Effects of Eco-Friendly Carrier on Low-Temperature Dyeing of Recycled Polyester Knit Fabrics

2021-10-22MAYanxue马颜雪YINYanhua殷燕华ZHANGRuiyun张瑞云LIULiuZHAOShuyuan赵树元WANGNiWANGXueli王学利

MA Yanxue (马颜雪), YIN Yanhua (殷燕华), ZHANG Ruiyun (张瑞云), , LIU Liu (刘 柳), ZHAO Shuyuan(赵树元) , WANG Ni (王 妮), WANG Xueli (王学利)

1 Key Laboratory of Textile Science & Technology, Ministry of Education, Donghua University, Shanghai 201620, China 2 College of Textiles, Donghua University, Shanghai 201620, China 3 Innovation Center for Textile Science and Technology, Donghua University, Shanghai 201620, China

Abstract: This work focused on effects of an eco-friendly carrier JYK on thermal properties, dye uptake, color yield (K/S values) and color fastness of recycled polyester knit fabrics. The study also explored optimization of the low-temperature carrier (LTC) dyeing and compared its dyeing performance to the high-temperature and high-pressure(HTHP) dyeing. Results showed that the eco-friendly carrier JYK had an obvious plasticizing effect on recycled polyester, which significantly reduced the glass transition temperature, thereby reducing the dyeing temperature and benefiting low-temperature dyeing. The optimal dyeing conditions were determined as follows: the disperse dye was 2% on weight of fabric (owf) and the eco-friendly carrier JYK was 2% owf at 98 ℃ dyeing temperature for 60 min. Compared with the HTHP dyeing, there was no significant difference in the K/S values and color fastness of recycled polyester fabrics dyed in the low-temperature method which demonstrated that the low-temperature method could be totally accepted. This study indicated that the low-temperature dyeing with a carrier JYK could be an effective and sustainable method for dyeing recycled polyester.

Key words: recycled polyester; eco-friendly carrier; low-temperature dyeing

Introduction

Polyethylene terephthalate (PET) is regarded as an excellent material for many applications and used wildly in textiles, apparel, automotive textiles and geotextiles, due to its proper mechanical performance, reasonable thermal stability, chemical resistance and color ability[1-2]. However, polyester is a non-degradable plastic in normal conditions, and complicated and expensive procedures need to be operated for degrading polyester biologically[3-4]. Increasing production and usage of polyester creates lots of wastes, and recycling of polyester products is the best way to economically reduce the waste[5-7]. The methods used to recycle polyester wastes range from mechanical recycling to various chemical recycling processes, and the recycling processes cause variations in structures and properties between virgin and recycled polyester[8-9]. Researches on recycling processes and characteristics of recycled fibers have been carried out, but only few studies discuss about fabrics properties produced from recycled polyester yarns[10-12].

Dyeing is an extremely important process for polyester fabrics applied in textile and apparel industry[13-14]. Polyester fibers are dyed with disperse dyes under high-temperature and high-pressure (HTHP) conditions[15]. This process is the most-used process over the world, but it requires costly machinery and consumes lots of energy to maintain the temperature of dye bath[16-17]. In addition, polyester is always blended with wool, silk, or elastic fibers or yarns to meet various consumer demands, but the blended products could not resist high temperature. Therefore, dyeing of polyester under low temperature is very necessary to develop its application in textiles. If the dyeing processes proceeded at 100 ℃, the disperse dyes have to be used with dispersing agents and carriers[18]. Recent studies have proposed polyester dyeing with non-toxic and degradable carriers in low temperature[19-21]. However, these studies mainly analyzed an eco-friendly carrier dyeing of virgin polyester, and did not pay enough attention to recycled polyester dyeing, which might limit the application of recycled polyester fabrics in the market.

In this paper, the study explored effects of an eco-friendly carrier JYK on thermal properties and dyeing performance of both mechanical recycled and chemical recycled polyester knit fabrics. Moreover, optimization of the low-temperature carrier (LTC) dyeing was determined and compared with HTHP dyeing, and color performance of dyed knit fabrics was tested.

1 Experiments

1.1 Materials

Materials used in the study were virgin PET from Zhejiang Tongkun Group, China, mechanical recycled PET from Shanghai Far Eastern Industries Co., Ltd., China, and chemical recycled PET filaments from Zhejiang Jiaren New Material Co., Ltd., China, and their linear densities were all 83 dtex/72 f. Three different PET filaments were knitted into single jersey fabrics on the hosiery knitting machine with 28 gauge. The disperse dye used was Blue 2BLN supplied by Zhejiang Runtu Co., Ltd., China. The eco-friendly carrier JYK was an amides compound, andN-alkyl-phthalimide was the chemical intermediate, which was non-toxic, odorless and degradable. The carrier JYK was supplied by Shanghai Jiecon Chemical High-Tech Co., Ltd., China.

1.2 Dyeing procedure

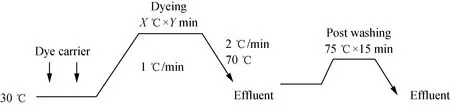

Figure 1 illustrated the dyeing process in the study. All knit samples were pretreated with 1% on weight of fabric (owf) of efficient detergent and 2% of anhydrous sodium carbonate at 30 ℃ for 30 min. In HTHP dyeing, the dye bath was prepared by dissolving 2% owf of Blue 2BLN disperse dyes, and the dyeing temperature was 130 ℃ for 50 min. In LTC dyeing, the quantity of dyes used were 2% owf, and the carrier concentrations were examined from 0.5%, 1.5%, 2.0%, 2.5% to 3.0% owf, and the dyeing temperature (X) and the holding time (Y) were optimized in the study. For each dyeing operation, the pH value was 4.5-5.0 adjusted by glacial acetic acid, and the bath ratio was 1∶20.

After dyeing, the samples were rinsed with water and dried, and post washing was performed in a reductive solution to remove all dye absorbed onto the fiber surface. The reducing solution consisted of 2 g/L sodium bisulfite, 2 g/L anhydrous sodium carbonate and distilled water, and the bath ratio was 1∶20.

Fig. 1 Diagram of dyeing process

1.3 Testing and characterization

The glass transition temperatures were measured by differential scanning calorimetry (DSC) through measuring energy difference by temperature change. The melting profile was that temperature was increasing from 30 ℃ to 300 ℃ at a rate of 10 ℃/min, and maintained for 1 min, and decreasing to 30 ℃ at a rate of 20 ℃/min, and then increasing to 300 ℃ again at a rate of 10 ℃/min.

Color depth was assessed in terms of the color yield (K/Svalue) of dyed samples. TheK/Svalue was determined by Datacolour 600 spectrophotometer with D65 light source and 10° visual angle.

Relative dye uptake was calculated using the following equation:

(1)

where,A1was the light absorbance value of residual dye solution andA0was the light absorbance value of initial dye solution that were all measured by UV-light spectral scanning instrument;n1was the dilution ratio of residual dye solution andn0was the dilution ratio of initial dye solution.

Color fastness to washing was tested according to GB/T 3921—2008 Textiles—Tests for color fastness—Color fastness to washing with soap or soap and soda. Dry and wet color fastness to rubbing was tested according to GB/T 3920—2008 Textiles—Tests for color fastness—Color fastness to rubbing.

2 Results and Discussion

2.1 Plasticizing effect of carriers on thermal property

Mechanical or chemical recycling could cause few changes in polymer structures of recycled PET, influencing their thermal performance and the dyeing process. The study firstly made a comparative analysis of the glass transition temperature of virgin PET, mechanical recycled PET and chemical recycled PET. To test plasticizing effect of the carrier JYK on the thermal property, the pretreated PET knit samples (1 g) were put into the solution with 1 g/L carrier JYK (bath ratio 1∶20) at 98 ℃ for 90 min, and then washed with water. The glass transition temperatures of samples were shown in Table 1.

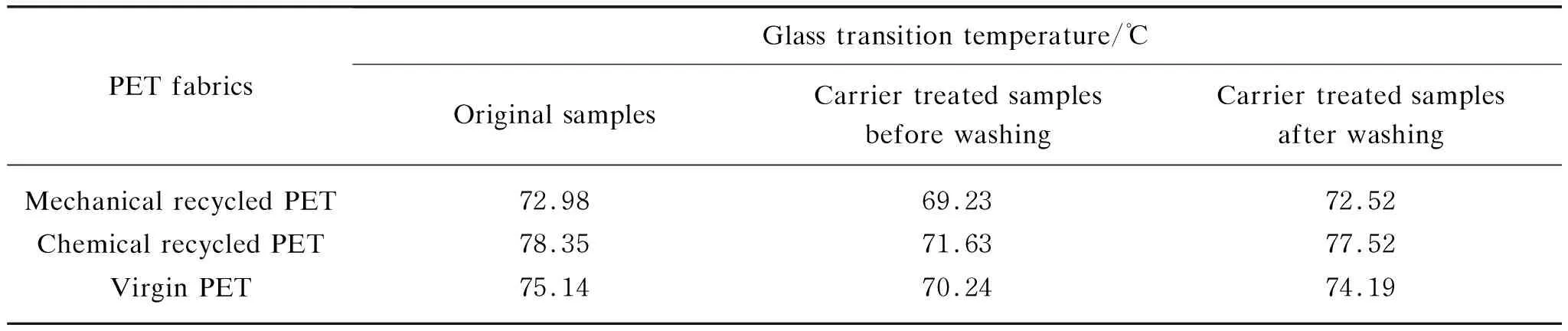

Table 1 Glass transition temperature of PET fabrics

Results described that the glass transition temperature (Tg) of virgin PET was higher than that of mechanical recycled PET, and was lower than that of chemical recycled PET. As shown in Table 1, when the PET fabrics were treated with the carrier JYK, the glass transition temperatures of all samples decreased. In particular, theTgdifference of chemical recycled PET samples reached 6.72 ℃. Tested data of carrier treated samples after washing presented that theTgwas declined and similar to their original level, indicating the carrier JYK was easily removed in washing. The carrier as a plasticizer could reduce the intermolecular forces in PET fibers and accelerate mobility of molecular chains[20, 22], leading to lower glass transition temperature and benefiting dyes diffusion. According to dyeing mechanism of disperse dyes, lower glass transition temperature could decrease the proper dyeing temperature[23].

2.2 Effects of carriers on dye uptake

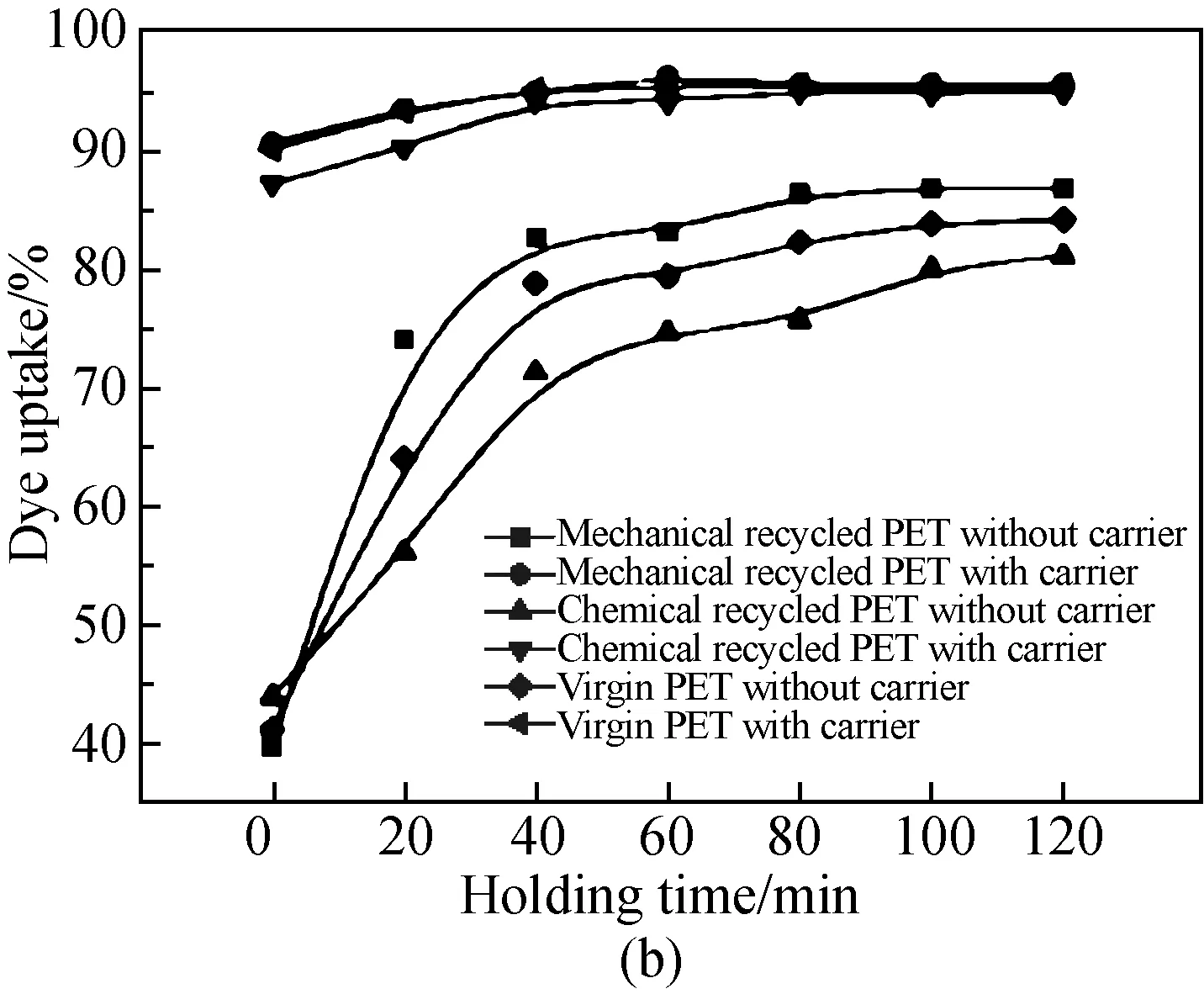

To investigate the effects of carriers on dyeing performance, the study compared the dye uptake of different PET knit fabrics dyed with and without the carrier JYK. In the experiment, the dyeing temperature was ranged from 0 to 98 ℃ and the holding time was changed from 20 min to 120 min. Measurements were shown in Fig. 2.

According to testing results, when the dyeing temperature was lower than 78 ℃ and no carrier JYK was used, the dye uptake almost zero. However, after adding the carrier, the dye uptake increased significantly, and the mechanical recycled PET fabrics presented the highest dye uptake. On one hand, as explained previously, the carrier could help reduce the glass transition temperature of PET fibers, and the mechanical recycled PET had a lowerTgthan chemical recycled PET and virgin PET. In the low-temperature dyeing, dye molecular could easily move into fibers with less orientation and more amorphous areas. On the other hand, the carrier could enhance dissolution of disperse dyes[24]. In dyeing with carriers, more dye molecular aggregated on the surface of PET fibers, and higher dye concentration decreased fiber surface tension and activation energy, so PET fibers could be dyed quickly.

Fig. 2 Dye uptake of different PET knit fabrics with and without the carrier:(a) dye uptake-temperature curves; (b) dye uptake-holding time curves

When the dyeing temperature reached 98 ℃, the dye uptake of the PET samples was accelerated as increased temperature. The use of the carrier JYK had a significant effect on improving the uptake of PET knit fabrics, but there was no significant difference between the dye uptake of recycled PET and virgin PET. Additionally, with increasing holding time from 20 min to 120 min, the dye uptake without the carrier was slowly growing, and that with carrier was almost the same. These results indicated that the holding time of dyeing did not influence the dye uptake while the dyeing temperature was 98 ℃ and the carrier was used.

2.3 Optimization of low-temperature dyeing with the carrier JYK

As presented before, recycled PET knit fabrics could be dyed with disperse dyes and the carrier JYK, but dyeing parameters, including dyeing temperature, carrier concentration and holding time, were worthy of further exploration to identify an optimal LTC dyeing. Therefore, in the study, effects of each dyeing parameter on color yield (K/Svalue) of recycled PET knit fabrics were analyzed.

2.3.1Dyeingtemperature

Mechanical recycled, chemical recycled and virgin PET knit fabrics were dyed with 2% owf of disperse dyes and 2% owf of the carrier JYK for 80 min at six levels of temperature (80 ℃, 90 ℃, 100 ℃, 110 ℃, 120 ℃, 130 ℃). TheK/Svalues of each sample dyed in different temperatures were shown in Fig. 3.

Generally, theK/Svalue increased as temperature increased. Rising dyeing temperature could increase dye uptake and dye diffusion, as well as the amorphous area in PET fibers, so more dye molecular could move into internal fibers and the dye adsorption would be enlarged[25]. That was the reason that theK/Svalue increased with higher temperature. When the temperature reached 98 ℃, changes in theK/Svalue became small; at 120 ℃, theK/Svalue was slightly declined. At that time, the dye concentration became balance between the dye solution and the PET fibers. If the temperature continued to raise, the dye adsorption would not increase obviously, and theK/Svalue maintained stable. As the glass transition temperature of the three PET fabrics after using the carrier JYK was similar (shown in Table 1),K/Svalues among them did not show a big difference when the dyeing temperature reached 90 ℃. In order to implement a low-temperature dyeing and ensure good color performance of dyed recycled PET fabrics, 98 ℃ was chosen as the optimal dyeing temperature in the LTC dyeing with disperse dyes.

Fig. 3 Effects of dyeing temperature on K/S value

2.3.2Carrierconcentration

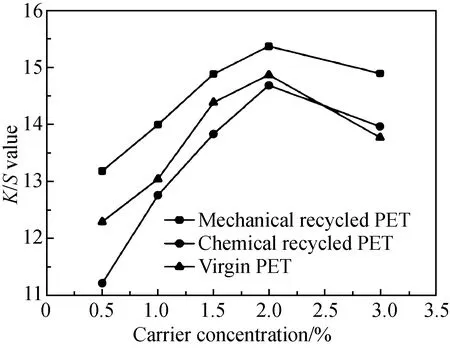

To identify effects of the carrier concentration on color yield, the recycled and virgin PET fabrics were dyed with 2% owf of blue disperse dyes at 98 ℃ for 80 min, and the carrier concentration was changed. Figure 4 illustrated changes in theK/Svalue with five levels of the carrier concentration.

It was clearly observed that theK/Svalue firstly rose and then declined following with the increase of carrier concentration, and 2% owf was an ideal percentage for the best color strength of recycled PET knit fabrics. When the carrier concentration was changed from 0.5% owf to 2% owf, plasticizing effect of carriers JYK on PET fibers was enhanced, providing lower glass transition temperature and more amorphous areas in the fiber[26]. This would benefit dye diffusion and dye uptakes. However, if the carrier concentration was above 2%, more disperse dyes were solubilized in the dye solution, thereby the dye adsorption of fibers was reduced, causing fallingK/Svalues. Generally, mechanical recycled PET knit fabrics had a higher color yield than others.

Fig. 4 Effects of carrier concentration on K/S value

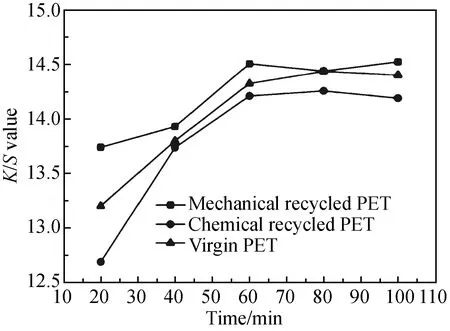

2.3.3Holdingtime

Figure 2 indicated that when dyeing temperature was 98 ℃, extending the holding time could not increase the dye uptake, but its influence on color yield should be studied further. In the experiment, all PET knit samples were dyed with 2% owf of Blue 2BLN disperse dyes and 2% owf of the carrier JYK at 98 ℃ for five levels of holding time from 20 min to 100 min.

As shown in Fig. 5, theK/Svalue was growing with the increase of holding time and maintained stable after 60 min. These results revealed that dyeing for 60 min was already enough for good dye uptake, and increasing the time could enhance color yield of the dyed PET fabrics. Considering dyeing performance, efficiency and cost, the research selected 60 min as the optimal holding time for recycled PET LTC dyeing.

Fig. 5 Effects of holding time on K/S value

2.4 Dyeing performance between two dyeing processes

To verify dyeing performance of the low-temperature dyeing with an eco-friendly carrier JYK, the research compared color yield and color fastness of both virgin and recycled PET knit fabrics to HTHP dyeing. In the HTHP dyeing, virgin PET knit fabrics, mechanical and chemical recycled PET knit fabrics were dyed at 130 ℃ for 50 min. The LTC dyeing was used parameters obtained in the study, which the dyeing temperature was 98 ℃ and the holding time was 60 min. Measurements ofK/Svalues and color fastness were listed in Tables 2 and 3.

From the results, it could be concluded thatK/Svalues of all PET knit fabrics in the two dyeing methods had no significant differences. The mechanical recycled PET fabric had a higher color yield in comparison with the chemical recycled PET and virgin PET fabrics, because of its lower glass transition temperature. In terms of color fastness to washing, no matter mechanical recycled, chemical recycled or virgin PET knit fabrics,measurements in the two dyeing processes were maintained the same. Staining of both recycled and virgin PET knit fabrics with acrylic fabrics and acetate fabrics were all 5, which meant the best color fastness. Dry and wet color fastness to rubbing of recycled and virgin PET knit fabrics had no variance. To sum up, the LTC dyeing of recycled PET fabrics especially mechanical recycled could achieve dyeing performance as good as the common HTHP dyeing.

Table 2 K/S value of dyed PET fabrics in different

Table 3 Color fastness of dyed PET fabrics in different dyeing methods

3 Conclusions

At present, no specific research was carried out to discuss low-temperature dyeing of recycled polyester. Therefore, in this study, a non-tonic, odorless and degradable carrier was used to examine its effects on dyeing performance of recycled polyester knit fabrics. According to results, the eco-friendly carrier JYK had obvious plasticizing effect on recycled polyester, significantly reducing the glass transition temperature and the dyeing temperature, and it was easily removed after washing. Moreover, the study concluded the optimal conditions in LTC. After being treated with 2% owf of disperse dyes and 2% owf of the eco-friendly carrier JYK at 98 ℃ for 60 min, theK/Svalues and color fastness of recycled polyester fabrics dyed in the low-temperature method were totally acceptable, which was no significant difference in comparison with the HTHP dyeing.

This study provided an effective and sustainable low-temperature dyeing for recycled polyester, and it will be beneficial to the extensive use of recycled polyester in fabrics, especially blended with other materials. This low-energy and sustainable dyeing process can promote an application of recycled polyester in textile and apparel industries, which will extend the life cycle of polyester products to solve the waste problems. In future research, effects of varied dye concentrations, different knit structures and other parameters on dyeing properties will be further investigated.

猜你喜欢

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Long Text Classification Algorithm Using a Hybrid Model of Bidirectional Encoder Representation from Transformers-Hierarchical Attention Networks-Dilated Convolutions Network

- Influence Mechanism of Clothing Anchor Features on Consumers’ Purchase Intention

- Estimating Mechanical Vibration Period Using Smartphones

- Application Research on K/S Value in Determination of Reactive Dyes Fixation Rate

- Influence of Fe2O3 on Release Mechanism of NH3 and Other Nitrogen-Containing Compounds from Pyrolysis of Three Typical Amino Acids in Urban Sludge

- Design and Characterization of Electrical Connections for Conductive Yarns