Effect of thermal processing and fermentation with Chinese traditional starters on characteristics and allergenicity of wheat matrix

2023-01-23HuanRaoXiLiWentongXue

Huan Rao, Xi Li, Wentong Xue,*

a College of Food Science and Biology, Hebei University of Science and Technology, Shijiazhuang 050018, China

b College of Food Science and Nutritional Engineering, China Agricultural University, Beijing 100083, China

Keywords:Chinese traditional starter Fermentation characteristics Thermal processing Allergenicity Wheat matrix

A B S T R A C T Wheat allergy has become a serious health threat worldwide and its prevalence has increased alarmingly in the past few years. Factors such as food matrix and food processing may alter the structure of wheat proteins, and hence affect its allergenic properties. However, few reports have focused on the inf luence of Chinese traditional starter fermentation on wheat allergy. In this study, 5 starters from different regions of China were used for fermentation,and protein characteristics were monitored by sodium dodecyl sulfate polyacrylamide gel electropheresis, and immunoreactivity analyzed by immunoassay with allergenic serum was obtained from New Zealand white rabbits.The allergenicity of steamed and baked matrices was also evaluated. The results showed that the allergenicity of wheat dough was basically increased at the beginning and then decreased during fermentation, but specif ic trends depend on different starters. With the progress of fermentation, especially as pH value decreased to 3.0-4.0,the allergenicity decreased signif icantly. Baking and steaming can reduce the allergenicity of wheat matrix, but fermentation is not a key factor affecting the allergenic activity of proteins. Our results can provide a theoretical basis for controlling wheat allergenicity in food processing or producing hypoallergenic food.

1. Introduction

Wheat, one of the 3 major grains, is widely planted around the world and is largely consumed in the daily diet. It can be used to make bread, Mantou (steamed bun), beer, biofuels, etc., and is rich in nutrition. However, it is also one of the 8 major food allergens, its consumption has been linked to several health issues. According to epidemiological surveys, wheat allergy accounts for 11% to 25% of the total incidence of food allergy. The proportion in China is lower than that in developed countries, but the positive rate of immunoglobulin E(IgE) in wheat increased yearly from 2007 to 2010 in China [1-3].

Sourdough, as a traditional starter for fermentation, is a mixture of f lour and water, and fermented with microorganisms mainly yeasts and lactic acid bacteria. Microorganisms are responsible for the acidif ication of the dough and for the synthesis of exopolysaccharides,aroma compounds, enzymes and/or antifungal compounds [4,5].Previous studies have shown that compared to commercial yeast,sourdough fermentation has a great advantage in improving the nutritional, texture, rheological, and shelf life of gluten-free breads and other wheat products [6]. In addition, studies have found that the metabolism of microorganisms in dough has a certain impact on the structure of wheat protein. In the process of dough fermentation,yeast fermentation produced CO2, alcohol, protease, gluten content and gluten index were all decreased signif icantly with the increase of fermentation time [7,8]. Joanna et al. [9] found that yeast fermentation increased the allergenicity, but the relationship between them has not been clarif ied. The immunoreactivity of wheat gluten decreased by lactic acid bacteria and baker’s yeast fermentation, but the degree of reduction was not significant [9]. Others also found that lactic acid bacteria can reduce allergic reactions by hydrolyzing wheat and rye protein [10].

Chinese steamed bread is a kind of staple food that is naturally fermented by sourdough (Laojiaotou), a natural fermentation with grain, water, and active microorganisms, such as lactic acid bacteria and yeast. This kind of starter contains a variety of yeasts and lactic acid bacteria [11,12]. However, the effect of Chinese traditional starter on wheat protein and its allergenicity has not been studied. In our daily life, fermented dough should be further processed, such as bake, roast, boil, steam, fry, etc. In China, steamed fermented dough called steamed bread is the most common staple food, while baked fermented dough, bread, is the homely food in Western countries [13].It should be investigated whether the different processing methods or fermentation is the key factor affecting the allergenicity of wheat matrices.

Several studies have shown that the microbial community in Chinese western sourdough was different from that of northern and southern [14,15]. Therefore, in our study, 5 Chinese traditional starters from 5 different regions were collected to explore their effects on protein characteristics and allergenicity. Considering the relationship between the dietary difference and the incidence rate of allergy in China and the Western countries, the influence of cooking methods on fermented wheat matrix and its allergenicity would be also investigated.

2. Materials and methods

2.1 Materials

Five starters were collected from Yulin Shannxi, Wanyuan Sichuan, Tianchang Anhui, Xi’an Shannxi, and Gongyi Henan in this study. Wheat flour was obtained from COFCO International Holding Company. The nutrient content of wheat flour can be seen in supplementary Table S1-1. Rabbit anti-wheat antibody was made by our laboratory, more details can be seen in the supplementary information. All other chemical reagents were of analytical grade or high-performance liquid chromatography (HPLC)-grade and were purchased from Solarbio (Solarbio Science & Technology Co., Ltd.,Beijing, China).

2.2 Preparation and processing of fermented dough

Wheat flour (500 g) was fermented with traditional sourdough starter (250 g, diluted 2:5 (m/V) in water) from 5 different areas of China at 30 °C and 85% relative humidity. Samples were extracted every 2 h, the final samples were obtained at 12 h to measure the pH value and physicochemical properties of the dough. Fermented samples (obtained at 4 h) were steamed at 100 °C or baked at 200 °C for 0 min to 40 min. All samples were frozen at -80 °C until required for further analysis.

2.3 pH value and titratable acidity (TTA)

Ten grams fermentation dough samples which were collected every 2 h, were mixed with 90 mL distilled water. The pH value of the mixture was measured. The mixture was titrated with 0.1 mol/L NaOH to pH 8.6, and the volume of 0.1 mol/L NaOH consumed was recorded as TTA.

2.4 Protein surface hydrophobicity (H0)

H0was determined by the hydrophobicity fluorescence probe according to the method reported by Huan et al. [16]. Protein sample were prepared in PBS (0.01 mol/L, pH 7.0) and diluted to 0.2, 0.1,0.05, 0.025 and 0.012 5 mg/mL. A volume of 4 mL of each protein solution was then added with 20 mL of 1-anilinonaphthalene-8-sulfonic acid (ANS). The fluorescence intensity of mixture was measured with a Hitachi F2500 fluorescence spectrometer (Tokyo,Japan), at wavelengths of 390 nm (excitation) and 470 nm (emission).The initial slope of fluorescence intensity versus protein concentration plot was used as an index ofH0.

2.5 Sodium dodecyl sulfate polyacrylamide gel electropheresis (SDS-PAGE) analysis

Prior to SDS-PAGE analysis, fermentation samples (10 mg)were extracted in 50 mmol/L Tris-HCl, pH 8.8 at 4 °C for 12 h.After centrifugation at 12 000 ×gfor 20 min at 4 °C, the supernatant was removed to a new tube. Samples were prepared with 50 µL of supernatant and 10 µL of loading buffer (5 × SDS-PAGE Loading buffer, Solarbio Science & Technology Co., Ltd., Beijing, China) were heated to 90 °C for 5 min and 10 µL/well of each sample loaded on a 12% gradient gel. Electrophoresis was performed for 30 min at 90 V for the stacking gel and 60 min at 200 V for the separating gel. The gels were stained with coomassie brilliant blue (R-250) for 30 min and then destained overnight in the washing buffer (50%V/Vmethanol, 10%V/Vacetic acid). The gray values were visualized with the Electrophoresis Gel Imaging Analysis System (Multi Gauge V3.1,Fujitsu, Japan).

2.6 Determination of allergic changes by enzyme linked immunosorbent assay (ELISA)

For each sample extract, a solution of 0.5 μg/mL of total soluble protein was prepared in coating buffer (0.015 mol/L Na2CO3,0.035 mol/L NaHCO3, pH 9.6) and incubated overnight at 4 °C. After washing with 0.01 mol/L TBST, wells were blocked with 200 mL/well of ELISA blocking buffer (0.01 mol/L TBS containing 0.1% (m/V)bovine serum albumin) for 2 h at 37 °C. The allergenic serum was obtained from New Zealand white rabbits sensitized with wheat protein, and the rabbit anti-wheat antibody were diluted 1:5 000 (V/V) in ELISA blocking buffer and incubated for 2 h at 37 °C. The plate was washed with ELISA wash buffer 4 times to remove any unbound primary antibody, and incubated with diluted 1:5 000 (V/V) horseradish peroxidase (HRP) conjugated secondary antibody in ELISA blocking buffer for 1 h at 37 °C. After removing any unbound secondary antibody by washing with ELISA wash buffer four times, the plate was incubated with 100 µL per well of TMB substrate for 30 min at room temperature in the dark. After 15 min, the enzymatic reactions were stopped by adding 100 µL per well of 1 mol/L HCl.

2.7 Statistical analysis

Analysis of each treatment was performed in triplicate and expressed as mean ± SD. Statistical analyses were performed by oneway analysis of variance (ANOVA) using SPSS 16.0 (SPSS 16.0 for Windows, SPSS Inc., Chicago USA) or GraphPad Prism 7.01(GraphPad Software, San Diego, CA, USA). Differences were considered to be significant (P< 0.05).

3. Results and discussion

3.1 Effect of Chinese traditional starters on characteristics of wheat matrix during fermentation

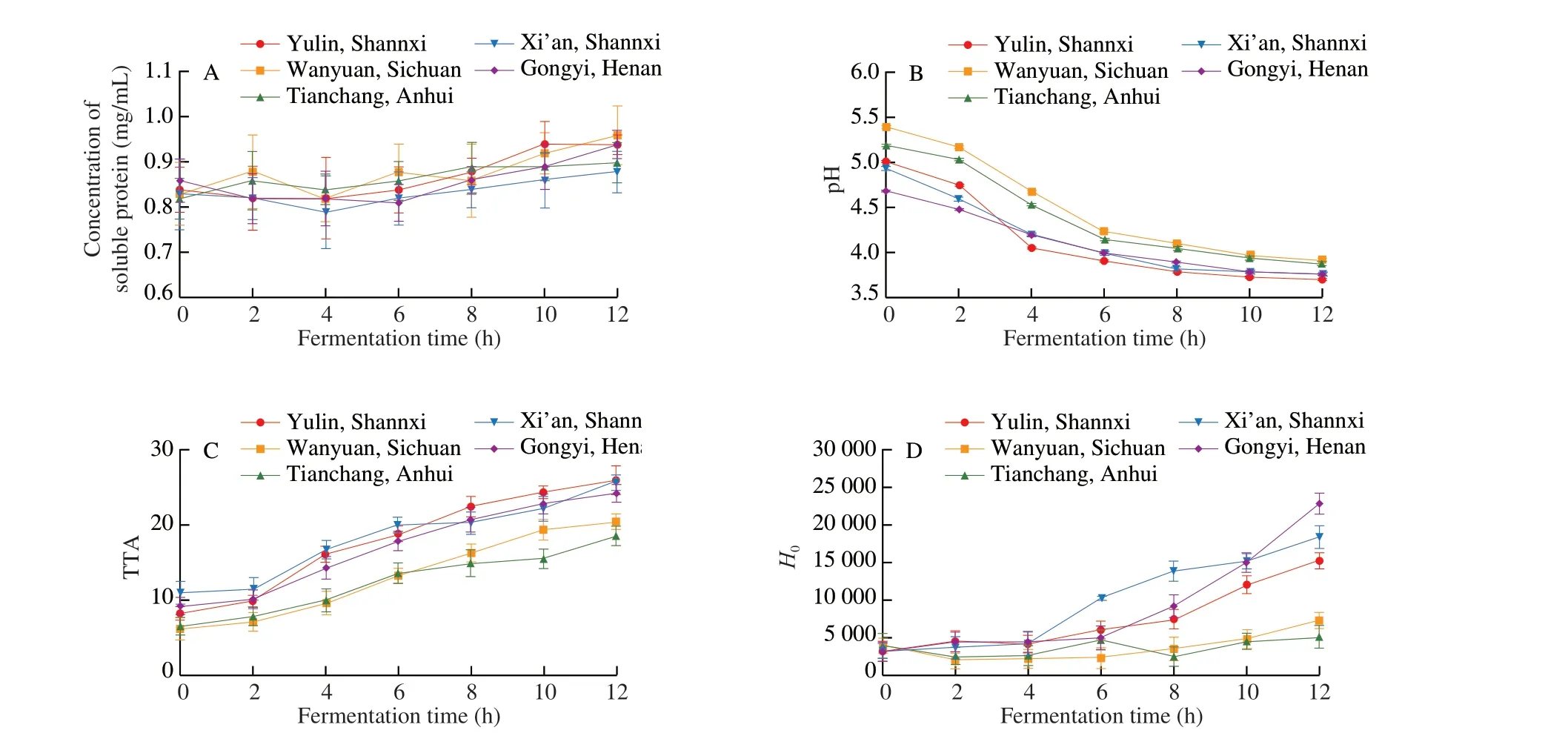

It can be seen from Fig.1A that the soluble protein content was almost unchanged and remained at about 0.8 mg/mL within 6 h during fermentation. But with the extent of fermentation time, the content of soluble protein increased in all groups. Gobbetti et al. [17]also found that organic acids produced by sourdough fermentation can enhance the hydrolysis of gluten, starch and arabinoxylan by lactic acid bacteria specific hydrolytic protease, or provide low pH value fermentation environment, which can increase the solubility and expansibility of gluten forming network structure, thus improving the extraction rate of protein. At the same time, ethanol is produced during yeast fermentation, which can dissolve gliadin and promote the extraction rate of soluble protein. Therefore, the increased of soluble protein extraction rate might be due to the lactic acid produced by lactic acid bacteria fermentation, and the decreased pH value, which improves the solubility of gluten protein.

The pH value and TTA were measured and results showed in Fig. 1B and Fig. 1C. Generally, the pH value decreased from around 5.0 to 4.0 rapidly within 8 h and stabilized at about 4.0 in the later stage.The starter of Wanyuan, Sichuan had the largest fluctuation range among those 5 groups. The titratable acidity gradually increased with the extension time of fermentation, and finally stabilized at 27 mL.During the process of fermentation, CO2and lactic acid were produced by yeast and lactic acid bacteria respectively, which led to the decrease of pH value. At the later stage of fermentation, the very low pH value inhibits the growth and reproduction of bacteria. With the lactic acid produced remaining constant, the pH value and TTA tend to be stable.

Fig. 1 The characteristics of wheat proteins during sourdough fermentation with different starters. (A) soluble protein content; (B) pH value during fermentation;(C) TTA during fermentation; (D) Changes of H0 of wheat proteins during fermentation. Each treatment was in triplicate and data were represented as mean ± SD.

Additionally, previous studies have proved that there were two kinds of metabolic types, homotype and heterotype, of lactic acid bacteria [18,19]. In the process of homolactic acid bacteria metabolism, lactic acid bacteria first use glucose for glycolysis pathway to produce pyruvate, and then pyruvate dehydrogenation to produce lactic acid. For the heterolactic acid bacteria metabolism,lactic acid bacteria start from glucose and through glucose 6-phosphate pathway to produce lactic acid, accompanied by the production of ethanol, carbon dioxide and acetic acid. In the dough fermentation process, in addition to glucose, lactic acid bacteria can also use other hexoses, and with the help of specific enzymes(hydrolase, phosphohydrolase, isomerase, etc.) to enter homo- or hetero-metabolism at the glucose-6-phosphate stage or fructose-6-phosphate stage [4,8,18]. No matter what type of metabolism, lactic acid is produced, leading to a decrease in pH value. It was pointed out that during the 24 h fermentation of steamed bread with yeast and lactic acid bacteria at 24 °C, the acidity and soluble sugar content of dough varied with the types of lactic acid bacteria [20]. The acid environment produced by lactic acid bacteria inhibits the growth of yeast, and yeast also affects the growth rate of lactic acid bacteria [21].It should be noted that the difference in initial pH value is mainly related to the acidity of traditional starters in different areas.

Weak intramolecular interactions such as hydrophobic interactions,hydrogen bonds, and van der Waals forces play a very important role in maintaining the tertiary structure of food allergen proteins and their allergenicity. Gromiha et al. [22] found that in the molecular interaction force, the main force maintaining the stability of heatresistant proteins including allergens is hydrophobic interaction.The surface hydrophobicity index is a quantitative indicator that characterizes the hydrophobic interactions on the protein surface.TheH0remained stable in the first 4 h, and gradually increased with time extension. Among 5 groups, Gongyi increased the most,from 3 179 to 33 388, which was 10 times of the original, while Xi’an and Yulin increased by 8.3 times, Tianchang and Wanyuan increased by 4.5 times and 4.8 times respectively (Fig. 1D). This is due to the fact that the fermentation strain is in the stage of gradual growth within 4 h before fermentation. The yeast ferments to produce CO2and ethanol under anaerobic conditions, which leads to the structural change of gluten and the exposure of hydrophobic groups,resulting in a significant increase ofH0. Lactic acid was produced in the fermentation process of lactic acid bacteria, and the pH value decreased, resulting in the decrease of dissociative residues on the surface of protein and the increase ofH0.

3.2 Effect of fermentation on wheat protein profile and allergenicity

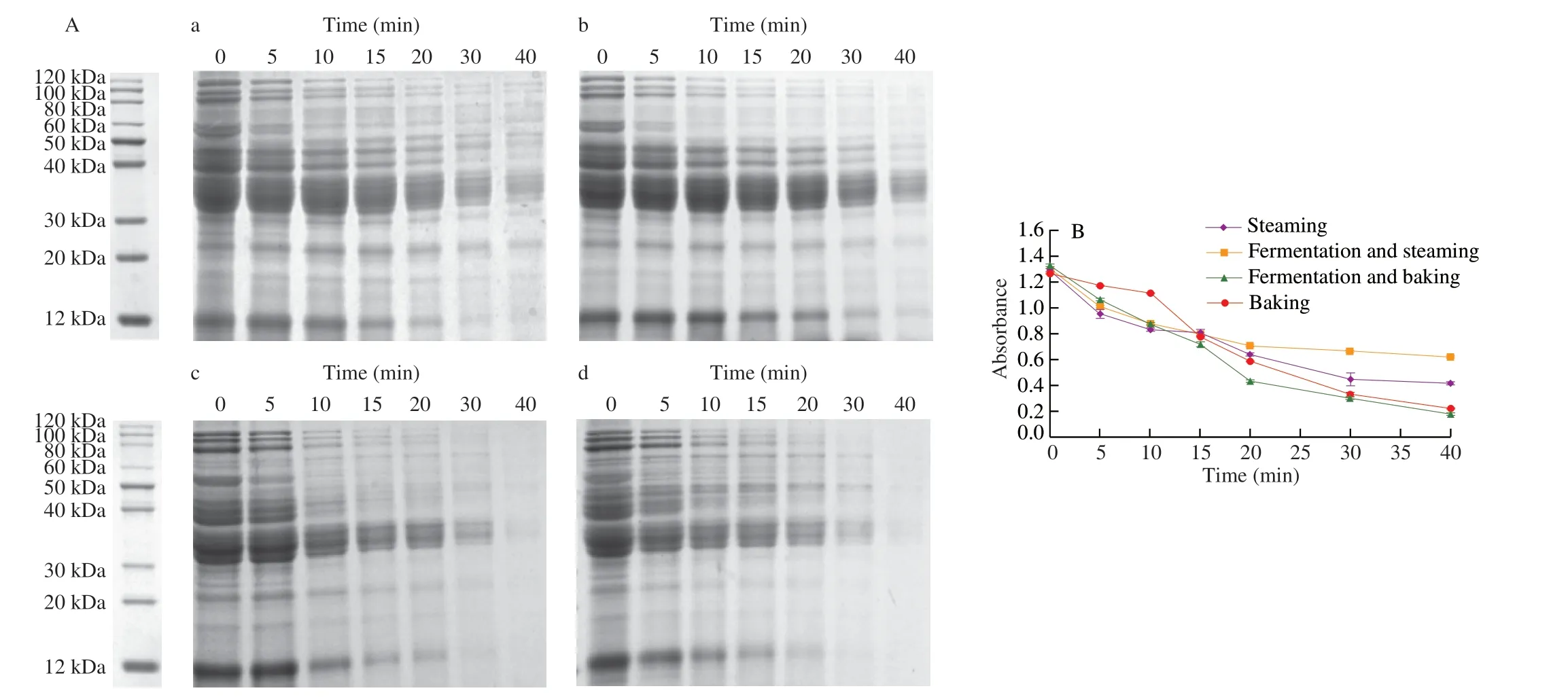

It can be seen from Fig.2A that the profile of proteins in different fermentation groups had no significant differences during the processing. It seemed that the molecular weight around 20-30 kDa in Xi’an, Shaanxi group was weaker than that in any other groups.After 24 h, the molecular weight of 80-120 kDa and 20-30 kDa protein decreased slightly, which indicated that one or several strains could decompose or utilize wheat protein. It was found that lactic acid bacteria could degrade gluten [23,24]. It was reported that plant lactic acid bacteria m616 had a strong degradation effect on dough protein in the process of dough fermentation, which showed that the content of total protein and different components of protein gradually decreased with the extension of fermentation time [25]. In this study,the profile of proteins almost no change. This might be because of the complicated bacteria environment of the traditional starter, resulting in the content and growth of bacteria that can effectively decompose protein was inhibited by other bacteria or metabolites. This led to a decrease in protease content and activity, and no protein is degraded until the later stage of the fermentation process.

Fig. 2 (A) Changes of protein composition in fermentation with different starter. a: Yulin, Shannxi; b: Wanyuan, Sichuan; c: Tianchang, Anhui;d: Xi’an, Shannxi; e: Gongyi, Henan; (B) Effect of fermentation with different starter on allergenicity of wheat protein.Each treatment was in triplicate and data were represented as mean ± SD.

In the process of fermentation, protein was degraded by acid and enzyme. Gocmen et al. [7] concluded that pH value had the most important effect on the hydrolysis of gliadin, and the highest value of gliadin hydrolysis was obtained at pH 4.0. Cagno et al. [26] found that lactic acid bacteria fermentation can produce bacteriocin and some important enzymes, which have protein hydrolysis activity. Its protein hydrolysis system generates amino acids and small peptides, which can change the protein composition of dough.

According to Fig.2B, in general, the allergenicity of dough fermented by different traditional starters was increased first and then decreased. However, starters from different regions had different effects on wheat protein allergenicity. The average allergenicity of Yulin group was the strongest, followed by Tianchang group. The largest decrease in binding capacity was observed in the Xi’an and Gongyi groups with the lowest allergenicity at 12 h. In the Wanyuan group, the change of allergenicity was relatively stable. The increasing allergenicity may be related to the stretching effect by CO2which is produced by yeast fermentation. With the help of the stretching effect,more antigenic determinants were exposed to antibody and led to higher allergenicity. Because of the different CO2produced abilities of different starters, the influence on allergenicity and the maximum time was also different. At the later stage of fermentation, with the increasing production of lactic acid by lactic acid bacteria, gluten protein was hydrolyzed, and allergenic epitopes were destroyed. It was found that the activity of wheat endogenous protease (optimum pH 3.0-4.0) was enhanced by dough acidification, which may further promote the specific protease hydrolysis activity of lactic acid bacteria and further degrade the protein in sourdough [7,23,27]. At the same time, as mentioned above, Chinese traditional starter has a complex microbial environment, and there is a close relationship with synergistic or antagonistic effect between the metabolism of yeast and that of lactic acid bacteria [26,28].

Fig. 3 (A) Effects of steamed and baked processing on wheat protein composition. a: steaming; b: fermentation and steaming; c: baking; d: fermentation and baking;(B) Effects of steamed and baked processing on wheat allergenicity. Each treatment was in triplicate and data were represented as mean ± SD.

In addition, our previous experiment compared the effects ofLactobacillus plantarumand yeast on the structure and allergenicity of fermented dough, and found that the pattern of hydrophobicity changes, disulfide bond content and allergenicity of dough which fermented by yeast were similar to those of Chinese traditional starter,which indicated that yeast fermentation was the main factor affecting wheat allergenicity in the process of Chinese traditional starter fermentation.

3.3 Effect of food processing on protein profile and allergenicity of wheat matrices

Based on our compared results of 5 starters, fermented sample with Wanyuan, Sichuan starter as its low allergenicity was chosen for baked or steamed treatment. SDS-PAGE experiments were carried out with the same quality of protein samples (Fig. 3A). It was found that with the increase of cooking and baking time, the protein content decreased gradually. Compared to steamed matrix, protein profile of the roasted matrix was only faintly visible from the protein-stained gel after 30 min. In addition, there were slight changes of profile between fermentation and un-fermentation groups. A previous study had found that the wheat proteins would transform into each other due to the effect of heat steam, and the water-soluble protein and gluten were transformed into the surplus protein, but the total protein content remained unchanged [7,12]. During the steaming process, protein molecules are denatured by heat, resulting in the change of protein spatial structure, destroying the original peptide bond sequence,promoting the binding of small molecular weight proteins and coagulation, thus becoming a part of macromolecular residual protein.In the process of steaming, the structure of protein changes and the peptide bond sequence is destroyed due to the heat steam. Heat effect also promotes the binding of small molecular weight proteins to form a part of large molecular weight proteins, at the same time, wheat protein was degraded by heating during baking [29].

It can be seen from Fig. 3B that the allergenicity of wheat matrices decreased significantly after both heat treatments, and the decline of baking treatment was greater than that of steaming treatment.Fermentation had little effect on the allergenicity of baked wheat matrix but promoted the binding capacity of steamed matrix. Previous studies found that there were only strong bound water and weak bound water in the steaming matrix. During the process of steaming,the weak bound water gradually becomes strong bound water, and leads to the increase of water binding with carboxyl or amino groups of protein, as well as an increased binding force [9,24]. Therefore,the conformation of antigenic determinants was protected by water,which resulted in higher binding capacity than baked samples. The higher allergenicity of fermented samples may be due to the exposure of more allergenic groups in the protein after fermentation.

4. Conclusions

In our study, the allergenicity of wheat matrix fermented by 5 starters from different parts of China was compared. The data presented here indicated that there was no significant difference in protein profile between different groups within 12 h of fermentation.With the progress of fermentation, especially pH value decreased to 3.0-4.0, the allergenicity also decreased. Different starters had different effects on wheat protein allergenicity, which may be due to the fermentation ability of yeast, CO2production, lactic acid,enzymes, and other metabolites. Baking induced degradation or mutual transformation between proteins, and the allergenicity of wheat was also reduced. Therefore, to reduce the wheat immunoreactivity in food processing or produce hypoallergenic food, we need to choose an appropriate starter, fermentation time and cooking methods.

Declaration of competing interest

The authors declare that there are no conflicts of interest.

Acknowledgments

This project was supported by the National Natural Science Foundation of China (31872904).

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in the online version, at http://doi.org/10.1016/j.fshw.2022.09.013.

杂志排行

食品科学与人类健康(英文)的其它文章

- The role of probiotics in prevention and treatment of food allergy

- Roles of fermented plant-, dairy- and meat-based foods in the modulation of allergic responses

- The role of gut microbiota and its metabolites short-chain fatty acids in food allergy

- Association of nutrients intake during pregnancy with the risk of allergic disease in offspring: a meta-analysis of prospective cohort studies

- Purif ication and immunoglobulin E epitopes identif ication of low molecular weight glutenin: an allergen in Chinese wheat

- Determination of egg and milk allergen in food products by liquid chromatography-tandem mass spectrometry based on signature peptides and isotope-labeled internal standard