Progress on Space Materials Science in China:Debris Shielding Fibrous Materials and High Specific Energy Lithium Sulfur Batteries*

2022-08-18WUNanLIUShuangkeZHANGXiaoshanSUNWeiweiZHENGChunmanWANGYingde

WU Nan LIU Shuangke ZHANG Xiaoshan SUN Weiwei ZHENG Chunman WANG Yingde

(College of Aerospace Science and Engineering, National University of Defense Technology, Changsha 410073)

Abstract The development of China’s space industry puts forward urgent requirements for high-performance debris shielding materials and high energy density rechargeable battery.In this review,the recent progress on debris shielding fibrous materials and high energy density Li-S battery are particularly summarized.According to the experimental results,basalt fibers and silicon carbide fibers were chosen as the effective filling shielding materials.The geometric structure of fabrics was also investigated.For the novel shielding materials,high-strength and flexible silicon carbide micro-nano fibrous membranes were designed and fabricated.The obtained membranes with excellent mechanical properties portend the potential applications in debris protection structure.Furthermore,the high specific energy lithium sulfur batteries have made remarkable progress in fundamental research and application research in recent years.In order to solve the key problems of polysulfides shuttle and slow redox kinetics in lithium sulfur battery,a series of transition metal compound@hollow carbon-based material as sulfur host with dual functions of catalysis and adsorption towards polysulfides were designed and constructed.The obtained Li-S pouch cells with high areal sulfur loading of 6.9 mg·cm–2 yield exceptional high practical energy density of 382 W·h·kg–1 under lean electrolyte of 3.5 μL·mg–1,demonstrating the great potential of realistic high-energy Li-S batteries.

Key words Space materials,Silicon carbide fibers,Debris shielding,Li-S battery

1 Research Progress of Space Debris Shielding Fibrous Materials

According to the design requirements of spacecraft reliability and the results of space debris risk assessment,space debris shielding design is required for Tiangong-1 and Tiangong-2 of China’s manned spaceflight project II and the Tiangong Space Station of the manned spaceflight project III.It is well known that the Tianhe core module,which was successfully launched on 29 April 2021,is used to unify the control and management of the space station assembly.It provides living and working space for astronauts and supports scientific research in some disciplines,while the Mengtian and Wentian experimental modules to be launched subsequently are mainly used to support space science and application research.The core module of the Tiangong Space Station is 18.1 m long,with a maximum diameter of 4.2 m,and has an orbital lifetime of 15 years,making it much more vulnerable to space debris.The results of the space debris risk assessment indicated that the Whipple shielding structure could not be used to protect the space station to meet the overall specifications.In response,the General Design Department of Beijing Space Vehicle adopted ceramic fibers into the debris shielding structure.A large number of numerical simulations and hypervelocity impact tests were carried out to complete the screening of the stuffed layer of ceramic fibers after thermal cycle tests and thermal vacuum tests[1].

1.1 Experimental Results of Silicon Carbide Fibers

To date,the General Design Department of Beijing Space Vehicle has tried more than a dozen materials such as carbon fiber fabrics,glass fiber fabrics,Kevlar fiber fabrics,silica fiber fabrics,basalt fiber fabrics,SiC fiber fabrics,SiC blankets,and PBO fiber fabrics.After engineering screening of these fabrics,two engineering schemes of SiC and basalt stuffed shields are finally determined.The comparative schematic diagrams of ballistic characteristics of the SiC stuffed shield,basalt stuffed shield,Nextel stuffed shield and three-layer aluminum plate shield are given inFig.1(the data above 7 km·s–1are the fitting results).The ballistic limits of the basalt stuffed shield at low velocities are slightly higher,and the ballistic limits of the SiC stuffed shield at high velocities are slightly higher.The overall protection property of the two stuffed shields is comparable to that of the Nextel stuffed shield used on the ISS,and much better than that of the three-layer aluminum plate shield of equal surface densities.

Fig.1 Comparison of ballistic limit curves of filled protective structures

For the excellent protection effect of SiC fibers,the shielding property of its structure under high-speed impacts in large diameter debris (diameter greater than 1 cm) was studied experimentally and compared with that of the three-layer aluminum shield,in which the surface density remains the same as the other two stuffed layers.Fig.2(a) shows the test results of a projectile with a diameter of 4.22 cm and a velocity of 3.16 km·s–1striking a SiC stuffed shield.Fig.2(b) shows the test results of a projectile with a diameter of 4.22 cm and a velocity of 3.23 km·s–1striking a three-layer aluminum plate shield.Under the given operating conditions,both the SiC stuffed shield and the three-layer aluminum plate shield are found slightly damaged,but the damaged condition of the former rear plate is smaller than that of the latter,but the difference is relatively insignificant.In addition,the protection property under hypervelocity impacts was also evaluated in tests.Fig.2(c) shows the test results of a projectile with a diameter of 6.50 cm and a velocity of 6.57 km·s–1striking a SiC stuffed shield,andFig.2(d)shows the test results of a projectile with a diameter of 6.50 cm and a velocity of 6.43 km·s–1striking a threelayer aluminum plate shield.Under the given operating conditions,a minor damage is found to occur in the SiC stuffed shield,while a severe burst damage is found to occur in the three-layer aluminum plate shield,which is a significant difference.

Fig.2 Structural damage of three-layer aluminum and SiC fibers after different impacting velocity and different projectile diameter

The comprehensive experimental study and simulation results demonstrate that the application of SiC fibers in the space station debris shield is feasible and can meet the safety threshold requirements of the space station.Later,research will carry on the improvement research on the weaving properties,scale preparation and cost reduction of SiC fibers.

1.2 Optimization of Silicon Carbide Fabric Structure

Based on the characterization analysis of SiC fiber properties,the optimized design of the fabric structure can further enhance the protection effect under the premise of meeting the requirements of the overall shield on the thickness of the fabric stuffed layer and the surface density index.The design of the fabric structure needs to take into account several aspects.

(1) The bending of the fibers in the fabric will cause some damage to itself,further reducing the mechanical strength of the fibers,which seriously affects the structural integrity of the fabric and the mechanical properties it exerts.

(2) The increase in the number of fiber yarns per unit area of the fabric can increase the number of SiC fibers that collide with the incident debris,which is conducive to a more adequate fragmentation of the projectile.

(3) The fiber convexity of the fabric surface is the initial contact point between the whole structure and the incident debris,and the design to increase the density of the convexity is conducive to increasing the impact point between the fabric and the debris within the unit surface density.

(4) The yarn orientation,winding method and entanglement point density in the fabric determine whether the response behavior of the stuffed layer tends to be rigid or flexible under the hypervelocity impact of the debris cloud,which is also of vital significance to whether the stuffed layer can effectively intercept the debris cloud.

1.2.1 Choice of Fabric Type

According to the above analysis,the fabric type was firstly studied.The original tissue of the two-dimensional fabrics includes plain,twill and satin weaves.In the shield,the fabric as the stuffed layer must have a certain degree of stiffness to resist the deformation brought about by the impact of the debris cloud,so as to achieve a better incision effect and interception effect on the debris.Therefore,it is required to use the type with high entanglement and stronger fabric structure for fabric in the stuffed layer,and finally the plain weave fabric type is preferred.

1.2.2 Optimization of Buckling Wave Height of Warp and Weft Yarns in Fabrics

The geometric structure of the fabric refers to the different coordination conditions of buckling wave heights in the interweaving of warp and weft yarns.The larger the buckling wave height of SiC fiber bundles in the interwoven state,the more severe the bending deformation.The fibers break when the radius of curvature formed by the buckling wave height is smaller than the minimum radius of curvature allowed to resist fracture.Judging from the mechanism of the fiber bundle fracture and disintegration,the fracture is caused not only by slip among fibers but also by fiber itself.The fiber fracture will seriously damage the strength of the fabric,so it is an effective way to prevent the loss of strength of the fabric to control the buckling wave height of the fiber bundle and choose the fabric structure rationally.

The supporting surface of the fabric refers to the ratio of the area of the fabric in contact with a certain plane under a certain pressure.In the 5th phase geometry,the warp and weft yarns have the same buckling wave height,and both warp and weft yarns are displayed on the fabric surface,so there are more surface supporting points.The supporting point is reflected in the hypervelocity impact protection as its impact point with the secondary debris cloud,which directly affects the ability of the stuffed fabric layer to break and intercept the secondary debris.Taking the above two aspects into consideration,the 5th phase of the fabric structure on the one hand can unify the buckling wave height of the fiber bundle in L0/2,which avoids the fiber damage caused by excessive bending of some yarns in the fabric(such as warp or weft),and ensures the integrity of the fabric structure.On the other hand,it also increases the impact point between the fabric surface and the debris cloud,which can effectively improve the capacity of the fabric to break and intercept the debris.

1.2.3 Determination of Geometric Structure Parameters of Fabrics

In order to reduce the fracture of SiC fibers during the weaving process,we focus on the following points from the perspective of fabric structure design:To avoid excessive bending of fibers and fiber bundles during interweaving of SiC fabrics,reasonable fabric weaves and interweaving structures are selected according to different fiber bundles and fabric densities.The warp and weft density and fabric tightness of SiC fabrics are reasonably determined to avoid excessive bending and fracture of SiC fabrics and fiber bundles during interweaving as far as possible.Although the elongation of the fiber is smaller than the calculated value due to the incline and the change of the inside and outside position of the fiber in the twisting process,the minimum allowable radius of curvature for the fiber not to be broken is reduced,and the actual woven density of the fiber fabric is increased.Therefore,the actual weaveable density and tightness of the non-compact structure fiber fabric can be greater than the calculated value in actual production.However,considering that SiC fibers are ceramic brittle fibers with low twist resistance,and twisting may make the fibers break easily,the SiC fabrics are generally not twisted during the weaving process.

In summary,the structural parameters of the SiC fiber fabric are preferably selected as follows.

(1) Determination of fabric type and thickness:Plain weave fabric type is adopted as required by protection properties for fabric fastness,with a preferred fabric thickness of 0.4 mm.

(2) Determination of geometric structure phase:On the one hand,it aims to make the buckling wave height of the warp yarn and the weft yarn the same and reduce the deformation damage of the fiber;in addition,the warp and weft yarns are subjected to external forces simultaneously in the protection process,so it is necessary to use the same supporting surface to increase the impact point between the fabric and the debris,so the 5th structural phase is preferred.

(3) Warp and weft yarn tightness:Considering the consistent tightness of warp and weft,the warp tightness is 48% and the weft tightness is 50%.

(4) Warp and weft yarn density:according to the warp and weft yarn tightness,the warp yarn density should be 48 threads/10 cm and the weft yarn density should be 50 threads/10 cm.

1.3 Micro-nano Ceramic Fibers for Space Debris Shielding

As is well known that the main yarn is the main body of energy absorption in the fabrics.Due to the failure model is tension fracture,the selected fibers with highstrength,high-fracture elongation is one of the effective ways to improve the energy absorption of three-dimensional fabrics.In addition,under the penetration of highspeed ballistics,the friction among multiple layers of fabric layers is negligible.The total absorbed energy by the whole fabric during ballistic penetration is equal to the product of the energy absorbed by the single-layer fabric and the number of layers.Therefore,the more layers there are,the more energy the fabric absorbs.In summary,SiC fibers with the decreased diameter,high strength and high modulus are beneficial to improve the shielding effect[2].

According to the above analysis,robust micro to nano SiC fibrous membranes were developed recently in China[3].The membranes composed of randomly oriented nanofibers with an average diameter of 550 nm were fabricated by a combination of electrospinning and postheat-treatment process.The mechanical properties of the as-prepared membranes were enhanced significantly through in-situ embedded nanoparticles into the SiC fibers.The optimized SiC fibrous membrane demonstrated a low flexural modulus of 7.79 kPa,a high tensile strength of 33.2 MPa and the elastic modulus of 618 MPa,respectively.The smaller flaw size,initiation of nanocracks and pinning effect by the in-situ formed nanoparticles are believed to contribute mostly to the enhanced mechanical properties.The obtained SiC fibrous membranes with good thermal stability and excellent mechanical properties display potential applications on debris shielding structures.

The space station operating in the earth orbits needs insulating treatment.The filled fabrics in the debris shielding structure with thermal insulation property are favorable for the weight reduction.It has been found that constructing porous structure is an effective way to reduce thermal conductivity of fibers.On the one hand,this structure can lengthen the heat transfer path,leading to solid heat transfer reduced.On the other hand,this structure contributes to enhance multiple reflection-absorption of IR radiation,which can decrease radiation heat transfer.Therefore,ceramic fibers with proper porous structure may effectively enhance their thermal insulation performance.

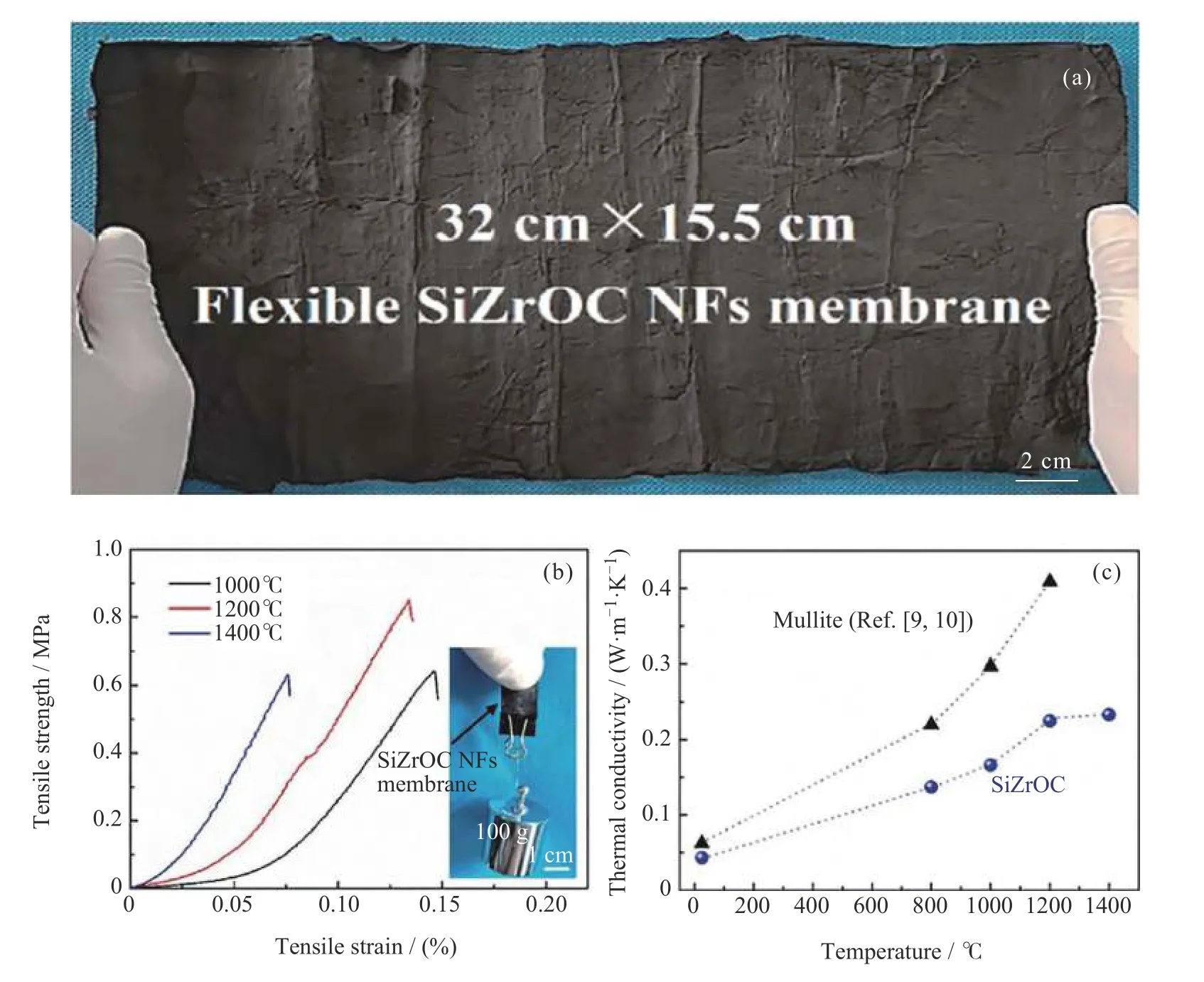

Based on the above demand,the SiZrOC NFs with integrated properties of high flexibility,excellent fire resistance,oxidation resistant (850℃ in air),high-temperature stability (1200℃ in Ar) and low thermal conductivity (about 0.0511 W·m–1·K–1at 25℃ in air) were fabricated (Fig.3)[4,5].Furthermore,the obtained SiZrOC NF membranes pyrolyzed at 1200℃ showed a maximum tensile strength of 0.812±0.086 MPa,which was similar to the most reported high-strength ceramic NF membranes.A piece of SiZrOC NF membrane (with a width of about 15 mm) pyrolyzed at 1200℃ exhibited robust mechanical strength that could hang a 100 g weight without fracture.The tensile strength (0.792±0.101 MPa)of the SiZrOC NF membranes was well maintained after the bending test.The ultralow thermal conductivity benefits from the reasonably designed multi-phase microstructure,which enhanced the phonon transfer barrier and effectively decreased the infrared radiation heat transfer.The excellent thermal stability is likely attributed to the formation of thermal stable Si-O-Zr structure.These outstanding properties of high strength and excellent thermal insulation make our SiZrOC NFs promising debris shielding materials in extreme conditions.

Fig.3 (a) Digital image of the large-scale SiZrOC NF membrane;(b) stress-strain curves of the SiZrOC NF membranes;(c) thermal conductivity of the SiZrOC NFs and reported mullite fibers membranes

2 Recent Progress of High Energy Density Li-S Battery

Due to the outstanding theoretical energy density of 2600 W·h·kg–1,natural abundance,low cost,environment-friendliness and good safety,lithium sulfur battery with sulfur as the cathode and lithium metal as the anode is regarded as one of the most promising new high energy density rechargeable battery technologies.

For the urgent demand for HALE UAVs,Near Space Airships,Electric Aircraft,and Submarines for high energy density rechargeable battery,many countries attach great importance to the research and development of high energy density lithium sulfur batteries.NASA has positioned it as one of the five key technologies “supporting the future space platform” and “new technology of earth observation technology and long-life secondary battery”.In the “Horizon 2020” R&D plan,the EU launched the ALISE plan,focusing on the research and development of new materials and electrochemical technology involving lithium sulfur battery,aiming to reach a 500 W·h·kg–1lithium sulfur battery that works stable.The Italian Space Agency launched the CORDIS program and jointly developed lithium sulfur batteries without metal lithium with research institutions in Germany,Britain,Sweden and other countries.

In view of the power supply demand for long-term air residence of stratospheric airships and solar aircraft,lithium sulfur batteries with high energy density and good performance under low-temperature are ideal working batteries.China has continuously funded the research and development of lithium sulfur batteries in major projects of high-resolution earth observation system.Supported by the National Natural Science Foundation of China and the Major Projects of High-Resolution Earth Observation System,our group has carried out systematic and in-depth research on high specific energy lithium sulfur batteries,and has made remarkable progress in fundamental research and application research in recent years.

Despite the outstanding advantages,the practical application of Li-S batteries is hindered by three major challenges:(i) the intrinsic insulating nature of S8molecules;(ii) the huge volumetric changes during discharge/charge processes;and (iii) the shuttle effects along with the intermediate lithium polysulfide (LiPSs)dissolution into ether-based electrolyte.All these problems will result in low utilization of sulfur,poor rate capability and cycling stability.

3 Structure Design and Preparation of High performance Sulfur Cathode

In order to solve the key problems of polysulfides shuttle and slow redox kinetics in lithium sulfur battery,we designed and constructed a series of transition metal compound@hollow carbon-based material as sulfur host with dual functions of catalysis and adsorption towards polysulfides.

Sunet al.[6]designed a multifunctional sulfur host based on yolk-shelled Fe2N@C nanoboxes (Fe2N@C NBs) as shown inFig.4through a strategy of etching combined with nitridation for high-rate and ultralong Li-S batteries.The highly conductive carbon shell physically confines the active material and provides efficient pathways for fast electron/ion transport.Meanwhile,the polar Fe2N core provides strong chemical bonding and effective catalytic activity for polysulfides,which is proved by density functional theory calculations and electrochemical analysis techniques.Benefiting from these merits,the S/Fe2N@C NBs electrode with a high sulfur content manifests a high specific capacity,superior rate capability,and long-term cycling stability.Specifically,even after 600 cycles at 1 C,a capacity of 881 mA·h·g–1with an average fading rate of only 0.036% can be retained,which is among the best cycling performances reported.Then they further designed and prepared catalytic FeSe2nanoparticles encapsulated with carbon nanoboxes (FeSe2@C NBs) with similar structures as a multifunctional sulfur host to restrain the polysulfide shuttle effect and accelerate the polysulfide redox conversion[7].The experimental results display that the S/FeSe2@C cathode exhibits better sulfur utilization,higher rate performance,and longer cycle life compared to S/Fe3O4@C cathode.Even after 700 cycles at 1 C,an ultralow capacity decay of 0.04% per cycle of S/FeSe2@C cathode can still be maintained.The Density Functional Theory (DFT) calculations reveal that FeSe2@C NBs possess stronger chemical affinity to polysulfides and lower energy gap between bonding and antibonding orbitals,which could promote the interfacial charge transfer kinetics,thus enabling better Li-S battery performance.The strategy provides an approach to the design and construction of yolk-shelled iron-based compounds@carbon nanoarchitectures as inexpensive and efficient sulfur hosts for realizing practically usable Li-S batteries.

Fig.4 (a) Schematic illustration of the fabrication process of yolk-shelled Fe2N@C NBs.SEM of Fe2O3 nanocubes (b) (c) and Fe2N@C NBs (d)(e).TEM images (f)(g) and elemental mapping images of Fe2N@C NBs (h)–(k)

In addition,Sunet al.[8]also reported similar yolkshell nanostructured polar Co9S8inlaid carbon nanoboxes(Co9S8@C NBs) as cathode host for high-performance Li-S batteries.In this integrated structure,Co9S8nanocrystals not only provide strong chemisorptive capability for polar LiPSs,but also act as a catalyst to accelerate polysulfide redox reactions,while carbon nanobox with large inner space can offer enough space to relieve the volume expansion and physically confine LiPSs’ dissolution.As a result,the S/Co9S8@C NBs cathode exhibits high specific capacity at 1 C and the capacity retention was about 83% after 400 cycles,corresponding to an average decay rate of only 0.043% per cycle.Liuet al.[9]reported a rational design and fabrication of multi yolk-shell Co-NC@nitrogen doped hollow carbon spheres (Co-NC@N-HCSs) as sulfur host for high performance Li-S batteriesviaa nano-confined synthesis strategy.The growth mechanism of multiyolk-shell ZIF-67s@N-HCSs nanostructure was studied and the ZIF-67 yolks were tunable by changing the reactant concentration.Regarding to multi-yolk-shell Co-NC@N-HCSs hybrid,the nitrogen doped carbon shell provides effective physical confinement,abundant sulfur loading space and volume expansion alleviation,while the multi polar Co-NC yolks can enhance the internal electron conductivity inside the cavity and offer stronger chemisorption capability for LiPSs as well as catalytic effects on the redox reaction of LiPSs.Benefiting from the unique multi yolk-shell design,the S/Co-NC@N-HCSs electrode with sulfur content of 80.82 wt%,exhibits high discharge capacity of 1173 mA·h·g–1at 0.1 C and 995.8 mA·h·g–1at 1 C.It also shows long cycle life up to 450 cycles with a slow capacity decay rate of 0.13% per cycle.

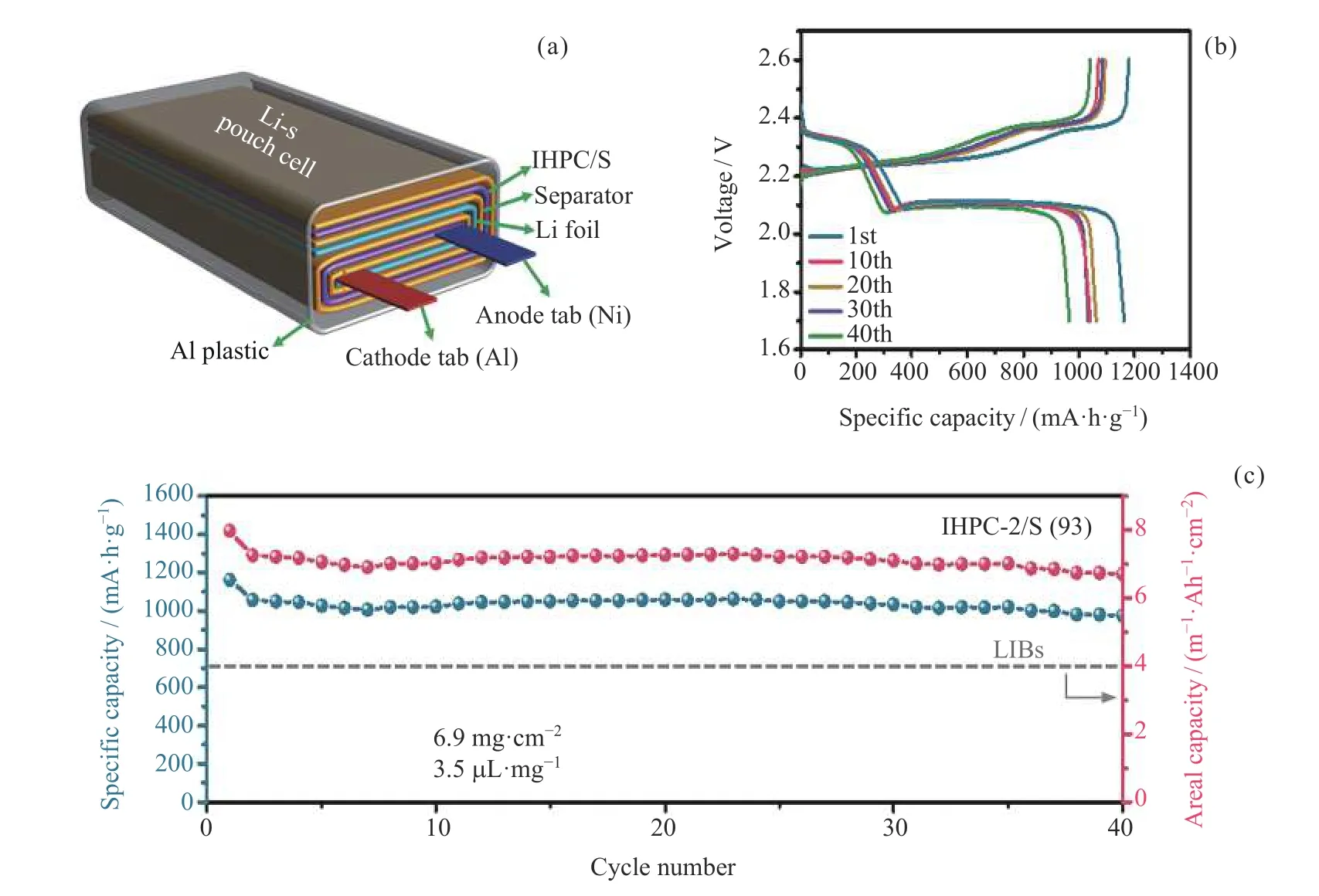

Despite the great progress of Li-S battery performance at coin-level,both key parameters and challenges at pouch cell scale to achieve practical high energy density require high-sulfur-loading cathodes and lean electrolytes.In order to improve the sulfur content and sulfur areal density while remain good electrochemical activity to obtain high energy density of Li-S battery at pouch cell level,constructing multifunctional carbon materials with high conductivity and high pore volume is very important.Wang and Liuet al.[10]reported a carbon-bubble-constructed 3 D interconnected hierarchically porous carbon with tunable wall thickness and ultrahigh pore volume through catalytic conversion of ethanol on ZnO foam template and subsequent template removal.The carbon foam integrated by hollow carbon bubble nanoreactors with ultrahigh pore volume up to 6.9 cm3·g–1is able to host 96 wt.% sulfur in the composite.Tailoring polysulfide trapping and ion/electron transport kinetics during the charge-discharge process can be achieved by adjusting the wall thickness of hollow carbon bubbles.And a further in-depth understanding of electrochemical reaction mechanism for the cathode is impelled by the in-situ Raman spectroscopy.As a result,the as-prepared cathode delivers high specific capacitances of 1269 and 695 mA·h·g–1at 0.1 and 5 C,respectively.As shown inFig.5,Li-S pouch cells with high areal sulfur loading of 6.9 mg·cm–2yield exceptional high practical energy density of 382 W·h·kg–1under lean electrolyte of 3.5 μL·mg–1,demonstrating the great potential for realistic high-energy Li-S batteries.

Fig.5 Assessment of electrochemical capability for the industrial grade Li-S pouch cells based on the IHPC-2/S (93)nanocomposite.(a) Schematic diagram of as-assembled Li-S pouch cells.(b) GCD curves and(c) cycling performance of the Li-S pouch cell at 0.1 C

杂志排行

空间科学学报的其它文章

- Recent Progress in Space Science and Applications of China’s Space Station in 2020–2022

- Overview of the Latest Scientific Achievements of Chang’E-4 Mission of China’s Lunar Exploration Project*

- Recent Status of Taiji Program in China*

- Construction Progress of Chinese Meridian Project Phase II*

- Introduction to the Chinese Hα Solar Explorer (CHASE) Mission

- Current Status and Main Scientific Outcomes of the CSES Mission*