High-dispersive mirror for pulse stretcher in femtosecond fiber laser amplification system

2022-08-31WenjiaYuan袁文佳WeidongShen沈伟东ChenXie谢辰ChenyingYang杨陈楹andYueguangZhang章岳光

Wenjia Yuan(袁文佳) Weidong Shen(沈伟东) Chen Xie(谢辰)Chenying Yang(杨陈楹) and Yueguang Zhang(章岳光)

1State Key Laboratory of Modern Optical Instrumentation,College of Optical Science and Engineering,Zhejiang University,Hangzhou 310027,China

2Ultrafast Laser Laboratory,Key Laboratory of Opto-electronic Information Science and Technology of Ministry of Education,College of Precision Instruments and Opto-Electronics Engineering,Tianjin University,Tianjin 300072,China

Keywords: optical coatings,dispersive mirror,ultrafast optics,pulse stretching

1. Introduction

Dispersive mirrors are indispensable components for dispersion control in femtosecond lasers, especially group delay dispersion (GDD) compensation for ultrashort pulse compression.[1–15]The multilayer dielectric dispersive mirrors have lower energy loss,higher damage thresholds. Moreover,dispersive mirror compensators are compact,robust,and easy to be inserted into laser systems, therefore they are gradually replacing conventional prisms and grating pairs. In femtosecond fiber lasers amplifiers, the third-order dispersion (TOD)introduced from the fiber stretcher and grating compressor will cause serious distortion to output pulse shape, which restricts a higher stretching ratio.[16,17]The compensation of TOD requires a combination design of fiber stretcher and grating pair.[18,19]The dispersive mirrors are more flexible in tailoring GDD compensation and can provide accurate control of high order dispersion. Gires–Tournois interferometer mirrors were employed in a femtosecond nonlinear amplification fiber laser system to provide around−10000 fs3TOD compensation to reduce the pulse pedestal.[20,21]Dispersive mirror can be a good alternative as pulse stretcher. However, there are few reports on such applications in femtosecond fiber laser amplification systems.

In this paper,we present a high-dispersive multilayer mirror for pulse stretching in a femtosecond fiber laser amplification system. The designed mirror can provide a considerable positive group delay dispersion of 600 fs2,and a high reflectance over 99.9%from 1010 nm to 1070 nm. The samples were prepared by dual ion beam sputtering deposition. The GDD characteristics of samples were tested by a home-made white light interferometer with an average GDD of +722 fs2from 1010 nm to 1070 nm. The mirrors were employed in a Yb-doped large-mode-area photonic crystal fiber amplification system, successfully to stretch an input pulse with autocorrelation function of 83 fs to 1.29 ps after 28 bounces between the dispersive mirrors. The results show that the multilayer dispersive mirror could be an effective and promising technique for pulse stretching in femtosecond fiber laser amplification systems.

2. Theoretical design and analysis

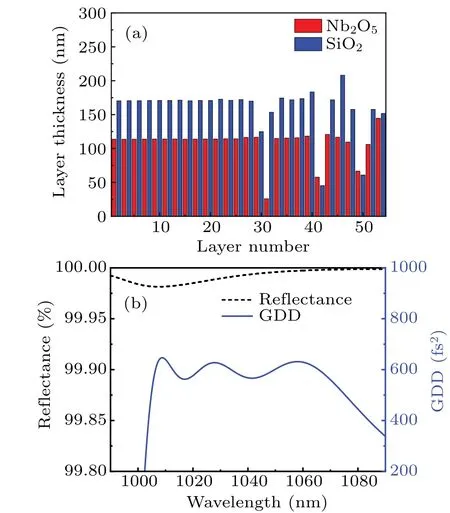

The dispersive mirrors were designed for the Yb-doped large-mode-area photonic crystal fiber oscillator. Nb2O5and SiO2are employed as high and low refractive index materials, respectively, and the substrate is BK7. The optical constants of Nb2O5and SiO2at different wavelengths are listed in Table 1. The refractive index of Nb2O5is 2.20 and SiO2is 1.48 at 1040 nm. The needle optimization method implemented in the Optilayer software was applied to design and analyze the design results of the dispersive mirrors. The structure of designed dispersive mirror is shown in Fig. 1, which consists of 54 layers alternating by Nb2O5and SiO2, and the total physical thickness is 7.3 µm. It can provide a positive group delay dispersion(GDD)of 600 fs2, with the GDD ripple under±50 fs2, and an average reflectance of over 99.9%from 1010 nm to 1070 nm.

Table 1. Optical constants of Nb2O5 and SiO2 at different wavelengths.

Fig.1. The design results of dispersive mirror: (a)structure of the multilayer dispersive mirror,(b)calculated reflectance and GDD curves of the designed multilayer dispersive mirror.

Fig. 2. Distribution of the electric field intensity inside the multilayer structure.

The distribution of electric field intensity inside the multilayer structure is demonstrated in Fig.2,to describe the mechanism of GDD compensation provided by multilayer coatings.The penetration depth represents the distance from the surface of the multilayer structure. The resonances with enhancement of intensity appear at the penetration depth of around 0.7µm,1.7 µm and 3 µm, respectively. The light of shorter wavelengths travels with deeper penetration while the longer wavelengths are reflected near the surface,therefore a positive GDD compensation can occur for pulse stretching.

The error analysis of manufacturing errors including refractive index and layer thickness are performed to evaluate the sensitivity of GDD characteristics, as plotted in Fig. 3.The area enclosed by two dashed lines neighboring the GDD designed curve represents the calculated results with a probability of 68.3%in random relative deviation of 1%for refractive index and layer thickness of each layer. The results show that GDD is highly sensitive to the refractive index and layer thickness deviations,the probably worst case is such that GDD deviation is around 970 fs2for refractive index and 805 fs2for layer thickness at 1010 nm. A decrease of GDD deviation is found in longer wavelengths. The error analysis results indicate that manufacturing of the dispersive mirror requires precise refractive index control and layer thickness monitoring.

Fig.3. GDD characteristics of the designed dispersive mirror(straight line)and the calculated deviations with random 1%refractive index errors(dashed line in blue)and thickness errors(dashed line in red).

3. Experimental results and discussions

The samples were prepared by ion beam sputtering deposition. Ion beam sputtering deposition is a highly stable process and considered as one of the best optical thin film deposition techniques. The coating plant was carried out in our home-made dual ion beam sputtering deposition system equipped with 16 cm and 12 cm RF ion sources(Veeco Inc.).The background pressure was 2×10−4Pa. Ar and O2were introduced into the system during the process and the working pressure was 5×10−2Pa. A planetary rotating substrate holder was employed to increase uniformity of layer thickness. Quartz crystal monitoring was implemented to control the layer thickness of thin films during the deposition process.

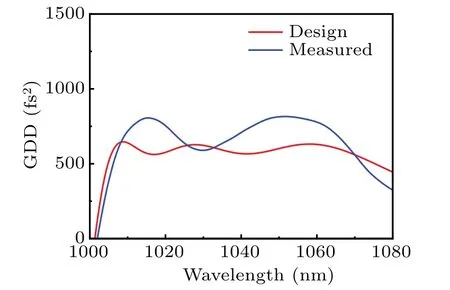

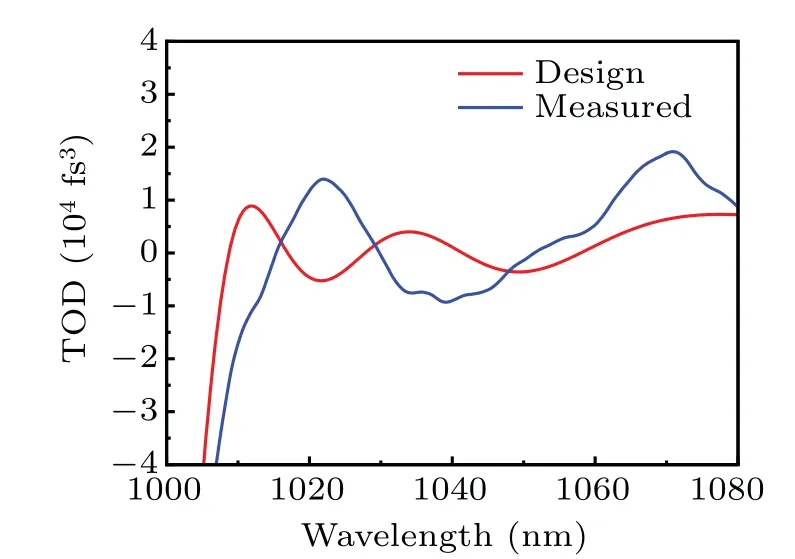

The transmittance curve of mirror was measured by a spectrophotometer (Perkin-Elmer Lambda 900). The GDD characteristics of the sample was tested by a home-made scanning white light interferometer.White light interferometer was a Michelson-type interferometer, which was used to record the interferograms of broadband light source with changing the length of reference arm and applying a specialized data processing to extract GD and GDD of the sample. The measured transmittance of the sample is plotted in Fig. 4, which shows a good agreement with the calculated results. The measured GDD characteristics of the sample are shown in Fig.5.The measured GDD is higher than the design results with a larger ripple, an average GDD of +722 fs2from 1010 nm to 1070 nm. TOD is introduced with the ripple of GDD, measured at an average of 1634 fs3from 1010 nm to 1070 nm.The deviations are at acceptable level due to manufacturing errors during the preparation.

Fig.4. Design and measured transmittance curves of the sample.

Fig.5. Design and measured GDD characteristics of the sample.

Fig.6. Design and measured TOD characteristics of the sample.

The experimental setup with implement of dispersive mirrors as pulse stretcher is demonstrated in Fig. 7. An original pulse is generated from Yb-doped large-mode-area photonic crystal fiber oscillator, and compressed by the gratings, with an FWHM of autocorrelation function of 83 fs. A total GDD of around +20000 fs2is provided by the dispersive mirrors with 28 bounces between them, which is enabled to output a stretched pulse with FWHM of 1.29 ps. A higher GDD compensation can be achieved for more bounces in demand. The results show that the multilayer dispersive mirror could be an effective and promising technique for pulse stretching in femtosecond amplification systems.

Fig.7.Experimental setup of Yb-doped large-mode-area photonic crystal fiber femtosecond laser amplification system employing with dispersive mirrors.

Fig.8. The autocorrelation trace of input pulse and stretched by dispersive mirrors.

4. Conclusion and perspectives

We have presented a high-dispersive multilayer mirror for pulse stretching in a Yb-doped large-mode-area photonic crystal fiber femtosecond amplification system. The mirror designed containing 54 layers with a total physical thickness of 7.3 µm can provide a considerable positive GDD of 600 fs2and a high reflectance over 99.9%from 1010 nm to 1070 nm.The samples were prepared by dual ion beam sputtering. The measured transmittance shows good agreement with the theoretical result. The GDD characteristics of the sample was tested by white light interferometer. The measured GDD is higher than the design results, an average GDD of +722 fs2from 1010 nm to 1070 nm. The TOD is introduced with the ripple of GDD at an average of 1634 fs3from 1010 nm to 1070 nm. The mirrors employed in the Yb-doped large-modearea photonic crystal fiber amplification system,an input pulse compressed by the gratings with autocorrelation function of 83 fs, is obtained with FWHM of 1.29 ps after 28 bounces between the dispersive mirrors. The results show that the multilayer dispersive mirror could be an effective and promising technique for pulse stretching in femtosecond amplification systems.

Acknowledgement

Project supported by the National Natural Science Foundation of China(Grant No.61705194).

杂志排行

Chinese Physics B的其它文章

- Direct measurement of two-qubit phononic entangled states via optomechanical interactions

- Inertial focusing and rotating characteristics of elliptical and rectangular particle pairs in channel flow

- Achieving ultracold Bose–Fermi mixture of 87Rb and 40K with dual dark magnetic-optical-trap

- New experimental measurement of natSe(n,γ)cross section between 1 eV to 1 keV at the CSNS Back-n facility

- Oscillation properties of matter–wave bright solitons in harmonic potentials

- Synchronously scrambled diffuse image encryption method based on a new cosine chaotic map