Meso-mechanical model of concrete under a penetration load

2020-01-07ChengWuWenbinLiXiojunShen

Cheng Wu ,Wenbin Li ,*,Xiojun Shen b

a Ministerial Key Laboratory of ZNDY,Nanjing University of Science and Technology,Nanjing,210094,China

b Beijing Special Electrical and Mechanical Research Institute,Beijing,100012,China

ABSTRACT The influence of concrete components on projectile penetration is significant.To study the relationship between the equivalent mechanical properties and components of concrete under a penetration load,concrete is simplified as a two-phase composite of coarse aggregate and mortar,and a meso-mechanical model is established,including the equivalent equation of state model,the equivalent confining pressure strength model and the equivalent dynamic tensile strength model,considering shear stress,large deformation and pore compression.Tests of the mechanical properties of mortar,concrete and limestone were conducted;the results show that the equivalent mechanical properties of concrete calculated by the meso-mechanical model are consistent with the test results,and the equivalent mechanical properties of concrete with different volume fractions of coarse aggregate are obtained.Meso-scale and macro-scale numerical simulations of a projectile penetrating into concrete are carried out,the penetration depths obtained by meso-scale and macro-scale numerical simulations are consistent for different volume fractions of coarse aggregate and different velocities of the projectile,which verifies the rationality of the meso-mechanical model.

Keywords:Meso-mechanical Inclusion model Concrete Penetration Projectile

1. Introduction

Concrete is widely used in military and civil fields,such as missile silos,military airstrips,bridges and dams.Penetration of a projectile into concrete is a fundamental problem in the military field.The mix proportion of concrete is not strictly standardized.For concretes with the same uniaxial compressive strength,there are differences in the aggregate type,aggregate volume fraction and mortar porosity.This results in great differences in mechanical properties under confining pressure.Therefore,the components of concrete has a great influence on the anti-penetration performance of concrete[1].

The influence of concrete components on projectile penetration is mainly studied by experiment[2-4]and meso-scale numerical simulation[5-7].However,there are many combinations of concrete components,resulting in high time and economic costs for experimental research.For the meso-scale numerical simulation,when the volume fraction of coarse aggregate is high or the quantity of coarse aggregate is large,the algorithm and efficiency of placing coarse aggregate have limitations.However,for the numerical simulation [8,9] and theory (such as dynamic cavity expansion theory[10,11])of penetration at the macro-scale,the penetration depth of projectile can be obtained by the equivalent mechanical properties of concrete,and the calculation efficiency is high.Therefore,it has engineering application value to establish a meso-mechanical model and calculate the equivalent mechanical properties of concrete with different components.

Related works have been carried out on the meso-mechanical model of concrete.For the equivalent elastic modulus model,Yang and Huang[12]simplified concrete as a three-phase composite of coarse aggregate,fine aggregate and cement paste,and Garboczi and Berryman[13]simplified concrete as a three-phase composite of aggregate,cement paste and interfacial transition zone.For the equivalent uniaxial compressive strength model,Yang and Huang[14],Kafka[15]and Miled et al.[16]considered the properties and volume fraction of coarse aggregate,the damage of matrix,and the size distribution of aggregate,respectively.Under ultra-high pressure,the shear stress of concrete is negligible(i.e.,it can be simplified as a fluid),which greatly simplifies the mesomechanics problem[17].However,the penetration load is usually medium pressure(several hundred MPa),in this case,the concrete undergoes large deformations and its mechanical properties are non-linear.Karinski et al.[18]established a model of equation of state for mortar considering pores,but the pore compression process adopted a macro-scale engineering method,and Zhutovsky et al.[19]established a meso-mechanical model of the equation of state for the pore compression process of mortar.The study of meso-mechanical model considering the influence of coarse aggregate on concrete under medium pressure needs further study.

In this paper,concrete is simplified as a two-phase composite material of coarse aggregate and mortar,then,a meso-mechanical model is established,including the equivalent equation of state model,the equivalent confining pressure strength model and the equivalent dynamic tensile strength model, considering shear stress,large deformation and pore compression.Tests of the mechanical properties and numerical simulations of the antipenetration performance of meso-scale and macro-scale concrete are carried out.

2. Meso-mechanical model under a penetration load

During the penetration process,the concrete near the projectile head is subjected to a triaxial pressure,and the material undergoes pore compression.Therefore,the equivalent mechanical properties can be characterized by the equation of state,strength model,elastic constants and density.For concrete far from the ballistic trajectory,the material generates cracks under the dynamic tensile stress,and their equivalent mechanical properties can be characterized by tensile strength,elastic constants and density.

The interface between coarse aggregate and mortar has less influence on penetration resistance(proved by numerical simulation of Deng et al.[7]),and the crack usually passes through coarse aggregate at high strain rate,therefore,this paper simplifies the concrete as coarse aggregate and mortar two-phase composite material.Wu et al.[20]proved by numerical simulation that the influence of coarse aggregate shape on penetration depth can be neglected,so the theory of this paper can simplify the coarse aggregate shape.

2.1. Equivalent equation of state model

Fig.1 shows the equivalent equation of state model of concrete.The concrete microelement is simplified to spherical coarse aggregate and coated mortar shell.The pressureP1-average volume strain relationship of the two-phase composite is equivalent to the equation of state of homogeneous concrete.Lagrangian spherical coordinate system is used,ris the radial material coordinate,andr0andr1are the radii of the coarse aggregate and the mortar shell,respectively.The volume fraction of coarse aggregate λgin concrete is

The stress and strain are positive in tension,and the spherical symmetry equilibrium equation is

whereuis radial displacement,σrand σθare the radial stress and tangential stress,respectively.

Under the radial pressure load,the strain of mortar is mainly volume strain,and the shear strain is small.Moreover,the strength of the mortar is greatly increased under the confining pressure,so it is assumed that the mortar does not undergo shear yielding.Thus,shear stress and shear strain can be expressed by Hooke's law,i.e.,

where εrand εθ are the radial and tangential strain,respectively.Gsis the shear modulus of mortar.

Since the shear strain is small(i.e.,εr-εθ is small),Eq.(3)can be further simplified to

The hydrostatic pressurePis positive in compression and expressed as

Substituting Eq.(5)into Eq.(3),

Mortar is a porous material,so its high-pressure equation of state is usually divided into an elastic stage,a pore compression stage and a dense stage.Under a penetration load,the hydrostatic pressure of the mortar is usually several hundred MPa,and it is difficult to reach the dense stage.For example,Holmquist et al.[9]and Johnson et al.[21]gave the parameters of three-stage equation of state for concrete in which the hydrostatic pressure of dense stage is higher than 800 MPa and 1050 MPa,respectively.Therefore,the equation of state of the mortar can be approximated by bilinear

For concrete,εVes,Ks,andKtsare replaced by εVe,K,andKt,respectively.For coarse aggregates,there is only the elastic stage,and the bulk modulus isKg.εVis the volume strain,i.e.,

Substituting Eq.(4)and Eq.(6)into Eq.(2)obtains an ordinary differential equation

The applied external pressureP1is

The radial stresses at the junction of the coarse aggregate and the mortar are equal,i.e.,

The average volume strain of the two-phase composite is

As increasing of external pressureP1,the mortar undergoes three stages,namely,an elastic stage,a coexistence stage of elasticity and pore compression,and a pore compression stage.The equation of state of concrete is simplified to bilinear in this paper,corresponding to the elastic stage and the pore compression stage of mortar,respectively.The stage of the coexistence of elasticity and pore compression represents a true transition between the two stages.However,since this transition stage is short,it can be simplified to the intersection of the elastic stage and the pore compression stage.Therefore,the equivalent equation of state of concrete is simplified into two stages:the elastic stage and the pore compression stage.

2.1.1. Elastic stage

At the elastic stage(-εV<-εVes),the mortar undergoes small deformation,so the true strain can be simplified to engineering strain.The equations of state Eq.(7)and Eq.(8),the equilibrium Eq.(9),the boundary conditions Eq.(10)and Eq.(11),and the mean volume strain Eq.(12)are respectively reduced to

Substituting Eq.(13a)into Eq.(13b),

Lettingu=rm,the second-order Euler Eq.(14)is transformed into

Thus,the general solution of Eq.(14)is obtained

wherec1andc2are integral constants.

Substituting Eq.(1),Eq.(13a)and Eq.(13c)~Eq.(13e)into Eq.(16),the equivalent equation of state of the elastic stage is obtained as follows:

2.1.2. Pore compression stage

The equation of state uses a pore compression stage(-εV≥-εVes),i.e.,

Substituting the equation of state Eq.(18)into the equilibrium Eq.(9),

LettingM(r)=u(r)+rand substituting it into Eq.(19),

The two sides of Eq.(20)are integrated:

wherec3is the integral constant.

Eq.(21)is transformed to obtain

Both sides of Eq.(22)are integrated to further obtain the expression ofM:

wherec4is the integral constant.

SubstitutingM=u+rand the average volume strain Eq.(12)into Eq.(23),a general solution ofuis obtained:

Substituting Eq.(1),Eq.(18)and Eq.(24)into boundary condition Eq.(11),

Substituting Eq.(1),Eq.(18)and Eq.(24)into boundary condition Eq. (10), the equivalent equation of state of the pore compression stage is obtained:

2.2. Equivalent confining pressure strength model

Concrete shows plastic properties and can withstand large shear deformation under confining pressure.Therefore,the confining pressure strength model of concrete is simplified to a cylindrical coarse aggregate and a coated mortar shell,as shown in Fig.2.

Loading is divided into two steps.The first step constrains the axial displacement and loads the radial stress σrbat the boundary of the cylindrical surface.In the second step,the radial stress σrbis kept constant,and the axial displacement is loaded;after the material reaches the yield,the corresponding axial resultant force isFz.Under the Lagrangian cylindrical coordinate system,ris the radial material coordinate.The volume fraction of coarse aggregate λgof the concrete is

2.2.1. Radial loading

The axial strain εzis 0,i.e.,

The stress and strain are positive in tension,and the cylinder symmetric equilibrium equation is

whereuis the radial displacement,σrand σθare the radial and hoop stress,respectively.

The mortar is subjected to radial pressure and axial displacement constraint,so the shear strain is small.Since the strength of mortar is greatly increased under confining pressure and the shear modulus of mortar is low,it is assumed that the mortar does not undergo shear yielding.Thus,shear stress and shear strain can be expressed by Hooke's law,i.e.,

where σzis the axial stress,εrand εθare the radial and hoop strain,respectively.

Since the shear strain is small(i.e.,εr-εθ is small),Eq.(30a)can be further simplified to

小葱沼气发酵产气潜力与特性研究……………………… 刘 明,郑 盼,尹 芳,杨 斌,博 林,刘健峰,郭 成,张无敌(102)

The hydrostatic pressurePis expressed as

Eq.(30a),Eq.(30b)and Eq.(32)are combined to obtain

Since the axial strain is 0,the volume strain εVis expressed as

Substituting Eq.(31)and Eq.(33)into Eq.(29)obtains a onedimensional differential equation:

The applied boundary radial stress σrbis

It can be known from Fig.2a that the radial stress and the hoop stress of the coarse aggregate are equal,and the radial strain and the hoop strain of the coarse aggregate are equal.The coarse aggregate is elastically deformed,and it is known by Hooke's law that

whereGgis the shear modulus of the coarse aggregate.

The radial stress σrgof the coarse aggregate obtained by Eq.(37a)and Eq.(37b)is

For different boundary radial stresses σrb,the mortar may have three states,namely,an elastic state,a coexistence state of elasticity and pore compression,and a pore compression state.The strength of concrete can be obtained by fitting the results under several typical confining pressures(such as 0,25,50,75 and 100 MPa,etc.).The state of coexistence of elasticity and pore compression is short,and the effect of this transition state on the fitting of overall strength is limited,so this state can be neglected.Therefore,the model is simplified into two states of elasticity and pore compression.

2.2.1.1. Elastic state.At the elastic state (-εV<-εVes), mortar undergoes small deformation,so the true strain can be simplified to engineering strain.The equations of state Eq.(7)and Eq.(34),radial stress Eq.(33),Eq.(31),equilibrium Eq.(35),and boundary conditions Eq.(36)and Eq.(38)are simplified to

Substituting Eq.(39a)into Eq.(39d)obtains

Lettingu=rn,the second-order Euler Eq.(40)is transformed into

Thus,the general solution of Eq.(41)is obtained:

wherec5andc6are integral constants.

Combining Eq.(27),Eq.(39a),radial stress Eq.(39b),hoop stress Eq. (39c), boundary conditions Eq. (39e) and Eq. (39f), and displacement Eq.(42),the solution of the radial stress,hoop stress and volume strain of mortar is

It can be seen from Eq.(43c)that the volume strain of mortar is independent of the coordinates.In order to ensure that the mortar is in the elastic state,-εV<-εVesshould be satisfied,otherwise the mortar is in the state of pore compression.

2.2.1.2. Pore compression state of mortar.At the pore compression state (-εV≥-εVes), the radial stress expression obtained by substituting equations of state Eq.(34)and Eq.(7)into radial stress Eq.(33)is

Substituting Eq.(34)and Eq.(7)into Eq.(35)obtains a onedimensional differential equation:

Integrating both sides of Eq.(45),

wherec7is the integral constant.

LettingN(r)=u(r)/rand substituting it into Eq.(46),

Transforming Eq.(47),

Integrating both sides of Eq.(48),

SubstitutingN(r)=u(r)/rinto Eq.(49)and simplifying the integral constants e^c7and e^(2c8)toc9andc10,respectively,the expression of the displacement is obtained:

Substituting the displacement Eq.(50)into the radial stress Eq.(44),

Substituting the displacement Eq.(50)and radial stress Eq.(51)into Eq.(30a),

The boundary radial stress σrbis

Eq.(38),Eq.(50)and Eq.(51)are combined to obtain

The coefficientsc9andc10/can be solved by Eq.(53)and Eq.(54).

2.2.2. Axial loading

Radial loading is kept constant,and axial loading is applied until the material yields,as shown in Fig.2b.Radial stress and hoop stress mainly depend on radial loading,so it can be approximated that the distribution of axial stress and hoop stress of mortar and coarse aggregate remain unchanged during the axial loading process,which greatly simplifies the establishment of the model.Since the material has a large shear modulus,the material needs to be loaded with only a small axial displacement when yielding,thus,the change in the cross-sectional area of the material at this stage is ignored.The stress of the mortar changes with the radial coordinate,and the average stress of the mortar is simplified to be the stress atr=(r0+r1)/2.The stress state is the same throughout the coarse aggregate.The equivalent axial stress σzais expressed as

where σzsais the average axial stress of the mortar atr=(r0+r1)/2,and σzgis the axial stress of the coarse aggregate.

When the dynamic compressive strength of concrete is measured by a Hopkinson rod,the essence of the strain rate effect of the axial stress is the lateral inertia constraint effect of large diameter specimens, rather than the strain rate effect of the strength [22]; thus, the strain rate effect of the compressive strength is ignored.The pseudo tensor strength model[23]can reflect the confining pressure enhancement effect of the strength of concrete-like materials.The equivalent strength σmaxof undamaged concrete and rock is wherea0,a1anda2are coefficients.

In Fig.2,if the volume fraction of coarse aggregate is 0,the radial and hoop stresses of the mortar are equal.After the addition of the coarse aggregate,for the compressive load,the value of the radial stress of the mortar is reduced(compression direction is negative),and the value of the hoop stress is increased.Therefore,the hoop stress of the mortar is the maximum principal stress.The axial stress is the minimum principal stress due to axial loading to the material yielding.Substituting the stress state of the mortar and coarse aggregate into Eq.(56),

where σθsaand σrsaare the hoop and radial stresses of mortar atr=(r0+r1)/2;a0s,a1sanda2sare the strength coefficients of mortar;a0g,a1ganda2gare the strength coefficients of coarse aggregate.

Known by Eq.(57a),

Known by Eq.(57b),

2.2.2.1. When step 1 loads the mortar into the elastic state.In the elastic state,the radial displacement of the boundary is small,and Eq.(55)is simplified to

Derived from Eq.(43a)and Eq.(43b),

From Eq.(58)to Eq.(61),the relationship between the confining pressure σrband the axial maximum stress σzacan be obtained,thereby the strength under low confining pressure is obtained.

2.2.2.2. When step 1 loads the mortar into the pore compression state.Substituting the displacement Eq.(50)into Eq.(55),

As seen from Eq.(51)and Eq.(52),

The equivalent axial stress σzais obtained by substituting Eq.(58),Eq.(59)and Eq.(63)into Eq.(62).The coefficientsc9andare determined using by Eq.(53)and Eq.(54).Thereby the strength under high confining pressure is obtained.

Under uniaxial compression without a confining pressure,the concrete has brittleness,and the plastic assumption in the equivalent confining pressure strength model will no longer be satisfied.The volume fraction of coarse aggregate has a limited influence on the uniaxial compressive strength[24,25],so the uniaxial compressive strength of concrete is approximately taken as the uniaxial compressive strength of mortar.Uniaxial compressive strength and confining pressure strength are brought into the Eq.(57c)to fit the strength curve coefficientsa0,a1anda2of concrete.In order to ensure that the dynamic tensile strength σcutis effective,the intersection point-a0a1/(a0a2+1)of the strength curve and the hydrostatic pressure axis should be guaranteed to be less than-σcutwhen fitting.

2.3. Equivalent dynamic tensile strength model

At high strain rates,the crack fails to bypass the coarse aggregate in time,and the tensile fracture surface passes through the coarse aggregate,as shown in Fig.3.It is approximated that the coarse aggregate and the mortar are simultaneously fractured,thus,the equivalent dynamic tensile strength σcutis

Among them,σcutsand σcutgare the dynamic tensile strengths of the mortar and coarse aggregate,respectively.

2.4. Equivalent density and equivalent elastic constants

In the linear elastic stage,the equivalent shear modulusGof the concrete is[26]

According to the relationship between the elastic constants,the equivalent Poisson's ratio ν is

The concrete density ρ is expressed as

where ρsand ρgare the densities of the mortar and coarse aggregate,respectively.

2.5. Flow chart of model

The calculation flow chart of the meso-mechanical model is shown in Fig.4.The constitutive parameters of mortar and coarse aggregate are brought into the corresponding equation to obtain the constitutive parameters of concrete.

3. Verification by mechanical testing

3.1. Test of the mechanical properties of mortar,concrete and limestone

To verify the meso-mechanical model, the mechanical properties of mortar,concrete and limestone were tested.The scheme is shown in Table 1.Fig.5 shows the deformation and cracks of typical specimens after testing.The mix proportion of the mortar in the concrete is the same as that of pure mortar.The coarse aggregate is limestone with a packing volume fraction of 59.0%and a nominal maximum coarse aggregate size of 31.5 mm(there are individual coarse aggregates larger than this size used to make limestone specimens).The volume fraction of coarse aggregate in the concrete is 0.405.Limited by the size of the coarse aggregate,the size of the limestone specimen is smaller.

Step 1 was triaxial loading.The confining pressure was loaded to a predetermined value of 0.5 MPa s-1to obtain the equation of state.Step 2 kept the confining pressure unchanged,the axial loading rate was 0.6 mm·min-1,the axial stress gradually reaches a peak value and then starts to decrease, thereby obtaining a confining pressure strength.Step 3 was unloading.For the uniaxial compression test,since the confining pressure is 0,it starts directly from step 2.

The equation of state test and the fitting results are shown in Fig.6.The bulk modulus of limestone was measured by strain gauges in a uniaxial compression test.The equation of state for the concrete and mortar was measured by extensometers in the 100 MPa confining pressure test. Limestone has the lowest compressibility,and mortar has the highest compressibility.The equation of state for limestone is linear,and the equations of state for concrete and mortar are bilinear.When the confining pressure is applied to 50 MPa,the equipment is suspended due to the need to replenish the hydraulic oil,resulting in material creep.Since the maximum confining pressure is limited by the equipment,proportional loading(axial stress is 2 times the confining pressure)was used,which increases the test range of the equation of state.

Concrete-like materials exhibit significant confining pressure enhancement effects,as shown in Fig.7.Limestone has the highest confining pressure strength,and mortar has the lowest confining pressure strength.The pseudo tensor strength model can fit the test data,and the strength growth trend outside the test range gradually slows,consistent with the characteristics of concrete-like materials.For limestone,the uniaxial compressive strength measured from φ 25 mm×20 mm and 18 mm×18 mm×36 mm specimens are consistent,which indicates that the specimen with a small height diameter ratio(φ 25 mm×20 mm)does not affect the measurement of the strength.

Table 1Scheme of the mechanical properties test.

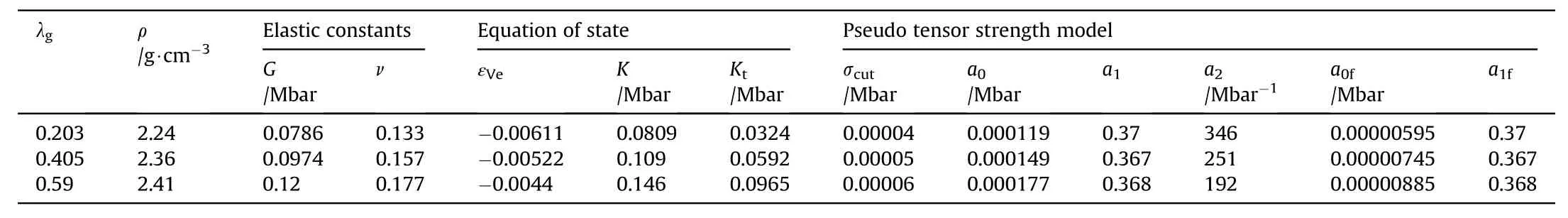

The material parameters are shown in Table 2. The static uniaxial compressive strength of the mortar and limestone obtained by the experiment are 37 MPa and 176 MPa,respectively.The static tensile strength of concrete is typically an order of magnitude lower than the static uniaxial compressive strength.For the dynamic tensile strength,the experimental method is not yet mature.Oˇzbolt et al.[27]used numerical simulation to prove that the true dynamic enhancement factor is not large,for example,the dynamic enhancement factor is only 1.7 when the strain rate is 103s-1.Due to the lack of experimental data,the dynamic tensile strengths of the mortar and limestone are taken as approximately 3 MPa and 8 MPa,respectively.After concrete fracture damage,a0anda1becomea0fanda1f[23],respectively.During the penetration process,the crack propagates forward,and in this case,thea0fshould be zero.However,with the projectile penetrating forward,the damaged concrete around the ballistic trajectory is compressed again,and then the concrete recovered a certain residual strength again.Therefore,in the penetration experiment,the target tunnel will not collapse.Since the damage mechanism of concrete is complicated,a0fis taken as approximately 0.05a0.It is approximated that the internal friction generated by the hydrostatic pressure is not affected after damage,that is,a1f=a1.

Table 2Constitutive parameters of mortar,concrete and limestone.

3.2. Equivalent mechanical properties of concrete with different volume fractions of coarse aggregate

The mechanical properties of the mortar and limestone are substituted into the meso-mechanical model,and the equivalent mechanical properties of concrete with different volume fractions of coarse aggregate are calculated.Moreover,the rationality of the model is verified via experimentation.

Fig.8 shows the equation of state of concrete with different volume fractions of coarse aggregate.For the concrete with a volume fraction of coarse aggregate of 0.405,the equivalent equation of state model is compared with the experimental results;and they are generally consistent,which verifies the rationality of the model.As the volume fraction of coarse aggregate increases, the compressibility of the concrete gradually decreases.

Fig.9 shows the strength curves of concrete with different volume fractions of coarse aggregate.The strength curve of model is obtained by fitting the calculated confining pressure strength(confining pressure is 25,50,75 and 100 Mpa,respectively)and the uniaxial compressive strength(approximating equal to the uniaxial compressive strength of mortar).For the concrete with a volume fraction of coarse aggregate of 0.405,the calculation result of confining pressure strength model is compared with the experimental data,and they are generally consistent.As the volume fraction of coarse aggregate increases,the strength curve of concrete increases accordingly.

Table 3 gives the calculated constitutive parameters.The volume fractions of coarse aggregate are 0.203,0.405 and 0.59,respectively.Among them,the results of equation of state and the confining pressure strength are the corresponding model curves in Figs.8 and 9.

4. Numerical simulation of the anti-penetration performance of macro-scale and meso-scale concrete

In this section,the macro-scale concrete constitutive parameters calculated by meso-mechanical model are applied to the numerical simulation of penetration and verified by meso-scale concrete numerical simulation. The three-dimensional finite element models of macro-scale and meso-scale concrete are established.Numerical simulations of a projectile penetrating into concrete with different volume fractions of coarse aggregate are carried out by using LS-DYNA dynamics software.The equation of state uses tabulated compaction[23],and the strength model uses pseudo tensor.

4.1. Establishment of the finite element model

Wu et al.[28]carried out the tests of projectile penetration into concrete target with different volume fractions of coarse aggregate.The mix proportions of the mechanical test specimens and penetration test targets are the same,and they are in the same batch.The projectile in the numerical simulation is consistent with that in the penetration tests;the projectile has a diameter of 29.9 mm,a length-diameter ratio of 7,a mass of 0.976 kg,and a caliber-radiushead of 4.The projectile head is not eroded in the penetration test,thus,the projectile is simplified as a rigid projectile.

The cross section of the meso-scale and macro-scale finite element structure is shown in Fig.10.The position and diameter of random coarse aggregate are generated by programming software[29],and then the results are imported into the grid generation software TrueGrid to generate the finite element mesh of two-phase media of coarse aggregate and mortar.Under impact load,since the crack of concrete usually passes through coarse aggregate,the complex interface transition zone is ignored,and the interface between coarse aggregate and mortar is simplified as common nodes.The coarse aggregate is simplified as a sphere with a maximum diameter of 31.5 mm in the meso-scale numerical simulation.Fuller continuous grading is used.To improve computational efficiency,only the grids of the target central area are fined.The coarse aggregate is small in size and cannot be placed outside the fined zone,thus,the equivalent concrete material is used outside the fined zone.For meso-scale numerical simulations,the material parameters of the coarse aggregate and mortar in the central fined zone are taken from Table 2,and the material parameters of the equivalent concrete outside the fined zone are taken from Table 3.For macro-scale numerical simulations,the parameters of the mortar target are taken from Table 2,and the parameters of the concrete targets with different coarse aggregate volume fractions(0.203,0.405 and 0.59)are taken from Table 3.When the volume fraction of coarse aggregate exceeds 0.4,the time to generate aggregates by using the program will increase significantly,accordingly,the volume fractions of coarse aggregate in meso-scale numerical simulation are selected to be 0.203 and 0.405,respectively.

Table 3Equivalent mechanical properties of concrete(model calculation).

4.2. Comparison of penetration depth

Fig.11 compares the penetration depths of the meso-scale numerical simulation,the macro-scale numerical simulation and the experiment.The numerical simulation results are consistent with the penetration experiment results,which indicates that the numerical simulation results are reliable.The mechanism of interaction between projectile and coarse aggregate is complex,and the process of establishing the meso-mechanical model has been simplified,resulting in deviations between meso-scale and macroscale numerical simulations, but the difference is small. For different volume fractions of coarse aggregate (Fig.11a) and different projectile impact velocities(Fig.11b),the numerical simulations of meso-scale and macro-scale are consistent, which proves that the results of the meso-mechanical model are reliable.When the volume fraction of coarse aggregate is high(Fig.11a,for a volume fraction of coarse aggregate of 59%),the coarse aggregate placement algorithm and placement efficiency are limited,while the numerical simulation of macro-scale homogeneous concrete is not limited by the volume fraction of coarse aggregate.The volume fraction of coarse aggregate decreases from 0.59 to 0,and the penetration depth increases by 70.9%,indicating that the volume fraction of coarse aggregate has a great influence on the antipenetration ability of the concrete target, it also shows that studying the anti-penetration ability of concrete from mesocomponents has practical engineering significance.

5. Conclusions

In this paper,the equivalent methods of the mechanical properties of concrete with different components are studied,and the verification of the mechanical properties tests and the antipenetration numerical simulations of meso-scale and macro-scale concrete are carried out.The conclusions are as follows:

(1)A meso-mechanical model of concrete under a penetration load is established,including the equivalent equation of state model,the equivalent confining pressure strength model and the equivalent dynamic tensile strength model.The equivalent equation of state model is a spherical coarse aggregate and a coated mortar shell.The equivalent confining pressure strength model is a cylindrical coarse aggregate and a coated mortar shell.The equivalent dynamic tensile model is a dynamic crack surface passing through the coarse aggregate.

(2)The equivalent mechanical properties of the concrete calculated by the meso-mechanical model are consistent with the experimental results.The equivalent mechanical properties of concrete with different volume fractions of coarse aggregate are also calculated by the meso-mechanical model.

(3)The penetration depths of the projectile corresponding to macro-scale and meso-scale concrete are consistent.For different volume fractions of coarse aggregate and different projectile initial velocities,the macro-scale and meso-scale numerical simulation results are consistent,which proves the rationality of the meso-mechanical model.

Acknowledgment

This work was supported by the National Natural Science Foundation of China[grant number 51278250].

猜你喜欢

杂志排行

Defence Technology的其它文章

- Round robin using the depth of penetration test method on an armour grade alumina

- Sonochemically assisted synthesis of nano HMX

- Effect of particle gradation of aluminum on the explosion field pressure and temperature of RDX-based explosives in vacuum and air atmosphere

- FEM analysis and experimental investigation of force and chip formation on hot turning of Inconel 625

- Study on liquid-filled structure target with shaped charge vertical penetration

- Thermal decomposition of ammonium perchlorate catalyzed with CuO nanoparticles