Energy-Efficient Process Planning Using Improved Genetic Algorithm

2016-12-01DaiMinTangDunbingHuangZhiqingYangJun

Dai Min,Tang Dunbing,Huang Zhiqing,Yang Jun

College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

Energy-Efficient Process Planning Using Improved Genetic Algorithm

Dai Min,Tang Dunbing*,Huang Zhiqing,Yang Jun

College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,P.R.China

Nowadays,energy consumption which closely contacts with environmental impacts of manufacturing processes has been highly commented as a new productivity criterion.However,little attention has paid to the development of process planning methods that take energy consumption into account.An energy-efficient process planning model that incorporates manufacturing time and energy consumption is proposed.Eor solving the problem,an improved genetic algorithm method is employed to explore the optimal solution.Einally,a case study for process planning is given.The experimental result generates interesting effort,and therefore allows improving the energy efficiency of manufacturing processes in process planning.

energy consumption;process planning;improved genetic algorithm;energy efficiency

0 Introduction

Nowadays,a new productivity criterion,energy efficiency has been highly commented in manufacturing processes owning to the increasing environmental awareness.Manufacturing companies have consumed a large amount of energy for production,and they are responsible for approximately 33%of the global total energy consumption;The associated amount of CO2emissions generated by energy is 38%[1].Therefore,reducing environmental impacts like energy consumption should be taken into account to improve energy efficiency of manufacturing processes.

Process planning,as one of the most significant compositions in manufacturing processes, plays a critical role in linking product design and manufacturing.Issues on manufacturing cost and time,like process planning,production criteria, have been widely discussed.However,decreasing energy consumption as one of objectives in process planning has been limited.

One of the most significant research works is the work by Sheng and Srinivasan,who presented an environmentally conscious multi-objective process planning approach based on manufacturing features[2],and they further explored local and global optimum process planning regarding process energy consumption,process time,waste mass and surface quality factors from the perspective of the micro and macro-planning level[3,4]. Ref.[5]designed a framework for environmental process planning to evaluate configurations of a product and its associated environmental impacts during the advanced product quality planning process.Ref.[6]developed a multi-objective mathematical model for environmental supportive process planning by considering cost,time and environmental impact simultaneously.Ref.[7] introduced energy consumption as one of objectives of process planning for computer numerical control(CNC)machining and confirmed that the energy consumption as a new performance indicator can be added to a multi-criteria process plan-ning system.Ref.[8]proposed a new process planning approach that considers environmental factors like carbon emissions,and a comparatively green and economical process plan was obtained.Ref.[9]discussed a methodology for the process planning of energy-efficient machining processes based on numerical simulations. Ref.[10]presented an approach to estimate energy consumption and material flows that were incurred in a highly automated manufacturing system considering multiple process plans.In summary,the efforts mentioned above provide an important starting point for exploring energy-efficient process plan decisions which alleviate environmental impacts while maintaining traditional production criteria like time and cost.However, it has some limitations in the literature.Eirst, much research is mainly concerned with the holistic framework of process planning with environmental-friendly design,and the implementation of the specific strategies like decision-making optimization needs to be further investigated.Second,process planning is also a combinatorial optimization problem and optimization algorithm needs to be more effective and efficient by employing intelligent meta-heuristic and searching approaches.Therefore,a bi-objective optimization problem of minimizing the manufacturing time and the total energy consumption is proposed in the paper and an improved genetic algorithm method is adopted to realize the optimization process.

*Corresponding author,E-mail address:d.tang@nuaa.edu.cn.

How to cite this article:Dai Min,Tang Dunbing,Huang Zhiqing,et al.Energy-efficient process planning using improved genetic algorithm[J].Trans.Nanjing Univ.Aero.Astro.,2016,33(5):602-609.

http://dx.doi.org/10.16356/j.1005-1120.2016.05.602

1 Problem Description

1.1 Representation of process planning

Process planning plays an important role in a product design and manufacturing process through the effective linkage of computer-aided design(CAD)with computer-aided manufacturing(CAM).According to the definition of process planning[11],the three major considerations are required:(1)to generate operations of a part based on features technology like feature extraction;(2)to identify manufacturing resources (e.g.machines and tools)available to the operations;(3)to determine the sequence of all the selected operations according to some cost-effective criteria like manufacturing cost and time.In process planning,there exist the precedence constraints due to the geometric and manufacturing interactions and technological requirements for a part,including datum interactions,material-removal interactions,feature priorities and fixed order of machining operations[12].All the operations sequencing of a part should satisfy these precedence constraints.

1.2 Energy consumption modeling for process planning

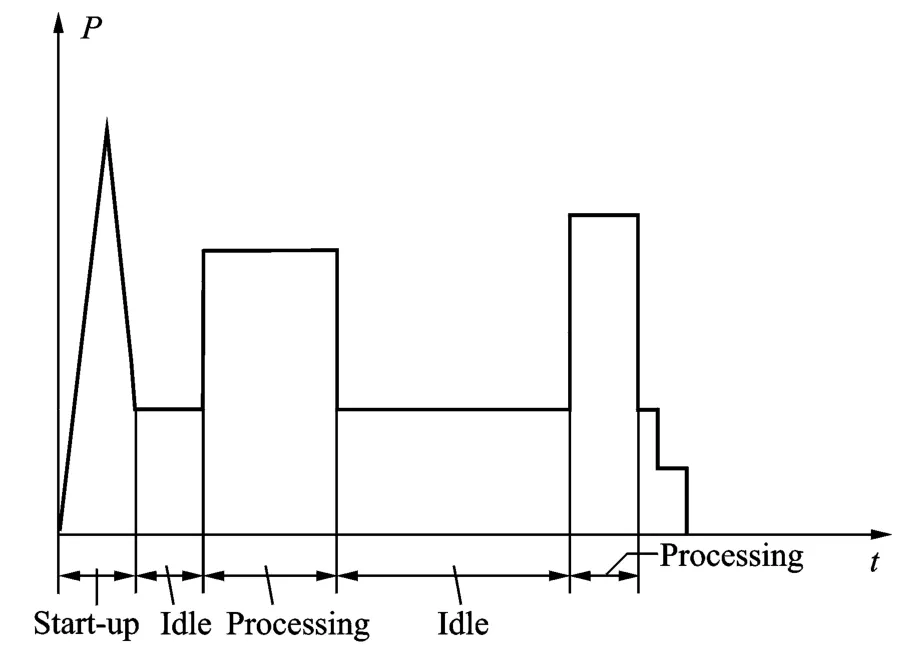

Due to the rising trend for environmentfriendly design and manufacturing,energy consumption becomes a significant consideration in process planning.A process plan for a part usually includes a series of operations,and each operation consumes an amount of energy.As is shown in Fig.1,one machine is allowed to process several operations,and the power profile for the machine consists of three energy consumption stages:start-up stage,idle stages and processing stages.According to the energy-consuming characteristic of one operation processed on one machine tool[13-15],the total energy consumption is consisted of the following energy modules at the three aforementioned stages.Assume that there are n operations processed for a part on m machines.

Fig.1 Power profile of machine for the machining operations

(1)When a machine tool is at the readiness operation stage,the energy is consumed to acti-vate machine components(like the start-up of the machine tool and spindle)and to ensure the operational readiness of the machine tool.The energy consumption E1can be expressed as

where Tirepresents the startup time of machine i and Pi(t)the input power of machine i over time.

(2)When a machine tool is at the idle running stage,the machine components that implement activities such as loading or unloading workpiece,positioning and clamping,and changing cutting tools have energy demand;In addition, the machine tool that waits for the next operation to be executed also consumes energy.The energy demand E2can be calculated as

where T2ijrepresents the idle time before the operation j is executed to process on machine i,andthe unload power when the operation j is executed to process on machine i.

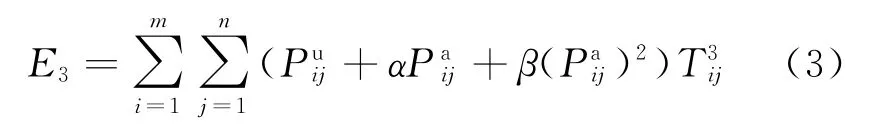

(3)When a machine tool is at the machining operation stage,the energy is consumed to remove workpiece material and to maintain the normal operation of machine components.The required energy E3is described as follows

where T3ijrepresents the processing time when the operation j is executed to process on machine i and Paijthe cutting power when the operation j is executed to process on machine i.α,βrepresent the coefficients of the load power,and they can be calculated by means of the equations of linear regression[13].

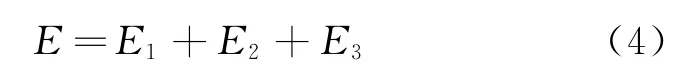

In the process plan of a part,the total energy consumption(E)is the sum of E1,E2and E3, and it is expressed as

1.3 Manufacturing time modeling for process planning

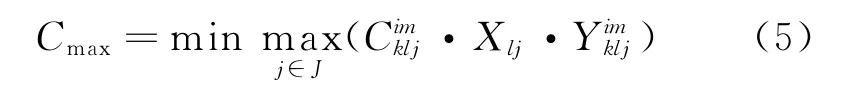

A mathematical model that minimizes the manufacturing time is considered as one of the optimization objectives for process planning.Here, the manufacturing time is defined as the maximum completion time of all jobs,namely, makespan.Two constraints need to be satisfied: one machine can process only one job at a time; the different operations of one job cannot be performed simultaneously.The objective function can be described as

where Cmaxis the makespan,Cimkljthe completion time of operation k,which is the i th position processed on machine m,in the l th alternative process plan of job j,and Xljthe integer variable that has two possible values:0 or 1.It is equal to 1 if the l th alternative process plan is picked for job j,and 0 otherwise.Yimkljis an integer variable that has two possible values:0 or 1.It is equal to 1 if operation k in the l th alternative process plan of job j is the i th position processed on machine m,and 0 otherwise.

2 Optimization Method

Genetic algorithm(GA)has been widely used for objective optimization problems[16].One of its prominent advantages is able to quickly obtain good results with high efficiency in a complex solution space.In order to enhance the performance of GA,an improved GA is adapted for the energy-efficient process planning in this section.

2.1 Population initialization

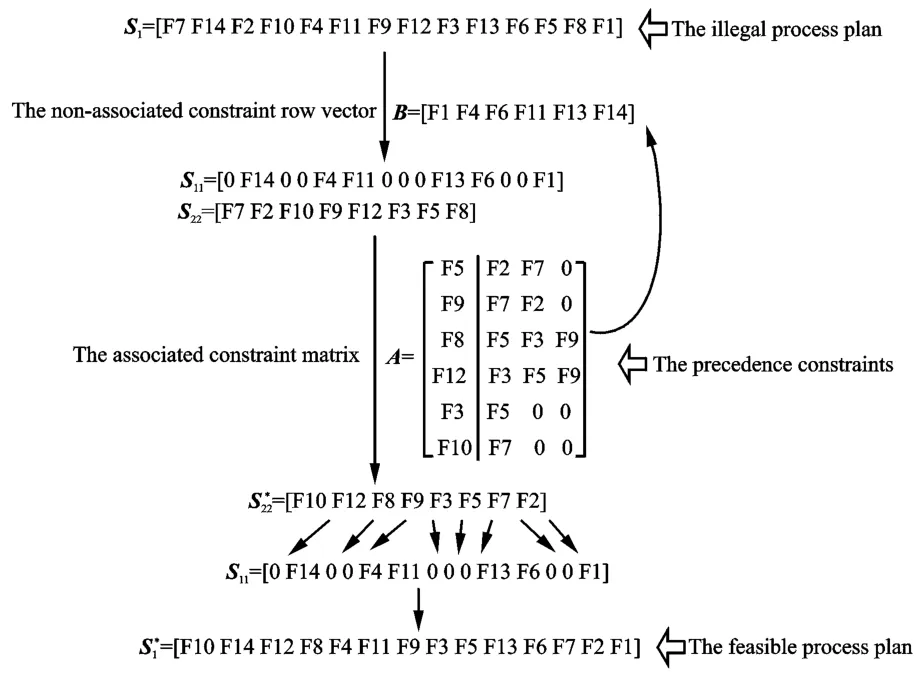

According to the precedence constraints between features for a part,a constraint matrix approach is developed to make each initial chromosome legal,and the procedure is described as follows.

Step 1 Construct an associated constraint matrix A based on the precedence constraint relationship between features.

(1)Determine the number of precedence constraints between features as the dimensions of the row vector for A and make sure the first element of each row for A is fixed and the sequence of the remaining elements in each row are random.

(2)Determine the number of the feature elements for each precedence constraint and select the maximum number as the column vector for A.If the number of feature elements for a precedence constraint is less than the maximum number,all the other elements are filled with 0.

Step 2 Query each element of the associated constraint matrix A and record the feature elements which are not in A to create a row vector B.

Step 3 Generate an initial process plan S1at random,retain the position of each element for B in S1and then replace the remaining positions of S1with 0 to produce a non-associated constraint process plan S11.

Step 4 Create an associated constraint process plan S22based on the elements of the remaining positions of S1and regenerate S22based on the ordinal relation of the elements in A.

Step 5 Copy the elements of the newto the positions of S11with 0 in order to obtain a legal process plan S*1.

Eor example,an illegal process plan with four precedence constraints given by Li,et al.[12]is illustrated in Table 1.The associated constraint matrix A based on the precedence constraints between features and the non-associated constraint row vector B can be obtained,and the process of a feasible process plan is shown in Fig.2.

Table 1 Example of illegal process plan with four precedence constraints

2.2 Fitness function

In this study,two following objectives are considered as the fitness functions to explore the energy-efficient process planning.

(1)Minimize the manufacturing time,namely,makespan.

(2)Minimize the total energy consumption.

Fig.2 Example process of constraint matrix approach

2.3 Selection operator

In the algorithm,the rank-based selection strategy has been employed for selection operator.In rank-based selection mechanism,the best chromosomes are selected from the parents and offspring individuals.In this way,as the rankbased selection will only accept improvements, the elitist population can be reproduced for the next generation.

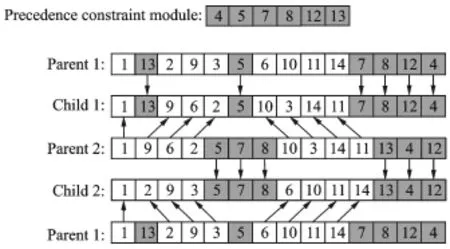

2.4 Crossover operator

Owning to illegal solutions generated in many existing approaches,these solutions should be transformed feasible plans using auxiliary methods like constraint adjustment method,penalty function method and finite search space method, and it is adverse to improve the searching efficiency of the algorithms.Thus,a new crossover operation method based on precedence constrain module is proposed to avoid yielding infeasible solutions.The procedure of crossover operation for energy-efficient process planning is designed as follows and a crossover instance is shown in Fig. 3.

Step 1 Divide precedence constraint modules for an initially generated process plan based on the associated constraint matrix.The precedence constraints between features which contact with each other are defined as one precedence constraint module.There is no constraint relationship between precedence constraint modules.In addition,the non-associated constraint row vector is defined as one of precedence constraint mod-ules.

Step 2 Pick a pair of parent individuals Parent 1 and Parent 2,and initial two empty children individuals Child 1 and Child 2.

Step 3 Select one precedence constraint module at random,and append the elements of the precedence constraint module included in Parent 1 and Parent 2 to the same positions of the corresponding individuals Child 1 and Child 2,respectively.

Step 4 Append the remaining elements of Parent 1 and Parent 2 to the remaining empty positions in Child 2 and Child 1 in sequence,respectively.

Fig.3 Crossover for a pair of chromosomes of energyefficient process planning

2.5 Mutation operator

A mutation operator,which satisfies a random probability(i.e.mutation probability)based on uniformly distributed rule,can be implemented to produce the solutions with greater fitness. In the proposed algorithm,the mutation operation is required to randomly select two elements and swap the elements in the two selected positions to obtain the resulting chromosome,and the feasibility of the chromosome is ensured by means of the constraint matrix approach.

3 Case Study

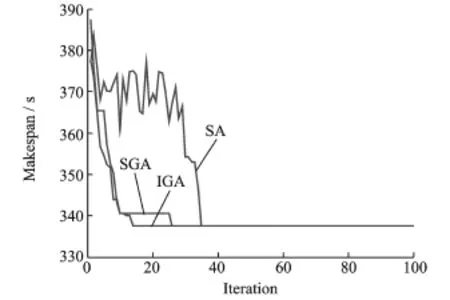

A prismatic part taken from the work of Li, et al.[11]is considered as a case study.There are fourteen defined manufacturing features need to be realized,and there are twenty machining operations processed on five machines.The detailed information of the features,operations,machines and precedence constraints for the part is listed in Tables 2,3.Several experiments are carried out for three different scenarios:(1)Makespan is used as the only objective;(2)energy consumption is used as the only objective;(3)both makespan and energy consumption are used as the objective.Meanwhile,the improved genetic algorithm(IGA)is compared with other algorithms such as standard genetic algorithm(SGA)and simulated annealing(SA).

Table 2 Technical specification for one part[11]

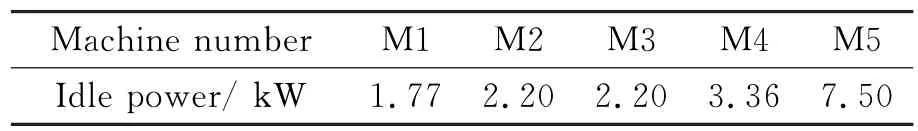

Table 3 Data for unload power consumption of each machine

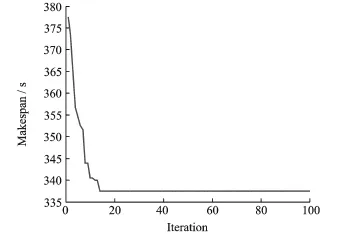

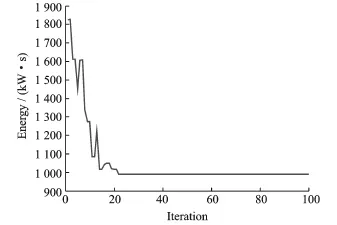

Based on IGA,the experimental results under Scenarios(1),(2)and(3)are shown in Figs.4,5 and 6,respectively.In Scenario(1), the best makespan is 337.5 s and the optimal sequencing of machining operations is found to be O1—O11—O6—O2—O12—O13—O14—O15—O16—O18—O17—O19—O20—O3—O5—O7—O8—O9—O10—O4.In addition,the corresponding energy consumption calculated is 1 134 k W·s. Given that the maximum completion time will be allowed to delay without affecting delivery time, and in Scenario(2),the optimal energy consumption is 989.24 k W·s and the corresponding makespan is 452 s,which means a 12.77%improvement in the energy consumption compared with the manufacturing time as the single objective.The associated process plan is given as: O1—O18—O6—O2—O17—O11—O3—O5—O7—O4—O8—O9—O10—O12—O13—O14—O19—O20—O15—O16.Eurthermore,the relationship between makespan and energy consumption has been explored.As is shown Fig.6,the experimental result illustrates that the relationship between makespan and energy consumption is prominently conflicting and that decision-makers should make a significant trade-off between them to implement an energy-efficient process planning.On the one hand,the energy consumption decreases as the makespan increases.Thus,the decision-makers can consider the manufacturing time without affecting delivery time,ranging from 380 s to 410 s.Compared with the single performance measure(i.e.,makespan),the average energysaving ratio is 6.95%.On the other hand,there is a significant amount of energy saving by assigning the importance weights between the makespan and energy consumption.Eor instance,the importance weights of the makespan and energy consumption are set to 0.6 and 0.4,respectively. The makespan is 412.5 s and the energy consumption is 1 038 k W·s.It can obtain 8.47%of energy saving and the optimal process plan is given by:O1—O2—O6—O5—O18—O11—O3—O4—O12—O13—O14—O17—O19—O20—O7—O8—O9—O10—O15—O16.At the same time,the proposed algorithm is further compared with SGA and SA in term of the optimum result for makespan.It is obvious that IGA is quickly able to converge to the optimal solution and outperforms SGA and SA as shown in Fig.7.

Fig.4 Optimal result of makespan for Scenario(1)

Fig.5 Optimal result of energy for Scenario(2)

Fig.6 Plots of energy versus makespan for Scenario(3)

Fig.7 Comparison of three algorithms for makespan

4 Conclusions

The model for the energy-efficient process planning has been developed in sustainable manufacturing processes,and new performance criterion energy efficiency is considered as one of optimization objectives.The effective improved genetic algorithm is adopted to search for the optimal solutions in different optimization objectives. The approach is then employed for a prismatic part;The result indicates that the energy-efficient process plan has approximately 13%energy saving without delaying delivery time compared with a process plan that only concerns manufacturing time.At the same time,bi-objective optimization problems with objectives of minimizing the energy consumption and makespan are tested.The experimental result shows that there is a significant trade-off between the energy consumption and makespan.There is a significant amount of energy saving by assigning the importance weights between the makespan and energy consumption based on decision-makers′preference. In addition,the comparison experiment with several other algorithms is given to verify the performance of the proposed algorithm.

Acknowledgements

This work was supported by a Marie Curie International Research Staff Exchange Scheme Eellowship within the 7th European Community Eramework Programme (No.294931),the National Science Eoundation of China (No.51175262),Jiangsu Province Science Eoundation for Excellent Youths(No.BK20121011),and Jiangsu Province Industry-Academy-Research Grant(No.BY201220116).

[1] International Energy Agency.Worldwide trends in energy use and efficiency[M/OL].(2008-07-07). http://www.iea.org/publications/freepublications/ publication/Indicators_2008.pdf.

[2] SHENG P,SRINIVASAN M.Multi-objective process planning in environmentally conscious manufacturing:a feature-based approach[J].CIRP Annals-Manufacturing Technology,1995,44(1):433-437.

[3] SRINIVASAN M,SHENG P.Eeature-based process planning for environmentally conscious machining—Part 1:Microplanning[J].Robotics and Computer-Integrated Manufacturing,1999,15(1):257-270.

[4] SRINIVASAN M,SHENG P.Eeature based process planning in environmentally conscious machining—Part 2:Macroplanning[J].Robotics and Computer-Integrated Manufacturing,1999,15(1):271-281.

[5] SINGH S,GOODYER J,POPPLEWELL K.Integrated environmental process planning for the design and manufacture of automotive components[J].International Journal of Production Research,2007,45 (18/19):4189-4205.

[6] KAI J,ZHANG H C,BALASUBRAMANIAM P, et al.A multiple objective optimization model for environmental benign process planning[C]//Industrial Engineering and Engineering Management.Beijing, China:IE&EM′09,2009:869-873.

[7] NEWMAN S T,NASSEHI A,IMANI-ASRAI R, et al.Energy efficient process planning for CNC machining[J].CIRP Journal of Manufacturing Science and Technology,2012,5(2):127-136.

[8] YIN R,CAO H,LI H,et al.A process planning method for reduced carbon emissions[J].International Journal of Computer Integrated Manufacturing,2014,27(12):1175-1186.

[9] NEUGEBAUER R,HOCHMUTH C,SCHMIDT G,et al.Energy efficient process planning based on numerical simulations[C]//17th CIRP Conference on Modelling of Machining Operations.Sintra,Portugal:Trans Tech Publications,2011:212-221.

[10]CHOI Y C,XIROUCHAKIS P.A production planning in highly automated manufacturing system considering multiple process plans with different energy requirements[J].International Journal of Advanced Manufacturing Technology,2014,70(5/6/7/8):853-867.

[11]LI W D,MCMAHON C A.A simulated annealingbased optimization approach for integrated process planning and scheduling[J].Int J Comput Integr Manuf,2007,20(1):80-95.

[12]LI W D,ONG S K,NEE A Y C.Hybrid genetic algorithm and simulated annealing approach for the optimization of process plans for prismatic parts[J].International Journal of Production Research,2002,40 (8):1899-1922.

[13]HU S,LIU E,HE Y,et al.An on-line approach for energy efficiency monitoring of machine tools[J]. Journal of Cleaner Production,2012,27:133-140.

[14]LI W,KARA S.An empirical model for predicting energy consumption of manufacturing processes:A case of turning process[C]//36th International Matador Conference.London,United Kingdom:SAGE Publications Ltd,2011:1636-1646.

[15]LI W,ZEIN A,KARA S,et al.An investigation into fixed energy consumption of machine tools[C]// 18th CIRP International Conference on Life Cycle Engineering:Glocalized Solutions for Sustainability in Manufacturing.Braunschweig,Germany:Springer Science and Business Media,2011:268-273.

[16]TANG C,WAN Z.Application of hybrid genetic algorithm in aeroelastic multidisciplinary design optimization of large aircraft[J].Transactions of Nanjing University of Aeronautics and Astronautics,2013,30 (2):109-117.

Dr.Dai Min received Ph.D.degree in College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics in 2015 and B.S.degree in College of Mechanical Engineering,Yangzhou University in 2011.He works on heuristic optimization algorithms in production scheduling.

Prof.Tang Dunbing is currently professor in College of Mechanical and Electrical Engineering at Nanjing University of Aeronautics and Astronautics in China.He received his Ph.D.from Nanjing University of Science and Technology in March 2000.His research interests include engineering design and manufacturing system modeling.

Mr.Huang Zhiqing received B.S.degree in College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics in 2015.He works on heuristic optimization algorithms in production scheduling.

Mr.Yang Jun is currently a Ph.D.candidate in College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics.He received B.S.degree from Nanjing University of Aeronautics and Astronautics in 2015.He works on heuristic optimization algorithms in product design.

(Executive Editor:Xu Chengting)

TH186 Document code:A Article ID:1005-1120(2016)05-0602-08

(Received 6 May 2015;revised 22 September 2015;accepted 27 October 2015)

杂志排行

Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Numerical Simulation of Warm Forming Behavior of High Strength Aluminum Alloy 7075

- Model of Autonomous Positioning Through Associating Environment Memory Information

- Principle and Experimental Verification of Flexible Caudal Fin Based on Active Torsion Propulsion Mode

- Dissolution Characteristics of New Titanium Alloys in Electrochemical Machining

- Design and Experimental Evaluation of PID Controller for Digital Electro-Pneumatic Cabin Pressure Control System

- Mission-Oriented Configuration Model of Aircraft Carrying Spares and Dynamic Optimization Policy