Comparative analysis of residence and diffusion times in rotating bed used for biogas upgrading☆

2018-11-15LiangZhangAkiberChufoWachemoHairongYuanYunzhiPangXiujinLi

Liang Zhang ,Akiber Chufo Wachemo ,2,Hairong Yuan ,Yunzhi Pang ,Xiujin Li,*

1 Department of Environmental Science and Engineering,Beijing University of Chemical Technology,Beijing 100029,China

2 Department of Water Supply and Environmental Engineering,Arba Minch University,P.O.Box 21,Arba Minch,Ethiopia

Keywords:Rotating bed Biogas upgrading Desorption Residence Diffusion Mass transfer

ABSTRACT Rotating bed can be used in desorption operation of biogas upgrading as a new technology.For enough time to desorb,it is important to study the relationship between the residence time of liquid in rotating bed and the material diffusion time of liquid droplet in desorption process.By theoretical deduction,the exponential relation between residence time and liquid flow rate and rotational speed and kinematic viscosity is obtained.By analyzing the solution of nonlinear partial differential equation,the time law of material diffusion in the droplet is obtained.Moreover,by comparing the residence and diffusion times,the diffusion time can be within or out of residence time range,which has a direct relationship to rotational speed and liquid flow.By experiment,the comparison between residence and diffusion times is more realistic when the rotational speed is higher.

1.Introduction

Biogas can be upgraded to biomethane to obtain high value bioenergy.There are a few upgrading technologies such as water scrubbing technology,chemical absorption technology,pressure swing adsorption,and membrane separation[1-4].High gravity rotating bed is a new technology for biogas upgrading.In the rotating bed,due to the presence of centrifugal force,there is high dispersion of the liquid in the packing layer,which could increase the turbulence and intensify the mixing process.As a result,the mass transfer efficiency could be improved significantly[5-7].The centrifugal acceleration environment,which uses rotation to simulate the super-gravity environment,obtains a sustained,steady and controllable centrifugal force field[8,9].The strong shear made by centrifugal force field forces the liquid material to tear into tiny membranes, filaments,and drops,that creates a rapidly updated phase interface[10,11].The rotating bed technology has been widely applied in gas separation field,and many theoretical and experimental research results have been reported on the bene fits of engineering application[12-15].However,much attention is focused on gas absorption rather than desorption.

The main components of biogas are CH4and CO2;as a result,the biogas upgrading using water to dissolve CO2(water scrubbing technology)is becoming an important technology in recent years[16-18].Although the technology has been applied in engineering,there are still some to be further improved.At present,the conventional packing tower is used fordesorption.Papers[19,20]use the same pilot-scale waterscrubber.In order to achieve the experimental results,the packed capacity of the desorption tower(height 155 cm×diameter 65 cm)is almost the same as that of the absorption tower(height 185 cm×diameter 60 cm).The absorption tower can enhance mass transfer by increasing pressure and decreasing temperature[19-21]to optimize and reduce the size,while the desorption towerdoes nothave any means to enhance mass transfer.The process ofCO2desorption is only physicalprocess,and the mass transfer process without enhancement is very slow and inefficient.Therefore,a large packed capacity for desorption is necessary,and with long time application bacteria reproduction will further reduce the efficiency of the tower[22].It is believed that the packed capacity required willbe reduced by meansofenhancing mass transferforreducing the cost.

When CO2is desorbed from the water,the main mass transfer resistance of the desorption process is in the liquid film side[23,24].The important way to realize the enhanced desorption is reducing the thickness of liquid film,and the adoption of rotating bed technology.The previous reports[8,25-27]show that when the rotating bed speed is more than 800 r∙min-1,the liquid in the packing gap exists mainly in the form of atomized droplets,and the larger the rotational speed,the smaller the average diameter of the droplets.A smaller dropletreduces the liquid film resistance,thereby reducing the required diffusion time in the liquid film side.A faster rotational speed leads to a shorter residence time of the liquid in the rotating bed,which could be detrimental to the effective desorption process in the rotating bed,and result in multi-stage rotating bed operation in practical engineering applications.Therefore,the residence and diffusion times need to be analyzed and compared,to provide a theoretical basis for the improvement of rotating bed technology for biogas upgrading.

Before applying the rotating bed technology for biogas upgrading,the basic hydromechanics parameters need to be clarified.Guo's work[8] finds that liquid back mixing occurs in a narrow region(7%)near the inner diameter where liquid entered into the rotating packing and the average residence time of liquid in rotating bed varies with liquid flow rate and rotational speed and ranges from 200 ms to 800 ms.Lin's work[28]gives a theoretical analysis for liquid holdup.Zhou's work[29]uses closed circuit method to determine liquid holdup and gets different parameters such as liquid flow,rotational speed,liquid viscosity and gas flow.Yang's work[30]uses noninvasive X-ray technique for determination of liquid holdup and gets a more precise formula.Burns'work[31]derives simplified theoretical formulas for liquid holdup and residence time and tests using water.Burn's work is very similar to the object for water scrubbing using rotating bed,and it is easy to apply for engineering because of simplified formulas.Yi's work[32]uses Ben field solution to absorb CO2by rotating bed and gets that the droplet diameter firstly increases with diameter of rotor and later decreases.Burns'work[25]and Zhang's work[26]focus on the average droplet diameter formula in rotating bed which is simple to apply.

In this study,a new water scrubbing biogas upgrading system is set up,which consists of a packed absorption tower and a rotating bed for desorption.The residence and diffusion times in rotating bed are analyzed and compared forimproving desorption performance ofthe rotating bed.Experiment is also set up,which is to verify the comparison between residence and diffusion times.

2.Methods

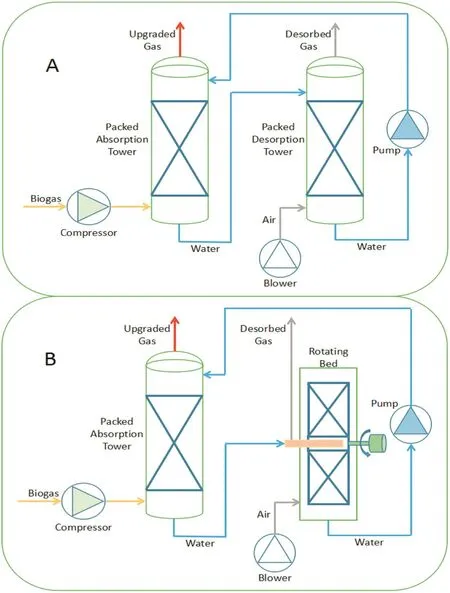

Traditional and new water scrubbing biogas upgrading systems can be seen in Fig.1.In the traditional system,biogas is compressed into packed absorption tower transferring substance to water.The water absorbing the CO2in biogas desorbs CO2in packed desorption tower,and due to the mass transfer resistance of desorption,the tower is dif ficult to get good results.In the new system,the rotating bed is used to replace the conventional packed desorption tower in order to achieve high efficiency desorption.

It is important to improve desorption performance of the rotating bed.One important method is to make residence time greater than diffusion time,which means that all the substance has enough time to be desorbed.The residence time can be derived from radial liquid velocity,while radial liquid velocity can be derived from liquid hold-up in literature.The diffusion time is complex for droplet shapes and equations difficult to determine,but through a series of simplifications,we can obtain the classical equations which are relatively easy to solve.

In order to verify the comparison between residence and diffusion times,by the new system experiment,we tested CO2concentration in the desorbed gas(seen in Fig.1)with the change of liquid(water,seen in Fig.1) flow rate(from high to low)at different rotational speed.When CO2concentration in the desorbed gas did not change,this meant that CO2concentration desorption reaches balance at this liquid flow rate(Lmax).Lmaxtested could be compared to Lmaxcalculated which was obtained from the comparison between residence and diffusion times.

The size of the rotating bed was ri=0.04 m,ro=0.13 m and h=0.2 m,and the bed was packed with wire mesh.Water temperature in this experiment was 25°C.The gas concentration was analyzed by a gas chromatograph(SP2100A,Beifen-Ruili)equipped with a thermal conductivity detector and a stainless steel column(2 m×3 mm).The final result from gas chromatography was the average of three reads.

Fig.1.Traditional(A)and new(B)water scrubbing biogas upgrading systems.

3.Results and Discussion

3.1.Residence time of liquid in rotating bed

Burns et al.[31]have studied the liquid hold-up in the rotating bed by the conductance method.The correlations between the liquid holdup and the acceleration of gravity,the apparent velocity of liquid and the dynamic viscosity of the liquid have been derived(Eq.(1)).

By integrating the whole rotating packed bed,the residence time of the droplet in the rotating bed can be expressed as follows.

From Eq.(5),the residence time tRis exponentially related to:the liquid flow rate L(-0.4),the rotational speed n(-1),and the kinematic viscosity of liquid ν(0.22).Different residence times are shown in Fig.2.

Fig.2.Residence time t R of liquid in the rotating bed.

When the liquid flow rate L increases,the residence time tRin the rotating bed decreases gradually,and decreases further with the increase of the rotational speed n.In the flow and speed range calculated,the minimum to maximum is approximately 2.1 s to 4.4 s.

3.2.Mass diffusion time in droplet

As the mass transfer is completed by diffusion,and the droplet system doesn't have chemical reaction,so the droplet inside diffusion can be obtained from Eq.(6)by Fick's Law(with sphericalcoordinates)[33].

Ignoring concentration change in ϕ and θ,we can simplify Eq.(6)to Eq.(7),

with initial condition t=0 and c=c0and boundary condition r=0,=0;r=RP,and c=cP.

We use c=cP+(c0-cP)c′,r=RPr′,and t=for dimensionless transformation,and obtain

with initial condition t′=0 and c′=1,and boundary condition r′=0,=0;r′=1,and c′=0.

Eq.(8)belongs to nonlinear partial differential equation[34],and it can be solved by the separation of variables method.The solution of Eq.(8)can be expressed by Eq.(9)[26].Figs.3 and 4 are obtained from Eq.(9).

Fig.3.Concentration diffusion varies along radius.

Fig.4.Concentration diffusion varies along times.

In Fig.2,we can see the basic law of the diffusion of the substance in the droplet:(i)At the initial time(t′=0.05),the concentration decreases rapidly along the radius,which is mainly due to the maximum concentration gradient between inner concentration and boundary concentration;thus the diffusion is faster than at other times;(ii)with the increase of time,the differences of inner concentration and boundary concentration are gradually getting smaller,and the curves of concentration change along the radius are gradually getting slower;(iii)later at t′=0.80,the concentration in the whole radius is not changing(close to zero),and the concentration diffusion can be considered as the end.Fig.4 also shows a similar trend like Fig.3.In the different radius positions,the trend of variation in the concentration drop with time is basically the same,and the closer to the outside(r′gets bigger),the faster the rate of concentration drops.When the time reaches t′=0.80,the concentration in the droplet reaches zero,which indicates that the concentration of the liquid drop and the boundary concentration corresponding to the vapor-liquid equilibrium are consistent.

3.3.Comparison between residence and diffusion times

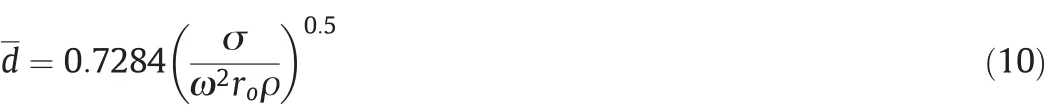

Average diameter of dropletsformed in a rotating bed can be represented by Eq.(10)[25,26].We can replace RPwith average diameter of dropletsand by dimensionless transformation t=,we obtain the actual diffusion time tDas the relative time t′is 0.80.

In Fig.5,the average diameter of the dropletsin the rotating bed is between 0.136 and 0.205 mm,and the corresponding diffusion time tDis between 1.96 and 4.45 s.By comparing the residence time tR(depends on liquid flow rate L,range 1.5-3.5 m3·h-1)at different speeds in Fig.6,we can obtain:(1)the diffusion time tDmay be within or out of the range of residence time tR;(2)when the rotational speed n is less than 800 r·min-1,the diffusion time tDis greater than the residence time tR,indicating that the material diffusion cannot be completed in the liquid flow range;(3)when the rotating speed n is greater than 1200 r·min-1,the diffusion time tDis less than the residence time tR,which shows that the material diffusion can be all completed in the liquid flow range;(4)when the rotational speed n is between 800 and 1200 r·min-1,whether the droplet can finish the material diffusion or not depends on the flow rate.

Fig.5.Average diameter of droplets at different speeds.

Fig.6.Comparison between residence and diffusion time.

3.4.Comparison between calculation and test

Fig.7.Comparison between calculation and test.

In Fig.7,Lmaxtested is compared to Lmaxcalculated.We can see that Lmaxtested has the same change trend to Lmaxcalculated.When the rotational speed increases,the gap is getting smaller and smaller.This means that Lmaxcalculated is ata certain extentreasonable athigh rotationalspeed.Itis because higher rotationalspeed makes dropletsmaller and more uniform,the calculation becomes more realistic.

4.Conclusions

1.The residence time tRis exponentially related to:the liquid flow rate L(-0.4),the rotational speed n(-1),and the kinematic viscosity of liquid ν(0.22).

2.The diffusion of the substance in the droplet varies regularly with time in different radius positions.Initially,due to the maximum concentration gradient between inner concentration and boundary concentration,the diffusion is faster than at other times.With the increase of time,the curve of concentration change along the radius is getting slower.In the later stage,the concentration in the whole radius is not changing(near zero),and the concentration diffusion is over.

3.The diffusion time tDcan be within or out of residence time range,and it has a direct relationship to rotational speed n and liquid flow rate L.In engineering application,according to the calculation and analysis method provided in this paper,by adjusting the rotational speed n and liquid flow rate L,the diffusion time tDcan be faster than the residence time tR,and the invalid operation of rotating bed for biogas upgrading can be reduced.When the rotational speed gets higher,Lmaxcalculated(compared with test)becomes more realistic.

Nomenclature

c molar concentration,mol·m-3

c′ molar concentration in dimensionless,dimensionless

cPmolar concentration of droplet surface,mol·m-3

c0initial molar concentration,mol·m-3

D diffusion coefficient,m2·s-1

g centrifugal acceleration,m·s-2

g0characteristic centrifugal acceleration(=100 m·s-2),m·s-2

h height of packing layer,m

L liquid flow rate,m3·h-1

Lmaxmax liquid flow rate when desorption completed,m3·h-1

n rotational speed,r·min-1

RPdroplet diameter,m

r radial coordinate,m

r′ radial coordinate in dimensionless,dimensionless

riinner radius of packing layer,m

roouter radius of packing layer,m

t time,s

t′ time in dimensionless,dimensionless

tDdiffusion time,s

tRresidence time,s

U liquid flow rate per unit area(super ficial velocity),m·s-1

U0characteristic flow rate per unit area(=0.01 m·s-1),m·s-1

u radial liquid velocity,m·s-1

εLliquid hold-up,dimensionless

ν kinematic viscosity of the liquid,m2·s-1

ν0characteristic kinematic viscosity(=1.0 × 10-6m2·s-1),m2·s-1

ρ density,kg·m-3

σ surface tension,N·m-1

ω angular velocity,rad·s-1

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Online measurement of solids motion in fluidized bed reactor with different distributor for Fischer-Tropsch synthesis☆

- Compressibility induced bubble size variation in bubble column reactors:Simulations by the CFD-PBE

- Meniscus behaviors and capillary pressures in capillary channels having various cross-sectional geometries☆

- Comparison of continuous homogenous azeotropic and pressure-swing distillation for a minimum azeotropic system ethyl acetate/nhexane separation☆

- Pressure relief-dipping-microwave assisted polymerization of melamine-L-aspartic acid resin at activated carbon for purification of L-threonine fermented crude product☆

- Conceptual design of an extractive distillation process for the separation of azeotropic mixture of n-butanol-isobutanol-water☆