急斜特厚煤层残留煤柱稳定性分析及其动力灾害防治

2021-08-27李云鹏崔峰杨文化尉迟小骞

李云鹏 崔峰 杨文化 尉迟小骞

摘 要:為研究急斜特厚煤层开采过程中残留煤柱的稳定性及其应力异常区引起的回采安全问题,以乌鲁木齐矿区乌东煤矿南采区87°急斜特厚煤层为研究背景,运用块体理论构建了残留煤柱滑移失稳力学模型,采用FLAC3D数值模拟软件分析开采扰动下残留煤柱的应力演化特征,提出了残留煤柱分段深孔爆破弱化的卸压措施。结果表明:当煤层倾角α,顶板侧围岩与残留煤柱的摩擦系数μ1,底板侧围岩与残留煤柱的摩擦系数μ2之间满足α>arctan(μ1+μ2)时,残留煤柱将发生滑移失稳;残留煤柱易使顶底板应力状态改变,在开采扰动和顶底板高应力双重作用下,残留煤柱极易诱发动力灾害;卸压措施有效削减残留煤柱内部储存的应力强度,降低动力灾害的发生频率,实现工作面安全通过煤柱危险区域。

关键词:急斜特厚煤层;残留煤柱;力学模型;动力灾害中图分类号:TD 353

文献标志码:A

文章编号:1672-9315(2021)04-0657-08

DOI:10.13800/j.cnki.xakjdxxb.2021.0411开放科学(资源服务)标识码(OSID):

Stability analysis and dynamic disasters prevention of residual coal

pillar in steeply inclined and extremely thick coal seam

LI Yunpeng1,CUI Feng2,3,YANG Wenhua2,3,YUCHI Xiaoqian2,3

(1.Department of Resources and Civil Engineering,Yantai Gold College,Yantai 265401,China;

2.College of Energy Science and Engineering,Xian University of Science and Technology,Xian 710054,China;

3.Key Laboratory of Western Mine Exploitation and Hazard Prevention,Ministry of Education,

Xian University of Science and Technology,Xian 710054,China)

Abstract:In order to study the stability of residual coal pillars and the safety problems caused by abnormal stress areas during the mining of steep and extra-thick coal seams,this paper takes the 87° steep extra thick coal seam,which was in the south mining area of Wudong coal mine in Urumqi mining area,as the research objects.The mechanical model is constructed of sliding instability of residual coal pillar using the block theory,and then the stress evolution characteristics are analyzed of the residual coal pillar during the mining disturbance adapting FLAC3D numerical simulation software.

The suggestion is made to use the segmentation of residual coal pillar to pressure relief measures for weakening of deep hole blasting.The results show that when the dip angle of coal seam α,friction coefficient between surrounding rock on roof side and residual coal pillar μ1,friction coefficient between surrounding rock and residual coal pillar at floor side μ2,meet with α>arctan(μ1+μ2),the residual coal pillar will slide and lose stability;residual coal pillar is easy to change the stress state of roof and floor,so under the dual action of mining disturbance and high stress of roof and floor,residual coal pillar tends to induce dynamic disaster; pressure relief measures effectively reduce the internal storage of residual coal pillar.The stress intensity reduces the frequency of dynamic disasters and ensures the safety of working face passing through the dangerous area of coal pillar.Key words:steeply inclined and extremely thick coal seam;residual coal pillar;mechanical model;dynamic disasters

0 引 言乌鲁木齐矿区急斜特厚煤层占世界急倾斜煤层储量的30%,煤层倾角45°~87°,煤层赋存环境复杂多变[1-5],其开采工艺与近水平煤层相差甚大,动力灾害频发[6-12]。随采深的增加,历史残留煤柱顶底板区域应力集中明显[13-17],严重影响邻近煤层和残留煤柱下分段煤层的安全高效开采。目前,许多专家学者针对残留煤柱进行了多角度的分析研究。秦凯等对近距离煤层群下伏工作面过遗留煤柱异常矿压显现规律进行了研究,揭示了下伏工作面进集中煤柱异常矿压的发生机理[18];付兴玉等对上覆房式采空区集中煤柱回采动载矿压问题进行了研究,提出了提前爆破集中煤柱的防治措施[19];李春元等根据残留煤柱对底板应力的扰动规律,分析计算了残留煤柱区域下伏煤层开采的扰动范围[20];周连春等采用数值模拟软件对煤柱应力集中区的应力分布规律进行研究,提出了有效的防范措施[21];马宁等采用数值模拟软件对煤柱的塑性区和支撑压力分布演化规律进行研究,提出了回采期间煤柱监测和卸压解危措施[22];周辉等综合运用数值模拟、理论分析、现场监测等研究方法,分析了大采高工作面回撤通道煤柱内支撑应力及塑性区分布规律,建立了“煤柱-顶板”力学模型[23];于洋等研究了采空区残留煤柱的应力环境和变形状态,分析了不同宽度窄煤柱条件下煤柱的垂直应力分布,提出了残留煤柱内巷道围岩控制原则和技术[24]。上述专家学者对煤柱的稳定性以及受力状态进行了大量的研究,但针对急斜特厚煤层残留煤柱的研究相对较少,以乌鲁木齐矿区南采区87°特厚煤层为工程背景,通过理论分析、数值模拟对残留煤柱的滑移失稳以及应力演化特征进行研究,提出了分段深孔

爆破的卸压措施,有效降低了动力灾害的发生频率。

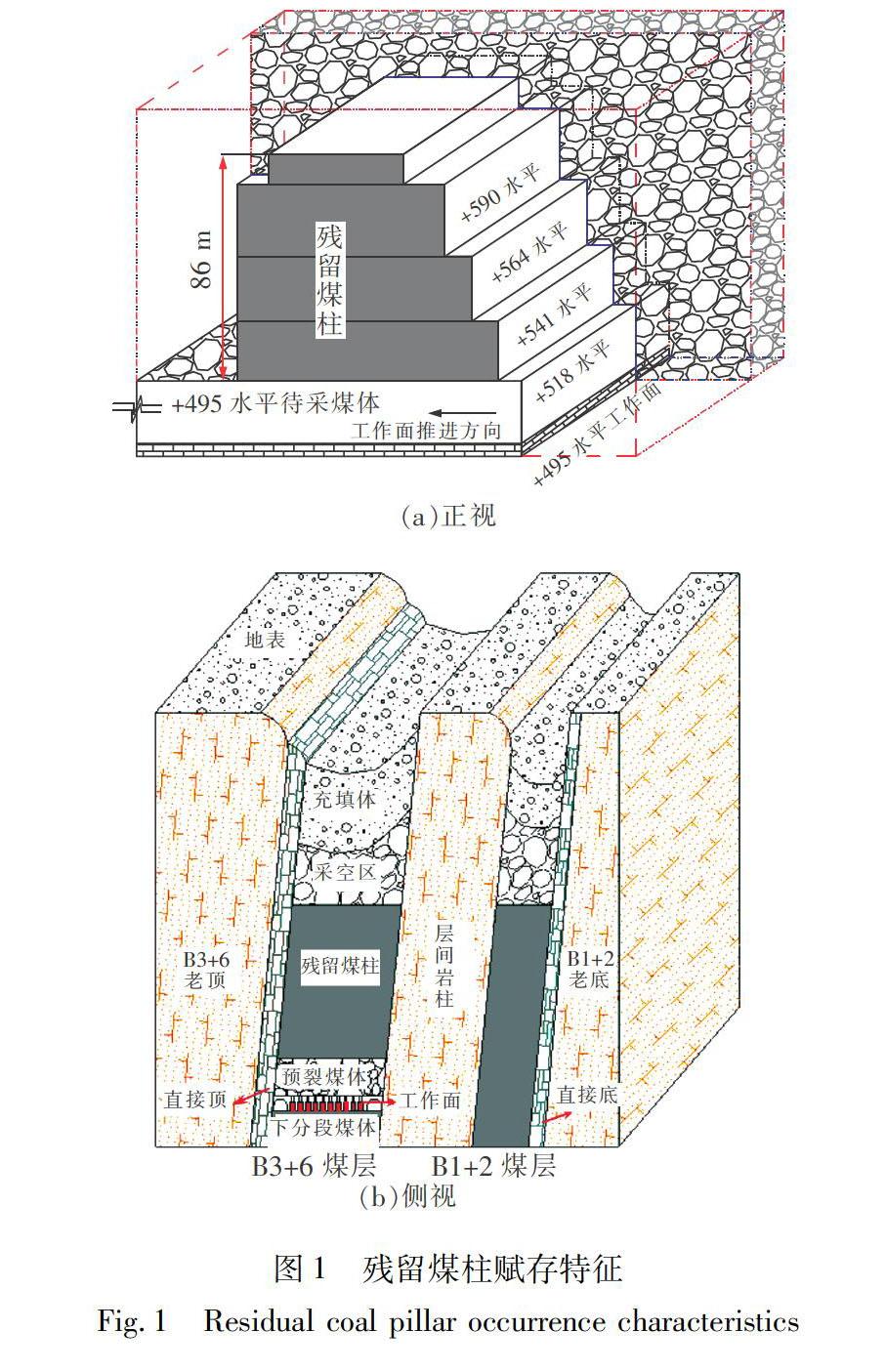

1 工程背景乌鲁木齐乌东煤矿南采区总储量达4.6亿t,主采煤层为B1+2与B3+6这2层平均倾角为87°的急斜特厚煤层,煤层厚度分别为30与40 m,且煤层之间夹杂有50 m厚的层间岩柱,层间岩柱即为B3+6煤层的底板,又为B1+2煤层的顶板。煤层老顶、老底均为粉砂岩,开采工艺为水平分段综放开采,段高为25 m,采放比达1

∶7,工作面沿煤层厚度布置。矿井初期为小煤窑仓储式开采,其中+518至+590水平东三采区有历史残留石门保护煤柱,残留煤柱高86 m,最大走向长度124 m。+495水平B3+6煤层回采穿过残留煤柱时,工作面巷道变形较大,矿压显现强烈,残留煤柱结构下易形成应力异常区进而诱发动力灾害。残留煤柱赋存特征如图1所示。

2 残留煤柱稳定性及力学特征分析

2.1 残留煤柱滑移失稳力学模型乌东煤矿南采区急斜特厚煤层开采工艺和工作面布置与缓斜煤层不同,煤层倾角越大,上覆岩层作用在残留煤柱沿倾向向下的分力以及残留煤柱自身重力沿倾向向下的分力则越大。由残留煤柱赋存结构可以看出,残留煤柱受顶底板的夹持作用,正上方以及前后均为采空区,当+495水平B3+6煤层回采穿过残留煤柱时,其正下方也将成为采空区,此时则可将残留煤柱视为一个块体。当作用在残留煤柱沿倾向向下的合力大于顶底板对其摩擦力的合力时,残留煤柱将沿倾向产生下挫运动,发生滑移失稳,从而诱发动力灾害,残留煤柱滑移失稳力学简化模型如图2所示。

在不考虑水平应力的前提下,残留煤柱受顶板侧上覆岩层非均布载荷q1(x)的作用,设其合力为F1,残留煤柱倾角为α,则F1沿残留煤柱切向分量为F1sinα

,法向分量为F1cosα;设残留煤柱受上分段采空区充填体均布载荷q2的作用,设其合力为F2,则F2沿残留煤柱切向分量为F2sinα,法向分量为F2cosα;设G为残留煤柱的重力,则重力沿残留煤柱切向分量为Gsinα,法向分量为Gcosα;设顶板侧围岩对残留煤柱的摩擦力为f1,摩擦系数为μ1,底板侧围岩对残留煤柱的摩擦力为f2,摩擦系数为μ2;残留煤柱受底板侧围岩沿法向均布载荷q3的作用,设其合力为F3。则当残留煤柱发生滑移失稳时有如下关系

F1sinα+F2sinα+Gsinα>f1+f2

f1=μ1F1cosα

f2=μ2(F1cosα+F2cosα+Gcosα)

(1)将(1)式进行化简最终可以得到

F1>

(G+F2)(μ2-tanα)

tanα-μ1-μ2

(2)

式中 F1,G,F2都是恒大于零的常数,煤层倾角α为87°,则分子是恒小于零的常数,要使式(2)恒成立,分母恒大于零时则等式恒成立,可以得到

α>arctan(μ1+μ2)

(3)当α>arctan(μ1+μ2)时残留煤柱将产生下挫运动,发生滑移失穩,从而诱发动力灾害。

2.2 残留煤柱应力场分布特征为了获得随+495水平B3+6煤层回采穿过残留煤柱时,残留煤柱的应力演化特征,采用FLAC3D数值模拟软件进行模拟计算与分析,模型如图3所示。煤层倾角为87°,B3+6煤层厚度为40 m,B1+2煤层厚度为30 m,直接顶、直接底厚度为8 m,残留煤柱高为86 m,层间岩柱厚度为50 m,模型尺寸为246 m×50 m×250 m(X×Y×Z),根据现场取样及岩体力学特性,选用摩尔-库伦本构模型,沿Y方向推进。在X方向施加梯度水平应力模拟构造应力对顶底板及煤层的压力,通过室内岩石力学实验获得煤岩体力学参数见表1。

图4为+495水平B3+6煤层回采穿过残留煤柱时,残留煤柱垂直应力与应力分布矢量特征。从图4(a)可以看出,随+495水平B3+6煤层工作面的推进,残留煤柱、B1+2煤层局部区域在垂直方向上都出现了明显的应力升高特征;随工作面的走向推进,残留煤柱悬空面积会随之增大,将会促使残留煤柱下方未采煤体应力集中程度进一步增大;当残留煤柱在垂直方向上的应力超过其承载能力时,将会发生剪切滑移破坏,从而诱发动力灾害;残留煤柱的存在致使+495水平B3+6煤层工作面顶板相对于残留煤柱呈现出应力降低特征,顶板不易发生变形,易形成悬空顶板,当悬空顶板突然垮落时,将诱发动力灾害。从图4(b)可以看出,残留煤柱将B3+6煤层上覆岩层的作用力传递到了层间岩柱上,即B1+2煤层的顶板上,使得B1+2煤层顶板处局部范围内出现应力集中现象,应力强度显著增大。残留煤柱不仅对+495水平以及+495水平以下B3+6煤层的安全开采有重要影响,还对邻近B1+2煤层的安全高效开采产生重要影响。因此,必须有效削减残留煤柱储存的应力强度,进而实现安全高效生产。

3 残留煤柱动力灾害防治

3.1 防治措施残留煤柱的滑移失稳以及其所产生的应力集中,极易诱发动力灾害。工作面的推进过程中,现场矿压显现强烈,巷道变形破坏严重,为了降低动力灾害的发生频率,确保工作面的安全高效开采,提出了如图5所示的残留煤柱分段深孔爆破弱化的卸压措施。利用东三采区各分段石门作为爆破工艺巷,对东三采区残留煤柱从+590到+518水平自上而下进行分段深孔爆破。在+590水平石门布置10排炮孔,排距5m,每排5个炮孔,总装药量25.6 t;+564水平石门布置7排炮孔,排距为7 m,每排6个炮孔,总装药量57.6 t;+541水平石门布置8排炮孔,排距为7 m,每排7个炮孔,总装药量55.2 t;+518水平石门布置11排炮孔,排距为5 m,每排11个炮孔,总装药量67.6 t。

3.2 现场综合实测及效果评价为了确定防治措施的作用效果,在对残留煤柱实施分段深孔爆破卸压后,现场通过钻孔窥视仪、地质雷达、电磁辐射仪对+495水平工作面前方待采煤体和残留煤柱进行了综合实测。为了查看残留煤柱实施卸压措施后,其内部的裂隙发育特征,在+495水平B3巷超前工作面15 m处,通过钻孔窥视仪对残留煤柱进行钻孔监测,监测方案如图6(a)所示,图6(b)为现场监测结果。可以看出,0~20 m处孔内煤壁相对完整,此处为+495水平待采顶煤,未进行深孔爆破;20~30 m处孔内煤壁出现大量裂隙,孔壁较为破碎;30~45 m处孔内煤壁破碎程度最为严重,说明深孔爆破卸压措施有效致裂了残留煤柱。

地质雷达通过发射高频电磁脉冲波和接收反射波来形成探测图像。完整煤体和破碎煤体的介电常数存在明显差异性,即存在明显的分界面,则发射波遇到不同的分界面将会产生不同的反射波。在+495水平B6巷超前工作面15 m处,通过地质雷达对残留煤柱进行测深60 m、走向测距100 m的平面立体探测,探测方案如图7(a)所示,图7(b)为现场探测结果。可以看出,在测深0~5 m范围内探测图以紫色、绿色和红色交错分布,表明此处煤体已发生破碎,但破碎程度较小,为巷道塑性区范围;5~20 m范围内探测图以红色为主,相对均匀分布,表明此处煤体较为完整,裂隙发育较小,因为此范围主要是+495水平待采顶煤,未进行深孔爆破;20~50 m范圍内探测图以绿色、黄色和紫色交错分布,颜色变化复杂且变化程度最大,表明此处煤体破碎程度最为严重,进一步说明了卸压措施有效的致裂了残留煤柱。

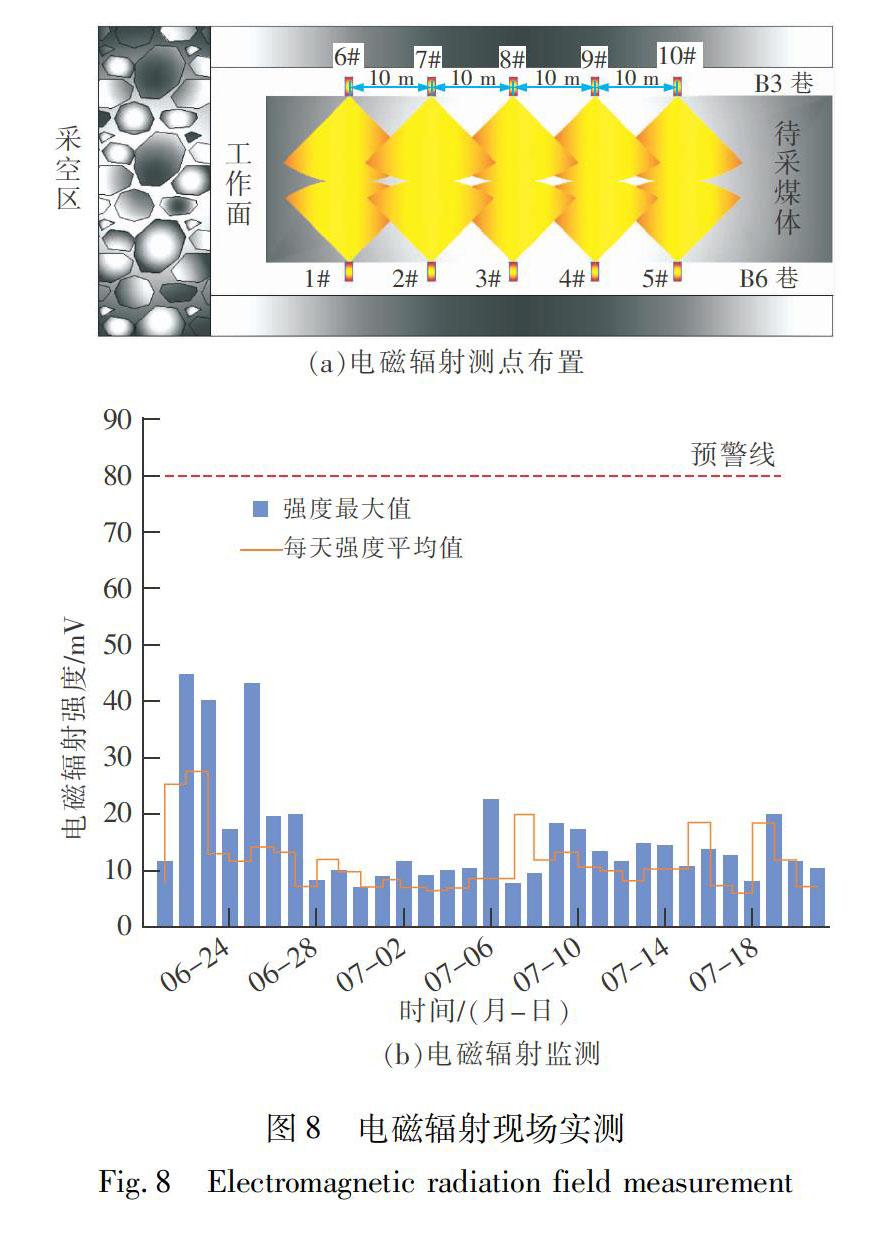

煤岩体内部应力越大,变形破裂程度将越大,则变形破裂所释放的电磁辐射能量也就越高,电磁辐射强度与煤岩体内部应力成正比关系。现场采用KBD-5电磁辐射仪对+495水平工作面前10~50 m范围内进行测点布置,在B6和B3巷各布置5个测点,测点间距10 m,测点随工作面的推进保持随动状态,测点布置方案如图8(a)所示,图8(b)为31 d的现场持续监测结果。可以看出,深孔爆破卸压后,工作面前方待采煤体电磁辐射强度值明显下降,每天平均强度值小于30 mV,每天强度最大值小于45 mV,远小于未实施卸压措施前,现场发生动力灾害时的预警值80 mV,说明卸压措施有效降低了+495水平工作面前方待采煤体的应力强度。

4 结 论1)运用块体理论构建了残留煤柱滑移失稳力学模型,得出当作用在残留煤柱沿倾向向下的合力大于顶底板对其摩擦力的合力时,残留煤柱将发生滑移失稳,从而诱发动力灾害,并获得了残留煤柱滑移失稳的必要条件为α>arctan(μ1+μ2)。

2)随工作面的推进,残留煤柱、B1+2煤层局部区域在垂直方向上出现了明显的应力升高特征;残留煤柱的存在将使B3+6煤层工作面的顶板侧应力降低,易形成悬空顶板;残留煤柱起到了应力传递的作用,使B1+2煤层顶板处局部范围内出现应力集中现象。3)现场钻孔窥视仪、地质雷达、电磁辐射仪综合实测结果表明:残留煤柱分段深孔爆破卸压措施效果显著,成功解除了由于上覆残留煤柱应力集中而可能导致工作面回采过程中发生的动力灾害,实现了动力学破坏过程中储能的改变与转移。

参考文献(References):

[1]

张宏伟,荣海,陈建强,等.基于地质动力区划的近直立特厚煤层冲击地压危险性评价[J].煤炭学报,2015,40(12):2755-2762.ZHANG Hongwei,RONG Hai,CHEN Jianqiang,et al.Risk assessment of rockburst based on geo-dynamic division method in suberect and extremely thick coal seam[J].

Journal of China Coal Society

,2015,40(12):2755-2762.

[2]来兴平,李云鹏,王宁波,等.基于梁结构的急斜煤层综放工作面顶板变形特征[J].采矿与安全工程学报,2015,32(6):871-876.LAI Xingping,LI Yunpeng,WANG Ningbo,et al.Roof deformation characteristics with full-mechanized caving face based on beam structure in extremely inclined coal seam[J].Journal of Mining and Safety Engineering,2015,32(6):871-876.

[3]鞠文君,李前,魏东,等.急倾斜特厚煤层水平分层开采矿压特征[J].煤炭学报,2006,31(5):558-561.JU Wenjun,LI Qian,WEI Dong,et al.Pressure character in caving steep-inclined and extremely thick coal seam with horizontally grouped top-coal drawing mining method[J].Journal of China Coal Society,2006,31(5):558-561.

[4]王宁波,张农,崔峰,等.急倾斜特厚煤层综放工作面采场运移与巷道围岩破裂特征[J].煤炭学报,2013,38(8):1312-1318.WANG Ningbo,ZHANG Nong,CUI Feng,et al.Characteristics of stope migration and roadway surrounding rock fracture for fully-mechanized top-coal caving face in steeply dipping and extra-thick coal seam[J].Journal of China Coal Society,2013,38(8):1312-1318.

[5]刘旭东.乌东煤矿南区急倾斜特厚煤层冲击地压发生机理与防治研究[J].煤炭工程,2016,48(1):62-65.LIU Xudong.Study on occurring mechanism and prevention of rock burst in extra-thick steep coal seam in southern area of Wudong coal mine[J].Coal Engineering,2016,48(1):62-65.

[6]来兴平,杨毅然,陈建强,等.急斜特厚煤层群采动应力畸变致诱动力灾害控制[J].煤炭学报,2016,41(7):1610-1616.LAI Xingping,YANG Yiran,CHEN Jianqiang,et al.Control of dynamic hazards induced by mining stress distortion in extremely steep and thick coal seams[J].Journal of China Coal Society,2016,41(7):1610-1616.

[7]来兴平,孙欢,蔡明,等.急斜煤层浅转深综放开采煤岩动力灾害诱发机理[J].西安科技大学学报,2017,37(3):305-311.

LAI Xingping,SUN Huan,CAI Ming,et al.Mechanism of dynamic hazards due to coal and rock mass instability in extremely steep coal seams with the deepening mining[J].Journal of Xian University of Science and Technology,2017,37(3):305-311.

[8]蓝航,杜涛涛.急倾斜特厚煤层开采冲击地压发生过程监测与分析[J].煤炭科学技术,2016,44(6):78-82.LAN Hang,DU Taotao.Monitoring and analysis of rock burst process during steeply inclined and ultra thick seam mining[J].Coal Science and Technology,2016,44(6):78-82.

[9]來兴平,王宁波,胥海东,等.复杂环境下急倾斜特厚煤层安全开采[J].北京科技大学学报,2009,31(3):277-280.LAI Xinping,WANG Ningbo,XU Haidong,et al.Safety top-coal-caving of heavy and steep coal seams under complex environment[J].Journal of University of Science and Niversity Beijing,2009,31(3):277-280.

[10]杨磊,蓝航,杜涛涛.特厚近直立煤层上覆煤柱诱发冲击地压的机制研究及应用[J].煤矿开采,2015,20(2):75-77.YANG Lei,LAN Hang,DU Taotao.Mechanism of rock-burst induced by overlying coal-pillar in extremely-thick and sub-erect coal-seam[J].Coal Mining Technology,2015,20(2):75-77.

[11]秦子晗,杜涛涛,杨磊.急倾斜特厚煤层开采的动力灾害防治技术研究[J].中国煤炭,2015,41(12):57-59.QIN Zihan,DU Taotao,YANG Lei.Study on prevention and control technology for dynamic disaster of steeply inclined and extremely thick coal seam[J].China Coal,2015,41(12):57-59.

[12]曹建涛,来兴平,崔峰,等.急斜特厚煤层开采扰动区(MDZ)煤岩体动力学变形失稳过程分析[J].西安科技大学学报,2015,35(4):397-402.CAO Jiantao,LAI Xingping,CUI Feng,et al.Characteristics on dynamical deformation and instability of coal and rock mass in Mining Disturbed Zone(MDZ)of steeply dipping heavy thick coal seams mining[J].Journal of Xian University of Science and Technology,2015,35(4):397-402.

[13]曹建涛,来兴平,闫瑞兵.急斜煤层残留高阶段煤柱动力失稳机理研究[J].采矿与安全工程学报,2018,35(1):133-139.CAO Jiantao,LAI Xingping,YAN Ruibing.Research and application of non-pillar mining technology in high cutting working face of thick coal seam[J].Journal of Mining and Safety Engineering,2018,35(1):133-139.

[14]谢广祥,杨科,刘全明.综放面倾向煤柱支承压力分布规律研究[J].岩石力学与工程学报,2006,25(3):545-549.XIE Guangxiang,YANG Ke,LIU Quanming.Study on distribution laws of stress in inclined coal pillar for fully-mechanized top-coal caving face[J].Chinese Journal of Rock Mechanics and Engineering,2006,25(3):545-549.

[15]陈建强,闫瑞兵,刘昆轮.乌鲁木齐矿区冲击地压危险性评价方法研究[J].煤炭科学技术,2018,46(10):22-29.

CHEN Jianqiang,YAN Ruibing,LIU Kunlun.Study on evaluation method of rock burst danger in Urumqi Mining Area[J].Coal Science and Technology,2018,46(10):22-29.

[16]程蓬.近距离煤层煤柱集中应力传递及巷道分区支护对策研究[J].煤矿开采,2016,21(6):31-34.CHENG Peng.Stress concentration transmission of coal pillar with contiguous coal seam and roadway partitioned supporting measures[J].Coal Mining Technology,2016,21(6):31-34.

[17]贾尚伟,樊志刚,宋祖光,等.近距离煤层残留煤柱下底板应力分析及回采巷道合理布置[J].煤炭工程,2020,52(10):11-15.JIA Shangwei,FAN Zhigang,SONG Zuguang,et al.Floor stress analysis and mining roadway reasonable layout under residual coal pillar floor in lower seam of continuous coal seams[J].Coal Engineering,2020,52(10):11-15.

[18]秦凯,王健达,李宏艳,等.集中煤柱诱发下伏近距离煤层异常矿压及机理研究[J].煤炭科学技术,2019,47(8):102-107.QIN Kai,WANG Jianda,LI Hongyan,et al.Study on abnormal mine pressure and mechanism of near-distance coal seam induced by concentrated coal pillar[J].Coal Science and Technology,2019,47(8):102-107.

[19]付兴玉,李宏艳,李凤明,等.房式采空区集中煤柱诱发动载矿压机理及防治[J].煤炭学报,2016,41(6):1375-1383.

FU Xingyu,LI Hongyan,LI Fengming,et al.Mechanism and prevention of strong strata behaviors induced by the concentration coal pillar of a room mining goaf[J].Journal of China Coal Society,2016,41(6):1375-1383.

[20]李春元,王泓博,石瑶玉.上覆遗留区段煤柱对下伏煤层开采扰动影响研究[J].煤炭科学技术,2020,48(3):232-239.LI Chunyuan,WANG Hongbo,SHI Yaoyu.Study on disturbing influence of overlying remaining coal pillars on underlying coal seam mining[J].Coal Science and Technology,2020,48(3):232-239.

[21]周连春,李望,王琰.上覆煤层煤柱下采掘工作面应力分布规律研究[J].煤炭工程,2020,52(5):121-125.ZHOU Lianchun,LI Wang,WANG Yan.Stress distribution law of mining face under coal pillar of overlying coal seam[J].Coal Engineering,2020,52(5):121-125.

[22]马宁,张臣,贾江锋.上分层遗留煤柱影响下工作面安全回采研究[J].煤矿安全,2019,50(12):192-196.MA Ning,ZHANG Chen,JIA Jiangfeng.Study on safe mining of working face under the influence of upper stratified coal pillar[J].Safety in Coal Mines,2019,50(12):192-196.

[23]周輝,谢福星.大采高工作面回撤通道间隔煤柱失稳机理[J].煤矿安全,2019,50(10):216-220.ZHOU Hui,XIE Fuxing.Study on failure mechanism of interval coal pillar in withdrawal channel of large mining height working face[J].Safety in Coal Mines,2019,50(10):216-220.

[24]于洋,陈勇,赵祥岍.采空区残留煤柱内巷道布置与围岩控制技术[J].煤炭工程,2019,51(9):66-69.YU Yang,CHEN Yong,ZHAO Xiangqian.Roadway layout and surrounding rock control technology in gob residual pillar[J].Coal Engineering,2019,51(9):66-69.