Effect of imidazole based polymer blend electrolytes for dye-sensitized solar cells in energy harvesting window glass applications

2019-02-09ManikandanYelilarasiSaravanakumarSenthamaraikannanAnishKhanAbdullahAsiri

K.M.Manikandan*,A.Yelilarasi*,S.S.Saravanakumar,P.Senthamaraikannan,Anish Khan,Abdullah M.Asiri

1Department of Physics,Kamaraj College of Engineering and Technology,K.Vellakulam,Virudhunagar,625 701 Madurai,Tamil Nadu,India

2 Department of Mechanical Engineering,Kamaraj College of Engineering and Technology,K.Vellakulam,Virudhunagar,625 701 Madurai,Tamil Nadu,India

3 Chemistry Department,Faculty of Science,King Abdulaziz University,Jeddah 21589,Saudi Arabia

4 Center of Excellence for Advanced Materials Research,King Abdulaziz University,Jeddah 21589,P.O.Box 80203,Saudi Arabia

Keywords:Polymer blend electrolyte Imidazole Dye-sensitized solar cell Surface roughness Ionic conductivity

ABSTRACT The exploration of polymer electrolyte in the field of dye sensitized solar cell(DSSC)can contribute to increase the invention of renewable energy applications.In the present work,the influence of imidazole on the poly(vinylidene fluoride)(PVDF)-poly(methyl methacrylate)(PMMA)-Ethylene carbonate(EC)-KI-I2polymer blend electrolytes has been evaluated.The different weight percentages of imidazole added into polymer blend electrolytes have been prepared by solution casting.The prepared films were characterized by Fourier transform infrared spectroscopy(FTIR),X-ray diffraction(XRD),thermogravimetric analysis(TGA),UV-visible spectra,photoluminescence spectra and impedance spectroscopy.The surface roughness texture of the film was analyzed by atomic force microscopy(AFM).The ionic conductivity of the optimized polymer blend electrolyte was determined by impedance measurement,which is 1.95×10−3 S·cm−1 at room temperature.The polymer electrolyte containing 40 wt%of imidazole content exhibits the highest photo-conversion efficiency of 3.04%under the illumination of 100 mW·cm−2.Moreover,a considerable enhancement in the stability of the DSSC device was demonstrated.

1.Introduction

Recently,dye-sensitized solar cell(DSSC)has received great attention due to there novel applications such as indoor charger devices and power generating building windows.DSSC is a third generation solar cell,and it consists of nanocrystalline TiO2coated onto a transparent conducting glass plate(photoanode),a dye sensitizer,a platinum coated counter electrode and an electrolyte containing I3−/I−redox couple[1,2].The important features of these DSSC panels are that they can be fabricated easily with low cost.The main factors limiting their use of silicon solar cells are high manufacturing cost and large area of installation.Compared to conventional silicon solar cells,DSSC provides remarkable photo-conversion efficiency at low manufacturing costs.The greatest advantages for DSSCs are low cost,simple manufacturing process,high efficiency,environmental stability,semi-transparent design[3-5],simple structural arrangement and flexibility when compared with silicon solar cells[6,7].However,one of the core issues of these devices is using liquid electrolytes that limit the long-standing stability[8-10].Recently,researchers are focused on the various ionic liquids[11,12],inorganic hole transport materials[13,14],organic hole conductors[15],solid-state polymeric materials[16,17],gel polymer electrolyte[2,18]and composite materials[19].

Numerous efforts have been made to replace liquid electrolytes with quasi-solid-state polymer electrolytes.The polymer based electrolytes are prepared from various polymers or co-polymers,such as PVDF,PMMA,PVA,PEG,PAN,PEO,etc.[20].Poly (vinylidene fluoride)(PVDF)has low melting point,low density,and excellent optical properties(~99%transmittance of visible light)[1]and a semi-crystalline thermoplastic fluoropolymer.Poly(methyl methacrylate)(PMMA)is a colorless transparent polymer containing--C=O functional group(carbonyl group)[21].It is often preferred because of its properties of easy processing,long-term stability and low cost.PMMA is used in an extensive range of applications such as TFT-LCD display,window panel,skylights,battery and solar cell.The unique characteristics of PMMA and PVDF are the main reason for the transparency and flexibility of DSSC.Hence it is made suitable for use in building integrated photo-voltaic(BIPV)[22].A heterocyclic aromatic organic compound is imidazole(C3N2H4).It is a polar compound with high electric dipole moment.Due to the high polarity it is easily soluble in polar solvents.Imidazole has amphoteric nature and it has two tautomeric structures.Moreover,another core issue of these devices is using liquid electrolyte causes corrosion of the counter electrode[1].The electrical conductivity also decreases due to corrosion of the counter electrode.An imidazole has been used extensively as corrosion inhibitors.Its derivatives are technologically important for electronic devices.Ethylene carbonate is an excellent plasticizer which holds the polymer chain segments together resulting in the formation of a polymer network structure[23].At least two polymers are mixed together to produce a novel material with excellent physical properties which is called polymer blend[24].The polymer blends can be classified into three categories,they are immiscible,compatible and miscible polymer blends.The advantages of miscible polymer blend electrolytes are single phase structure and one glass transition temperature.The polymer blend electrolytes exhibited excellent interface surface contact between photoanode and counter electrode for DSSC[25].

In this paper,the miscible polymer blend PVDF/PMMA homopolymer system consisting of KI salt and iodine and ethylene carbonate with various concentrations of imidazole has been prepared by solution cast process and characterized by FT-IR,XRD,TGA,impedance spectroscopy,UV-vis spectroscopy,photoluminescence and AFM for the application of DSSC.From the literature survey,no report has been available by choosing PVDF-PMMA-EC-Imidazole-KI-I2polymer blend for DSSCs.The quasi-solid-state DSSC tailored with PVDFPMMA-EC-Imidazole-KI-I2polymer blend electrolytes yields maximum photo-conversion efficiency of 3.04% and long-term stability.Hence,it is suitable for commercial DSSC window panel.

2.Experimental

2.1.Materials

Fluorine-doped tin oxide(FTO)glass plates with average resistance 7 Ω/sq.were supplied by Sigma Aldrich.Titanium dioxide(P 25)was provided by Degussa,Germany.N-719 dye and Platisol (platinum paste)were purchased from Solaronix,Switzerland.PVDF was supplied by S.d.Fine,India.PMMA was obtained from Otto,India.Imidazole was purchased from Avra Synthesis,India.Triton-X 100,acetonitrile and tertbutyl alcohol were supplied by Loba Chemie,India.Potassium iodide(KI),iodine (I2)and Ethylene carbonate (EC)were purchased from Himedia,India.N,N-dimethyl formamide(DMF)was purchased from Merck,India.The purification process was not necessary for all reagents.

Fig.1.Schematic representation of the components of dye-sensitized solar cell.

Fig.2.FT-IR spectra of(a)PMMA,(b)PVDF,(c)Imidazole,PVDF-PMMA-EC-KI-I2with(d)10,(e)20,(f)30,(g)40,and(h)50%of imidazole.

2.2.Polymer blend electrolyte preparation

Initially,0.20 g of PVDF,0.1 g of PMMA,0.3 g of EC,0.03 g of KI,0.006 g of I2and various weight percentages of Imidazole(IM)(10%,20%,30%,40%and 50%)with respect to EC were dissolved in 20 ml of DMF solvent and continuously stirred for about 4 h at 60°C.Finally,homogeneous and viscous polymer blend electrolyte was transfer into dirt free petri dish and permit for evaporation of solvent at room temperature.The uniform thickness of films was obtained after complete evaporation of solvent for further characterization.

Fig.3.X-ray diffraction pattern of Imidazole,PVDF,PMMA and PVDF:PMMA:EC:KI:I2electrolytes with various wt%of imidazole with respect to EC;(S1)10%,(S2)20%,(S3)30%,(S4)40%and(S5)50%.

2.3.Dye-sensitized solar cell fabrication procedure

A piece(2 cm×2 cm)of FTO glass that conducts electricity is used as both photoanode and counter electrode for DSSC.Firstly,TiO2paste was prepared by grinding the TiO2(P 25)powder with two or three drops of Triton X-100 to get a highly viscous paste.Using doctor blade technique,the paste was put onto the FTO glass and consistently spread over the surface then heated at 450 °C for 30 min to get the photoanode.0.3 mmol·L−1of N 719 dye solution was prepared by a 1:1 ratio of tert-butyl alcohol and acetonitrile.At 80°C,the photoanode was put into dye solution and left overnight.The platinum paste was coated on another FTO glass plate and heated at 450°C for 30 min to get the counter electrode.The prepared electrolyte was introduced between the photoanode and counter electrode of DSSC device.Finally,the photovoltaic measurements were carried out with a 0.5 cm2DSSC sensitized area.The pictorial demonstration of the components of DSSC was shown in Fig.1.

Fig.4.TG(a)and DTG(b)analysis of PVDF:PMMA:EC:KI:I2electrolytes with various wt%of imidazole with respect to EC;(S1)10%,(S2)20%,(S3)30%,(S4)40%and(S5)50%.

Table 1 The degradation parameters for the PVDF-PMMA-EC-KI-I2with different weight%of imidazole content polymer electrolyte(heating rate 20 K·min−1)

2.4.Characterization and measurement

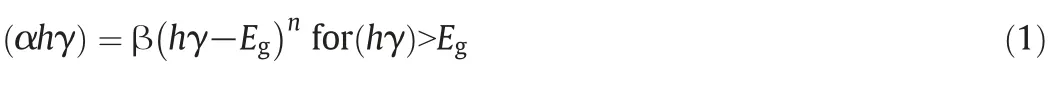

Fourier transform infrared(FTIR)spectroscopy was carried out using a FTIR spectrometer instrument Perkin Elmer Spectrum Version 10.03.09 over the wave number range from 4000 to 400 cm−1.A PANalytical X'Pert PRO powder X-ray Diffractometer with a scanning rate of 2°·min−1was used to determine the degree of crystallinity of the polymer samples.Thermogravimetric analyses (TGA)were performed on a TGA Instruments model 4000 Perkin Elmer at a rate of heating 20 K·min−1under N2flow 20 ml·min−1.The absorption spectra of the different polymer electrolytes were taken with a Shimadzu Model UV-1601 scanning double beam UV-visible spectrophotometer.The indirect band gap(Eg)values were determined from(αhγ)1/2versus(hγ)plot.The absorption coefficient for amorphous materials to incident photon energy was related using equation[26]:

Fig.5.Optical absorption for PVDF:PMMA:EC:KI:I2electrolytes with various wt% of imidazole with respect to EC;(S1)10%,(S2)20%,(S3)30%,(S4)40%and(S5)50%.

Fig.6.(a)The plots of (αhν)1/2 versus hν for PVDF:PMMA:EC:KI:I2electrolytes with various wt%of imidazole with respect to EC;(S1)10,(S2)20,(S3)30,(S4)40 and(S5)50.(b)The variation of band gap in the polymer films with different wt%of imidazole.

where‘Rb’is the bulk resistance of the sample,‘t’is the thickness,and‘A’is the surface area of the electrode/polymer electrolyte contact.The photocurrent-voltage curve of the solar cell was recorded on a Keithley electrometer.An illumination of solar cell was used a high intensity light source of 300 W Xenon lamp(Oriel,USA)and under an irradiance of 100 mW·cm−2.The photovoltaic parameter was calculated using equations:where Jscwas the short circuit current density(mA·cm−2),Vocwas the open circuit voltage (V)and Pinwas the incident light power(mW·cm−2).Jmaxand Vmaxwere the maximum current density and voltage respectively.Atomic force microscopy(AFM)was conducted by Park XE-70 Model with XEI image processing software.

3.Results and Discussion

3.1.FTIR analysis

FTIR spectrum was used to identify the presence of functional groups in the system.The intensity variation,band shift and broadening of the FTIR spectra of the pure component and blend system are due to the chemical interaction[28].The FTIR spectra of PMMA,PVDF and Imidazole were shown in Fig.2(a-c)and compositions of the PVDF-PMMAEC-Imidazole-KI-I2polymer electrolytes were shown in Fig.2(d-h).The characteristic peaks of pure PMMA are 673,759,835,981,1182,1728 and 2924 cm−1.The side chain of PMMA consists of an ester functional group(--COOCH3).In the side chain the--COOCH3group can easily interact with other functional groups [29].The peak at 1728 cm−1corresponds to symmetrical stretching of carbonyl group(C=O).The CH3asymmetric stretching mode of vibration is observed at 2924 cm−1.The characteristic peaks at 673 and 835 cm−1were assigned to C--C out of plane bending and stretching of C--O bonds[30].The peaks at 759,981 and 1182 cm−1correspond to the CH2rocking,wagging,and twisting modes of PMMA.The characteristic peaks of pure PVDF are 490,850,877,978,1060,1164 and 3024 cm−1.The peaks at wave numbers 490,850 and 877 cm−1correspond to CF2wagging,CH2rocking and--C=CH2group[31].The peaks at 978 and 1060 cm−1correspond to out of plane C--H bending and C--C stretching.The peak at 1164 is assigned to CH2stretching vibration.The peaks observed at 1211 and 3024 cm−1correspond to CF2and C---F stretching vibration of PVDF.

The peak at 3018 cm−1is attributed to secondary amine N--H stretching of imidazole.The peaks observed at 1446 cm−1and 659 cm−1are corresponding to C--N stretching and out of plane NH2bending of imidazole.These peaks indicated that there was a slight change in the hydrogen bonding in the samples of imidazole content present in the polymer electrolytes.The peak's slight shift to 1812 cm−1is due to the presence of EC.The chemical interactions of PMMA/PVDF resulted in slight changes in the band shift from 1728 cm−1(Fig.2(d-h))and broadening and also changed the intensity.The reduction of peak intensity was due to the higher concentration of imidazole content in polymer electrolyte.As a result,an interaction takes place between polymer matrix and salt.

3.2.XRD analysis

Fig.3 shows the XRD pattern of PVDF,PMMA,Imidazole and their blend complexes.The broad diffraction peak is at 2θ=24° for pure PMMA.This is the characteristic of amorphous polymers.The sharp peaks observed at 2θ=20°,18°and 26°are due to the crystalline structure of PVDF [32].The diffraction peaks at 2θ=20.71°,25.93° and 30.68° correspond to imidazole.It shows that,the decrease in the trend of the intensity of the peak which appeared at 2θ=20°is due to the increase in the imidazole content in the polymer blend.Theamorphous character was increased up to 40 wt%of imidazole content and it has slightly changed its semi-crystalline nature into amorphous nature [33].Further increases of imidazole content (50 wt%)show more number of sharp peaks which is due to the insolubility of imidazole in the polymer blend system.The peak intensity has been reduced significantly with the increase of addition of imidazole content which leads to reduced degree of crystallinity.There is no characteristic sharp peak found in the sample S4.It is clearly evident that its amorphicity increases that helps to provide fast ion mobility in the polymer network and it gives enhanced photo-conversion efficiency from IV characteristics[34].Further,higher concentration of imidazole in the polymer blend system(S5)exhibits that some additional peaks found in the XRD pattern are due to complete insolubility of imidazole.

Table 2 Ionic conductivity and photovoltaic performance of PVDF-PMMA-EC-KI-I2with different wt%of imidazole content polymer electrolyte

Fig.7.Photoluminescence emission spectra of PVDF:PMMA:EC:KI:I2electrolytes with various wt%of imidazole with respect to EC;(S1)10,(S2)20,(S3)30,(S4)40 and(S5)50.

3.3.Thermal analysis

Fig.8.Complex impedance plot of PVDF:PMMA:EC:KI:I2electrolytes with various wt%of imidazole with respect to EC;(S1)10,(S2)20,(S3)30,(S4)40 and(S5)50.

Fig.9.The photo current density-voltage curves of the DSSCs fabricated with PVDFPMMA-EC-KI-I2containing(S1)10,(S2)20,(S3)30,(S4)40,and(S5)50%of imidazole.

The TG and DTG curves for polymer blend electrolytes are shown in Fig.4a(S1-S5).The DTG curve(Fig.4b)of the film shows that the multistage degradations in the degradation system are relatively complex[35].The onset(Ts),endset(Te),and maximum(Tmax)temperatures for the degradation and the char residue of the samples are listed in Table 1.The polymer blends with various wt% of imidazole exhibit three stages of mass loss.The initial mass loss of the polymer blend takes place around 100°C with a weight loss of 5 wt%.It is due to the removal of physisorbed water molecules and evaporation of moisture content.The first stage degradation reaction for the polymer blend electrolyte found in the range of 250°C-260°C is due to the loss of low molecular weight compounds such as ethylene carbonate(plasticizer).The first decomposition temperature for the film S4 is found to be 290°C which is a slightly higher value compared to the values of other complexes and also the ionic conductivity is found to be higher for this film[30,36].The beginning of the second step degradation reaction for the polymer blend electrolyte was found in the range of 340 °C-395°C for all the samples.The polymer blend S4,displayed the second degradation temperature is 380 °C.The degradation reaction was completed at 450 °C and the char residue at 700 °C is 36%.In an overall comparison,the initial degradation temperature is the most important factor for the thermal stability.This indicates that the optimized system has a good thermal stability with minimum wt%loss than others.

3.4.UV-vis analysis

Fig.10.The long term stability of the optimized polymer blend electrolyte,S4 based DSSC.

The UV-vis spectra of polymer blend films which were collected in the wavelength range of 250-900 nm at room temperature are shown in Fig.5.The absorption edge was found in between 240 nm and 290 nm.The variation in the optical energy band gap reveals the shift in absorption edge.A maximum absorbance of the peak was observed for the polymer system containing 40 wt%of imidazole.It is clear that imidazole absorb UV light due to the presence of conjugated pi(π)bonding systems(π-π*transition)and non-bonding electron system(n-π*transition)[37].The graph(αhν)1/2versus hν indicating the indirect energy band gap(Eg)of the polymer blend system is shown in Fig.6(a).The indirect transition from valence band to conduction band should be connected with a magnitude of phonon [38].The Egvalues of all the samples were summarized in Table 2.Fig.6(b)shows the decreasing trend of Egas a function of different wt%of imidazole up to the system S4.For higher concentration,S5 sample(50 wt%imidazole)shows that the higher optical band gap value is due to the decrease in the degree of disorder in the polymer film.Thus,the 40 wt% imidazole added polymer electrolyte showed the lowest bandgap(2.41 eV)and these results are a good agreement with the ionic conductivity and photovoltaic studies[39].

Fig.11.(a)3-D roughness surface texture of the polymer electrolyte film(S4),(b)2-D roughness surface texture of S4,(c)2-D line diagram for roughness measurement of film S4 and(d)roughness parameters of S4.

3.5.Photoluminescence analysis

Photoluminescence emission spectroscopy is a technique commonly used to estimate the optical and electronic properties of the materials.The polymer blend electrolytes observed at an excitation wavelength of 300 nm is shown in Fig.7.Thus by measuring the emission spectrum,the sample S4 shows the lowest emission intensity compared to other system that corresponds to the reduction of local viscosity [28].The ionic conductivity of the polymer blend electrolyte was absolutely controlled by the local viscosity of the polymer electrolyte.It has been proven that the local viscosity is directly proportional to the intensity of the emission spectra and inversely proportional to the mobility of charge carrier of the polymer blend electrolytes[26,40].

3.6.Ionic conductivity studies

The complex impedance plots for the sample PVDF/PMMA/EC/KI/I2with different wt%of imidazole are shown in Fig.8.The highest ionic conductivity has been observed for the sample,S4.It was observed that the increasing trend of an ionic conductivity is due to different wt%of imidazole content[41].Therefore,the mobility of charge carriers in the polymer matrix-salt complexes also increases.In this system,the plasticizer EC was added into the polymer electrolyte which enhances the polymer segmental mobility.From Table 2,one polymer blend electrolyte sample,S4 has been optimized based on a maximum ionic conductivity value of 1.95×10−3S·cm−1.Due to the addition of the plasticizing agent ethylene carbonate (EC)to polymer combinations,the viscosity of the complex gets reduced and also enhances ionmigration in the polymer blend electrolytes [42].Further addition of imidazole,ionic conductivity of polymer electrolyte is slightly reduced owing to the maximum possibility of ion aggregations.Moreover,the mobility of ions and charge carriers was reduced due to the ion aggregation.Hence,the decrease in conductivity is due to increase in imidazole composition[43].

3.7.Photovoltaic performances

The current density-voltage(J-V)curves of the DSSC using PVDFPMMA-EC-KI-I2electrolyte with various amounts of imidazole(10 wt%,20 wt%,30 wt%,40 wt%and 50 wt%of EC)were employed in DSSCs under the illumination of AM 1.5 as shown in Fig.9.The detailed photovoltaic parameters were listed in Table 2.The high Jscvalues obtained in the 40 wt% imidazole added polymer electrolyte may be due to high ionic mobility of the iodide ions in the electrolyte than other systems.This can be due to the high conductivity and the high density of redox mediators in the electrolyte.The cell with polymer blend electrolyte having 40 wt% of imidazole shows that Vocis 659 mV,Jscis 7.96 mA·cm−2and η is 3.04%.Electrolyte with the lowest imidazole content of 10 wt%shows that Vocis 571 mV,Jscis 5.91 mA·cm−2and η is 2.13%.

One of the most significant characteristics in DSSC is life time.We presented the long term stability of DSSC with PVDF-PMMA-EC-Imidazole(40 wt%)-KI-I2polymer electrolytes with Vocand Jscvalues.Fig.10 shows the decay of photovoltaic performance during a period of 10 days.It is clear that,stability of the DSSC is relatively high due to minor changes that occur in Vocand Jscvalues.The Vocand Jscwere maintained stable over the 10 days and also slightly decreased due to the solidification of electrolyte leading to a decrease in the mobility of polymer blend electrolytes.Hence~90%of the initial values of Vocand Jscwere maintained after the long term stability of ten days.However,DSSCs can be applied as power generating sources in windows and roof panels(skylights)[44].

3.8.AFM analysis

Fig.11a,b shows the 3-D roughness surface texture and 2-D roughness surface texture of polymer blend electrolyte film(S4)which were optimized for 40 wt%of imidazole content in the PVDF-PMMA-EC-KII2,respectively.The average roughness,Ravalue of the optimized system,S4 is 72.934 nm.The roughness skewness,Rskof S4 is−1.240 nm.The higher negative value of roughness skewness,Rskof the sample indicated its porous nature[45].The roughness kurtosis,Rkuis a vital parameter that is used to classify the nature of the surface such as rough (Rku<3)or spiky (Rku>3)surface.Rkuvalue of S4 is 5.883 nm indicate spiky surface.The surface roughness,Rqor Rrmsof S4 is 96.345 nm.However,the surface of the sample entrapping the electrolytes is due to its porous nature,which is responsible for fast ion movement[46].

4.Conclusions

The quasi-solid-state polymer blend electrolyte with different wt%of imidazole was prepared by solution casting technique.The complex formation of the polymer electrolytes was confirmed by FTIR.The XRD pattern of the blend polymer electrolytes shows the amorphous nature which enhances the properties of ion transport in the electrolyte.The maximum ionic conductivity of 1.95×10−3S·cm−1was obtained for the optimized system,S4.The optimized system has a good thermal stability with minimum mass loss.The surface of the polymer blend electrolyte film showed porous in nature was analyzed by AFM.The average roughness,Ravalue of the optimized system,S4 was found to be 72.934 nm.Additionally,the presence of the imidazole based polymer electrolyte significantly enhanced the stability of the DSSC.The highest photo-conversion efficiency of DSSC was 3.04%under an illumination of 100 mW·cm−2.40%of imidazole doped PVDF/PMMA/EC/KI/I2polymer blend electrolyte was optimized as the best composition for low-cost and better stability of the DSSC in energy harvesting window glass applications.

Acknowledgments

This project was funded by Deanship of Scientific Research(DSR),King Abdulaziz University,Jeddah,under grant No.(DF-779-130-1441).The authors gratefully acknowledge DSR technical and financial support.The authors are thankful to Department of Physics,Alagappa University,Karaikudi,Tamilnadu for providing the XRD facility.The authors are also thankful to Centre for SREC,Coimbatore,Tamil Nadu for providing solar simulator studies.

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Scaling of the bubble/slug length of Taylor flow in a meandering microchannel☆

- Analyzing of mixing performance determination factors for the structure of radial multiple jets-in-crossflow☆

- Particle-resolved simulation of packed beds by non-body conforming locally refined orthogonal hexahedral mesh☆

- Visual study on the characteristics of liquid and droplet in a novel rotor-stator reactor☆

- Molecular dynamics simulation of supercritical CO2microemulsion with ionic liquid domains:Structures and properties☆

- Modeling bubble column reactor with the volume of fluid approach:Comparison of surface tension models☆