Study on Hexagon-enveloping Leaf-stripping Mechanism for Corn Stalk

2015-11-18LiLiqiaoLiChaoLiDonghongWangMoYuKeqiangYangXingZhangQuanchaoWangDefuandHeYuan

Li Li-qiao, Li Chao, Li Dong-hong, Wang Mo, Yu Ke-qiang,, Yang Xing, Zhang Quan-chao, Wang De-fu*, and He Yuan

1College of Engineering, Northeast Agricultural University, Harbin 150030, China

2College of Mechanical Engineering, Heilongjiang Science and Technology University, Harbin 150027, China

3Agricultural Machinery Department of Heilongjiang Province Land Reclamation Jiansanjiang Branch Bureau Honghe Farm, Jiamusi 156332,Heilongjiang, China

Study on Hexagon-enveloping Leaf-stripping Mechanism for Corn Stalk

Li Li-qiao1, Li Chao1, Li Dong-hong1, Wang Mo1, Yu Ke-qiang1,2, Yang Xing1, Zhang Quan-chao1, Wang De-fu1*, and He Yuan3

1College of Engineering, Northeast Agricultural University, Harbin 150030, China

2College of Mechanical Engineering, Heilongjiang Science and Technology University, Harbin 150027, China

3Agricultural Machinery Department of Heilongjiang Province Land Reclamation Jiansanjiang Branch Bureau Honghe Farm, Jiamusi 156332,Heilongjiang, China

In order to deeply study the leaf-stripping principle for corn stalk, the hexagon-enveloping leaf-stripping experimental device was designed. To achieve higher leaf-stripping percent and provide important

for the separation equipment for corn stalk, it is necessary to find out the laws of leaf-stripping of such mechanism and to select the main influencing factors of separation performance from a number of factors. Through the study on hexagon-enveloping leaf-stripping mechanism for corn stalks, the leafstripping principle of such mechanism was more clear, and the optimization of structural and kinematic parameters achieved by the experiment whose influencing factors were the four selected ones (feeding speed, rotary speed of leaf-stripping roll, clearance and included angle between two leaf-stripping plates) could be directly applied to the development of efficient rind-pith or leaf-stripping separation for corn stalks.

hexagon-enveloping, leaf-stripping, corn stalk

Introduction

In China, annual production of corn stalk is about 250 million tons, which is one third of the total annual production of all kinds of stalks (Han et al., 2002). As a valuable renewable resource, corn stalk has been utilized in the field of crop farming, raising livestock,industrial production, etc (Yang et al., 1996; Liu,2003; Cui et al., 2008). But utilization of corn stalk is still at the primary stage, because of the limitation of economic and technological development (Gao et al.,2008).

Corn stalk is mainly composed of leaves, rinds and piths, which are of different chemical compositions and nutrient levels. Pith and leaf can be utilized as livestock fodder, because they are rich in crude protein, crude fat, sugar, etc. And the main component of rind is cellulose and lignin, which can be utilized in the field of paper-making and man-made board (Yang et al., 1995). In general, there are interferences among them, during the process of being utilized as a whole directly, so it is difficult to develop new applications(Wang et al., 2012; Li, 2014). Meanwhile, collecting corn stalk requires huge investment in human resources and transportation cost, for the reason thatcorn stalk is of scattered distribution, fluffy, small bulk density, high proportion of leaf (mass ratios of leaf, rind and pith are about 50%, 35%, and 15%,respectively) and large storage space. Therefore, in order to improve the utilization rate of corn stalks,as well as to promote the sustainable development of agriculture and to increase farmers' income, the way of making the best use of corn stalks became the critical issue of comprehensive utilization of corn stalks and hot spots or difficult problems of the society.

All in all, it is necessary to separate leaves, rinds and piths from corn stalks (Chen et al., 2012; Liu,2011). According to the physiological characteristics of corn stalks, the first question for this should be to solve the separation of stems and leaves of corn stalks.

At present, a number of studies about the separation of stem and leaves of corn stalks have been carried out in China (Sun and Guo, 2001; Gao, 2001; Zhang,2002; Gao et al., 2003; Zhu et al., 2012), such as flatten-rubbed method, and shock-separation method. But there are lots of problems with these methods,for instance, easily broken shock components, great damage to the rind, complicated structure, low productivity or low leaf-stripping percent. Therefore,in order to avoid those problems and to deeply study the leaf-stripping principle for corn stalk, the hexagonenveloping leaf-stripping experimental device was designed. To achieve higher leaf-stripping percent and to provide important references for the separation equipment for corn stalks, it is necessary to find out the laws of leaf-stripping of such mechanism and to select the main influencing factors of separation performance from a number of factors.

Design Idea of Hexagon-enveloping Leaf-stripping

Corn is a C4 plant, and the photosynthetic efficiency of it is higher than that of C3 plant. The base of leaves grows on the node of stem, and is wrapped around the internodes of stem. Moreover, leaves are on both sides of the stem alternate, so stem nodes and leaves are of the same number. With the decrease of the diameter of corn stalks, the mass ratio of leaves increases, but the stem is on the other foot.

The results of previous studies by Gao et al. (2003)showed that the differences of binding strength of stem and leaf among different varieties of corn stalks were insignificant, usually 10.1 to 10.3 N · mm-1; binding strength of stems and leaves increased from down to up sequentially on the whole; the longitudinal tensile strength of leaves that wrapped around the internodes of stems was two to four times of the one in the lateral direction. The reasons for these results were that leaves began to become yellow and dry when corn plant grew to a certain stage.

The above analyses showed that there were large differences in structure and characteristics among different components of corn stalk and the same parts of corn stalks in different positions. To realize the effective separation of stems and leaves, the differences between stems and leaves of corn stalks and their own characteristics must be taken into account comprehensively. Meanwhile, in order to provide conditions for the separation of rind and pith of corn stalks, as well as to ensure the integrity of stem during the separation process, the design idea of hexagonenveloping leaf-stripping was proposed and the overall scheme was designed on the basis of hypothesis of stripping leaves with the help of variable-diameter sleeve.

Device's Overall Structure and Working Principle

To design appropriate leaf-stripping mechanism for corn stalks to realize the effective separation of stem and leaves, it is necessary to make a statistical analysis of the dimensions of corn stalks firstly, such as height and diameter. The measurement object was corn stalks that harvested from the Xiangfang Experimental Base of NEAU (Northeast Agricultural University) in spring. To get the accurate evaluation of separation,it is necessary to select stalks that having reached thematurity, integral rind, no diseases and more integral leaves. The measurement result of large quantities of corn stalks showed that the height was generally 2 271-3 100 mm, and the average diameters of 1st,4th and 8th nodes counting from the roots of stems were 25.6 mm, 24.1 mm and 18.6 mm, respectively.

Overall structure

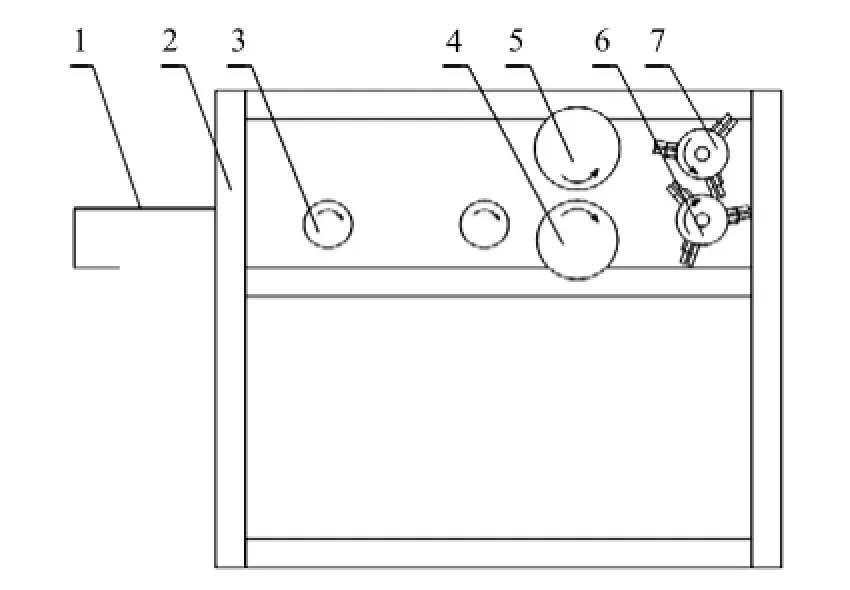

Fig. 1 Sketch map of leaf-stripping experimental device for corn stalk

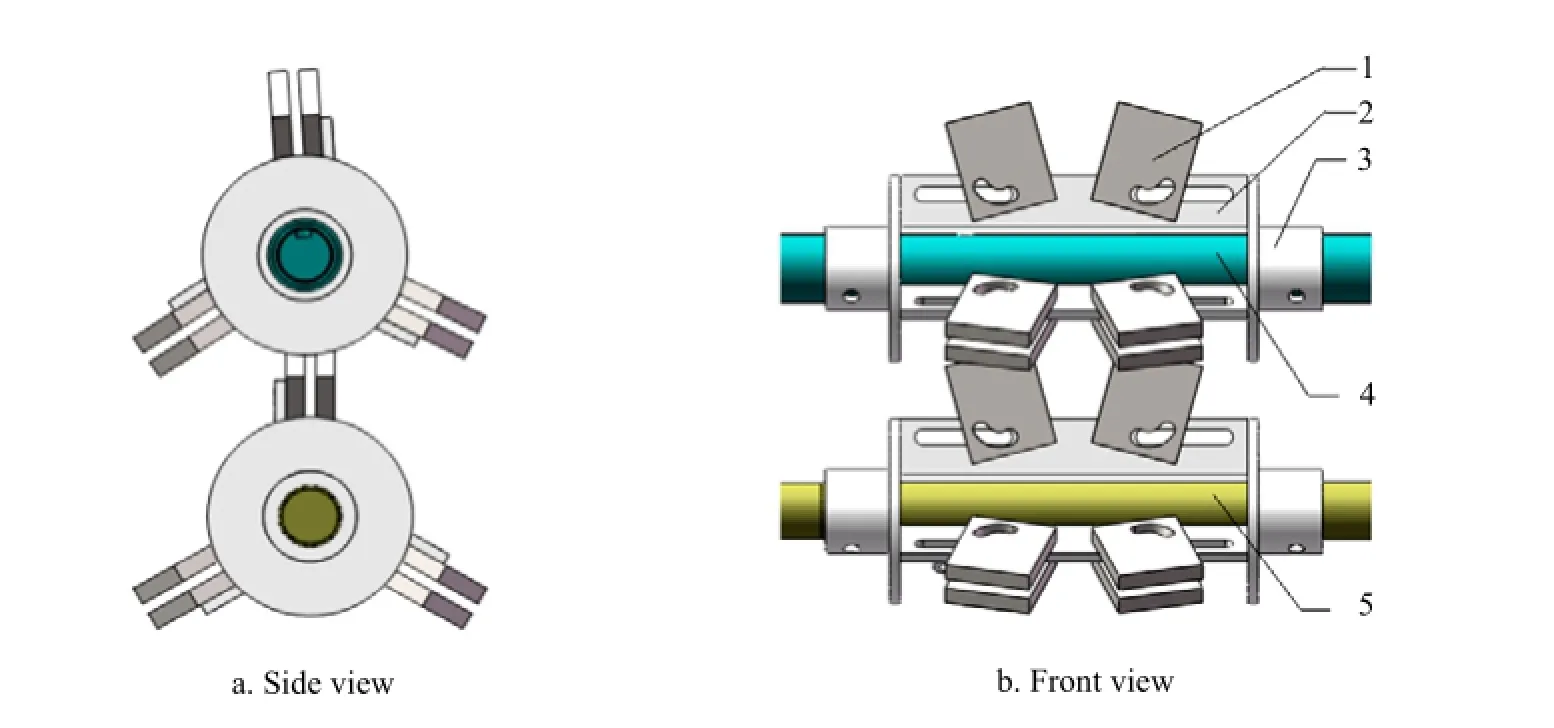

This leaf-stripping experimental device is mainly composed of feeding mechanism, leaf-stripping mechanism, transmission mechanism, frame, the motor and other components, as shown in Fig. 1. two leaf-stripping rolls was 144 mm, which could make the stress that stalks, bearing more even so as to avoid the break of corn stalk during the leaf-stripping process. To study the leaf-stripping principle and to get the optimal parameter values of the leaf-stripping device, three pairs of leaf-stripping plates that could change the angle were uniformly installed on each leafstripping roll. V-shaped leaf-stripping plate was an important part of leaf-stripping mechanism, and its main dimensions was 50 mm×60 mm×10 mm. Transmission mechanism was composed of belt transmission, chain transmission and gear transmission. Two sets of threephase asynchronous motors whose speed controlled by frequency converter were installed on the device to provide power for each roll. To increase the pushing force and exert the intermittent action on corn stalks,six small steel plates were uniformly installed on the surface of the conveying shaft.

The components that installed on each leaf-stripping roll were key parts to realize the separation of stem and leaves. Steel wires, as the most common leafstripping components, were prone to bending and winding in the high speed operation environment, and individuals were independent from each other, so that the durability of steel wires was poor and the service life was short. The use of rubber materials made the service life shorter. Therefore, the suitable materials of leaf-stripping components should be of good stiffness and abrasion resistance, and the steel plate could be the right choice.

The assemblies of shaft sleeve and connecting plate were used to fix and position leaf-stripping plates,and the maximum rotating diameter of the assemblies was 110 mm. Slotted holes on connecting plates and the axle of leaf-stripping rolls were parallel to each other, and there were two pairs of leaf-stripping plates installed on each connecting plate, the length of the median line of the triangle that made by a pair of leafstripping plates was close to the average diameter of corn stalks.

In order to reduce fatigue and fatigue-related experimental errors caused by prolonged physical

Feed mechanism is composed of feeding table,conveying roll, supporting roll, clamping roll, in which the latter two reverse at the constant speed. The device mainly uses the rubbed force and the shock force that acted by the high speed rotating leaf-stripping mechanism along the circumferential direction of corn stalks. Clamping roll is used to grip corn stalks and produce the pressure on the contact surface to prevent stalk from jumping and swinging during the leaf-stripping process, and the connecting force between stems and leaves will become smaller. Supporting roll is used to support the clamped stalk to better feed. Leaf-stripping mechanism, as shown in Fig. 2, was composed of a pair of symmetrically distributed leaf-stripping rolls that reversed at the constant speed and the center distance between theexertion, feeding table and frame were designed according to the combination of the height of corn stalk, human morphology, and the design standards set in the product evaluation of ergonomics.

Using SolidWorks software to check the interference and clearance of assemblies during the simulated operation, the overall scheme of the device was more reasonable, when there was no problem. And then there would be the process of manufacturing and assembling of the device, the physical map of the device is shown in Fig. 3. To ensure higher reliability, the device also needed to be checked, adjusted and tested.

Fig. 2 3D model of leaf-stripping mechanism

Fig. 3 Physical map of leaf-stripping experimental device for corn stalk

Working principle

Stalk's root was fed forward by feeding mechanism,because the diameter of stalk's root was so large that clamping roll could easily grip corn stalks and fold up leaves. The linear velocity direction of leaf-stripping rolls was contrary to the natural growth direction of leaves. If stalk's tip was fed forward by feeding mechanism, it would be not easy for leaves to find the right entrance, and corn stalks would deviate from the right entrance as a whole, so that it was not possible to conduct the leaf-stripping operations, even blocked. And then corn stalk was delivered to leaf-stripping mechanism. When stalk went through the gap between upper and underneath leaf-stripping roll, the high speed rotating leaf-stripping plates would rub leaves of stalk for many times, since the feeding speed was less than the linear velocity of leaf-stripping rolls. When the applied force that acted on corn stalks by leafstripping plates was greater than the connecting force between stems and leaves (generally 0.7-16 N) (Gao et al., 2003), leaves would be detached from stems.

Theoretical Analyses

Analytical purposes

According to the pre-experiment results, the leafstripping experimental device could achieve a better leaf-stripping effect, when the operational parameters of the device were appropriate, which also proved the feasibility and rationality of the device. Degree of stripping leaves from stems was an important index to evaluate the separation performance of the experimental device. So the leaf-stripping percent,the ratio of the quality of stripped leaves after corn stalks passing through the machine to the quality of all the leaves on the stalk would be chosen as the evaluation index. Furthermore, the bigger its value was, the better it was (Li et al., 2015). Through a large number of pre-experiments and observation analysis,in order to achieve higher leaf-stripping percent, it was necessary to find out the laws of leaf-stripping of such mechanism and to select the main influencing factors of separation performance from a number of factors from feeding speed, varieties of corn stalks, the quality of all the leaves on the stalk, the motion of corn stalks during the leaf-stripping process, the applied force that acted on corn stalk by leaf-stripping plates, the frequency or density of feeding stalks, rotary speed of leaf-stripping rolls, the amount and distribution of leafstripping plates in the circumferential direction of each leaf-stripping roll, the size of the hexagon-enveloping area, etc. For the convenience of discussion, the size of the hexagon-enveloping area could be considered as a function between clearance and included angle between two leaf-stripping plates. Clearance L included angle θ between two leaf-stripping plates is shown in Fig. 4.

In order to reach effective results, visual analyses by using the high-speed camera technology and dynamic analyses during the leaf-stripping process were conducted and the results could provide references for the development of efficient leaf-stripping and rindpith-leaf separation device for corn stalks.

Fig. 4 Clearance and included angle between two leafstripping plates

Visual analyses by using high-speed camera technology

The leaf-stripping process and the separation principle were studied through the use of Phantom V5.1 high-speed camera. According to the measurement size of corn stalks and the pre-experiment results,the observational condition was that feeding speed 1.5 m · s-1, rotary speed of leaf-stripping rolls 800 r · min-1,clearance between two leaf-stripping plates 27 mm,included angle between two leaf-stripping plates 30°, in parallel, the speed difference between feeding speed and rotary speed of leaf-stripping rolls was 4.53 m · s-1. The shooting site is shown in Fig. 5. The shooting interval between adjacent pictures was 0.225 s, and six pictures shot by the high-speed camera are shown in Fig. 6. Leaves of the previous stem node had been stripped from stem in Fig. 6, and the device was ready to repeat the leaf-stripping process to the next stem node.

Fig. 5 Shooting site

Fig. 6 Pictures shot by high-speed camera during leaf-stripping process

Dynamic analyses

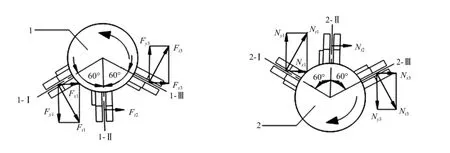

To study the applied force that acted on corn stalks by leaf-stripping plates of each leaf-stripping roll, three special positionsⅠ, Ⅱ(vertical), and Ⅲ in the range of 120° that a single pair of leaf-stripping plates actually acted on corn stalk were analyzed. The applied force that acted on corn stalks by each leaf-stripping roll is shown in Fig. 7.

According to the assembly relation between upper and underneath leaf-stripping roll, when leaf-stripping plates of upper leaf-stripping roll were in positionsⅠ, Ⅱand Ⅲ respectively, leaf-stripping plates of underneath leaf-stripping roll would be in positionsⅡ, Ⅲ and Ⅱ, correspondingly. By the direction of rotation of leaf-stripping rolls, the interval of between adjacent leaf-stripping plates was 60°, and the longest time spent in completing the process of changing position fromⅠtoⅡwas 0.025 s, when rotary speed of leaf-stripping rolls ranged from 400 to 1 200 r · min-1. The position transformation of leaf-stripping plates was very fast, so the action of corn stalks bearing was continuous.

Meanwhile, the angle (acute angle, set to δ) between leaf-stripping plates and y direction during the process of changing position fromⅠtoⅡbecame smaller, the angle (acute angle, set to γ) between leaf-stripping plates and y direction during the process of changing position fromⅡto Ⅲ became larger. Fig. 7 showed that both δ and γ ranged from 0 to 60°. It also showed that there were two horizontal forces of the same direction, Fx1and Fx3(upper leaf-stripping roll), Nx1and Nx3(underneath leaf-stripping roll), when leafstripping plates of a single leaf-stripping roll were in positionsⅠand Ⅲ. Fx1and Fx3, Nx1and Nx3were equal and opposite, respectively. For a single leafstripping roll, there was only one force in the direction of motion, Ftcosδ and Ftcosγ (upper leaf-stripping roll), Ntcosδ and Ntcosγ (underneath leaf-stripping roll), during the process of changing position fromⅠtoⅡ, fromⅡto Ⅲ, respectively. Therefore, there was an instant applied force that acted on corn stalk, when leaf-stripping plates of a single leaf-stripping roll were in positionsⅠand Ⅲ.

Fig. 7 Applied force acted on corn stalks by each leaf-stripping roll

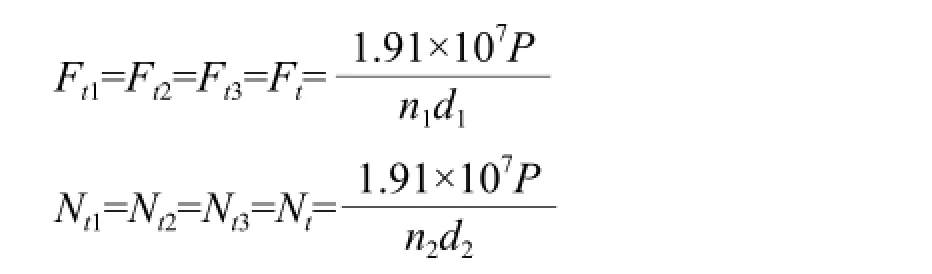

In conclusion, force conditions of corn stalks could be obtained, when leaf-stripping plates were in different positions, as shown in the following formulas.

For the same leaf-stripping roll:

Among them, Ftkand Ntk(k=1, 2, 3) denoted the circumferential force acted by upper and underneath leaf-stripping roll, when leaf-stripping plates of a single leaf-stripping roll were in positionsⅠ, Ⅱ and Ⅲ,respectively; P denoted the input power, kW; nqand dq(q=1, 2) denoted the rotary speed and diameter of corn stalks at the position that contacting with leafstripping plates of upper and underneath leaf-stripping roll, respectively. Because upper and underneath leafstripping roll were of the same structural parameters and their speeds were controlled by the gear transmission of constant speed ratio, n1=n2, d1=d2, Ft=Nt=Ftk=Ntk.

After the analyses of the applied force that acted on the corn stalk by each leaf-stripping roll, it was necessary to analyze the force during the leaf-stripping process, as shown in Fig. 8. For the convenience of discussion, r denoted the average radius of corn stalks,and R denoted the nearest distance between the center of the cross section of corn stalk and work sides of leaf-stripping plates.

Fig. 8 Force analysis during leaf-stripping process

When leaf-stripping plates of upper leaf-stripping roll were in positionsⅠand Ⅲ respectively, leafstripping plates of underneath leaf-stripping roll would be in positionⅡ, the applied forces that acted on corn stalks by each leaf-stripping roll at this time were as follows:

x direction:

y direction:

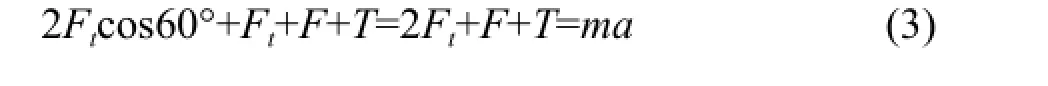

During the process of leaf-stripping plates of upper leaf-stripping roll changing positions fromⅠtoⅡor fromⅡto Ⅲ, and the applied forces were as follows:

x direction:

y direction:

The rubbed force that acted on corn stalks at the contact position with leaf-stripping plates was as follows, regardless of the positions of upper and underneath leaf-stripping roll.

Among them, F denoted the total force that acted on corn stalks by leaf-stripping rolls in the longitudinal direction; T denoted the total force of that acted on corn stalks by supporting roll and clamping roll in the longitudinal direction; m denoted the quality of corn stalks; a denoted the accelerations of corn stalks; N denoted the support force that acted on corn stalks by leaf-stripping plates in the lateral direction; f denoted the coefficient of friction between stalk and leafstripping plates; Pcdenoted the rubbed force that acted on corn stalks at the contact position with leafstripping plates.

In conclusion, the direction of the applied force that acted on corn stalks by upper and underneath leaf-stripping roll in x direction was the same as that of motion of stalk, but contrary to the natural growth direction of leaves, which made it easy to realize the effective separation of stem and leaves. When leafstripping plates of a single leaf-stripping roll were in positionsⅠand Ⅲ, the applied forces that acted on corn stalks by this leaf-stripping roll in y direction were equal and opposite, and the applied force of another leaf-stripping roll acted on corn stalks in y direction was zero, so that it ensured that corn stalks could move in a straight line and be pressed by leaf-stripping plates to prevent it from jumping and swinging.

Corn stalk was mainly subject to the rubbed force and the shock force that acted by leaf-stripping plates,during the leaf-stripping process. Among them, the rubbed force was exerted the moment high speed rotating leaf-stripping rolls came into contact with corn stalk and was due to the pressure of leaf-stripping plates, and it was affected by the rotary speed of leafstripping rolls. The support force that acted on corn stalks by leaf-stripping plates was perpendicular to working sides of plates, moreover, the support force and the rubbed force were affected by the clearance and included angle between two leaf-stripping plates. It was easy to realize the effective separation of stem and leaves when the rubbed force was large enough to damage leaves that close to the stem and reduce the effective contact area between stem and leaves. The high speed rotating leaf-stripping plates rubbed and shocked the leaves of stalks for many times at a high linear velocity, so as to complete the leaf-stripping process. When there was no force that acted by clamping roll, corn stalk would be mainly subject to the shock force, so as to do accelerated motion, since the velocity difference between leaf-stripping rolls and corn stalk was too small to continue stripping leaves from stem.

When clearance between two leaf-stripping plates L was constant, with the increase of included angle θ,the distance R would decrease, the gap between leafstripping plates and corn stalks that determined by the difference between R and r would decrease.

When R was less than or equal to r, leaf-stripping plates would contact with corn stalks closely, and the support force that acted on corn stalks by leafstripping plates in the lateral direction N would be larger. Because the interval of changing positions was very short, it could be considered that there were four contact points between leaf-stripping plates and corn stalks at the same time. As a result, there would be four rubbed forces in the circumferential direction of corn stalks. At the same time, considering the contact between the connecting plates and corn stalks, there would be six contact points between leafstripping plates and corn stalks at times, so it could beconsidered as the hexagon-enveloping leaf-stripping process. The clearance and included angle between two leaf-stripping plates were related with R and r. With the decrease of the clearance, the contact area between leaf-stripping plates and corn stalks increased,the support force that acted on corn stalks by leafstripping plates in the lateral direction increased, the rubbed force that acted on corn stalks at the contact position with leaf-stripping plates increased. With the increase of the clearance, the leaf-stripping percent increased. Because the increase of the clearance would lead to the decrease of side spacing between leafstripping plates and corn stalks, the effective actions of rubbing and shocking increased. When R was larger than r, the clearance would be of a larger value, the contact area between leaf-stripping plates and corn stalks would decrease, so would the rubbed force,which was difficult to strip leaves that close to the stem.

Determination of Main Influencing Factors of Separation Performance

Therefore, it is necessary to make a comprehensive analysis of various influencing factors of separation performance to distinguish the primary and secondary factors, according to visual analysis, dynamic analysis,the professional knowledge and relevant literature. The screening process was as follows.

Varieties of corn stalks

Varieties of corn stalks had few influences on the bonding strength of stems and leaves, according to the relevant information, that is to say, the impact on the effect of leaf-stripping was small. So it would not be considered as the influencing factor of separation performance.

Quality of all the leaves on stalks

It was difficult to achieve the unity of leaves' qualities,and the procedure was very complicated. In order to reduce experimental errors caused by the inconsistency in quality, it was necessary to increase the number and accuracy of experiments. And the leaf-stripping percent was the ratio of the quality of stripped leaves after corn stalks passing through the machine to the quality of all the leaves on the stalks, which helped to reduce experimental errors to some extent. So it would not be considered as the influencing factor of separation performance.

Frequency or density of feeding stalks

The pre-experiment results showed that the overlap,due to the high-frequency or high-density of feeding stalks would directly affect the leaf-stripping effect or quality, so it was difficult to study the leaf-stripping principle of the hexagon-enveloping leaf-stripping experimental device. Therefore, the study would use the way of feeding stalks one after another, which could be realized by the quantitative feeding device or the oriented feeding device for rind-pith separation equipment for corn stalks, each of them having been applied for China patent. So it would not be also considered as the influencing factor of separation performance.

Feeding speed

Feeding speed determined the amount of feeding stalks in a unit of time, which had great effect on the leaf-stripping effect and productivity. The increase of feeding speed would reduce the frequency of the applied force that acted on stalk by leaf-stripping plates, and the velocity difference between feeding speed and rotary speed of leaf-stripping rolls would decrease, each of them could weaken the leaf-stripping strength. The maximum leaf-stripping percent was most likely to occur under the circumstances of minimum feeding speed and maximum rotary speed of leaf-stripping rolls. So it would be considered as the influencing factor of separation performance.

Rotary speed of leaf-stripping rolls

According to formulas (1) and (2), with the increase of rotary speed of leaf-stripping rolls, the circumferentialforce acted by upper and underneath leaf-stripping roll decreased, but the velocity difference between feeding speed and rotary speed of leaf-stripping rolls would increase. So it would be also considered as the influencing factor of separation performance.

Size of hexagon-enveloping area

The size of the hexagon-enveloping area that determined by the clearance and included angle between two leaf-stripping plates had effects on the contact area between leaf-stripping plates and corn stalks, which had great effects on the leaf-stripping percent. So clearance and included angle between two leaf-stripping plates would be also considered as the influencing factors of separation performance.

Motion of corn stalks and applied force acted on it

Each of the motion of corn stalks and the applied force that acted on it by leaf-stripping plates during the leafstripping process had significant effects on the leafstripping percent, according to the results of visual and dynamic analyses. But they were affected by the above four selected influencing factors. So it would not be considered as the influencing factor of separation performance.

Amount and distribution of leaf-stripping plates

The amount and distribution of leaf-stripping plates in the circumferential direction of each leaf-stripping roll had great effects on the leaf-stripping percent,because they could affect the frequency of the applied force that acted on stalks by leaf-stripping plates. In this study, three pairs of leaf-stripping plates that could change the angle were uniformly installed on each leafstripping roll. Two, four or more pairs of leaf-stripping plates could also be installed, but for the convenience of study, three pairs of plates were only be considered. And the optimization of structural parameters of this study could be used appropriately and selectively in the design of different pairs of leaf-stripping plates. So the amount and distribution of leaf-stripping plates would not be also considered as the influencing factor of separation performance.

The above analyses showed that the four main influencing factors of separation performance of the hexagon-enveloping leaf-stripping experimental device for corn stalk were feeding speed, rotary speed of leafstripping rolls, clearance and included angle between two leaf-stripping plates.

Conclusions

Through the study on hexagon-enveloping leafstripping mechanism for corn stalks, the leaf-stripping principle of such mechanism was more clear,and the optimization of structural and kinematics parameters achieved by the experiment under the four selected influencing factors (feeding speed, rotary speed of leaf-stripping roll, clearance and included angle between two leaf-stripping plates) experimental condition could be directly applied to the development of efficient rind-pith or leaf-stripping separation for corn stalks.

Chen Z G, Wang D F, Li L Q, et al. 2012. Experiment on tensile and shearing characteristics of rind of corn stalk. Transactions of the Chinese Society of Agricultural Engineering, 28(21): 59-65.

Cui M, Zhao L X, Tian Y S, et al. 2008. Analysis and evaluation on energy utilization of main crop stalk resources in China. Transactions of the CSAE, 24(12): 291-296.

Gao G C, Lu W, Zhang G L, et al. 2008. Comprehensive utilization of corn stalk in agricultural ecological system. Journal of Jilin Agricultural Sciences, 33(4): 59-61.

Gao M X. 2001. Study on the separation mechanism of stalk and leaves of corn straw. Northwest A&F University, Shanxi.

Gao M X, Guo K Q, Yang Z P, et al. 2003. Study on mechanical properties of corn stalk. Transactions of the Chinese Society of Agricultural Machinery, 34(4): 47-49.

Gao M X, Yang Z P, Guo K Q, et al. 2003. Experimental study on shocked separation of stalks and leaves of cornstalk. Transactions of The Chinese Society of Agricultural Machinery, 34(2): 40-42.

Han L J, Yan Q J, Liu X Y, et al. 2002. Stalk resources and their utilization in China. Transactions of the Chinese Society of Agricultural Engineering, 18(3): 87-91.

Li L Q. 2014. Experimental study on stem-leaf separation device for corn stalk. Northeast Agricultural University, Harbin.

Li L Q, Wang D F, Ma L J. 2015. Experimental study on leaf-stripping mechanism for rind-pith separation equipment for corn stalk. Journal of Agricultural Mechanization Research, 3: 207-210.

Liu L L. 2011. The experimental research on separating cover-pithleave of corn straw. Northeast Agricultural University, Harbin.

Liu Y. 2003. Treatment and comprehensive utilization of crop straw. Liaoning Agricultural Sciences, 1: 18-23.

Sun Z Y, Guo S M. 2001. Husk and stalk separation and pulping experiment of corn stalk. China Pulp & Paper Industry, 22(5): 41-42. Wang D F, Chen Z G, Yu K Q. 2012. Parameter optimization on separating mechanism for rind and pith of corn straw. Transactions of the Chinese Society for Agricultural Machinery, 43(10): 90-94.

Yang Z P, Yang L Q, Guo K Q, et al. 1996. Study on the industrialized processing technology of corn stalks. Transactions of the CSAE,12(4): 185-188.

Yang Z P, Yang L Q, Guo K Q, et al. 1995. A preliminary study on the technology of making corn stalk cuticles particle board. Journal of Northwest Forestry College, 10(3): 67-72.

Zhang Z X. 2002. Experimental research on mechanism of the type of sugarcane stripper with combing brush. South China Agricultural University, Guangzhou.

Zhu X H, Yang Z P, Wu Y F, et al. 2012. Design and experiment on stem-leaf separator for corn straw. Journal of Northwest A&F University, 40(3): 229-234.

S817.19 Document code: A Article lD: 1006-8104(2015)-04-0037-11

Received 29 December 2014

Supported by the National Science and Technology Support Funded Project (2011BAD20B08)

Li Li-qiao (1988-), female, Ph. D, engaged in the research of livestock machinery. E-mail: liliqiao1108@163.com

*Corresponding author. Wang De-fu, professor, Ph. D, engaged in the research of livestock machinery. E-mail: dfwang640203@sohu.com

杂志排行

Journal of Northeast Agricultural University(English Edition)的其它文章

- Effects of Ιnitial Ιnfestation Levels of Callosobruchus maculatus (F.)(Coleoptera: Chrysomelidae) on Cowpea and Use of Nicotiana tabacum L. Aqueous Extract as Grain Protectant

- Ιmpact of Microbial Ιnoculants on Microbial Quantity, Enzyme Activity and Available Nutrient Content in Paddy Soil

- Phenotypic and Genetic Characterization of Bacillus Species Exhibiting Strong Proteolytic Activity Ιsolated from Terasi, An Ιndonesian Fermented Seafood Product

- Effect of Quercetin on Egg Quality and Components in Laying Hens of Different Weeks

- Screening of Adoptive Elite Tea (Camellia sinensis) Clones

- Optimal Scheme Selection of Agricultural Production Structure Adjustment — Based on DEA Model; Punjab (Pakistan)