双向对冲流灌水器水力性能和消能机理模拟与验证

2017-11-24王新端

郭 霖 ,白 丹 ※,王新端 ,何 靖 ,周 文 ,程 鹏

(1. 西安理工大学水利水电学院,西安 710048;2. 华北水利水电大学水利学院,郑州 450011)

·农业水土工程·

双向对冲流灌水器水力性能和消能机理模拟与验证

郭 霖1,白 丹1※,王新端1,何 靖1,周 文2,程 鹏2

(1. 西安理工大学水利水电学院,西安 710048;2. 华北水利水电大学水利学院,郑州 450011)

为研究双向对冲流灌水器的水力性能和消能机理,安排25组试验方案,开展流量测试与模拟计算,选取模拟精度较高的湍流模型计算不同压力区间的流态指数、正反向水流流量比,分析正反向水流分布情况。结果表明,RNGk-ε模型的流量计算值与实测值的相对误差为1.656%~3.151%,与其他模型相比,RNGk-ε模型的相对误差较小;灌水器的流态指数为0.414~0.483,水力性能良好,尤其在低压区间,流态指数为0.414~0.456,正反向水流流量比趋近于1,水力性能更加突出;随压力的增大,反向水流的流量增幅较快,流量比减小,水力性能降低;正反向水流在挡水装置的齿尖形成对冲与混掺是消能的核心,而水流分布不均会影响灌水器的消能效果;在灌水器边壁增加多个改变流向的挡水装置,可优化双向水流配比,提高水力性能,从而验证不同压力区间、不同流量比与水力性能的内在关系。研究可对灌水器结构优化、水力性能提高提供参考。

消能;数值分析;流量;灌水器;水力性能

0 引 言

灌水器通过流道结构和形式的变化起到调节压力和稳定流量的目的,并可将射流状水流变为滴水状[1]。流道内流量对压力变化的敏感程度以及灌水器出流的均匀性,统称为灌水器的水力性能[2-3],是衡量灌水器性能优劣的重要指标[4-5],其中灌水器的结构[6]和流道的消能形式[7]对调压稳流性能影响很大。因此,灌水器结构设计、消能机理分析是灌水器研究的重点。

灌水器水力性能和消能机理的分析方法主要有试验测试[8-9]和基于Fluent软件的数值模拟[10-11],前者主要测试不同压力下的流量值[12];后者多用于分析流场特性,探究消能和流动机理[13-14],一定程度上弥补了试验测试的不足。国内外很多学者以 Fluent模拟软件为基础,对传统迷宫流道灌水器进行了深入分析,常莹华等[15]采用Fluent软件分析齿形迷宫流道的齿宽、齿底距、齿高对水力性能的影响,通过参数调整提高其水力性能;喻黎明等[16-17]基于流体单向流模型和欧拉-拉格朗日液固多相湍流模型分析流道流体运动以及固体颗粒轨迹、速度分布,优化流道结构以提高工作性能;Wei等[18-19]提出通过改善流道断面形式、优化流道拐角可提高灌水器性能;王文娥等[20]应用VOF多相流模型和标准k-ε模型得到内镶齿形片状流道内速度呈周期性变化;Celik等[21-22]提出结构的细微变化对灌水器性能的影响很大。同时,一些学者在传统流道结构基础上提出了新的灌水器结构类型,Li等[23-24]以 Mandelbrot[25]的分形理论为基础,设计了分形流道灌水器,优化速度滞留区的流道边界,改善其水力性能;Zhang等[26]设计了新型流量调节器,指出弹性膜片的厚度与弹性模数影响压力补偿能力;此外,绕流式灌水器[27]、涡流式灌水器[28]、双向流流道灌水器[29]的设计为灌水器类型的多样性提供参考。

依据灌水器流道结构形式和消能方式,常用灌水器主要分为紊流迷宫式和压力补偿式[30-32]。前者结构较为简单、使用寿命长,但消能方式比较单一[7,33],后者虽调压稳流效果明显,但结构较复杂,内部弹性膜片易变形,降低调压稳流性能,且膜片变形度难以精确控制[34-36];同时,大量研究都是针对灌水器结构参数与性能之间的关系,鲜少从消能机理角度出发,研究灌水器性能。近年来,笔者及所在研究团队研制了一种双向对冲流灌水器[37],已开展了流量测试和流道局部损失计算,初步分析了流道几何参数对水力性能的影响。本文对灌水器流道进行 Fluent数值模拟,分析不同压力区间和双向水流不同流量比对水力性能的影响,从宏观和微观 2个角度阐明灌水器的消能机理和水力性能影响因素,以期为灌水器设计、流道优化以及提高水力性能等方面提供依据。

1 数值模拟方法与灌水器样机设计

1.1 基本控制方程

灌水器流道内的水流可视为黏性不可压缩流体运动。连续性方程为

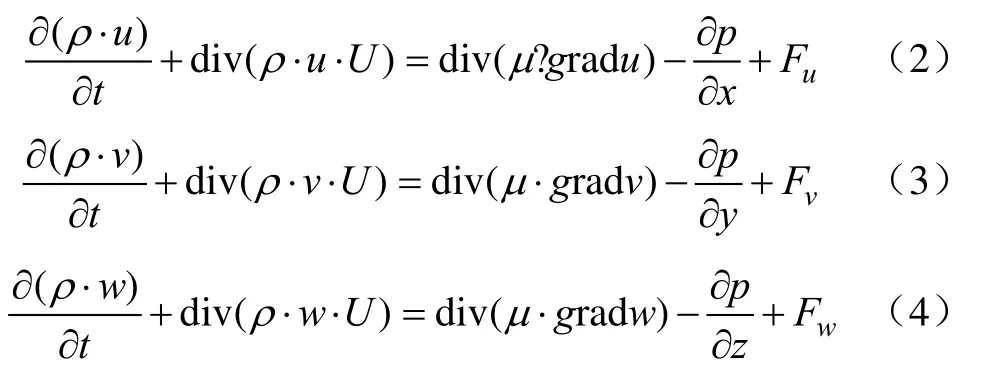

动量方程为

式中U为流体速度,m/s;u、v、w分别为流速在x、y、z坐标轴上的分量,m/s;ρ为水的密度,kg/m3;μ为动力黏度系数,N·s/m2;p为流体的压力,Pa;div为散度;grad为梯度;Fu、Fv、Fw为微元体在x、y、z坐标轴上的体力,N/m3,当体力只有重力,且z轴竖直向上,则Fu=0,Fv=0,Fw=-ρg。

1.2 Fluent软件基本模拟方法设置

1.2.1 计算方法设置

利用Gambit软件可构建灌水器三维模型,并对灌水器流道内部进行网格划分,流道网格单元选择0.1 mm的非结构化四面体混合型网格[38]。数值计算采用定常的非耦合隐式算法,灌水器的进口边界设置为压力进口(pressure inlet),在Fluent软件的选项Boundary conditions中选择pressure inlet,并按照压力范围50~250 kPa,每隔20 kPa压力计算一次流量,逐次设置灌水器的进口压力,灌水器的出口边界设置为压力出口(pressure outlet)。模型计算通常设置为second order upwind格式,为使迭代计算尽可能减小误差,残差一般为10-5,并采用精度较高的Simple方式计算,模型主要参数设置如表1所示。

表1 模型主要参数Table 1 Main parameters of model

1.2.2 湍流模型选择

Fluent软件常用湍流模型为k-ε和k-ω系列,主要包括 5类湍流模型,由于各模型适应的流动问题与应用工况侧重点不同,需要选择适宜模拟该种灌水器的模型。

1.3 灌水器流道结构与几何参数设计

双向对冲流灌水器流道三维模型如图 1所示。灌水器关键几何参数如图 2所示,其参数选取以及对各参数的定义可参照文献[37]。灌水器关键几何参数尺寸取值范围如下:S为0.6~1.0 mm,T为0.6~1.0 mm,W为0.6~1.0 mm,Z为1.0~1.4 mm,每隔0.1 mm取值,每个参数各取5组值,d为0~1.2 mm,每隔0.3 mm取值,取5组值;灌水器的深度为固定值(0.8 mm)。

图1 流道三维模型Fig.1 Three dimensional model of flow channel

图2 灌水器关键几何参数Fig.2 Key geometry parameters of emitter

2 灌水器试验

2.1 试验组合与系统布置

对该类灌水器每个几何参数取 5个水平,按照正交试验设计表 L25(56)安排灌水器流道几何参数组合方案,具体组合方案详见文献[37]。根据灌水器组合方案及测试规范[4]布置试验系统,如图3所示。试验系统主要设备的参数包括:水源为自来水,通过500 L的不锈钢水箱供水;2台型号为15WG0.8-20的水泵,额定流量720 L/h;过滤器规格为200目筛网式过滤器;压力表型号为YB-150,精度等级为0.25级,允许误差值为0.4 kPa;量筒精度为0.001 L;电子称型号为JT1201N,精度为0.1 g。

图3 试验系统Fig.3 Experimental system

2.2 灌水器测试

灌水器的测试压力通过进口压力表前端控制阀进行调节,测试压力与数值模拟的压力范围和测试间隔相同,每个间隔压力测试3次,每次5 min,流量取3次测试的平均值,采用量筒容积法测量不同压力的灌水器流量,电子称校核。

2.3 计算方法

灌水器压力和流量的关系为

式中q为流量,L/h;Kd为流量系数;H为灌水器进口压力,kPa;x′为流态指数。

将式(5)取对数得到下式

流态指数可表示为

3 结果与分析

3.1 湍流模型确定

采用不同湍流模型计算25组灌水器方案的流量值,并与实测值进行误差对比,结果表明,各模型的模拟值与实测值最大相对误差为 4.192%,最小相对误差为1.656%。当采用标准k-ε模型计算时,与实测值相对误差2.055%~3.986%;采用RNGk-ε模型计算时,相对误差1.656%~3.151%;采用Realizablek-ε模型计算时,相对误差2.297%~4.192%;采用标准k-ω模型计算时,相对误差1.760%~3.462%;采用SSTk-ω模型计算时,相对误差1.917%~3.882%。对比5种模型流量计算的相对误差,RNGk-ε模型相对误差最小。以相对误差较小(方案18)和相对误差较大(方案10)的2组试验方案为例(图4),RNGk-ε模型与实测值决定系数为0.998,尤其当压力为50~150 kPa时,相对误差为1.28%~1.89%,与实测值吻合度更高,因此,选用RNGk-ε模型对灌水器性能进行深入研究。

图4 不同湍流模型的流量Fig.4 Flow rate of different turbulence model

3.2 灌水器水力性能分析

3.2.1 不同压力区间与水力性能的关系

在灌水器性能研究中,流态指数反映了流量对压力变化的敏感程度,其值越小说明灌水器的水力性能越好[39-41]。流态指数的计算通过压力与流量的多元回归拟合得到,不同压力区间对应的值有所不同[39,42-43],因此,对灌水器在不同压力区间的水力性能应进行深入分析。

对灌水器进行流量数值模拟,并计算不同压力区间的流态指数,其结果如表 2所示。双向对冲流灌水器的流态指数为0.414~0.483,相比迷宫式流道灌水器的流态指数较小[29,42-43],在水力性能方面有明显提高。而同类型灌水器在不同压力区间内的流态指数有所差异,低压和中压区间的流态指数相对较小,在低压区间,流态指数为0.414~0.456。双向对冲流灌水器在低压和中压区间的水力性能优于高压区间的水力性能,对于节能、降低滴灌管壁厚度、减少工程投资方面有一定的优势。

表2 灌水器不同压力区间的流态指数Table 2 Flow index of emitter in different pressure range

3.2.2 双向水流不同流量比与水力性能的关系

灌水器的水流分区如图 5所示。本文定义:灌水器总流量为q,正向水流流量为Q1,反向水流流量为Q2,其中q=Q1+Q2,正向水流与反向水流的流量比为Q1/Q2。流量q、Q1、Q2通过Fluent软件中的Report数据读取功能计算不同截面的流量值。计算得到50~250 kPa范围内的正向水流与反向水流的流量比Q1/Q2,其结果如表3所示。依据表 3的计算结果,在低压区间,双向水流流量比Q1/Q2较大,而在高压区间,流量比Q1/Q2较小。对比表2和表3的结果,Q1/Q2的数值越趋近于1,即正向水流流量与反向水流流量占灌水器流量的比例越近似,混掺效果越强,流态指数越小,水力性能越好;反之,正向水流流量与反向水流流量相差越大,流态指数越大,水力性能越差。

图5 双向对冲流分区Fig.5 Division of two-ways mixed flow

表3 灌水器不同压力区间的流量比Table 3 Flow ratio of emitter in different pressure range

以流态指数较小和较大的 4种灌水器方案为例,对双向水流流量比和水力性能进一步分析。图6为4种灌水器方案的双向水流流量比与水力性能的关系,随压力的增大,正向水流的流量增幅较慢,而反向水流的流量增幅较快,双向水流流量比Q1/Q2逐渐减小;随着流态指数的减小,Q1/Q2的曲线变化越平缓,Q1/Q2比值越趋近于1。

图6 不同压力流量比与水力性能关系Fig.6 Relationship between flow ratio and hydraulic performance in different pressure

3.3 灌水器流场分布与消能机理分析

不同灌水器方案的流场速度分布和消能机理类似,因此为使流场分析具有代表性,选择水力性能居中的灌水器方案22对流场速度分布与消能机理进行分析。图7为灌水器方案22不同压力的流场速度分布图,从整体流速分布看,流体进入灌水器后受到流道的分流作用被分成正向水流和反向水流,其中正向水流沿灌水器边壁与分水装置之间的过水通道流出,由于挡水装置的阻隔和流道的收缩作用,反向水流改变原有的流动方向,并加快流动速度,与正向水流混掺,在混掺区域由于流速大、混掺剧烈,形成较大的能量损失,使得流体均匀和稳定出流,是该类型灌水器消能稳流的核心内容。

图7 试验方案22不同压力下流场速度分布Fig.7 Flow velocity distribution in different pressure for experimental scheme 22

对速度分布进行局部对比(图7),通过Fluent软件中的速度场计算以及Tecplot速度提取功能可得到灌水器不同截面的正向水流和反向水流的平均流速,当压力为50 kPa时,正向水流平均流速为0.8 m/s,反向水流为1.4 m/s,由于正向水流区域的横截面大于反向水流区域的横截面,即正向水流和反向水流的流量相差较小;当压力增大到250 kPa时,正向水流平均流速为1.7 m/s,反向水流为4.1 m/s,反向水流的流速增幅明显大于正向水流的流速增幅,使正向水流和反向水流的流量相差越大。由于正反 2股水流的对冲混掺是消能稳流的核心,在对流道设计时,适度增加正向水流的流量,使 2股水流的流量在数值上接近时,能更好地达到双向水流能量充分抵消的效果,提高灌水器水力性能。灌水器流道的流场速度分布从微观角度进一步分析了不同压力区间、不同流量比与水力性能之间的关系。

3.4 基于消能机理的双向水流配比优化

文中着重从宏观和微观 2方面对双向对冲流灌水器的不同压力区间、不同流量比与水力性能之间的关系做了深入分析,揭示了消能机理,研究发现,正向水流和反向水流的流量在数值上相同时,可达到双向流充分混掺的效果,流态指数降低,水力性能提高。因此,在不改变流道几何参数的前提下,仅从灌水器的消能机理角度考虑,适当增加正向水流的流量,对双向水流配比进行优化,可在每个灌水器流道单元之间增加 1个改变流向的边壁挡水装置。三角形高0.1~0.3 mm、底0.3~0.6 mm,经多次模拟尝试,最终确定使正反向水流流量近似的边壁挡水装置的尺寸大小,如图8所示。

图8 灌水器优化Fig.8 Optimization of emitter

为进一步说明增加正向水流的流量,使正反向水流流量近似,可提高水力性能的结论,仅以灌水器方案 22为例,在其边壁增加挡水装置,其150 kPa工作压力的流场速度分布如图9所示。

图9 优化后试验方案22 在150 kPa压力下的流场速度分布Fig.9 Flow velocity distribution at 150 kPa for experimental scheme 22 after optimization

边壁增加挡水装置后,正向水流的流速加快,平均流速为2.4 m/s,而反向水流为2.7 m/s,正向水流和反向水流的流量基本相同;对灌水器的流量模拟计算,在低压、中压、高压3个压力区间的流态指数分别为0.422、0.431和0.445,相比表2流态指数明显减小,水力性能有很大的提高。通过双向水流的配比优化,一方面验证了研究结论的可靠性,为灌水器水力性能的研究提供参考,另一方面可对后期灌水器水力性能的提高从消能机理角度提供一种新的分析思路。

4 结论与建议

1)本文以双向对冲流灌水器为研究对象,计算得到Fluent软件中RNGk-ε模型的模拟精度较高,与实测值相对误差为1.656%~3.151%,能准确反映灌水器的真实流量,为水力性能和消能机理研究提供准确的理论依据。

2)采用正交试验获得灌水器的流态指数为 0.414~0.483,水力性能良好,尤其在低压区间水力性能更突出;正向与反向水流的流量比越趋近1,则流态指数越小,水力性能越好;压力增大,反向水流增幅较快,流量比减小,水力性能降低。

3)流道形成正向和反向水流的对冲混掺,是消能的本质;在灌水器边壁设置改变流向的挡水装置,可加快正向水流流速,增加正向水流流量,优化双向水流配比,提高水力性能;正反双向水流混掺越充分,消能效果越好,水力性能更优越,从微观角度揭示了流道的消能机理。

本文主要从消能机理角度对灌水器水力性能进行了深入分析,初步探明适度增加正向水流的流量,达到双向流能量充分抵消的效果,可减小流态指数,提高水力性能,对其水力性能和消能机理的研究有一定的参考价值,有深入研究的必要。但由于研究角度的不同,还可从流道结构角度出发进行几何参数优化,建议后期应结合 2种分析思路,并借助粒子图像测速技术综合研究不同几何参数、不同压力区间、不同流量比对水力性能和抗堵性能的影响,更加全面和系统的分析灌水器结构、消能机理以及性能三者的关系,弥补灌水器性能研究的不足,以增强在农业生产中的应用。

[1] 微灌工程技术规范:GB/T 50485-2009[S].

[2] Zhang Lin, Merkley G P. Relationships between common irrigation application uniformity indicators[J]. Irrigation Science, 2012, 30(2): 83-88.

[3] 张林,吴普特,朱德兰,等. 基于制造偏差的滴灌系统综合流量偏差率[J]. 农业机械学报,2013,44(12):135-139.Zhang Lin, Wu Pute, Zhu Delan, et al. Integrated flow deviation rate of drip irrigation system based on manufacturing variation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(12): 135-139.(in Chinese with English abstract)

[4] 农业灌溉设备滴头和滴灌管技术规范和试验方法:GB/T 17187-2009[S]. 北京:中国标准出版社,2010.

[5] Madramootoo C A, Morrison J. Advances and challenges with micro-irrigation[J]. Irrigation and Drainage, 2013, 62(3):255-261.

[6] Gilaad Y, Krystal L, Zanker K. Hydraulic and mechanical properties of drippers[C]//Proceedings of the 2nd International Drip Irrigation Congress. Riverside, USA: University of California, 1974.

[7] 苑伟静,魏正英,楚华丽,等. 分流式灌水器结构优化设计与试验[J]. 农业工程学报,2014,30(17):117-124.Yuan Weijing, Wei Zhengying, Chu Huali, et al. Optimal design and experiment for divided-flow emitter in drip irrigation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014,30(17): 117-124. (in Chinese with English abstract)

[8] 蔡耀辉,吴普特,朱德兰,等. 硅藻土微孔陶瓷灌水器制备工艺优化[J]. 农业工程学报,2015,31(22):70-76.Cai Yaohui, Wu Pute, Zhu Delan, et al. Preparation technology optimization of diatomite porous ceramic irrigation emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015,31(22): 70-76. (in Chinese with English abstract)

[9] 刘春景,唐敦兵,王雷,等. 滴灌梯形迷宫滴头水力性能多目标优化[J]. 干旱区地理,2016,39(3):600-606.Liu Chunjing, Tang Dunbing, Wang Lei, et al. Multi output optimization of the hydraulic performance for drip irrigation trapezoidal labyrinth channel of emitter[J]. Arid Land Geography, 2016, 39(3): 600-606. (in Chinese with English abstract)

[10] Glatzel T, Litterst C, Cupelli C, et al. Computational fluid dynamics (CFD) software tools for microfluidic applications-A case study[J]. Computers & Fluids, 2008, 37(3): 218-235.[11] Philipova N, Nikolov N, Pichurov G, et al. Numerical simulation and a mathematical model of pressure losses depending on geometric parameters of drip emitter labyrinth channel[J]. Comptes rendus de I’Acad é mie bulgare des Sciences, 2009, 62(7): 891-898.

[12] 冯俊杰,费良军,邓忠,等. 自适应滴灌灌水器的水力性能试验[J]. 农业工程学报,2013,29(4):87-94.Feng Junjie, Fei Liangjun, Deng Zhong, et al. Hydraulic performance experiment of an adaptive drip irrigation emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013,29(4): 87-94. (in Chinese with English abstract)

[13] 王福军,王文娥. 滴头流道CFD分析的研究进展与问题[J].农业工程学报,2006,22(7):188-192.Wang Fujun, Wang Wen’e. Research progress in analysis of flow passage in irrigation emitters using Computational Fluid Dynamics techniques[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2006, 22(7): 188-192. (in Chinese with English abstract)

[14] Al-Muhammad J, Tomas S, Anselmet F. Modeling a weak turbulent flow in a narrow and wavy channel: Case of micro-irrigation[J]. Irrigation Science, 2016, 34(5): 361-377.

[15] 常莹华,牛文全,王维娟. 滴灌灌水器迷宫流道的内部流体数值模拟与流动分析[J]. 西北农林科技大学学报:自然科学版,2009,37(2):203-208.Chang Yinghua, Niu Wenquan, Wang Weijuan. Numerical simulation and flow analysis of labyrinth path of drip irrigation emitters[J]. Journal of Northwest A&F University:Natural Science Edition, 2009, 37(2): 203-208. (in Chinese with English abstract)

[16] 喻黎明,邹小艳,谭弘,等. 基于CFD-DEM耦合的水力旋流器水沙运动三维数值模拟[J]. 农业机械学报,2016,47(1):126-132.Yu Liming, Zou Xiaoyan, Tan Hong, et al. 3D numerical simulation of water and sediment flow in hydrocyclone based on coupled CFD-DEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 126-132.(in Chinese with English abstract)

[17] 喻黎明,吴普特,牛文全. 迷宫流道偏差量对灌水器水力性能及抗堵塞性能的影响[J]. 农业机械学报,2011,42(9):64-68.Yu Liming, Wu Pute, Niu Wenquan. Influence of the offset of labyrinth channels of drip emitters on hydraulic and anti-clogging performance[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(9): 64-68. (in Chinese with English abstract)

[18] Wei Zhengying, Cao Meng, Liu Xia, et al. Flow behaviour analysis and experimental investigation for emitter microchannels[J]. Chinese Journal of Mechanical Engineering,2012, 25(4): 729-737.

[19] 周兴,魏正英,苑伟静,等. 压力补偿灌水器流固耦合计算方法[J]. 农业工程学报,2013,29(2):30-36.Zhou Xing, Wei Zhengying, Yuan Weijing, et al. Fluidstructure interaction analysis method for pressure compensating emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2013, 29(2): 30-36. (in Chinese with English abstract)

[20] 王文娥,王福军. 迷宫滴头水力特性非定常数值模拟研究[J]. 水利学报,2010,41(3):332-337.Wang Wen’e, Wang Fujun. Numerical simulation of unsteady flow in labyrinth emitters of drip irrigation system[J]. Journal of Hydraulic Engineering, 2010, 41(3):332-337. (in Chinese with English abstract)

[21] Celik H K, Karayel D, Caglayan N, et al. Rapid prototyping and fl ow simulation applications in design of agricultural irrigation equipment: Case study for a sample in-line drip emitter[J]. Virtual and Physical Prototyping, 2011, 6(1): 47-56.

[22] Patil S S, Nimbalkar P T, Joshi A. Hydraulic study, design &analysis of different geometries of drip irrigation emitter labyrinth[J]. International Journal of Engineering and Advanced Technology, 2013, 2(5): 455-462.

[23] Li Yunkai, Liu Haisheng, Yang Peiling, et al. Analysis of tracing ability of different sized particles in drip irrigation emitters with computational fluid dynamics[J]. Irrigation and Drainage, 2013, 62(3): 340-351.

[24] Wu Dan, Li Yunkai, Liu Haisheng, et al. Simulation of the flow characteristics of a drip irrigation emitter with large eddy methods[J]. Mathematical and Computer Modelling,2013, 58(3/4): 497-506.

[25] Mandelbort B B. The Fractal Geometry of Nature[M]. New York: Freeman W H and Company, 1982.

[26] Zhangzhong Lili, Yang Peiling, Ren Shumei, et al. Numerical simulation and optimization of micro-irrigation flow regulators based on FSI[J]. Irrigation and Drainage, 2013,62(5): 624-639.

[27] 魏青松,史玉升,芦刚,等. 内镶式滴灌带绕流流道水力性能研究[J]. 农业工程学报,2006,22(10):83-87.Wei Qingsong, Shi Yusheng, Lu Gang, et al. Hydraulic performances of the round-flow channel in an in-line drip-tape[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006,22(10): 83-87. (in Chinese with English abstract)

[28] Wei Qingsong, Lu Gang, Liu Jie, et al. Evaluations of emitter clogging in drip irrigation by two-phase flow simulations and laboratory experiments[J]. Computers and Electronics in Agriculture, 2008, 63(2): 294-303.

[29] 田济扬,白丹,于福亮,等. 基于Fluent软件的滴灌双向流流道灌水器水力性能数值模拟[J]. 农业工程学报,2014,30(20):65-71.Tian Jiyang, Bai Dan, Yu Fuliang, et al. Numerical simulation of hydraulic performance on bidirectional flow channel of drip irrigation emitter using Fluent[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(20): 65-71. (in Chinese with English abstract)

[30] 刘杨,仵峰,彭贵芳,等. 齿形迷宫流道滴头消能过程的试验研究[J]. 灌溉排水学报,2008,27(2):39-42.Liu Yang, Wu Feng, Peng Guifang, et al. Experimental research on dissipating process in the interior of labyrinth emitter[J]. Journal of Irrigation and Drainage, 2008, 27(2):39-42. (in Chinese with English abstract)

[31] 王立朋,魏正英,邓涛,等. 压力补偿灌水器分步式计算流体动力学设计方法[J]. 农业工程学报,2012,28(11):86-92.Wang Lipeng, Wei Zhengying, Deng Tao, et al. Step-by-step CFD design method of pressure compensating emitter[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(11): 86-92. (in Chinese with English abstract)

[32] 田济扬,白丹,任长江,等. 滴灌双向流流道灌水器水力特性分析[J]. 农业工程学报,2013,29(20):89-94.Tian Jiyang, Bai Dan, Ren Changjiang, et al. Analysis on hydraulic performance of bidirectional flow channel of drip irrigation emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013,29(20): 89-94. (in Chinese with English abstract)

[33] 李治勤,马静. 迷宫灌水器水流流态试验[J]. 农业工程学报,2012,28(1):82-86.Li Zhiqin, Ma Jing. Experiment on flow pattern in labyrinth emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012,28(1): 82-86. (in Chinese with English abstract)

[34] 魏正英,苑伟静,周兴,等. 我国压力补偿灌水器的研究进展[J]. 农业机械学报,2014,45(1):94-101.Wei Zhengying, Yuan Weijing, Zhou Xing, et al. Research progress of pressure compensating emitters in microirrigation systems in china[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(1): 94-101.(in Chinese with English abstract)

[35] 党思思,朱德兰,牛文鹏,等. 弹性膜片硬度和厚度对调压装置水力性能的影响[J]. 灌溉排水学报,2013,32(2):15-18.Dang Sisi, Zhu Delan, Niu Wenpeng, et al. Impact of elastic diaphragm parameters on hydraulic performance of pressure regulators[J]. Journal of Irrigation and Drainage, 2013, 32(2):15-18. (in Chinese with English abstract)

[36] 何静,李光永,刘志烽. 典型压力补偿滴头结构分析[J]. 节水灌溉,2006(5):29-31.He Jing, Li Guangyong, Liu Zhifeng. Analysis on the structure of typical pressure compensating emitters[J]. Water Saving Irrigation, 2006(5): 29-31. (in Chinese with English abstract)

[37] 郭霖,白丹,王新端,等. 双向对冲流滴灌灌水器水力性能与消能效果[J]. 农业工程学报,2016,32(17):77-82.Guo Lin, Bai Dan, Wang Xinduan, et al. Hydraulic performance and energy dissipation effect of two-ways mixed flow emitter in drip irrigation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(17): 77-82. (in Chinese with English abstract)

[38] 张琛,李光永. 灌溉系统直动式压力调节器动力学模型与数值模拟[J]. 农业工程学报,2015,31(20):80-87.Zhang Chen, Li Guangyong. Dynamic model and numerical simulation of direct-acting pressure regulator for irrigation system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015,31(20): 80-87. (in Chinese with English abstract)

[39] 杜少卿,曾文杰,施泽,等. 工作压力对滴灌管迷宫流道灌水器水力性能的影响[J]. 农业工程学报,2011,27(增刊2):55-60.Du Shaoqing, Zeng Wenjie, Shi Ze, et al. Effects of working pressure on hydraulic performances of labyrinth path emitters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011,27(Supp.2): 55-60. (in Chinese with English abstract)

[40] Vekariya P B, Subbaiah R, Mashru H H. Hydraulics of microtube emitters: a dimensional analysis approach[J].Irrigation Science, 2011, 29(4): 341-350.

[41] 郑耀泉,李光永,党平,等. 喷灌与微灌设备[M]. 北京:中国水利水电出版社,1998.

[42] 李云开,杨培岭,任树梅,等. 滴灌灌水器迷宫式流道内部流体流动特性分析与试验研究[J]. 水利学报,2005,36(7):886-890.Li Yunkai, Yang Peiling, Ren Shumei, et al. Experimental study on flow characteristics in labyrinth path emitters[J].Journal of Hydraulic Engineering, 2005, 36(7): 886-890. (in Chinese with English abstract)

[43] 马晓鹏,龚时宏,王建东,等. 常压灌水器在低压条件下水力性能试验研究[J]. 灌溉排水学报,2009,28(5):7-9.Ma Xiaopeng, Gong Shihong, Wang Jiandong, et al.Hydraulic performance of emitters under low operating pressure[J]. Journal of Irrigation and Drainage, 2009, 28(5):7-9. (in Chinese with English abstract)

Numerical simulation and verification of hydraulic performance and energy dissipation mechanism of two-ways mixed flow emitter

Guo Lin1, Bai Dan1※, Wang Xinduan1, He Jing1, Zhou Wen2, Cheng Peng2

(1.Institute of Water Resources and Hydroelectric Engineering,Xi’an University of Technology,Xi’an710048,China;2.School of Water Conservancy,North China University of Water Resources and Electric Power,Zhengzhou450011,China)

The two-ways mixed flow emitter is a new kind of drip irrigation emitter. The main working principle is forming the mixed phenomenon of forward and backward flow to increase more local head loss and eliminate extra inlet pressure.Computational Fluid Dynamics (Fluent software) plays an important role in analyzing hydraulic performance, flow field characteristic and energy dissipation mechanism of drip irrigation emitter. In order to study the hydraulic performance and the energy dissipation mechanism, we chose 5 key geometric parameters as factors and designed 25 sets of experimental schemes according to the orthogonal experimental design method. The flow rate and flow index under different pressures were determined by testing and simulating. Laboratory experiments were carried out in State key laboratory Base of Eco-hydraulic Engineering in Arid Area, Xi’an University of Technology. In this paper, 5 turbulence models including standardk-εmodel,RNGk-εmodel, realizablek-εmodel, standardk-ωmodel and SSTk-ωmodel were chosen and compared, respectively. Based on the flow rate of each experimental scheme within the range of 50-250 kPa, the relative errors of the experimental and simulated flow rate of these 5 models were compared, respectively. The more precision turbulence model was chosen. The flow index, the flow ratio of the forward flow to the backward flow, and the flow field distribution in different pressure were calculated and analyzed, and the relationship between them was explored. The results showed that the simulated results of RNGk-εmodel were better than that of the other 4 models. The relative error between the test value and the simulated value of RNGk-εmodel was from 1.656% to 3.151%, which was the minimum error among these 5 models. Especially, when the pressure was in the range of 50-150 kPa, the simulated values were much closer to the test values with the determination coefficient of 0.998 and the relative error of 1.28%-1.89% in the pressure of 50-150 kPa, which could accurately reflect the flow rate of the emitter. So RNGk-εmodel could be used to accurately simulate the flow rate and flow mechanism of two-ways mixed flow emitter. In addition, the simulated flow index ranged from 0.414 to 0.483 under different pressures,indicating excellent hydraulic performance. In the low pressure range, the flow index was from 0.414 to 0.456, the flow ratio of the forward flow to the backward flow tended to 1, and the hydraulic performance was more prominent. However, for the two-ways mixed flow emitter, the high pressure could lead to the fast increase amplitude of the backward flow, resulting in the less flow ratio and the poor hydraulic performance. The flow velocity distribution showed the forward flow and the backward flow joined together and strongly mixed near blocking water device tooth, meanwhile, produced large local head loss and eliminate more fluid energy. In the high pressure range, the greatly uneven distribution of the forward flow and the backward flow would reduce the effect of energy dissipation. Therefore, the appropriate increase of the forward flow would help to speed up the flow mixing, enhance effect of energy dissipation, and improve irrigation quality. In order to change flow direction,setting up a number of blocking water device in the flow channel side wall of emitter could increase forward flow rate,optimize the flow ratio of the forward flow to the backward flow, and improve hydraulic performance. Flow field analysis revealed that after increasing blocking water device of side wall, the forward and backward flow rate were similar and the flow index under high, medium and low pressures was 0.445, 0.431 and 0.422, respectively. It verified the optimum of emitter based on mechanism of energy dissipation was reliable. These conclusions can provide the method guidance for structure optimization and hydraulic performance improvement.

energy dissipation; numerical analysis; flow rate; emitter; hydraulic performance

10.11975/j.issn.1002-6819.2017.14.014

S275.6

A

1002-6819(2017)-14-0100-08

郭 霖,白 丹,王新端,何 靖,周 文,程 鹏. 双向对冲流灌水器水力性能和消能机理模拟与验证[J]. 农业工程学报,2017,33(14):100-107.

10.11975/j.issn.1002-6819.2017.14.014 http://www.tcsae.org

Guo Lin, Bai Dan, Wang Xinduan, He Jing, Zhou Wen, Cheng Peng. Numerical simulation and verification of hydraulic performance and energy dissipation mechanism of two-ways mixed flow emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(14): 100-107. (in Chinese with English abstract)

doi:10.11975/j.issn.1002-6819.2017.14.014 http://www.tcsae.org

2017-03-19

2017-07-10

国家自然科学基金资助项目(51279156、41571222);高等学校博士学科点专项科研基金联合资助课题(20116118110010)

郭 霖,男,甘肃天水人,博士生,主要从事节水灌溉技术研究。西安 西安理工大学水利水电学院,710048。Email:guolinedu@126.com※通信作者:白 丹,男,重庆开县人,教授,博士生导师,主要从事节水灌溉理论与技术研究。西安 西安理工大学水利水电学院,710048。

Email:baidan@xaut.edu.cn