma source.The magnetic flux density varies from 15 to 60 mT.Figures 7(a) and (b) show the corresponding changes in plasma distribution for different magnetic flux densities inside the chamber and at the monitoring line.As shown in figure 7(a), when the magnetic flux density is 15 mT, the plasma density is concentrated at the two sides of the chamber.When the magnetic flux density is adjusted to 45 mT, the plasma distribution in the chamber becomes more uniform,and the plasma density in the middle region increases significantly at the same time.But when the magnetic flux density continues to be increased to 60 mT,the plasma distribution will show a tendency to extend to the two sides again.As shown in figure 7(b),the plasma density raises along with the increasing of magnetic flux density, because higher magnetic flux density can reduce the complexation of charged particles at the walls.Increasing the magnetic flux density appropriately contributes to improving plasma uniformity, but excessive magnetic flux density leads to poor uniformity instead.It may be due to the fact that electromagnetic waves gradually attenuate as they are propagated in the axial direction.But an appropriately higher magnetic flux density helps to suppress the decay of electromagnetic waves,which means that the electromagnetic waves can travel further in the axial direction.As a result, increasing the magnetic field appropriately can improve the plasma uniformity to some extent, and 45 mT is the best choice.In this case, the relative deviation of plasma is within −14.2% to 16.3%.

By the analysis above, after optimizing the microwave power, chamber pressure, and magnetic flux density, respectively, the properties of plasma are given in table 2.According to the data in table 2, it is shown that higher microwave power, lower chamber pressure, and relatively higher magnetic field all have positive effects on improving plasma uniformity.Among them,the microwave power has a prominent enhancement on plasma uniformity.It is because the microwave power directly affects the transport of microwaves in the plasma, which determines the characteristics of the plasma.It is also found that only optimizing one parameter cannot make plasma homogeneity satisfy the process requirements of the in-line PECVD device.

3.4.Optimal parameter recipe and wafer position

In this section, the variation of plasma homogeneity for different parameter combinations is discussed to explore the optimal parameter recipe.It should be noted that the adjustments of parameter are based on previously standard parametric recipe (i.e.microwave power is set at 1800 W,chamber pressure at 25 Pa, and magnetic flux density at 30 mT),the results are shown in figures 8(a)–(d).First of all,as described in section 3.1,the microwave power is increased up to 2000 W, and the corresponding plasma density distribution is plotted in figure 8(a).It is shown that the plasma density in the intermediate region is significantly lower than the average,with relative deviations ranging from −23.1%to 11.9%, which indicates that increasing the microwave power to 2000 W is inadequate to sustain the energy attenuation during microwave transmission over a length of up to 1550 mm.However,in figure 8(b),after decreasing the chamber pressure to 15 Pa, the plasma homogeneity improved dramatically, especially in the intermediate region where the plasma density is higher than the average.The relative deviation of plasma density ranges from −4.2% to 6.1%.

Figure 8.Plasma density distribution and relative deviation when parameters are adjusted to (a) microwave power 2000 W, (b) microwave power 2000 W and chamber pressure 15 Pa,(c)microwave power 2000 W and chamber pressure 15 Pa and magnetic flux density 45 mT,(d)chamber pressure 15 Pa and magnetic flux density 45 mT.

On the basis of figures 8(b), (c) presents the plasma density distribution when the magnetic flux density is adjusted to 45 mT.It can be seen that the plasma density is distributed very evenly, the plasma density at two sides of the device is slightly higher than that in the intermediate region.The relative deviation is in the range of −3.7% to 3.9%, which fully satisfies the requirements of process uniformity of in-line PECVD devices (±4%).By the way,the average plasma density is the highest in this case.When the microwave power is fixed, if the chamber pressure is adjusted to 15 Pa and the magnetic flux density to 45 mT,the corresponding distribution of plasma density is shown in figure 8(d).The plasma density relative deviation is within −7% to 8%.Consequently, the optimal parameter recipe is to change the microwave power to 2000 W, the chamber pressure to 15 Pa,and the magnetic flux density to 45 mT simultaneously.

The position of the wafer in the in-line PECVD device is crucial for the film quality.If the wafers are too close to the linear microwave plasma source, massive charged ion bombardment will damage the film quality.But if they are placed too far away, the lower density of excited state atoms would lead to a lower film deposition rate.Therefore, the best process position for silicon wafers should be where the value of the density of excited state atoms divided by electron density is maximized.Figure 9 shows the distribution of electron density and excited state atoms density atz= 800 mm under the optimal parameter recipe.It can be seen from figure 9 that the valuenwArs/neis maximized atr= 88 mm.It means that when the wafer is 88 mm away from the copper antenna, a proper balance between deposition rate and film quality can be achieved.

Figure 9.Distribution of electron density and excited state atom density under the optimal parameter recipe (at z = 800 mm).

4.Conclusion

Enlarging the length of the linear microwave plasma source in the in-line PECVD from 1340 to 1550 mm could increase production capacity by 17%.Based on the COMSOL Multiphysics, a numerical model of coupling microwave fields,magnetic fields, plasma fields as well as thermal fields has been developed and validated.Optimization of the plasma uniformity is achieved by adjusting the microwave power,chamber pressure, and magnetic flux density.The main findings and conclusions are summarized as follows:

(1) Under the standard parameter recipe,increasing the length of the linear microwave plasma source to 1550 mm results in a dramatic decrease in plasma homogeneity with a relative deviation within −90% to 13.8%, which is unacceptable for the PECVD process.Either increasing the microwave power or decreasing the chamber pressure contributes to the homogeneity of the plasma generated by the linear microwave plasma source.An appropriate increase in the magnetic flux density facilitates homogeneous plasma generation, but excessive magnetic flux density will have negative influence on the plasma homogeneity.Among them, the microwave power is the most decisive factor.

(2) For the linear microwave plasma source with a length of 1550 mm, plasma homogeneity is optimal when simultaneously adjusting the microwave power to 2000 W, the chamber pressure to 15 Pa,and the magnetic flux density to 45 mT,and the relative deviation of the plasma density is within −3.7%to 3.9%,which fully satisfies the process uniformity requirements of the in-line PECVD device.

(3) Under the optimal parameter recipe, the optimum position of the wafer is 88 mm from the copper antenna.

Acknowledgments

This work was funded by Hunan Provincial Science and Technology Department ‘Key Field Research and Development Project’(No.2019WK2011).We thank B X Zhao,Y Z Lu,H B Zhou and H Yi for discussions and experimental and technical assistance.

猜你喜欢

杂志排行

Plasma Science and Technology的其它文章

- Effect of edge turbulent transport on scrapeoff layer width on HL-2A tokamak

- Spatio-temporal evolution characteristics and pattern formation of a gas–liquid interfacial AC current argon discharge plasma with a deionized water electrode

- Turbulent boundary layer control with a spanwise array of DBD plasma actuators

- Plasma activation towards oxidized nanocarbons for efficient electrochemical synthesis of hydrogen peroxide

- Spatio-temporal evaluation of Zr plasma parameters in a single-beam-splitting double-pulse laser-induced plasma

- Enhanced electrocatalytic activity of carbon cloth by synergetic effect of plasma and acid treatment