Changes in the Composition of Volatiles Emitted from Newhall Nucellar Navel Oranges (Citrus Sinensis (L.) Osbeck)During Anaerobic Storage

2016-03-19YANGGengZHANGYujieLIUShuluYUYuegang

YANG Geng, ZHANG Yu-jie, LIU Shu-lu, YU Yue-gang

(College of Environmental Sciences and Engineering, Anhui Normal University, Wuhu 241003, China)

Changes in the Composition of Volatiles Emitted from Newhall Nucellar Navel Oranges (Citrus Sinensis (L.) Osbeck)During Anaerobic Storage

YANG Geng,ZHANG Yu-jie,LIU Shu-lu,YU Yue-gang

(College of Environmental Sciences and Engineering, Anhui Normal University, Wuhu 241003, China)

Clssification No: TS207.3Document Code: APaper No:1001-2443(2016)04-0364-07

Newhall nucellar navel oranges (Citrus sinensis (L.) Osbeck) originating as a limb sport of Washington navel oranges are native to USA and now widely planted in middle part of China. The fruit of Newhall is oval-shaped, 6.48-7.18cm in long and 6.65-7.71cm in diameter, and it weights approximately from 250 to 350 g for each orange, containing 15.5% for soluble solids, 85-105g L-1for sugars, 10-11g L-1for titratable acids and 0.47-0.64g L-1for vitamin C, respectively[1].

Newhall nucellar navel oranges are the most popular navel orange cultivar in China because of their bright color, rich nutrition, sweet flavor and pleasant smelling. The attractive and pleasant flavor of citrus fruit is attributed to a combination of alcohols, aldehydes, ketones, esters, hydrocarbon terpenes, sulfur volatiles and so on in specific proportions[2-4]. For Newhall nucellar navel oranges, forty-two volaitle organic compounds including twenty-seven oxygenated volatiles, thirteen terpene hydrocarbons and three sulfides were identified and quantified in the gases from their fresh fruit in previous studies[5].

During their commercial packing and storage, citrus fruit not excepting Newhall nucellar navel oranges are usually exposed under various anaerobic conditions such as storing in modified or controlled atmospheres, coating with waxes or films, packing in plastic liners and holding in containers or trailers[6,7,4]. These anaerobic or anoxia storage and handing process can inhibit deterioration development of fruit, but anaerobic metabolism is induced, leading to decreases in aroma-active volatiles and accumulation of off-flavor volatiles such as ethanol, acetaldehyde and ethyl acetate[8,9,6,4]. The composition changes of volatiles from citrus fruit could lead to an altered balance of orange aroma away from what is considered “fresh” or desirable and thus becoming “rotten”[2-4]. Thus, measurement of the composition changes of volatiles from citrus fruit based on relative percentage may serve reliable and convenient information for quality evaluation.

Fresh Newhall nucellar navel oranges maintain their external and internal quality in regular atmospheres for only 2-3 weeks after harvest, and thus anaerobic or anoxia storage is often needed when they are to be kept for longer than 3 weeks after harvest. Consequently, in this study Newhall nucellar navel oranges were incubated under N2 atmospheres to stimulate anaerobic respiration in laboratory, and the relative compositional changes of volatiles and the possible artifacts of Newhall nucellar navel oranges were investigated during storage under anaerobic conditions for a period of 90 days.

1 Materials and Methods

1.1Materials and chemicals

Fresh ripe Newhall nucellar navel oranges (Citrus sinensis (L.) Osbeck) were obtained from a commercial orchard in the city of Ganzhou in China in November 2012. Fruits at ripe stage were classified as those possessing totally orange-yellow color. Fruits were carefully selected for uniformity size, color, and absence of physical damage, and were randomly divided into three groups for the anaerobic treatment.

All volatiles listed in Table 1 were purchased from Sigma-Aldrich Inc. (Saint Louis, MO, USA) and were of analytical grade.

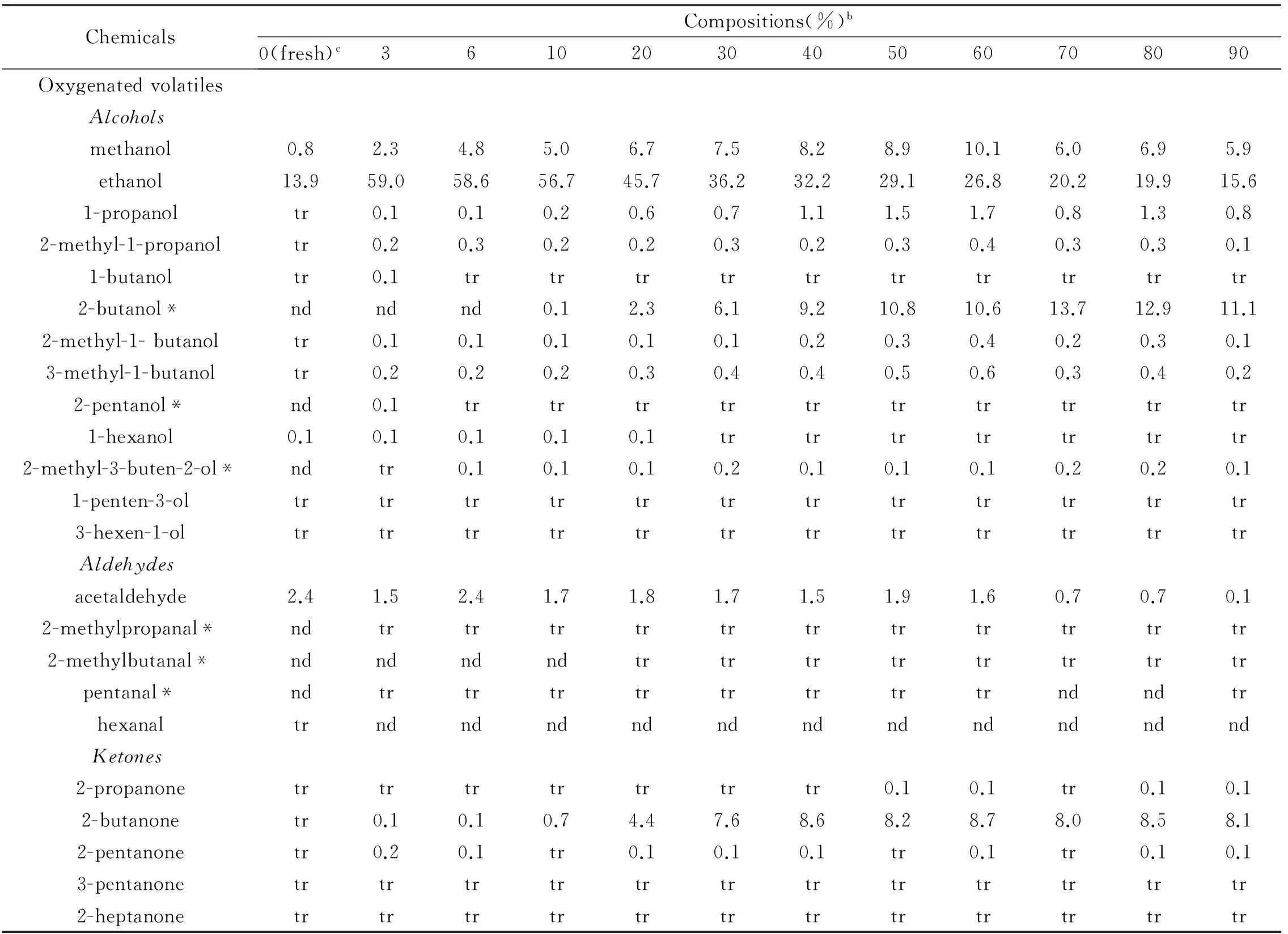

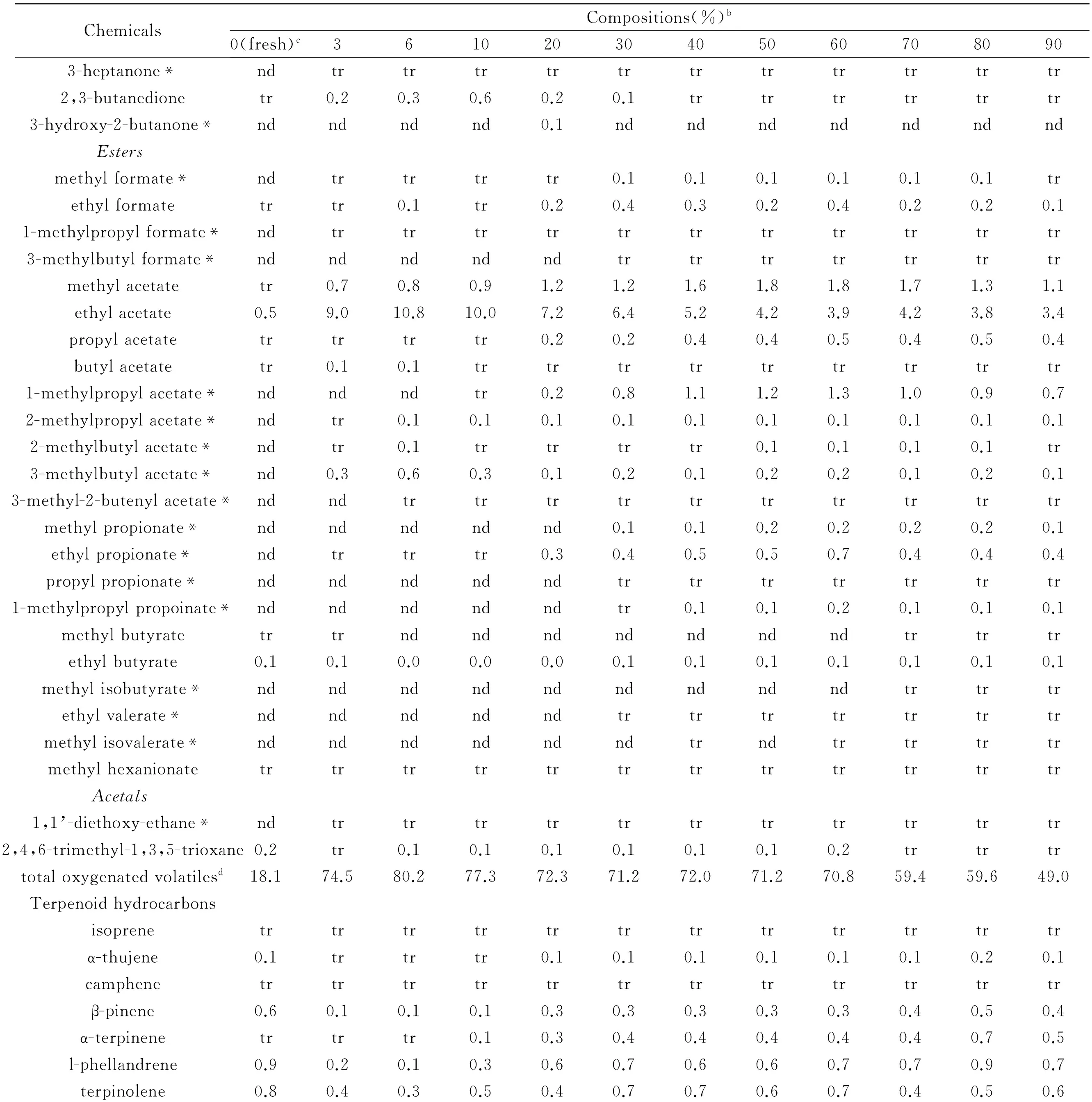

Table 1 Compositional changes of volatiles emitted from Newhall nucellar navel oranges during the anaerobic storagea

续表1

ChemicalsCompositions(%)b0(fresh)c361020304050607080903-heptanone*ndtrtrtrtrtrtrtrtrtrtrtr2,3-butanedionetr0.20.30.60.20.1trtrtrtrtrtr3-hydroxy-2-butanone*ndndndnd0.1ndndndndndndndEstersmethylformate*ndtrtrtrtr0.10.10.10.10.10.1trethylformatetrtr0.1tr0.20.40.30.20.40.20.20.11-methylpropylformate*ndtrtrtrtrtrtrtrtrtrtrtr3-methylbutylformate*ndndndndndtrtrtrtrtrtrtrmethylacetatetr0.70.80.91.21.21.61.81.81.71.31.1ethylacetate0.59.010.810.07.26.45.24.23.94.23.83.4propylacetatetrtrtrtr0.20.20.40.40.50.40.50.4butylacetatetr0.10.1trtrtrtrtrtrtrtrtr1-methylpropylacetate*ndndndtr0.20.81.11.21.31.00.90.72-methylpropylacetate*ndtr0.10.10.10.10.10.10.10.10.10.12-methylbutylacetate*ndtr0.1trtrtrtr0.10.10.10.1tr3-methylbutylacetate*nd0.30.60.30.10.20.10.20.20.10.20.13-methyl-2-butenylacetate*ndndtrtrtrtrtrtrtrtrtrtrmethylpropionate*ndndndndnd0.10.10.20.20.20.20.1ethylpropionate*ndtrtrtr0.30.40.50.50.70.40.40.4propylpropionate*ndndndndndtrtrtrtrtrtrtr1-methylpropylpropoinate*ndndndndndtr0.10.10.20.10.10.1methylbutyratetrtrndndndndndndndtrtrtrethylbutyrate0.10.10.00.00.00.10.10.10.10.10.10.1methylisobutyrate*ndndndndndndndndndtrtrtrethylvalerate*ndndndndndtrtrtrtrtrtrtrmethylisovalerate*ndndndndndndtrndtrtrtrtrmethylhexanionatetrtrtrtrtrtrtrtrtrtrtrtrAcetals1,1’-diethoxy-ethane*ndtrtrtrtrtrtrtrtrtrtrtr2,4,6-trimethyl-1,3,5-trioxane0.2tr0.10.10.10.10.10.10.2trtrtrtotaloxygenatedvolatilesd18.174.580.277.372.371.272.071.270.859.459.649.0Terpenoidhydrocarbonsisoprenetrtrtrtrtrtrtrtrtrtrtrtrα-thujene0.1trtrtr0.10.10.10.10.10.10.20.1camphenetrtrtrtrtrtrtrtrtrtrtrtrβ-pinene0.60.10.10.10.30.30.30.30.30.40.50.4α-terpinenetrtrtr0.10.30.40.40.40.40.40.70.5l-phellandrene0.90.20.10.30.60.70.60.60.70.70.90.7terpinolene0.80.40.30.50.40.70.70.60.70.40.50.6

aTable includes all identified chemicals and percentages add to 100% for each sample.bMean percentage of individual volatile constituents from triplicate experiments.cDays of incubation.dSum of alcohols, aldehydes, ketones, esters and acetals.*Artifact volatiles. nd, not detected. tr, trace (<0.05%).

1.2Anaerobic treatment

For laboratory simulation study, about 2 kg fresh shredded Newhall nucellar navel oranges were weighed and placed in glass reactors with a volume of approximately 8 L. Treatments were tested in triplicate and incubated at room temperature (25±0.5℃) for 90 days. Pure N2gas was maintained between 40-60mL min-1per reactor, which was identified in preliminary work as sufficient to ensure that the O2containers were less than 0.5% for the anaerobic storage. When sampling, 1L Teflon sampling bags (SKC Inc., USA) was used to collect gas from the air outlet of each reactor. Volatile measurements were performed on days 0, 3, 6, 10, 20, 30, 40, 50, 60, 70, 80 and 90 during the incubation.

1.3Volatiles analysis

Volatiles were analyzed by an Entech Model 7100 Preconcentrator (Entech Instruments Inc., CA, USA) coupled with a gas chromatography/mass spectrum (GC/MS, Agilent 5973N). Detailed analysis steps were described elsewhere[10].

1.4Statistical Analysis

Statistical analysis was performed using SPSS 10.0 for Windows. A one-way ANOVA was performed to test the significant variance between the samples. A post hoc examination was conducted to test the significance using the LSD test. The significance level was set as p<0.05.

2 Results and Discussion

2.1General

Fig.1 Typical chromatograms showing selected volatiles from fresh Newhall nucellar navel oranges at day 0 when fresh(A) and at day 50(B).

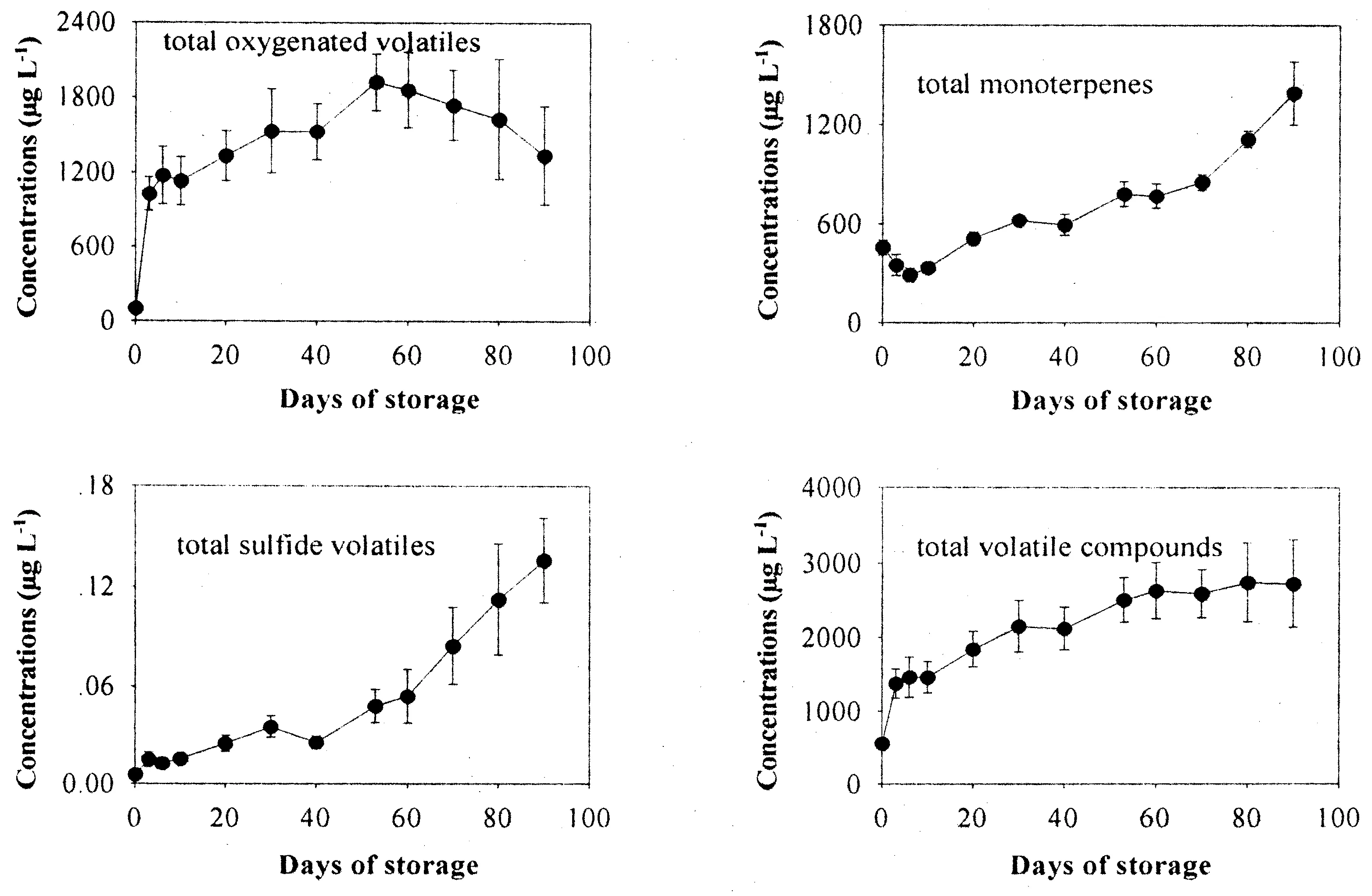

As presented in Fig.1, differences between the chromatogram of the fresh oranges and that of the oranges at day 50 were noticeable. Several new peaks of artifact compounds occurred at day 50. The peak identities and their relative percentages, and the artifacts identified, are listed in Table 1 according to functional classes. In total, sixty-seven volatiles were identified, among which twenty-four volatile chemicals were absent in gases of fresh Newhall nucellar navel oranges and occurred as artifacts in the following storage process, consisting of 3 alcohols(2-butanol, 2-pentanol and 2-methyl-3-buten-2-ol), 3 aldehydes(2-methypropanal, 2-methylbutanal and pentanal), 2 ketones(3-heptanone and 3-hydroxy-2-butanone), 15 esters(methyl formate, 1-methylpropyl formate, 3-methylbutyl formate, 1-methylpropyl acetate, 2-methylpropyl acetate, 2-methylbutyl acetate, 3-methylbutyl acetate, 3-methyl-2-butenyl acetate, methyl propionate, ethyl propionate, propyl propionate, 1-methylpropyl propionate, methyl isobutyrate, ethyl valerate and methyl isovalerate) and 1 acetals (1,1’-diethoxy-ethane) (Table 1 and Fig.1(B)). The concentration of total volatile chemicals gradually rose up to 2729.1μg L-1upon 90 days of storage, approximately 5 times higher than that at day 0(558.8 μg L-1)(Fig.2), and the percentage of total artifact volatiles increased with storage time and attained the peak at day 70, sharing 15.9% of total volatile chemicals released (Table 1). For volatile groups or individual volatile chemicals, their compositions changed significantly during the anaerobic storage of Newhall nucellar navel oranges.

The numbered peaks indicate compounds: 1 acetaldehyde; 2 methanol; 3 ethanol; 4 methyl acetate; 5 2-propanol; 6 2-methyl-propanal; 7 1-propanol; 8 2-butanone; 9 ethyl acetate; 10 2-butanol; 11 2-methyl-1-propanol; 12 2-methyl-butanal; 13 1-butanol; 14 ethyl propionate; 15 propyl acetate;16 3-methyl-1-butanol; 17 2-methyl-1-butanol; 18 1-methylpropyl acetate; 19 2-methylpropyl acetate; 20 2-methyl-3-buten-2-ol; 21 2,4,6-trimethyl-1,3,5-trioxane; 22 ethyl butyrate; 23 butyl acetate; 24 3-hexen-1-ol; 25 1-hexanol; 26 3-methylbutyl acetate; 27 2-methylbutyl acetate; 28 α-thujene; 29 α-pinene; 30 camphene; 31 sabinene; 32 β-pinene; 33 β-myrcene; 34 l-phellandrene; 35 Δ-3-carene; 36 α-terpinene; 37 limonene; 38 γ-terpinene; 39 terpinolene.

Fig.2 Concentrations of three volatile groups and total volatile compounds released from Newhall nucellar navel oranges during the anaerobic storage. Error bars represent the standard deviation

2.2Change in oxygenated volatiles

Fifty-one oxygenated volatiles were determined during the anaerobic storage of Newhall nucellar navel oranges(Table 1), and the concentration of total oxygenated volatiles increased rapidly to attain the maximum(1924.2μg L-1) at day 50, about 18 times higher than that at day 0(101.7 μg L-1)(Fig.2). Methanol, ethanol, 2-butanol, acetaldehyde, 2-butanone and ethyl acetate dominated and were the most important oxygenated volatiles. For the total oxygenated volatiles or major oxygenated compounds except acetaldehyde, their relative percentages showed a significant increasing trend during the anaerobic incubation. The relative percentage of total oxygenated volatiles increase from 18.1% to 49.0% upon 90 days of anaerobic storage, attaining the maximum (80.2%) at day 6. Also, oxygenated compounds were the most predominant function group after 3 days, although they were less than terpenes to some extent again after 90 days. The observably growing oxygenated volatiles were methanol (from 0.8% to 5.9%), ethanol (from 13.9% to 15.6%), 2-butanol (from 0.0% to 11.1%), 2-butanone (from>0.05% to 8.1%) and ethyl acetate (from 0.5% to 3.4%). Particular for ethanol, its ratio reached the peak (59.0%) at day 3 and it became the first abundant volatile chemicals. 2-Butanol and ethyl acetate were the third abundant volatile chemicals at day 40 and at day 3, respectively. For acetaldehyde, it decreased steadily to 0.1% at day 90, but its concentration actually increased and reached a peak at day 50 during the anaerobic storage.

The relative changes of the oxygenated compounds from Newhall nucellar navel oranges on the anaerobic storage were in accordance with reports on commercial packing and storage of navel oranges[7]. The considerable enhancements of the oxygenated compounds could be related to secondary metabolites of orange substrates from biochemical reaction caused by enzymes[11]or microorganisms[12,13]. The production of alcohols, aldehydes, ketones and esters from fruit under anoxic or anaerobic conditions had been reported[9,6]. For example, methanol, ethanol, acetaldehyde and ethyl acetate as anaerobic metabolites were reported to be strongly accumulated in fruit such as mandarin[14], grapefruit[14]and pear[15]on storage under conditions favoring anaerobiosis. As well known, ethanol as major component of wines is produced from anaerobic fermentation of substrates, and its biosynthesis in fruit such as apples enhanced at greater rate under hypoxic or anoxic storage conditions[9]. 2-Butanol as undirable constituent was found in spirits of grape pomace, which fermented under anaerobic conditions[16]. 2-Butanone had been reported in gases purged and trapped from cherry fruit homogenates after storage under controlled atmosphere (anoxic condition)[8]. The production of esters in fruit could be attributed to esterification of various alcohol moieties and acetyl CoA[9]. Actually, a good correlation were between total alcohols and total esters (r=0.77,p<0.01), particularly between ethanol and ethyl acetate (r=0.90,p<0.01). As also reported by[8], qualitative and quantitative changes in ester production, particularly ethyl acetate, were coincident with the accumulation of ethanol. Acetals were usually produced during the anaerobic fermentation of fruit and grain. For example, 1,1’-diethoxy-ethane was present in grape wine[17]and Chinese ‘Yanghe Daqu’ liquor, which was made from the anaerobic fermentation of grains[18].

2.3Change in isoprene and monoterpenes

As shown in Table 1, isoprene was merely a trivial constituent detected in emitted volatiles and was under 0.05% during the whole anaerobic storage. β-Myrcene, sabinene, α-pinene and Δ-3-carene were the major monoterpenes in addition to limonene during the anaerobic storage of Newhall nucellar navel oranges. During the early 6 days, the concentration of total monoterpenes decreased sharply from 457.1μg L-1to 288.6μg L-1(Fig.2). Also, the relative percentages of total monoterpenes decreased abruptly from 81.9% to 19.8%, as much loss of limonene (from 54.9% to 15.8%), β-myrcene (from 10.8% to 1.8%), sabinene (from 6.6% to 0.8%), α-pinene (from 5.0% to 0.4%) and Δ-3-carene (from 2.0% to 0.3%). Some slight dropping also occurred for α-thujene (from 0.1% to <0.05%), β-pinene (from 0.6% to 0.1%), l-phellandrene (from 0.9% to 0.1%) and terpinolene (from 0.8% to 0.3%). The decrease of monoterpene hydrocarbons from Newhall nucellar navel oranges during the early stage was in accordance with reports on storage of some citrus fruit oil such as Yuzu[19], and Daidai[20]. The monoterpene hydrocarbons can be lost through chemical process and/or physical process. Chemical degradation such as polymerization, oxidation and rearrangement of monoterpene was reported by[19]. For example, limonene could be oxidized to cis- and trans-limonene oxides as artifacts in the citrus fruit oil[12]and also be cyclized to camphene, α-pinene and β-pinene as previously noted[21]. Mycrene could be cyclized to γ-terpinene, α-terpinene, limonene and terpinolene[21]. This process would imply an increase of some monterpenes such as α-pinene and β-pinene and terpinolene, which was inconsistent with the data in this study. For this reason, we assume that this process can be neglible for the loss of monoterpenes. Physical evaporation of inherited constituents could be mainly responsible for the observed relative decrease of monnoterpnes. Oranges as a pool of monoterpenes were shredded before incubation, making these compounds not to be locked in clumps but volatilize rapidly due to increased surface area. For camphene, α-terpinene and γ-terpinene, their percentages were merely trivial and kept steady during the early 6 days of anaerobic incubation, but their concentrations had a decreasing trend.

After the early 6 days of incubation, the concentration of total terpenes increased progressively to reach the peak upon 90 days (1391.9μg L-1), about three times higher than that at day 0 (457.1μg L-1) (Fig.2). The relative percentages of total monoterpenes and all monoterpene hydrocarbons except camphene also grew steadily until the end of the experiment. Monoterpenes shared 51.0% of total volatiles released and became the prevailed class upon 90 day again. The preminently enhanced monoterpenes were limonene (from 15.8% to 36.0%), β-myrcene (from 1.8% to 6.6%), α-pinene (from 0.4% to 2.9%) and Δ-3-carene (from 0.3% to 1.4%). Some slight growing also occurred for α-thujene (from <0.05% to 0.1%), β-pinene (from 0.1% to 0.4%), l-phellandrene (from 0.1 to 0.7%), α-terpinene (from <0.05 to 0.5%), γ-terpinene (from 0.2% to 0.8%), terpinolene (from 0.3% to 0.6%) and sabinene (from 0.8% to 1.0%). For camphene, its percentage still kept trivial and steady. The results indicated that monoterpenes emitted after 6 days were mainly secondary production, most probably the microbial degradation of pectin, which had high contents in oranges and would emit a high rate of monoterpenes when biologically metabolized.

References:

[1]CHEN J. Newhall Navel Oranges[M]. Beijing: Jindun Press. (In Chinese). 2006:1-12.

[2]BRAT P, REGA B, ALTER P, REYNES M, BRILLOUET J-M. Distribution of volatile compounds in the pulp, cloud, and serum of freshly squeezed orange juice[J]. Journal of Agricultural & Food Chemistry, 2003,51:3442-3447.

[3]ROUSEFF R L, PEREZ-CACHO P R, JABALPURWALA F. Historical review of citrus flavor research during the past 100 years[J]. Journal of Agricultural & Food Chemistry, 2009,57:8115-8124.

[4]TIETEL Z, PLOTTO A, FALLIK E, LEWINSOHN E, PORAT R. Taste and aroma of fresh and stored mandarins[J]. Journal of the Science of Food and Agriculture, 2011,91:14-23.

[5]WANG X M, WU T. Chemical composition analysis of volatile components in Newhall navel oranges[J]. Food Science, 2013,34(06),160-163.(In Chinese)

[6]PESIS E. The role of the anaerobic metabolites, acetaldehyde and ethanol, in fruit ripening, enhancement of fruit quality and fruit deterioration[J]. Postharvest Biology and Technology, 2015,37:1-19.

[7]OBENLAND D, COLLIN S, SIEVERT J, et al. Commercial packing and storage of navel oranges alters aroma volatiles and reduces flavor quality[J]. Postharvest Biology and Technology, 2008,47:159-167.

[8]MATTHEIS J P, BUCHANAN D A, FELLMAN J K. Volatile constituents of Bing sweet cherry fruit following controlled atmosphere storage[J]. Journal of Agricultural & Food Chemistry, 1997,45:212-216.

[9]RUDELL D R, MATTINSON D S, MATTHEIS J P, et al. Investigations of aroma volatile biosynthesis under anoxic conditions and in different tissues of “Redchief Delicious” apple fruit (Malus domestica Borkh.). Journal of Agricultural & Food Chemistry, 2002,50:2627-2632.

[10]WANG X M, WU T. Release of isoprene and monoterpenes during the aerobic decomposition of orange wastes from laboratory incubation experiments[J]. Environmental Science & Technology, 2008,42:3265-3270.

[11]PETERSON D, REINECCIUS G A. Biological Pathways for the Formation of Oxygen-Containg Aroma Compounds[M]//In: Reineccius G A, Reineccius T A. Eds., Heteroatomic Aroma Compounds Washington: American Chemical Society, 2002:227-242.

[12]PEREZ-CACHO P R, ROUSEFF R L. Fresh squeezed orange juice odor: A Review[J]. Critical Reviews in Food Science and Nutrition, 2008,48:681-695.

[13]ARREBOLA E, SIVAKUMAR D, KORSTEN L. Effect of volatile compounds produced by Bacillus strains on postharvest decay in citrus[J]. Biological Control, 2010,53:122-128.

[14]SHI J X, PORAT R, GOREN R, GOLDSCHMIDT E E. Physiological responses of ‘Murcott’mandarins and ‘Star Ruby’ grapefruit to anaerobic stress conditions and their relation to fruit taste, quality and emission of off-flavor volatiles[J]. Postharvest Biology and Technology, 2005,38:99-105.

[15]MATTHEIS J P, RUDELL D. Responses of ‘d’Anjou’ pear (Pyrus communis L.) fruit to storage at low oxygen setpoints determined by monitoring fruit chlorophyll fluorescence[J]. Postharvest Biology and Technology, 2011,60:125-129.

[16]SILVA M L, MALCATA F X. Relationships between storage conditions of grape pomace and volatile composition of spirits obtained therefrom[J]. American Journal of Enology and Viticulture, 1998,49:56-63.

[17]LEE S-J, NOBLE A C. Characterization of odor-active compounds in californian chardonnay wines using GC-olfactometry and GC-mass spectrometry[J]. Journal of Agricultural & Food Chemistry, 2003,51:8036-8044.

[18]FAN W L, QIAN M C. Identification of aroma compounds in Chinese ‘Yanghe Daqu’ liquor by normal phase chromatography fractionation followed by gas chromatography/olfactometry[J]. Flavour and Fragrance Journal, 2006,21:333-342.

[19]NJOROGE S M, UKEDA H, SAWAMURA M. Changes in the volatile composition of Yuzu (Citrus junos Tanaka) cold-pressed oil during storage[J]. Journal of Agricultural & Food Chemistry, 1996,44:550-556.

[20]NJOROGE S M, UKEDA H, SAWAMURA M. Changes of the volatile profile and artifact formation in Daidai (Citrus aurantium) cold-pressed peel oil on storage[J]. Journal of Agricultural & Food Chemistry, 2003,51:4029-4035.

[21]DIECKMANN R H, PALAMAND S R. Autoxidation of some constituents of hops. I. The monoterpene hydrocarbon, myrcene[J]. Journal of Agricultural & Food Chemistry, 1974,22:498-503.

date:2015-10-21

Sponsored by National Natural Science Foundation of China(41273095 and 41103067).

The composition of volatiles emitted from Newhall nucellar navel oranges were investigated during laboratory-controlled anaerobic storage for a period of 90 days, using preconcentrator coupled with gas chromatography-mass spectrum (GC-MS). Major relative changes occurred for oxygenated volatiles and monoterpene hydrocarbons, while no observable changes were found for sulfides. Before storage, terpenoid hydrocarbons and oxygenated volatiles dominated, with the most abundance of limonene, ethanol, β-myrcene, sabinene, α-pinene, acetaldehyde and Δ-3-carene. During the early 6 days of storage, terpenoid hydrocarbons decreased sharply as much loss of limonene, β-myrcene, sabinene, α-pinene and Δ-3-carene, while oxygenated volatiles increased abruptly and became the first predominant class, with observable growing of methanol, ethanol and ethyl acetate. After 6 days of storage, terpenoid hydrocarbons rose up progressively with storage time, whereas oxygenated volatiles dropped down gradually until the end of the experiment. It is worth noting that twenty-four oxygenated volatiles as artifacts were formed, with predominance of 2-butanol and methyl acetate.

volatiles; compositions; newhall nucellar navel oranges; anaerobic storage

纽荷尔脐橙(Citrus sinensis (L.) Osbeck)厌氧保存过程中挥发性风味物质组成变化

杨耿,张玉洁,刘书路,于越刚

(安徽师范大学 环境科学与工程学院,安徽 芜湖241003)

采用预浓缩系统与气相色谱质谱联用技术分析检测纽荷尔脐橙在实验室控制厌氧条件下保存90天过程中释放出来的挥发性风味物质组成变化.结果表明,纽荷尔脐橙厌氧保存过程中含氧化合物和萜烯化合物两类挥发性风味物质组成比例变化明显,含硫化合物变化不明显.在尚未保存前,纽荷尔脐橙释放出来的挥发性风味物质主要是含氧化合物和萜烯化合物两类化合物,其中柠檬烯、乙醇、β-月桂烯、桧烯、α-蒎烯,乙醛和蒈烯是最主要的成分.在保存的前6天,由于柠檬烯、β-月桂烯、桧烯、α-蒎烯和蒈烯5种化合物大量减少导致萜烯类化合物比例随时间急剧下降,同时由于甲醇、乙醇和乙酸乙酯3种化合物大量增加使得含氧化合物比例随时间急剧升高,成为最主要的挥发性风味物质.在保存6天以后到实验结束,萜烯类化合物比例随时间逐渐增高,而含氧化合物比列随时间逐渐降低.特别值得注意的是纽荷尔脐橙保存过程中有24种含氧化合物是新生成的,其中最主要是2-丁醇和乙酸甲酯.

挥发性风味物质;纽荷尔脐橙;厌氧保存

Author’s brief:YANG Geng(1968-),Female,born in Tongcheng,Anhui Province, senior experimentalist.

引用格式:杨耿,张玉洁,刘书路,等.纽荷尔脐橙(Citrus sinensis (L.) Osbeck)厌氧保存过程中挥发性风味物质组成变化[J].安徽师范大学学报:自然科学版,2016,39(4):364-370.

DOI:10.14182/J.cnki.1001-2443.2016.04.011