Internal friction behavior of Zr59Fe18Al10Ni10Nb3 metallic glass under different aging temperatures

2021-03-11IsraaFaisalGhaziIsraaMeftenHashimAravindhanSurendarNalbiySalikhovichTuguzAseelAljeboreeAyadAlkaimandNisithGeetha

Israa Faisal Ghazi, Israa Meften Hashim, Aravindhan Surendar, Nalbiy Salikhovich Tuguz,Aseel M.Aljeboree, Ayad F.Alkaim, and Nisith Geetha

1Department of Materials Engineering,Engineering College,University of Al-Qadisiyah,Qadisiyyah,Iraq

2Nursing College,University of Al-Qadisiyah,Qadisiyyah,Iraq

3Department of Pharmacology,Saveetha Dental College and Hospital,Saveetha Institute of Medical and Technical Sciences,Chennai,India

4Department of Higher Mathematics,Kuban State Agrarian University,Krasnodar,Russian Federation

5College of Sciences for Women,University of Babylon,Babylon,Iraq

6Department of Electrical and Electronics Engineering,Sengunthar College of Engineering,Tiruchengode,India

Keywords: metallic glass,internal friction,relaxation,dynamic analysis

1. Introduction

Metallic glasses(MGs)are novel amorphous alloys with outstanding chemical,mechanical and physical properties.[1,2]However,perception of their structural configuration has been an enduring trouble in condensed matter physics. In this regard, researchers have been evaluated different aspects of glassy alloys, i.e. thermodynamics, kinetics and atomic arrangements, to find the inherent features of MGs.[3–5]On the other hand, the structural heterogeneity is one of the remarkable characteristics of amorphous alloys giving meaningful information on their mechanical and physical properties.[6–8]As a physical viewpoint,some features such as glass transition,[9]crystallization evolution,[10,11]mechanical relaxation,[12,13]rejuvenation behavior[14,15]and physical aging[16,17]are connected to the structural heterogeneity. For instance, the existence of nano-scale heterogeneity is closely related to a wide range of structural zones with various relaxation times leading to the appearance of α and β relaxation spectra under a thermal experiment or a dynamic agitations.[18,19]Hence,it is concluded that understanding of relaxation features in a glassy material opens ways to study different practical events such as deformation behavior,mechanical and physical properties.[20]

The nature of structural heterogeneity in the glassy alloys is responsible for local atomic rearrangements caused by external agitations. This event leads to an energetic dynamic fluctuations associated to β relaxation. When the mechanical or thermal excitations are induced in a glassy system, the atomic rearrangements occur and subsequently the primary units of β relaxation such as free volumes are formed and percolated. This process is foundation of macroscopic flow in MGs.[21–23]Moreover, the thermodynamic viewpoint describes that the non-equilibrium state of MGs leads to the locally structural evolution under physical aging or any mechanical relaxation process.[24,25]Hence, it is concluded that the structural-based origins of their mechanical behavior is closely related to the local structural heterogeneity. One of the main ways for studying the atomic rearrangements and energetic fluctuations in the glassy alloys is to measure the internal friction evolution under an applied mechanical or thermal agitation.[20,24]In fact, the change in internal friction defines the mechanical relaxation of atomic structure in the glassy alloy and is closely related to the atomic mobility. As an illustration, Wang[26]reported that the stiffening of atomic interaction enhances the activated mobile atoms so that higher atomic movement will occur in the glassy system,which leads to the intensification of energy dissipation and internal friction. Lv and Chen[27]used multi-function high-precision internal friction instrument to investigate the relaxation behavior of a Fe-based alloy. They found that the internal friction can be divided into three main regions: high strength region, superplastic region and crystallizing region. Cui et al.[28]studied the effects of crystallization friction on the β relaxation and showed that La-based alloys have a reversible relaxation behavior which is related to the local atomic cooperative motions. Wang et al.[29]studied the correlation between the internal friction behavior of Zr-based MGs and their quenching temperatures. It was revealed that the increase in quenching temperature leads to the decline activation energy at sub-Tg.Qiao et al.[30]unveiled the fundamental mechanism of the internal friction process in MG composites and characterized the meta-stability of the in situ phases. They also found abnormal internal friction trend in Ti-based MG composites and established a close relation between internal friction and the brittlement.[31]

In this work, mechanical spectroscopy is applied to investigate the internal friction under an isothermal stress relaxation. The main aim is to evaluate the structural heterogeneity of a novel MG alloy (Zr59Fe18Al10Ni10Nb3) in wide ranges of frequency and temperature, and show how the variety in dynamic response of the material leads to the appearance of different regions of energy landscape.

2. Experimental procedure

In this work,Zr59Fe18Al10Ni10Nb3alloying composition was considered for the production of glassy alloy. For this purpose,the mentioned alloy with high purity constitutes was produced using the arc-melting technique in a protective atmosphere.It is worth mentioning that the alloy was re-melted five times to obtain an acceptable elemental homogeneity. After the preparing the primary ingots,copper mold casting method was used to fabricate the bulk amorphous alloy in the form of rods with 1 mm diameter. The x-ray diffraction (XRD)analysis was carried out using Rigaku Ultima IV instrument with Cu Kα radiation. The differential scanning calorimetry(DSC, Perkin-Elmer DSC 7) test was also performed at the heating rate of 20 K/min under argon atmosphere to determine the thermal properties of the Zr59Fe18Al10Ni10Nb3alloy.

For investigating the relaxation of internal friction in the glassy alloy as a function of frequency and temperature, dynamic mechanical analysis (DMA, TA instrument DMA850)with a single cantilever mode under a protective environment was applied.For the constant situation,heating rate of 5 K/min and frequency of 1 Hz was considered,while various temperature(500–680◦C)and frequency values(1,3,6,12 Hz)were selected for studying the evolution of relaxation under the aging process. From the recorded data, the loss modulus E′′and storage modulus E′along with loss factor(tanδ =E′′/E′)were calculated.[28]

3. Results and discussion

At the first step, it is required to identify the inherent features of bulk Zr59Fe18Al10Ni10Nb3alloy. As shown in Fig.1, there are no sharp peaks in the XRD spectrum; however, a broad diffraction peak appears at 2θ =38◦indicating the amorphous nature of our cast alloy. Moreover, the DSC results clearly show the glass transition temperature (Tg) and onset crystallization temperature Txat 699 K and 772 K, respectively. An exothermic shoulder under the glass transition event is related to the relaxation enthalpy ∆H associated to the stored energy in the amorphous structure of BMG.

Fig.1. (a)XRD pattern and(b)DSC profile of the cast sample.

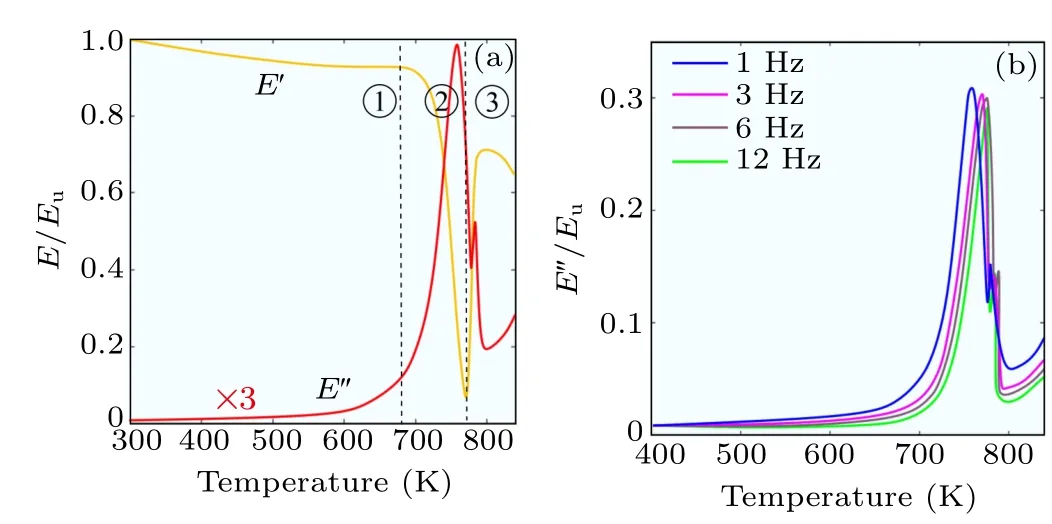

Dynamic thermal properties of Zr-based amorphous alloy are shown in Fig.2(a). The storage(E′)and loss(E′′)moduli are normalized to present meaningful data. As observed,it is not possible to distinguish the β and α relaxations from each other. In other words,the β relaxation is merged into the α relaxation including the huge part of stored energy in the structure of BMG.As reported in many works,[19,20,32]the dynamic thermal features of Zr-based BMG is detached into three distinct zones. At temperatures below 680 K (zone 1), the temperature variations insignificantly affect the E′and E′′values.This means that the BMG structure elastically responds to the mechanical excitations at low temperatures,while there are no signs of viscoelastic and viscoplastic components related to the atomic rearrangement in the material. With the increasing temperature, a marked rise in E′′value occurs, while the E′tends to show a sudden decline. This event is closely related to the relaxation,specially defined as the α relaxation,in which the atoms tend to change the structural configuration by the irreversible large scale rearrangements. The atomic movement in zone 2 is associated to the anelastic component manifested as the mechanical response of the glassy alloy in the form of sudden changes in E′and E′′values. Zone 3 is compatible with the onset crystallization,in which the E′value increases and the E′′value shows a slight increasing trend with the subsequent decrease. In fact,this behavior in thermal features at crystallization zone is related to the marked stability in the microstructure with the decrease in atomic movement.Figure 2(b) shows the dependence of E′′on temperature for different frequencies. As can be seen, the change in driving force leads to the different responses of dynamic mechanical relaxation. However, the frequency is not able to change E′′behavior at low temperatures. When the temperature rises to a critical value,the E′′significantly increases and a peak appears at a certain temperature in E′′–T curves. This peak,created at the Tgneighborhood, is sensitive to the frequency so that the peak position has a straight relation with the frequency value.

Fig.2. (a) Dynamic mechanical analysis curve of the as-cast sample with the heating rate of 5 K/min and frequency of 1 Hz (the E′′ curve has been multiplied by 3). (b)The normalized E′′for the as-cast sample under the frequencies of 1,3,6 and 12 Hz.

The latter step is to evaluate the role of structural stability on the thermal properties of the Zr-based BMG.For this purpose,a sample was aged at 0.9Tgfor five hours. As shown in Figs.3(a)and 3(b), under same experimental parameters, the E′value for the aged sample show a higher trend; however,the E′′value for the as-cast sample, especially at zone 2, is meaningfully higher than the aged one. In general,the relaxation event in a glassy alloy is accompanied with the annihilation of free volume and shear transformation zones. For the aged sample,the atomic rearrangement leads to the formation of high-density structure causing a material with high elastic modulus. In this situation, the short range and medium scale orders increase in the BMG configuration so that the material tends to have more stable structure. In other words,the sub-Tgannealing process intensifies the local packed atomic structure with shorter atomic distances, leading to the minimization of local defects such as free volumes,so that the relaxed structure includes denser glassy state with higher elastic modulus.[24]This event justifies why the aged sample shows a weaker E′′trend at zone 1 and has the lower loss factor. Figure 3(c)indicates the internal friction(tanδ)as a function of temperature at different applied frequencies. It can be seen that the internal friction at low temperatures is independent,while with the rise in temperature up to Tg, a sharp incline of loss factor occurs. One readily concludes that a delay in the peak creation happens in the internal friction and the peak intensification declines with the rise in the applied frequency. The collaborative atomic movement in the MG alloy leads to the internal friction variations.[28]With the rise in the temperature,the atoms tend to break their caged positions and reach higher energy states.At this time, the structural configuration of MG alloy experiences an anelastic component leading to a local mechanical relaxation in the material. With the increase in temperature,the number of atoms captured in local rearrangement exponentially rises. This structural relaxation is the prerequisite of glass transition happened at the higher temperature. Moreover,passing the glass transition,the material involves in a severe structural instability related to a phase transition,namely crystallization event. According to Fig.3(d),the reciprocal of frequency and internal friction parameter create a direct correlation at the phase transition temperature. Other researchers also reported this result at the phase transition temperature and suggested that the increase of E′′peak with the frequency enhancement is due to the nature of time-temperature superposition principles in glassy alloys.[20]

Fig.3. (a) E′ and (b) E′′ for the as-cast and aged samples. (c) Loss factor as a function of temperature under different frequencies. (d)Correlation between loss factor and frequency.

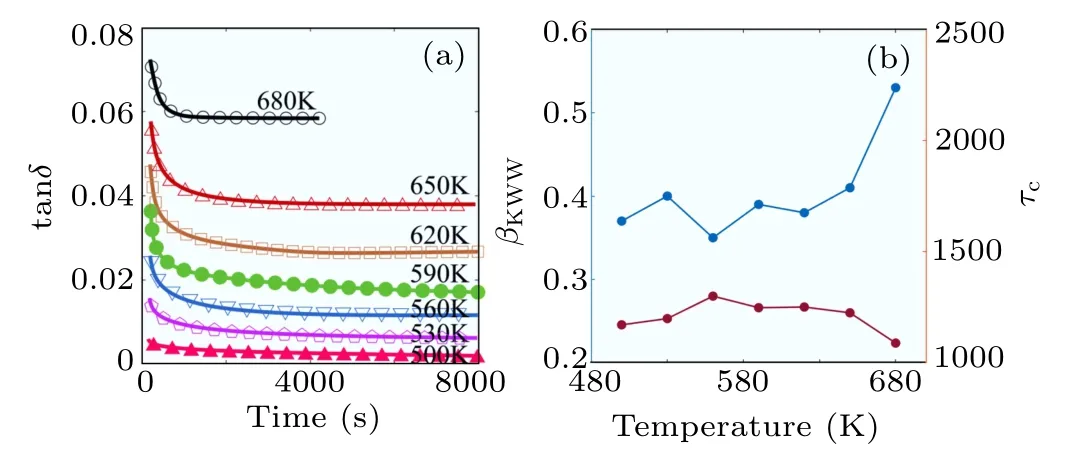

Figure 4(a)indicates the isothermal internal friction measurements of the Zr-based alloy in a specific temperature range. The results show that the internal friction has a sharp decline at the primary time of annealing process and then moves to a steady state at the longer annealing time. In general, the annealing process under the Tgvalue leads to the atomic rearrangement in the glassy alloy. On the other hand,the internal friction variations are consistent with the energy dissipation, reflecting the structural relaxation in the MG.[33]This means that the annealing process induces the free volumes,i.e.,energetic atomic sites,to rearrange their configuration and move to a thermodynamically stable situation. In an isothermal annealing process,the free volumes are annihilated so that the internal friction significantly decreases with the time evolution. It is also revealed that the rate of free volume annihilation strongly depends on the annealing temperature.Regarding the annealing temperature,one can see that atomic movement is intensified with the temperature causing a greater loss factor in the experiment. As mentioned,the internal friction is indicator of atomic structural changes in the glassy material. Hence,the higher internal friction at the higher annealing temperature indicates that a larger portion of atoms are anelastically activated and move to the stable condition during the thermal process. When the temperature is low,the elastic strain is dominant on the system and the atomic movement is restricted to the negligible mobility,while at the high temperature,the anelastic component comes into play and leads to the collaborative movement. To elaborate the inherent features of relaxation using the internal friction evolution, it is required to analyze the relaxation time during an aging process. Using the phenomenological KWW equation, it is possible to correlate the internal friction and relaxation time to each other.The following equations show how the internal friction can be explained as a function of annealing time:[34]

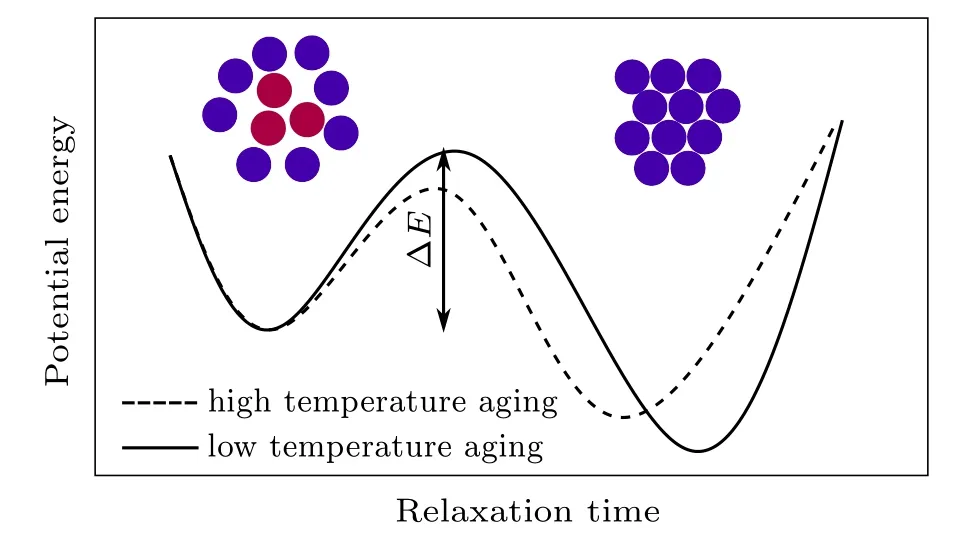

where τcdefines the characteristics time of internal friction,tanδ(t) is the loss factor as a function of time, and βKWWis the Kohlrausch exponent introducing the distribution of internal friction times. According to Fig.4(b),the increase in temperature of the annealing process leads to the rise in βKWW,while τcshows a decreasing trend. It is also worth mentioning that the decreasing and increasing trends of τcand βKWWare intensified at the high temperatures. The drop in characteristics time of internal friction is closely related to the rate of atomic rearrangement under the dynamic excitation so that at the higher temperatures, i.e., near the Tgvalue, the driving force for the collaborative movement of atoms is easily provided and the mean relaxation time significantly decreases.On the other side,the βKWWvalue introduces the distribution of relaxation time related to the dynamic heterogeneity in the MG alloys. As observed, the βKWWvalues for all the samples are lower than 1,which means that the relaxation process has an inhomogeneous behavior in the glassy structure. With the increase in temperature,the βKWWvalue shows an upward trend. This event confirms that the higher temperatures lead to the decrease of the dynamic heterogeneity in a relaxation process. As given in Fig.5,when the temperature approaches the Tgvalue, the barrier energy for the atomic rearrangement decreases and consequently the internal friction has a maximum value. However, the relaxation time significantly declines,which leads to a rapid relaxation in the glassy structure(see Figs.4(a)and 4(b)).

Fig.4. (a)Loss factor variations in an isothermal dynamic experiment under 1 Hz frequency,(b)the trend of KWW parameters as a function of temperature.

Fig.5. Schematic of energy landscape under low and high annealing temperatures.

4. Conclusion

This work aimed to elaborate the effects of annealing temperature on the internal friction behavior of Zr59Fe18Al10Ni10Nb3glassy alloy. According to the dynamic mechanical analysis, the aging process shifts the stored energy to higher values in the material; however, the loss module trend has a small decrement,especially at the glass transition temperature. Moreover, it is revealed that the loss factor has a reverse correlation with the applied frequency. Based on the KWW equation, the higher aging temperature leads to the enhancement of internal friction at the primary time of dynamic analysis;however,with the passing time,a considerable decrease is detected. It is suggested that the sharp variations in the internal friction value are closely related to the rate of atomic rearrangement under the dynamic relaxation.

杂志排行

Chinese Physics B的其它文章

- Novel traveling wave solutions and stability analysis of perturbed Kaup–Newell Schr¨odinger dynamical model and its applications∗

- A local refinement purely meshless scheme for time fractional nonlinear Schr¨odinger equation in irregular geometry region∗

- Coherent-driving-assisted quantum speedup in Markovian channels∗

- Quantifying entanglement in terms of an operational way∗

- Tunable ponderomotive squeezing in an optomechanical system with two coupled resonators∗

- State transfer on two-fold Cayley trees via quantum walks∗