基于履带式底盘的改进型森林消防车通过性

2018-09-03孙术发任春龙陈建伟马文良储江伟

孙术发,任春龙,李 涛,陈建伟,马文良,储江伟

基于履带式底盘的改进型森林消防车通过性

孙术发1,任春龙1,李 涛2,陈建伟3,马文良3,储江伟4

(1. 东北林业大学工程技术学院,哈尔滨 150040; 2. 内蒙古大兴安岭重点国有林管理局防火办,牙克石 022150;3. 哈尔滨松江拖拉机有限公司,哈尔滨 150010; 4. 东北林业大学交通学院,哈尔滨 150040)

通过对林区复杂地形和现有消防设备的分析,在第一代消防车(LY1102XFSG30)结构上对底盘及上装进行了优化改造,由4个支重轮增加到5个支重轮,设计了一台大型履带式消防车(LF1352JP)。采用CREO软件对整车结构进行了三维设计与仿真,对消防车横向、纵向稳定性以及垂直越障和跨越壕沟进行了理论分析,分析表明,LF1352JP消防车满载时在斜坡上横向行驶所允许的最大斜坡角度为40.6°,空载时45.1°;纵向行驶时,满载时最大纵向上坡角度为52.0°,空载时60.9°,满载时最大下坡角度为47.2°,空载时45.8°;满载时越障高度为405 mm,空载时615 mm;满载时跨越壕沟宽度为1 248 mm,空载时983 mm。最后在试验场地进行了纵向爬坡、纵向下坡、跨越壕沟试验,试验验证了改造后整车牵引力和稳定性能方面都有了较大的提升,能够满足现阶段大型林区火灾作业的需求。

机械化;设计;优化;履带式;消防车;稳定性;越障能力

0 引 言

随着天然林保护工程的实施,林区由木材采伐作业为主转变为林木保护为主,森林火灾是森林最大的威胁。森林火灾突发性强、破坏性大、危险性高,是全球发生最频繁、处置最困难、危害最严重的自然灾害之一,是生态文明建设成果和森林资源安全的最大威胁,甚至引发生态灾难和社会危机[1-3]。中国总体上是一个缺林少绿、生态脆弱的国家,是一个受气候影响显著、森林火灾多发的国家。据统计,“十二五”期间,全国年均发生森林火灾3 992起,受害森林面积1.7万hm2,因灾伤亡61人[4]。

目前国内林区消防车主要有轮式消防车和履带式消防车2种[5-6]。国内森林消防车的发展相对较晚,王哲等[7]设计的轮式消防车虽然动力性能与越野性能较强,但其轮式底盘只适合在通过性能良好的道路上行驶,在林区复杂道路上通过性能较差。哈尔滨第一机械集团有限公司[8]研制的全地形双节履带车(蟒式消防车)采用全动力、全地形的履带式底盘,虽然其对地形适应性强,但造价昂贵、普及成本高。美国研制的奥什科什·不死鸟[9]质量达20 t,虽功能齐全,但其造价更加昂贵[10-12]。目前国内市场上现有的履带消防车多为坦克底盘改装,虽然具有结实耐用的特点,但其底盘较低,难以适应林区多壕沟、多倒木的复杂地形。本文在第一代森林消防车(LY1102XFSG30)基础上设计并制造一台新型履带式森林消防车(LF1352JP型),并对现车和原车在林区通过性方面进行了理论计算和试验分析。

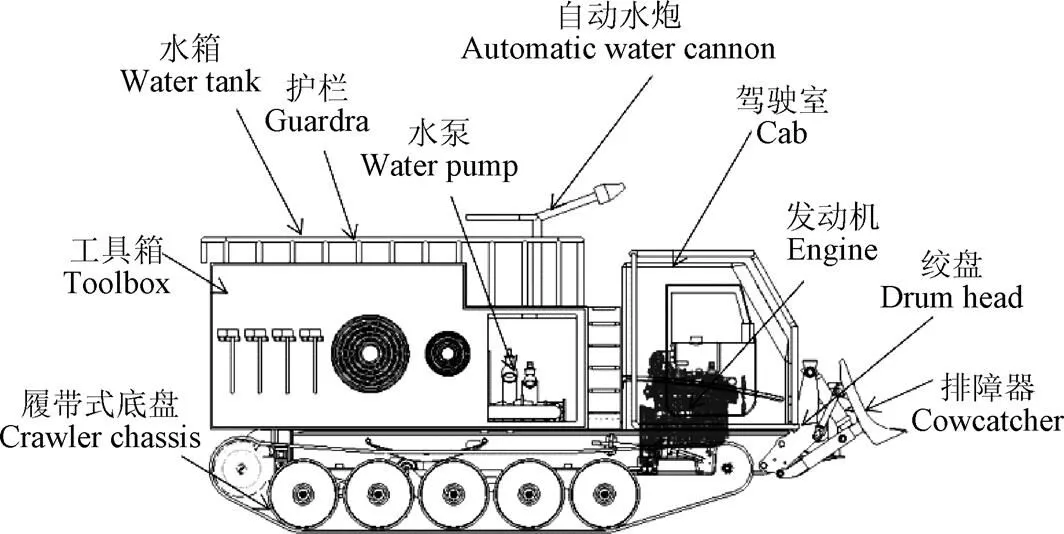

1 整机结构设计

现车与原车相比,底盘在长度和宽度上都有所增加,由4个支重轮增加到5个支重轮,轴间距离由2 040改为2 720 mm,轨距由原来的1 546增加为1 974 mm,加长增宽后的底盘在稳定性能力方面优于原底盘。保持了原底盘的离地间隙以保证其良好的通过性能,发动机功率由85增加为99.3 kW,功率增大后的发动机在车辆爬坡和遇到复杂障碍物时可提供足够的动力,另外增加了排障器,使其在行驶过程中可推倒林区灌木、推平土堆等障碍物。

改进的消防车由动力系统、履带式底盘、控制系统、排障器、液压绞盘、水炮和水箱等组成,消防车结构如图1所示,该车具有森林灭火、运送给养、绞盘自救和他救等功能。在进行森林灭火时,可使用多种水源供水,自身装载的泵站可以使其不需要其他辅助设施即可实现远距离供水。增加的排障器可使其排除灌木等路障缩短其到达火灾区的时间。

图1 CREO环境下LY1352JP整机简图

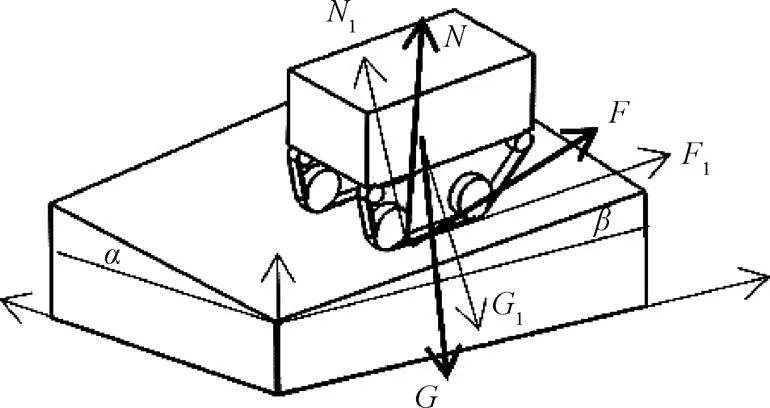

2 稳定性分析

林区路况复杂且斜坡较多,消防车在斜坡上发生纵向倾翻和横向侧翻的概率几乎占到事故总数的50%[13-17]。林区地形多为三维坡度,即既存在横向坡度又存在纵向坡度。消防车在三维坡度上行驶时的受力简图如图2所示。

注:G为重力,N;G1为重力的分力,N;N为支撑力,N;N1为支撑力沿横向方向的分力,N;F为摩擦力,N;F1为摩擦力沿纵向方向的分力,N;α为横行坡度,(°);β为纵向坡度,(°)。

在三维坡度分析中,消防车受到坡面对其的支撑力、摩擦力以及重力作用,为简化分析,将其力进行分解,简化为沿纵向方向和横向方向的作用力,本文从横坡和纵坡2个方向分别讨论其满载和空载时的稳定性。

2.1 横坡行驶时受力分析

消防车满载时在斜坡上横向行驶时的受力分析情况如图3所示。

注:O为质心;N2,N3分别为地面对左右支重轮沿横向方向的支撑力;Z1与Z2均为地面作用于履带的力,N;S为轨距(1 974 mm);e为质心偏移距离(0 mm);h为质心高度(满载时为1 150 mm,空载时为950 mm)。

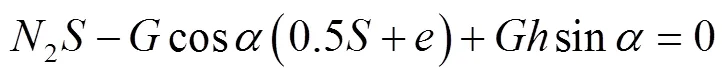

消防车在横坡匀速行驶时,其总体受力集合等于0,其整机力矩是平衡的[18]。对点取力矩可得

对式(1)进行变形后可得

若消防车在横坡上稳定行驶,1需大于0,即cos(0.5+)−sin>0,设消防车稳定行驶的极限横向坡度为α,其中=0,由以上分析可得

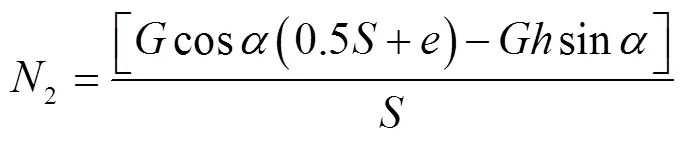

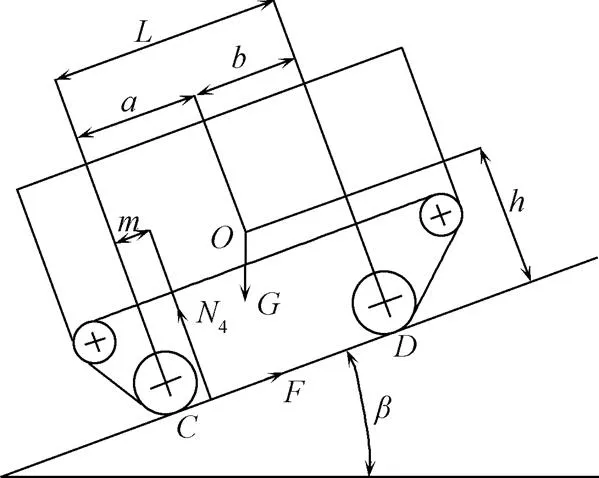

从图4中可以看出,极限坡度随着质心高度的增加而减少,当质心高度相同时,极限坡度与轨距成正比,当质心高度较小而轨距较大时极限坡度最大。对消防车进行三维模拟仿真,得出其满载和空载时各相关参数,如表1所示。由表1中可知,相对于原车,现车无论满载还是空载其质心高度都低于原车,将表1参数代入式(3)中,计算得到现车满载时横向行驶所允许的极限坡度为40.6°,空载时45.1°,原车满载时横向行驶所允许的极限坡度为31.9°,空载时为35.1°,可见现车相比于原车横坡行驶能力显著提高。

表1 消防车的相关参数

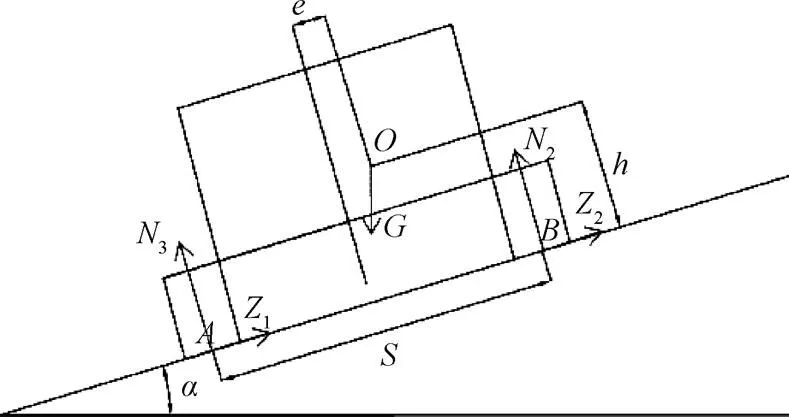

2.2 纵向行驶时稳定性分析

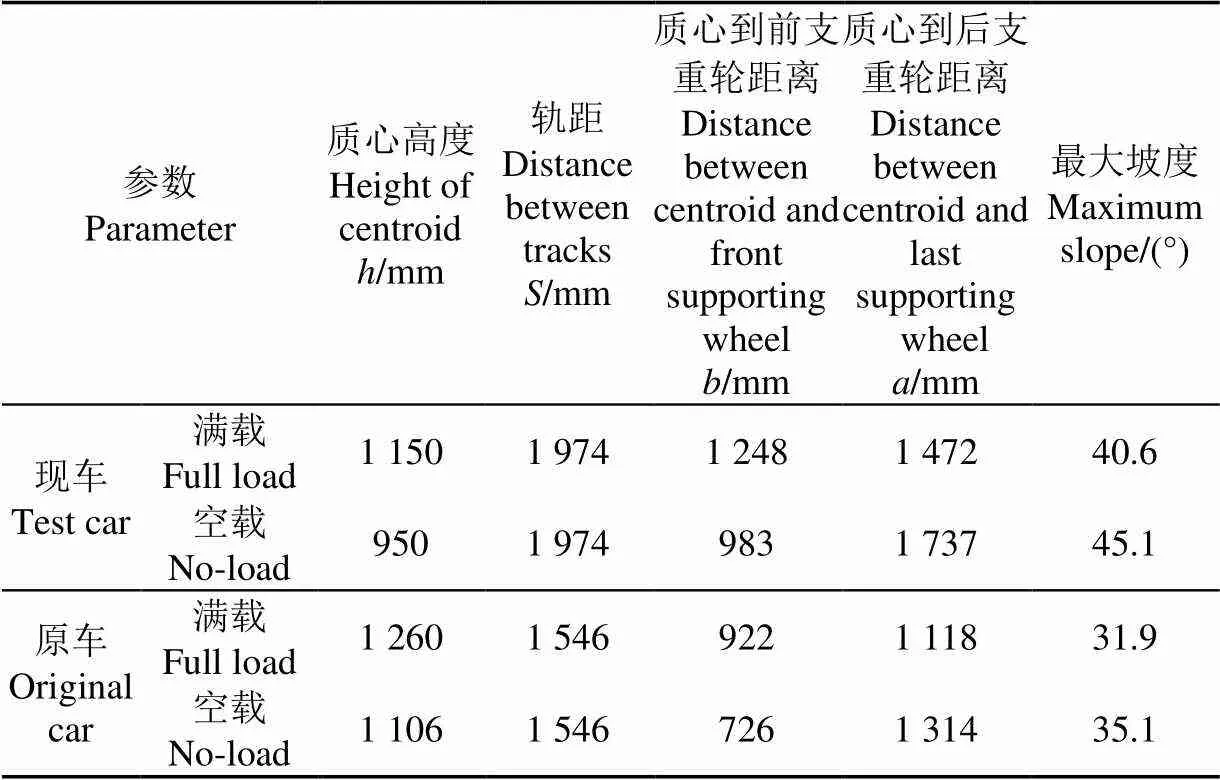

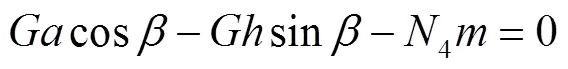

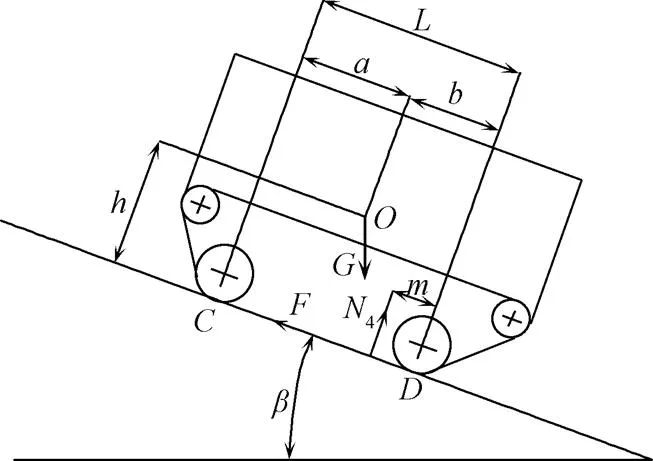

消防车纵向上坡行驶时,其受力主要为重力的分力和地面对其的反力以及地面摩擦力,其受力分析图如图5所示。

注:m为支重轮B与垂直反力之间的距离,mm;N4为地面对整车沿纵向方向的支撑力,N。

消防车纵坡匀速行驶时,整车受力处于平衡状态,即其所受合力为零,对支重轮和分别取力矩,上坡时对支重轮取力矩可以得到

在竖直方向上所受合力为零,即4=cos

由式(4)得

使消防车在纵向上坡时不发生倾翻的临界条件是=0,即

即

式中β1为纵向上坡最大坡度角,(°)。

图6 下坡行驶时的受力简图

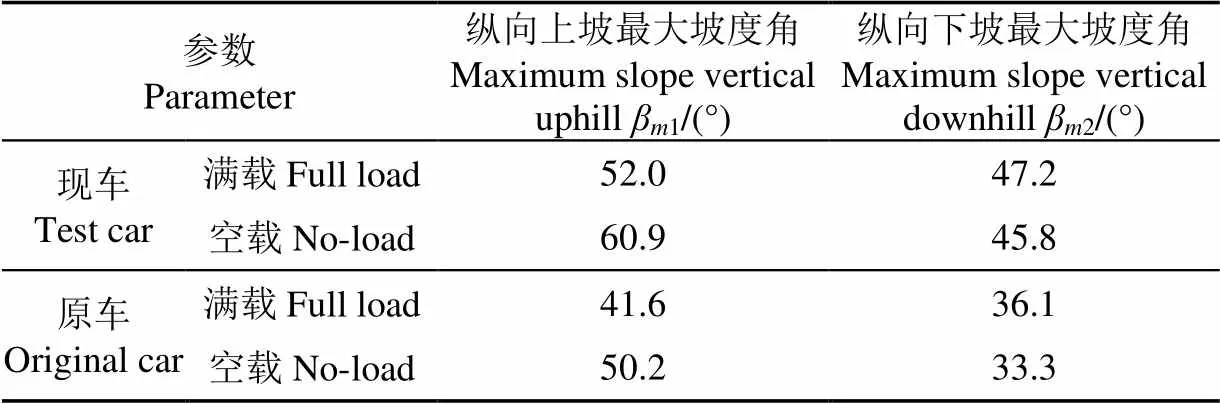

由图7可知,消防车在上坡和下坡时,质心的高度和质心与支重轮的距离是影响斜坡最大角度的主要因素,当质心距支重轮的距离一定时,最大角度与质心高度成反比例关系,当质心高度一定时,最大角度随着质心到支重轮距离的增大而增大。根据以上分析和表1数据计算可得,不同工况下的消防车极限爬坡角度如表2所示。由表2可知,现车相比于原车在爬坡能力方面有显著提高。

图7 最大爬坡角度和参数的关系

表2 不同工况下的极限爬坡角度

3 越障能力分析

林区中的典型路障包括2种:壕沟和倒木,当消防车行驶过程中攀越倒木时,可将倒木视为垂直障碍物[19-22]。下面对现车的越障能力进行分析。

3.1 垂直越障能力

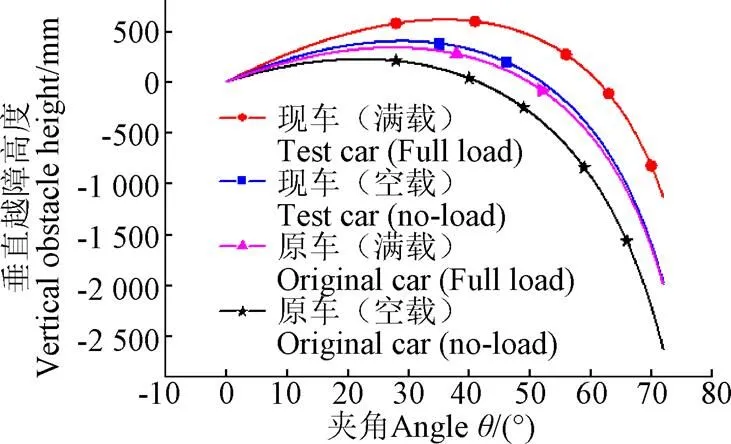

消防车的越障能力可以定义为其可顺利通过垂直障碍物的最大高度,根据消防车的实际攀爬情况,可以将整个越障过程分为3个阶段[23-26]:第一阶段,消防车导向轮与垂直障碍物在点接触,如图8a所示,此时由于牵引力的推动作用消防车将发生旋转,随后近壁侧开始上升,开始进行越障;第二阶段,此阶段是决定消防车是否可以成功越障的阶段,在此过程中,随着消防车导向轮的上升主体重心不断提高,消防车缓慢前移时,底盘与地面的夹角逐渐增大,随着消防车的前移,其主体重心恰好在台阶边缘线正上方时此时是消防车攀越垂直壁的临界状态,如图8b所示;第三阶段,消防车的质心作用线越过垂直壁边缘,消防车重新回到水平面,消防车完成越障如图8c所示。

根据式(8)和消防车相关参数模拟出其在越障过程底盘与地面的夹角与垂直壁高度0的关系图,如图9所示。由图9可知,当消防车垂直越障时,随着车身的前移,夹角值逐渐增大,垂直越障高度也随之增加,当达到抛物线的顶峰时垂直越障高度最大,当夹角继续增大时,垂直越障高度开始下降。另外,消防车的重心越低,到后支重轮的距离越大时,消防车面对垂直障碍物时的通过性能越好。根据以上分析,计算出现车与原车的最大爬坡角度和最大垂直越障高度,如表3所示。由表3可知,现车相比原车在垂直越障能力方面具有显著提升。

注:为消防车重心与后支重轮中心线的距离,mm;0为垂直越障高度,mm;1为消防车重心距支重轮轮心的纵向距离,mm;为攀越垂直路障时底盘与地面的夹角,(º)。

Note:is distance between fire fighting truck core and back thrust wheel center line, mm;0is vertical obstacle height, mm;1is vertical distance of fire fighting core to thrust wheel center, mm;is angle between chassis and ground in climbing vertical barricade,(º).

图8 攀越垂直路障过程

Fig.8 Process of climbing vertical barricade

图9 最大垂直壁高度与夹角的关系

表3 不同工况下的垂直越障极限参数

3.2 跨越壕沟

壕沟是消防车在林区执行任务时常见的一种路障,也是消防车越障能力的重要体现之一。根据履带车的行驶方式及相关参数,模拟出履带式消防车跨越壕沟的分析模型[27-29],如图10所示。消防车跨越壕沟时,对其跨越能力可以界定为:当不考虑消防车坠入沟道内时,消防车低速匀速行驶,且车辆不发生坠落。当消防车的前支重轮触碰到壕沟的另一侧时其质心应未越过近侧沟道边界线,如图10a所示;当消防车后支重轮离开沟道边界线时,其质心应已经越过沟道的近侧边界线,如图10b所示,否则认定消防车跨越壕沟失败。

图10 消防车跨越壕沟过程

根据以上分析,消防车可跨越壕沟的最大宽度应为min(,),根据质心位置分析计算可得,现车满载时可跨最大壕沟宽度为1 248 mm,空载时最大为983 mm。原车满载时可跨最大壕沟宽度为922 mm,空载时最大为726 mm。现车相比与原车在跨越壕沟能力方面有显著提高。

4 试验验证

4.1 试验条件

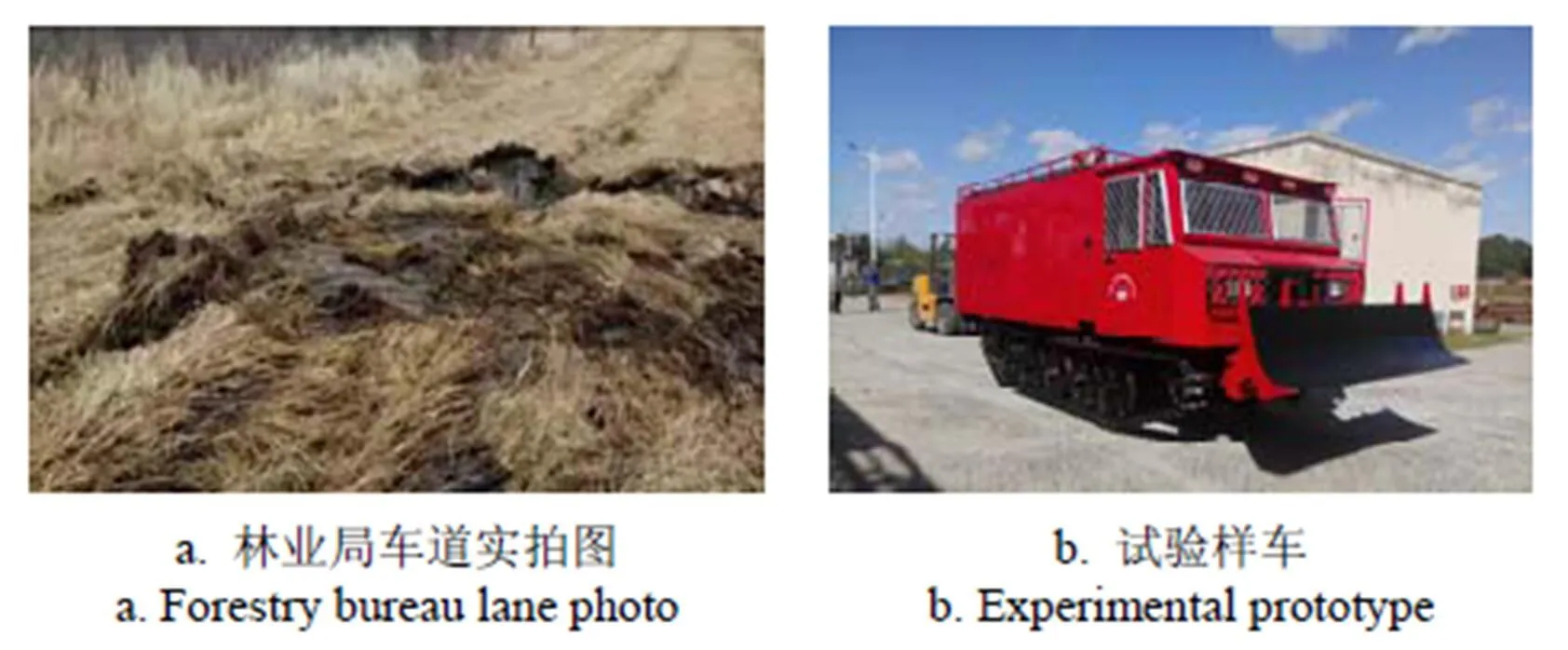

本文试验分2个阶段进行,2017年5月在哈尔滨榆树试验场进行第一阶段的纵向爬坡试验,2017年10月在内蒙古自治区牙克石林业局进行第二阶段的纵向下坡、跨越壕沟试验。图11a为林业局行车道实拍图,试验样机为哈尔滨松江拖拉机厂制造出的LF1352JP型履带式森林消防车样机,如图11b所示。

图11 试验场地及样车

4.2 试验结果分析

4.2.1 纵向爬坡试验

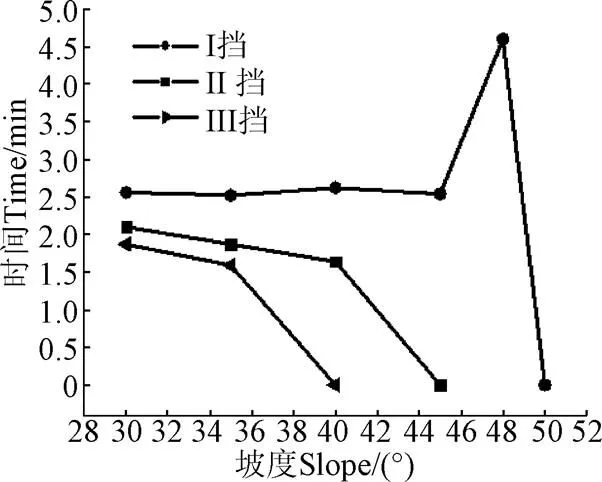

第一阶段在哈尔滨榆树试验场进行底盘负载通过性实验,此时还未对整车进行上装设计(包括驾驶室也是使用J-50驾驶室),采用模拟加载的方法测试底盘的通过性试验结果,试验场地设置了不同角度的纵坡,测试不同挡位、不同角度的爬坡时间。由图12可知,消防车以Ⅰ挡进行爬坡时,随着坡度的缓慢增大爬坡时间并没有明显的变化,当坡度增加到48°时消防车达到最大爬坡角度。以Ⅱ挡和Ⅲ挡进行爬坡时,由于其牵引力较小,在坡度较低时就出现了爬坡失败的现象,试验所得的最大爬坡角度和上文理论上理论分析得到的最大角度52.0°相比误差为7%,误差的原因是:理论计算所得的最大角度是在理想的环境下得到的,而实际中林区路面土壤湿度较高,爬坡过程中路面易发生松动导致摩擦产生的推动力较小。

图12 爬坡时间随坡度的变化

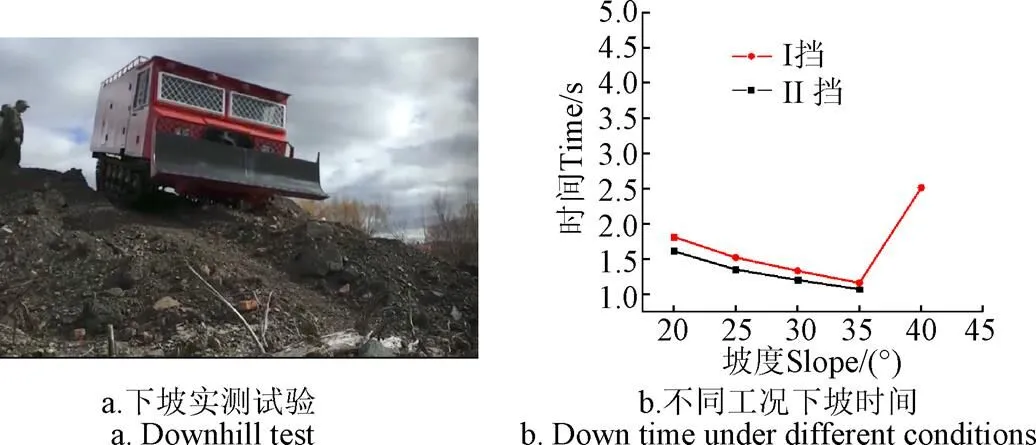

4.2.2 纵向下坡试验

该试验为满载情况下以不同挡位、不同坡度进行下坡时间测试。下坡试验及试验结果如图13所示。从图13b可以看出,在下坡试验中,消防车的下坡时间与坡度呈反比例关系。具体试验结果为:当消防车以Ⅰ挡在角度在小于35º斜坡向下行驶时,行驶速度较稳定,当角度增加到35°时消防车有滑动的趋势,采取刹车制动以更低的速度可缓慢的驶下斜坡如图13b,出于驾驶安全考虑不以Ⅱ挡进行角度大于35°的试验。试验得出的极限坡度40°与前文理论上得到的极限坡度47.2°相比,误差为15%,误差的最大原因在于理论上斜坡是完全理想化的,而实际上路面在承受巨大压力时会出现下陷的趋势。

图13 下坡试验

4.2.3 跨越壕沟试验

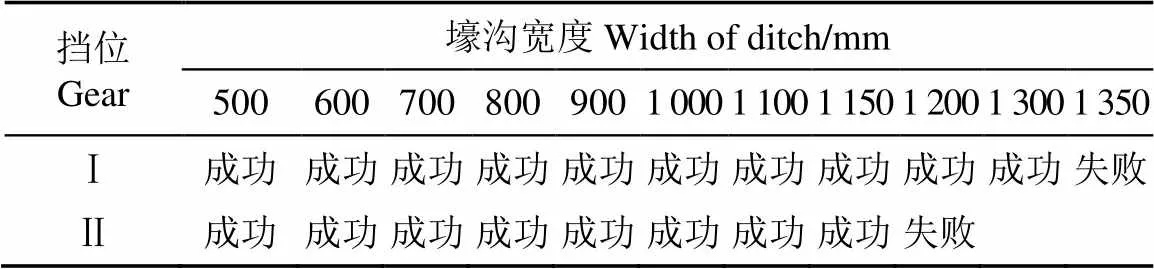

本试验对Ⅰ挡和Ⅱ挡下跨越不同宽度的壕沟进行测试,测试结果如表4所示。在此试验中,由于Ⅲ挡和Ⅳ挡的牵引力有限,为了防止消防车陷入壕沟中发生安全事故,选择Ⅰ挡和Ⅱ挡作为试验挡位。

表4 不同挡位不同壕沟宽度通过结果

当壕沟宽度增大到接近理论值时,使用Ⅱ挡在跨越宽度为1 150 mm的壕沟,消防车较为困难的完成跨越。使用Ⅰ挡跨越宽度为1 300 mm的壕沟时,消防车较为困难的完成跨越。实际值1 300 mm与理论值1 248 mm相比,误差为4%,误差原因为理论值未考虑消防车跨越过程中后支重轮陷入沟道内但由于前轮摩擦推力的存在仍可成功越障的情况。

5 结 论

本文设计并制造了一台LF1352JP型履带式消防车,对该车结构进行三维模拟仿真,对其通过性进行了理论分析,并对整车进行了试验测试,试验结果与理论值较吻合,现车相比于原车在爬坡能力和越障能力都有显著提高。具体结论如下:

1)对第一代LY1102XFSG30型森林消防车进行改造,设计并制造了LF1352JP型履带式消防车,增大了发动机功率,由85增加为99.3 kW,整车动力性得到增强;增加了排障功能,可排除通行道路上灌木等路障;对底盘进行加宽和加长,使整车的稳定性得到改善。

2)采用CREO软件对消防车进行三维仿真分析,对消防车横向、纵向稳定性以及垂直越障和跨越壕沟进行了理论分析,通过计算得出:满载时横向行驶极限坡度为40.6°,空载时为45.1°;满载时纵向上坡行驶极限坡度为52.0°,空载时为60.9°;满载时纵向下坡行驶极限坡度为47.2°,空载时为45.8°;满载时垂直越障极限高度为405 mm。空载为时为615 mm;满载时可跨壕沟最大宽度为1 248 mm,空载时为983 mm。

3)试验样机分别在哈尔滨榆树试验场和内蒙古自治区牙克石林业局进行了纵向爬坡试验、纵向下坡试验,跨越壕沟试验。试验结果为:纵向爬坡行驶极限坡度为48°,纵向下坡行驶极限坡度为40°,可跨壕沟最大宽度为1 300 mm,试验结果与理论分析较吻合。

[1] 苏立娟,何友均,陈绍志. 1950-2010年中国森林火灾时空特征及风险分析[J]. 林业科学,2015,51(1):88-96.

Su Lijuan, He Youjun, Chen Shaozhi. Temporal and spatial characteristics and risk analysis of forest fires in China from 1950 to 2010[J]. Scientia Silvae Sinicae, 2015, 51(1): 88-96. (in Chinese with English abstract)

[2] 梁爱军,孙龙,刁柄奇,等. 森林火灾损失分类方法和评估指标评述[J]. 森林工程,2014,30(5):6-10,17.

Liang Aijun, Sun Long, Diao Bingqi, et al. Review of forest fire damage assessment index and classification methods[J]. Forest Engineering, 2014, 30(5): 6-10, 17. (in Chinese with English abstract)

[3] 高仲亮,王秋华,舒立福,等. 森林火灾扑救消防车装备的种类及使用技术[J]. 林业机械与木工设备2014,42(8):10-14.

Gao Zhongliang, Wang Qiuhua, Shu Lifu,et al. Kinds of fire engines and technology used[J].Forestry Machinery & Woodworking Equipment, 2014, 42(8): 10-14. (in Chinese with English abstract)

[4] 张惠莲. 当前气候变化下如何加强森林火灾预测预报[J].森林防火,2010(4):33-36.

Zhang Huilian. How to strengthen forest fire forecast and forecast under current climate change[J]. Forest Fire Prevention, 2010(4): 33-36. (in Chinese with English abstract)

[5] 姜晨龙,丛静华,汪东. 地面大型森林消防装备发展现状研究[J]. 安徽农业科学,2014,42(12):3595-3597.

Jiang Chenlong, Cong Jinghua, Wang Dong. Study on development status of ground large forest fire-fighting equipment[J]. Journal of Anhui Agri. Sci, 2014, 42(12): 3595-3597. (in Chinese with English abstract)

[6] 乔启宇. 水灭火森林消防设备系统研究[J]. 北京林业大学学报,2002(增刊1):191-195.

Qiao Qiyu. Techniques of forest fire fighting by using water and their development in China[J]. Journal of Beijing Forestry University, 2002(Supp.1): 191-195. (in Chinese with English abstract)

[7] 王哲,郑燕萍,汪东,等. 轮式多功能森林消防车的设计[J]. 消防科学与技术,2016,35(2):244-247.

Wang Zhe, Zheng Yanping, Wang Dong, et al. Design of wheel multiffunctional forest fire fighting vehicle[J]. Fire Science and Technology, 2016, 35(2): 244-247. (in Chinese with English abstract)

[8] 黄郁馨,纪树东,周忠海,等. 蟒式全地形车关键零件加工与装备[J]. 世界制造技术与装备场,2016(2):88-91.

Huang Yuxin, Ji Shudong, Zhou Zhonghai, et al. The key parts processing and equipment of the anaconda[J]. World Manufacturing Technology and Equipment Field, 2016(2): 88-91. (in Chinese with English abstract)

[9] 丛静华,何瑞银,王家胜. 森林消防车的发展现状和功能分析[J]. 林业机械与木工设备,2006(8):4-6,13.

Cong Jinghua,He Ruiyin,Wang Jiasheng. Current situation and function analysis on forest fire fighting vehicle[J]. Forestry Machinery & Woodworking Equipment, 2006(8): 4-6,13. (in Chinese with English abstract)

[10] 郑楠,茹煜,汪东,等. 三级林用消防泵内部流场模拟及分析[J]. 林业工程学报,2017,2(3):124-130.

Zhang Nan, Ru Yu, Wang Dong, et al. Flow field simulation and working condition analysis of triple-stage forest fire pump[J]. Journal of Forestry Engineering, 2017, 2(3): 124-130. (in Chinese with English abstract)

[11] 刘平义,彭凤娟,李海涛,等. 丘陵山区农用自适应调平底盘设计与试验[J]. 农业机械学报,2017,48(12):42-47.

Liu Pingyi, Peng Fengjuan, Li Haitao, et al. Design and experiment of adaptive leveling chassis for hilly area[J]. Transactions of the Chinese Society of Agricultural Machinery, 2017, 48(12): 42-47. (in Chinese with English abstract)

[12] 杨政,范桦,金义重. 对我国消防部队装备管理及建设的思考[J]. 消防科学与技术,2009,28(12):949-952.

Yang Zheng, Fan Hua, Jin Yizhong. Reflections on the equipment management and construction of China’s fire-fighting force[J]. Fire Science and Technology, 2009, 28(12): 949-952. (in Chinese with English abstract)

[13] 陈思成,陈劭,杨越. 森林消防车制动安全性评价与试验研究[J]. 林业机械与木工设备,2015,43(11):10-13.

Chen Sicheng, Chen Shao, Yang Yue. Analysis on driving stability of caterpillar tractor on ramp[J]. Forestry Machinery & Woodworking Equipment, 2015, 43(11): 10-13. (in Chinese with English abstract)

[14] 曹付义,周志立,徐立友. 履带车辆液压机械差速转向系统参数优化[J]. 农业工程学报,2013,29(18):60-66.

Cao Fuyi, Zhou Zhili, Xu Liyou. Parameter optimization of hydro-mechanic differential turning system for tracked vehicle[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2013, 29(18): 60-66. (in Chinese with English abstract)

[15] 杨秀建,王增才,路玉峰,等. 极限工况下汽车稳定性的最优保性能控制[J]. 农业机械学报,2008,39(6):38-41.

Yang Xiujian,Wang Zengcai,Lu Yufeng,et al. The optimal performance control of vehicle stability under extreme conditions[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(6): 38-41. (in Chinese with English abstract)

[16] 汪伟,赵又群,黄超,等. 新型机械弹性车轮的建模与通过性研究[J]. 中国机械工程,2013,24(6):724-729.

Wang Wei, Zhao Youqun, Huang Chao, et al. Modeling and trafficability analysis of New mechanical elastic wheel[J]. China Mechanical Engineering, 2013, 24(6): 724-729. (in Chinese with English abstract)

[17] 李建桥,张广权,王颖,等. 仿螃蟹步行机构及其通过性试验[J]. 农业工程学报,2016,32(14):47-54.

Li Jianqiao, Zhang Guangquan, Wang Ying, et al. Bionic crab walking mechanism and its kinematic characteristics analysis[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2016, 32(14): 47-54. (in Chinese with English abstract)

[18] 王鑫,赵强,何法,等. 线性二自由度汽车操纵稳定性仿真分析[J]. 森林工程,2016,32(1):64-67,76.

Wang Xin, Zhao Qiang, He Fa, et al. Simulation analysis on automobile handling stability with linear two degrees of freedom[J]. Forest Engineering, 2016, 32(1): 64-67,76. (in Chinese with English abstract)

[19] 杨卫杰,孟兆新,秦国新. 联合采伐机六足行走装置单足力学解算与分析[J]. 森林工程,2015,32(1):66-69,74.

Yang Weijie, Meng Zhaoxin, Qin Guoxin. The mechanics calculation and analysis of a single foot withinthe six legged walking device of combined harvesting machine[J]. Forest Engineering, 2015, 32(1): 66-69, 74. (in Chinese with English abstract)

[20] 朱磊,陈伟,郑云峰,等. 采用水文分析法对林区道路涵洞选址的研究[J]. 森林工程,2017,33(3):85-88.

Zhu Lei, Chen Wei, Zheng Yunfeng, et al. Research on hydrological analysis for locating forest road culvert[J]. Forest Engineering, 2017, 33(3): 85-88. (in Chinese with English abstract)

[21] 李卫朋,孙建,沙玉坤,等. 西南地区亚高山典型林区土壤碳排放及影响因子[J]. 农业工程学报,2015,31(1):255-263.

Li Weipeng, Sun Jian, Sha Yukun, et al. Carbon emission and its influence factors of subalpine forest soilin Southwest China[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2015, 31(1): 255-263. (in Chinese with English abstract)

[22] 王亚,陈思忠,李海涛,等. 高地面仿形性动力底盘的设计与试验[J]. 农业工程学报,2012,28(增刊1):39-44.

Wang Ya, Chen Sizhong, Li Haitao, et al. Design and experiment of high performance profiling terrain chassis with power train[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2012, 28(Supp.1): 39-44. (in Chinese with English abstract)

[23] 葛晓雯,侯捷建,王立海. 集材机可更换三角形履带跨越壕沟动力学仿真分析[J]. 林业工程学报,2016,1(1):111-117.

Ge Xiaowen, Hou Jiejian, Wang Lihai.Trench-crossing dynamic simulation of the replace able triangular track of skidder[J]. Journal of Forestry Engineering, 2016, 1(1): 111-117. (in Chinese with English abstract)

[24] 黄晗,李建桥,吴宝广,等. 轻载荷条件下轻型车辆车轮牵引通过性模型的建立与验证[J]. 农业工程学报,2015,31(12):64-70.

Huang Han, Li Jianqiao, Wu Baoguang, et al. Construction and verification of lightweight vehicle wheel tractive trafficability model under light load[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2015, 31(12): 64-70. (in Chinese with English abstract)

[25] 张德,邹树梁. 履带式防核辐射挖掘机越障过程动力学建模及影响因素研究[J]. 南华大学学报:自然科学版,2017,31(3):1-8,24.

Zhang De, Zou Shuliang. Dynamic model of crawler anti-radiation excavator climbing over obstacles and analysis on its influential factors[J]. Journal of University of South China: Science and Technology, 2017, 31(3): 1-8, 24. (in Chinese with English abstract)

[26] 牛建业,王洪波,史洪敏,等. 变自由度轮足复合机器人轨迹规划验证及步态研究[J]. 农业工程学报,2017,33(23):38-47.

Niu Jianye, Wang Hongbo, Shi Hongmin, et al. Trajectory planning verification and gait analysis of wheel-legged hybrid robot with variable degree of freedom[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(23): 38-47. (in Chinese with English abstract)

[27] 刘平义,王振杰,李海涛,等. 行星履带式农用动力底盘设计与越障性能研究[J]. 农业机械学报,2014,45(增刊1):17-23.

Liu Pingyi, Wang Zhenjie, Li Haitao, et al. Design and overcoming obstacles ability research of tracked driving chassis with planetary structure[J]. Journal of Agricultural Machinery, 2014, 45(Supp.1): 17-23. (in Chinese with English abstract)

[28] 杨春梅,赵洪元,宋文龙,等. 间伐材伐区用小型抓木机的设计与分析[J]. 林业工程学报,2017,2(3):112-116.

Yang Chunmei, Zhao Hongyuan, Song Wenlong, et al. The design and analysis of a small timber grab used in theinning plots[J]. Journal of Forestry Engineering, 2017, 2(3): 112-116. (in Chinese with English abstract)

[29] 赵治国,方宗德,黄英亮,等. 车辆动力学稳定性系统变结构滑模控制研究[J]. 中国机械工程,2003(2):68-72,6.

Zhao Zhiguo, Fang Zongde, Huang Yingliang, et al. Research on structural sliding mode control of vehicle dynamics stability system[J]. China Journal of Mechanical Engineering, 2003(2): 68-72, 6. (in Chinese with English abstract)

Trafficability analysis of improved forest fire engine based on crawler chassis

Sun Shufa1, Ren Chunlong1, Li Tao2, Chen Jianwei3, Ma Wenliang3, Chu Jiangwei4

(1.&,150040,; 2.,,022150,; 3..,150010,; 4.,,150040,)

There are a large number of fallen trees and slopes in forest areas, which leads to complicated terrain. Most of the existing fire engines are wheeled fire engines and Caterpillar fire engines. However, the existing fire engines are limited in passage performance. A large Caterpillar forest fire engine (LF1352JP) was designed in this article. The fire engine was built on the basis of the first generation of Caterpillar forest fire engines (LY1102XFSG30) and performance optimization and transformation were carried out. The chassis of Caterpillar fire engine (LF1352JP) was modified on the basis of the chassis of the original skidding (J-50)crawler tractor, and the engine power increased from 85 to 99.3 kW. The width and length of the chassis were increased on the basis of the original chassis, and the cowcatcher and hydraulic capstan were added on the basis of the original vehicle to ensure the advantages of the existing vehicle function. It maintained the advantages of the elastic chassis of the original vehicle and the large gap from the ground. CREO three-dimensional simulation software was applied to Caterpillar forest fire engine (LF1352JP). The three-dimensional design simulation of the chassis, upper mount, barrier device and waterway system was carried out. The density of each structure was input into the CREO three-dimensional simulation software to simulate the center of gravity. The lateral and longitudinal stability of the fire engine and the performance of the vertical obstacle crossing and crossing the trench were analyzed theoretically. The results are as follows: When Caterpillar forest fire engine runs laterally, its maximum slope angle allowed on the slope at full load is 40.6°, and at no load it is 45.1°; when it runs longitudinally, the maximum longitudinal upslope angle is 52.0° at full load, and 60.9° at no load, and the maximum angle of downslope is 47.2° at full load and 45.8° at no load. The height of obstacle crossing is 405 mm at full load and 615 mm at no load. The width of crossing the trench is 1 248 mm at full load and 983 mm at no load. Compared with the first generation of Caterpillar forest fire engine (LY1102XFSG30), the vehicle has significant improvement in the performance including running upward and downward longitudinally, running horizontally, and crossing the trenches and vertical obstacles. The tests were performed at Yushu in Harbin, Heilongjiang and Yakeshi test site in Inner Mongolia Autonomous region. It included 4 experiments: longitudinal upslope, longitudinal downslope, crossing trenches, and 200 m velocity measurement. When the upslope experiment was carried out, the Caterpillar forest fire engine (LF1352JP) was made in different gears and different slope angles and then its upslope time was recorded, and the result showed that longitudinal upslope maximum angle was 48° according to the actual measurement when the current vehicle was at full load. In the longitudinal downslope experiment, the Caterpillar forest fire engine (LF1352JP) was made in different gears and different slope angles and then its downslope time was recorded. According to the actual measurement when the current vehicle was at full load, the vehicle would show the slipping trend. The maximum span width of crossing trenches experiment was 1 300 mm, which was not enlarged because of the safety considerations of fire engines. The experiment verified the upslope performance and obstacle surmounting performance of the vehicle, and the theoretical analysis results were verified by the experimental results. The performance of LF1352JP fire engine can meet the requirements of mountain fire fighting in complex terrain in forest area. It is a kind of large forest fire engine with excellent performance.

mechanization; design; optimization; crawler type; fire engine; stability; obstacle climbing ability

2018-01-27

2018-06-30

中央高校基金科研业务费专项基金项目(2572016CB12);哈尔滨市应用技术研究与开发项目(2015RAQXJ043)。

孙术发,副教授,主要从事林业运输装备方面研究。 Email:ssfangel@163.com

10.11975/j.issn.1002-6819.2018.17.009

S776

A

1002-6819(2018)-17-0061-07

孙术发,任春龙,李 涛,陈建伟,马文良,储江伟. 基于履带式底盘的改进型森林消防车通过性[J]. 农业工程学报,2018,34(17):61-67.doi:10.11975/j.issn.1002-6819.2018.17.009 http://www.tcsae.org

Sun Shufa, Ren Chunlong, Li Tao, Chen Jianwei, Ma Wenliang, Chu Jiangwei. Trafficability analysis of improved forest fire engine based on crawler chassis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17): 61-67. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.17.009 http://www.tcsae.org