应用于太阳能集热再生系统的除湿效率模型

2016-04-09彭冬根张小松南昌大学建筑工程学院南昌33003东南大学能源与环境学院南京0096

彭冬根,张小松(.南昌大学建筑工程学院,南昌33003;.东南大学能源与环境学院,南京0096)

应用于太阳能集热再生系统的除湿效率模型

彭冬根1,张小松2

(1.南昌大学建筑工程学院,南昌330031;2.东南大学能源与环境学院,南京210096)

摘要:溶液除湿装置是太阳能空气预处理分级溶液集热/再生系统的重要组成部分,预测填料预除湿器空气出口参数变化是这种新型溶液再生系统设计时必须考虑的。文章通过定义湿度效率和等焓率预测填料型溶液除湿器的空气出口参数,采用实验和理论相结合的方法,分析影响湿度效率和等焓率变化的因素。发现当液气比小于2.0时,溶液和空气入口参数变化对湿度效率影响显著;溶液和空气入口温度对等焓率影响大;随液气比增加,湿度效率增加,等焓率下降。文章最后通过线性拟合方法得到湿度效率和等焓率的数学表达式,为太阳能空气预处理分级溶液集热再生系统理论建模提供理论基础。

关键词:模型;太阳能;溶液除湿;湿度效率;等焓率;液气比

彭冬根,张小松.应用于太阳能集热再生系统的除湿效率模型[J].农业工程学报,2016,32(01):206-211.doi:10.11975/j.issn.1002-6819.2016.01.029 http://www.tcsae.org

Peng Donggen, Zhang Xiaosong.Dehumidification efficiency model for solar thermal regeneration system[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2016, 32(01): 206-211.(in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.01.029 http://www.tcsae.org

0 引言

太阳能溶液除湿蒸发冷却空调系统[1-4]由于具有低能耗而受到越来越多关注,太阳能溶液再生装置[5-7]是该系统最重要部件之一。作者设计一种新型太阳能溶液再生系统——太阳能空气预处理分级溶液集热再生系统,其中需采用一种溶液预除湿装置。国内外学者对各种溶液除湿装置性能进行大量实验[8-9]和理论研究。理论研究所采用的模型主要有有限差分模型[10-11]、效率模型[12-13]和简化模型[14]。效率模型以其简单和精确性较高而成为国内外学者研究热点。文献[15]仿照冷却塔的效率模型,推导出用于填料除湿器的ε—NTU效率模型,并和实验和数值模型计算结果进行比较。Martin综合大量实验研究结果,拟合出一组新型填料除湿/再生过程的湿度效率公式[16]。文献[17]对绝热型和内冷型溶液除湿器的各种效率模型进行较为详细介绍。文献[18]定义焓效率、温度效率和湿度效率,并对数值模拟结果进行线性回归得到3个效率的拟合关系式。清华大学Liu等给出顺流、逆流和叉流3种流态的全热效率和湿度效率的解析模型[19]。Ren在近似定义溶液平衡湿度与溶液温度和含水量呈线形变化基础上,推导出溶液除湿过程中溶液和空气间传热传质势差的理论解,并进一步得到绝热和内冷型填料除湿过程的ε—NTU理论解析模型[20-21]。本文采用一个经试验验证的填料除湿数值模型进行溶液除湿效率理论分析,并定义等焓率表征溶液除湿的空气出口温度变化。最后得到填料除湿过程的空气湿度效率和等焓率的数学表达式,为太阳能空气预处理分级溶液集热再生系统数学模型建立提供理论基础。

1 叉流填料除湿装置及流程

本文选用规则填料(蒙特GLASdekII介质),其装置及填料结构图片见图1(a)所示,外形尺寸为0.5 m(宽)×0.5 m(高)×0.3 m(长)。为计算方便,填料中空气流动通道可近似为三角形和菱形,通道的当量直径采用三角形和菱形两种几何形状作为计算依据,见图1(b)。文中试验所用填料器的空隙率及比面积见图1(c)。

本文采用的填料除湿流程见图2,底部溶液槽内溶液通过溶液泵进入填料除湿装置上部的溶液喷管,溶液在填料内靠重力作用由上向下流动与空气直接接触,由于空气中水蒸气分压力高于溶液表面水蒸气压力,溶液吸收空气中水分被稀释,较干燥空气排出填料装置,稀释后溶液汇聚与溶液槽。为保证填料除湿装置能连续运行,溶液槽分别设有浓溶液液入口和稀溶液出口,它们分别和太阳能空气预处理分级溶液集热再生系统中的一级太阳集热再生装置的溶液出口和进口相连。系统中设置一个换热器对循环溶液进行预冷以改变除湿溶液入口温度。

2 叉流除湿模型及实验验证

按照除湿溶液与空气流动方向不同,可以将填料除湿装置分为顺流、逆流[22]与叉流[23]3种形式,本文中采用的是叉流式填料除湿装置。在分析溶液和空气热、质交换中,采用如下假设:

图1 填料结构及参数Fig.1 Structure and parameters of packing

图2 填料除湿流程图Fig.2 Schematic diagram of packed bed dehumidifier

1)溶液和空气热、质交换过程是稳态的,物性参数为常数;

2)填料除湿装置与环境之间不存在热、质交换,为绝热除湿过程;

3)溶液均匀喷洒,传热与传质界面相同;

4)只考虑在溶液和空气流动方向上的热湿传递,因此叉流除湿过程简化为二维传热传质问题;

5)只考虑溶液和空气在流动方向的对流传热、传质,忽略它们的导热和质量扩散。

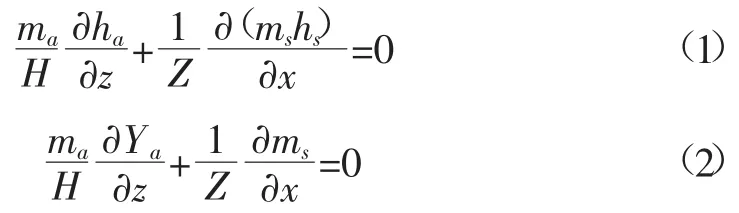

假设填料除湿装置高度为H,m;长度为Z,m;宽度为W,m。x轴与溶液喷淋方向一致,z轴与空气流动方向一致。叉流除湿过程的溶液和空气能量和质量守恒方程分别为:

溶液中盐分质量守恒方程为:

式中ma,ms为空气和溶液质量流量,kg/s;ha,hs为空气和溶液比焓,kJ/kg;Ya为空气含湿量,kg/kg;ξ为溶液中含盐分浓度。

空气侧能量和质量传递方程为:

式中heL为溶液平衡含湿量,kg/kg;hfg为水的蒸发潜热,kJ/ kg;刘易斯数Le和传质单元数NTUm定义为:

式中h为传热系数,kW/(m2·K);hm为传质系数,kg/(m2·s);Cpa为空气比热容,kJ/(kg·K);A为填料面积,m2。

为验证叉流除湿模型假设及模型求解正确性,文中利用第1节介绍的实验装置进行变空气流量除湿实验并和理论模拟结果进行比较,两组比较结果见图3所示。图3比较空气出口温度Ta,out和除湿率mde,显示除湿率的模拟和实验值相差在5%内,空气出口温度的模拟和实验值相差在0.5℃内,比较结果显示理论模拟和实验结果相一致。

3 填料器除湿效率模型及理论分析

填料除湿器的性能可通过2个除湿效率——湿度效率εy和全热效率εh来预测,其计算式分别为:

式中Ya,in,Ya,out为空气进、出口含湿量,kg/kg;YeL,in为溶液入口平衡含湿量, kg/kg;ha,in,ha,out为空气进、出口比焓,kJ/kg;heL,in为溶液入口平衡比焓,kJ/kg。

式(8)能较好表征空气除湿过程含湿量变化,但同时由于空气除湿过程会释放水蒸气中潜热致使空气出口温度升高,因此有必要对除湿过程中空气温度变化进行定义。尽管式(9)的全热效率综合了空气湿度和温度变化但不直观,需定义一个单独变量来表征空气温度变化程度。文献[18]类似换热器原理直接定义温度效率,但是溶液除湿过程伴随温度和湿度的耦合作用与纯换热原理有本质区别。

图3 叉流除湿实验和模拟比较Fig.3 Comparison between results of experiments and simulation of cross-flow dehumidification

为此,文中定义等焓率εeh为溶液除湿过程空气吸收显热占整个除湿潜热的比值,见式(10)。如果空气在除湿器内进行等焓除湿(即溶液除湿释放的潜热完全被空气吸收)时,等焓率εeh=1;如果空气进行等温除湿时,等焓率εeh=0。一般来说εeh界于0~1之间,如果εeh<0说明空气除湿过程不但要释放潜热而且要释放显热,这是由于溶液温度低于空气入口温度所致;如果εeh>1说明空气不但完全吸收释除湿过程放潜热而且要部分吸收溶液释放的显热,这是由于溶液温度高于空气入口温度所致。

式中Ta,in,Ta,out为空气进、出口温度,℃。

由于实验装置结构单一,实验参数变化受局限,为此文中采用数值模拟方法研究溶液和空气入口参数及填料结构参数变化对湿度效率及等焓率影响。

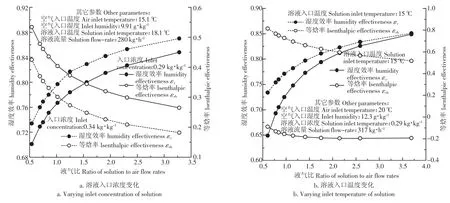

图4为溶液(LiCl-H2O[24])入口参数变化对除湿效率作用,图中比表面积和除湿长度乘积aZ为110。图4(a)为0.29 kg/kg和0.34 kg/kg两种不同溶液入口浓度下除湿效率比较。从图中比较可知,当LiCl溶液浓度从0.29上升0.34时,湿度效率略提高0.022~0.033,提高幅度达2.6~4.7%;等焓率降低0.08~0.11,降幅达20~30%。图4(b)为15℃和25℃两种不同溶液入口温度下除湿效率比较。当溶液入口温度由15℃上升到25℃时,湿度效率上升,特别是在液气比小于1.0时湿度效率提高更明显。在等焓率的变化上,溶液入口温度变化对其影响巨大,当Ts,in<Ta,in时等焓率εeh为负值,这是由于空气通过对流传热向溶液释放显热,而除湿潜热也完全被溶液吸收;反之则溶液和空气同时吸收除湿潜热,空气除湿的等焓率为正值且小于1.0,并随液气比增大而有所降低。

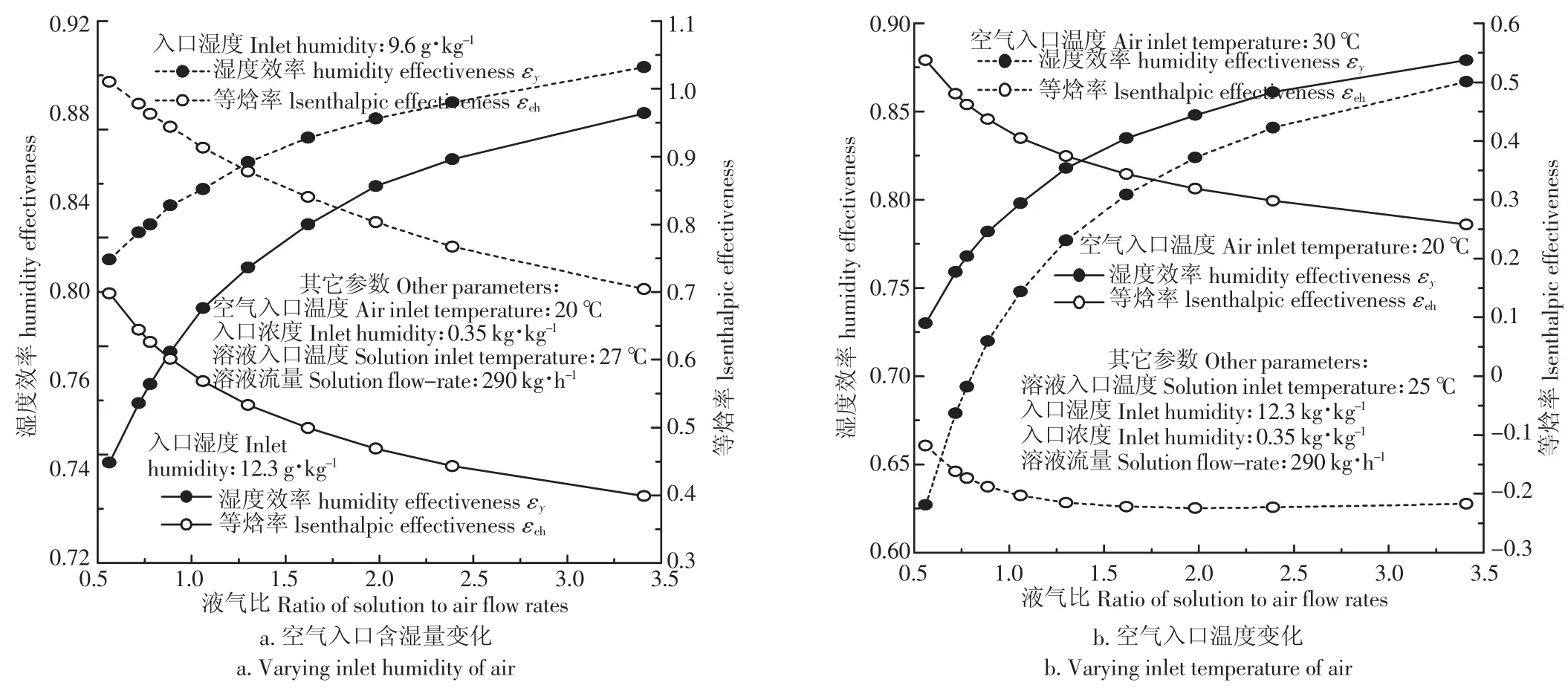

图5为空气入口参数变化对除湿效率的影响,图中比表面积和除湿长度乘积aZ为110。图5(a)为9.6g/kg和12.3g/kg两种不同空气入口含湿量下除湿效率比较。图中比较可知,当空气入口含湿量从12.3 g/kg下降到9.6 g/kg时,湿度效率随液气比下降而提高0.017~0.075,提高幅度2~10%;等焓率上升0.3左右,说明空气除湿潜热越小,其越接近的等焓过程。图5(b)为20℃和30℃两种不同空气入口温度下除湿效率比较。空气入口温度越高,湿度效率越低,并且液气比越低空气入口温度变化对湿度效率影响越大。空气入口温度对等焓率的作用与溶液入口温度相似,表现为当空气入口温度高于溶液温度时等焓率为负,反之则为正。

综上分析可知,当液气比大于2.0时,溶液和空气入口参数变化对湿度效率的影响并不明显,但是对等焓率的影响却非常显著,特别是入口温度变化会直接导致等焓率的巨大波动,甚至出现负值情况。

除液气比及入口参数对湿度效率存在影响外,填料器物理结构尺寸也是影响除湿效率的重要因素。Chung[25]采用复合变量(aZ)衡量填料尺寸结构,它表示填料比表面积a和填料空气流道长度Z乘积,是一个无量纲量。图6 为aZ=110和180两种规格的填料器的除湿效率比较。由图可知,当aZ由110提高到180时,湿度效率提高0.1左右,但是等焓率基本重合,说明随空气流道长度增加湿度效率提高明显,但除湿潜热在空气和溶液间的分配比例基本维持不变。

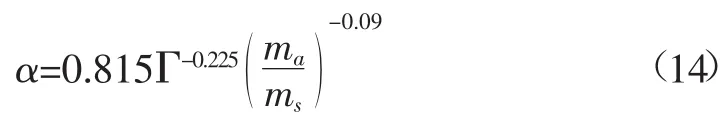

综合上述除湿效率性能分析数据,可得到类似Chung提出的LiCl溶液叉流除湿湿度效率及等焓率数学表达式,见式(11)~(13)。等焓率数学模型拟合分为εeh>0和εeh<0两种情况,其中包括等温除湿过程线方程α,其物理含义为当填料进行空气等温除湿时,溶液和空气入口温度所需满足的比例关系,见式(14)。当溶液和空气入口温度满足式(14)时,等焓率εeh计算值为零。

图4 溶液入口参数对除湿效率影响Fig.4 Effect of inlet parameters of solution on dehumidification effectiveness

图5 空气入口参数对除湿效率影响Fig.5 Effect of inlet parameters of air on dehumidification effectiveness

图6 填料结构参数对除湿效率影响Fig.6 Effect of structure parameters of packing on dehumidification effectiveness

其中,α为等温除湿过程线,具体表达式如下:

Γ为无量纲蒸汽压力,如下:

式中:Pw为与溶液等温度的纯水饱和水蒸气分压力,Pa;Ps为溶液表面水蒸气分压力,Pa。

上述拟合公式中,湿度效率拟合平均误差为4%;等焓率拟合平均误差为7%。

4 结论

1)文章介绍一种叉流规则填料除湿装置结构及实验流程;通过提出叉流除湿过程物理假设,建立叉流除湿控制方程,并与相关实验结果对比验证模型正确性。

2)当LiCl溶液浓度从0.29 kg/kg上升0.34 kg/kg时,湿度效率提高幅度达2.6%~4.7%;等焓率降低降幅达20%~30%。当溶液入口温度由15℃上升到25℃时,湿度效率在液气比小于1.0时提高明显;当溶液入口温度小于空气入口温度时等焓率为负值。当空气入口含湿量从12.3 g/kg下降到9.6 g/kg时,湿度效率提高幅度达2%~10%;等焓率上升0.3左右;空气入口温度越高,湿度效率越低,当高于溶液温度时等焓率为负。当填料比表面积和填料空气流道长度乘积(aZ)由110提高到180时,湿度效率提高0.1左右,但是等焓率基本重合。另外,湿度效率随液气比增加而增加;等焓率随液气比增加而下降。

3)最后文章利用线性回归方法对所有理论计算结果进行拟合得到湿度效率和等焓率随溶液和空气流量以及入口参数变化的拟合关联式,拟合结果具有较好精度。

[参考文献]

[1] Armanasco F, Colombo L P M, Lucchini A, et al.Performance analysis of a solar cooling plant based on a liquid desiccant evaporative cooler [J].International Journal of Refrigeration, 2015, 53: 163-176.

[2] Mohaisen A K, Ma Z.Development and modelling of a solar assisted liquid desiccant dehumidification air-conditioning system[J].Building Simulation, 2015, 8(2):123-135.

[3] Qi Ronghui; Lu Lin; Huang Yu.Energy performance of solarassisted liquid desiccant air-conditioning system for commercial building in main climate zones[J].Energy Conversion and Management, 2014,88:749-757

[4] Abdel-Salam A H, Ge G, Simonson C J.Thermo-economic performance of a solar membrane liquid desiccant air conditioning system[J].Solar Energy, 2014, 102: 56-73.

[5] Cheng Qing, Zhang Xiaosong.Review of solar regeneration methods for liquid desiccant air-conditioning system[J].Energy and Buildings, 2013, 67:426-433

[6] Elsarrag E.Evaporation rate of a novel tilted solar liquid desiccantregenerationsystem.SolarEnergy,2008,82(7):663-668.

[7] Qi Ronghui, Lu Lin, Yang Hongxing, et al.Investigation on wetted area and film thickness for falling film liquid desiccant regeneration system[J].Applied Energy, 2013, 112: 93-101.

[8] Zhang L, Hihara E, Matsuoka F, et al.Experimental analysis of mass transfer in adiabatic structured packing dehumidifier/ regenerator with liquid desiccant [J].International Journal of Heat and Mass Transfer, 2010, 53(13-14): 2856-2863.

[9] Bassuoni M M.An experimental study of structured packing dehumidifier/regenerator operating with liquid desiccant [J].Energy, 2011, 36(5): 2628-2638.

[10] Fumo N, Goswami D Y.Study of an aqueous lithium chloride desiccantsystem:airdehumidificationanddesiccantregeneration [J].Solar energy, 2002, 72(4): 351-361.

[11] Liu X H, Jiang Y, Qu K Y.Heat and mass transfer model of cross flow liquid desiccant air dehumidifier/regenerator [J].Energy Conversion and Management, 2007, 48(2): 546-554.

[12] Stevens D I, Braun J E, Klein S A.An effectiveness model of liquid desiccant system heat/ mass exchangers[J].Solar Energy, 1989 42(6): 449-455.

[13] Jain S, Bansal P K.Performance analysis of liquid desiccant dehumidificationsystems[J].InternationalJournalof Refrigeration.2007, 30(5): 861-872.

[14] Gandhidasan P.A simplified model for air dehumidification with liquid desiccant[J].Solar Energy 2004, 76(4): 409-416.

[15] Sadasivam M, Balakrishnan A R.Effectiveness-NTU method for design of packed bed liquid desiccant dehumidifiers [J].Chemical Engineering Research and Design, 1992, 70(A6): 572-577.

[16] Martin V, Goswami, D Y.Effectiveness of heat and mass transfer processes in a packed bed liquid desiccant dehumidifier/ regenerator[J].Hvac&R Research, 2000, 6(1): 21-39.

[17] Luo Yimo, Yang Hongxing, Lu Lin.A review of the mathematical models for predicting the heat and mass transfer process in the liquid desiccant dehumidifier [J].Renewable & Sustainable Energy Reviews, 2014, 31: 587-599.

[18] Qi Ronghui, Lu Lin, Yang Hongxing.Development of simplified prediction model for internally cooled/heated liquid desiccant dehumidification system [J].Energy and Buildings, 2013, 59: 133-142.

[19] Liu Xiaohua, Jiang Yi, Xia Jianjun.Analytical solutions of coupled heat and mass transfer processes in liquid desiccant air dehumidifier/regenerator[J].Energy Conversion and Management, 2007, 48(7): 2221-2232.

[20] Ren C Q.Corrections to the simple effectiveness-NTU method for counterflow cooling towers and packed bed liquid desiccant-air contactsystems[J].InternationalJournalofHeatandMassTransfer, 2008, 51(1-2): 237-245.

[21] Ren C Q, Tu M, Wang H H.An analytical model for heat and mass transfer processes in internally cooled or heated liquid desiccant–air contact units[J].International Journal of Heat and Mass Transfer, 2007, 50(17-18): 3545-3555.

[22]路则锋,陈沛霖.逆流填料式液体除湿系统传热传质过程的分析解法及应用[J].太阳能学报,2000,21(3):439-446.Lu Zefeng, Chen Peilin.Analytical solution of heat and mass transfer processes in packed: type counterflow liquid desiccant systems and its application.Acta Energiae Solaris Sinica [J].2000, 21(3): 439-446(in Chinese with English abstract)

[23]戴智超,殷勇高,张小松.波纹填料叉流除湿性能实验研究[J].建筑科学,2014,31(12):102-105.Dai Zhichao, Yin Yonggao, Zhang Xiaosong.Experimentalresearch on the performance of cross-flow dehumidification of corrugated packing[J].Building Science, 2014, 31(12): 102-105 (in Chinese with English abstract)

[24] Conde M R.Properties of aqueous solutions of lithium and calcium chlorides: formulations for use in air conditioning equipment design[J].International Journal of Thermal Sciences, 2004, 43(4): 367-382.

[25] Chung T W.Predictions of moisture removal efficiencies for packed-bed dehumidification systems [J].Gas Separation and Purification, 1994, 8(4): 265-268.

Dehumidification efficiency model for solar thermal regeneration system

Peng Donggen1, Zhang Xiaosong2

(1.School of Civil Engineering and Architecture, Nanchang University, Nanchang, 330031, China; 2.School of Energy and Environment, Southeast University, Nanjing, 210096, China)

Abstract:Solar liquid desiccant air-conditioning system has attracted many attentions because of low-energy consumption, and solar liquid regenerator is one of important units in that system.A novel solar liquid regenerator designed by the author is the solar air-pretreatment solution grading collector/regenerator.The proposed liquid regeneration system needs a packed bed dehumidifier, and the prediction of outlet parameters of air in that dehumidifier must be considered for the design of the novel solar liquid regeneration system.A structured packing dehumidifier was designed and the systemic experiments were made at Southeast University in Nanjing, China in 2009.The structured packing dehumidifier has the size of 0.5 m(width)×0.5 m(height)×0.3 m(length)with cross-flow mode.In order to increase flow rate of desiccant solution, instead of injecting directly strong solution into the interior of packed bed, a circulation solution pump was used for supplying solution for the dehumidifier.At the same time, a water-cooled heat exchanger was used to cool circulating solution in advance to control inlet temperature of solution.The experiments were performed under varying conditions including varying flow rates of air and solution and their inlet parameters.However, because of single structure of the experimental unit and limited variation range of experimental parameters, a method of numerical stimulation was used in this paper to study the effects of the inlet parameters of solution and air and the structure parameters of packing on the humidity effectiveness and the isenthalpic effectiveness.The previously experimental data were used to validate numerical model.For this purpose, several assumptions in physics were made, which were followed by the models of cross-flow dehumidification.The numerical simulation showed that as the concentration of LiCl solution increased from 0.29 to 0.34 kg/kg, the humidity effectiveness was increased by 2.6%~4.7% and the isenthalpic effectiveness was reduced by 20%~30%.As the inlet temperature of solution rose from 15 to 25℃, the humidity effectiveness went up, especially when the liquid-gas ratio was less than 1.0.As for isenthalpic effectiveness, the solution inlet temperature had large impact on it and when the inlet temperature of solution was less than that of air, the isenthalpic effectiveness was negative.As the air humidity ratio at the inlet dropped from 12.3 to 9.6 g/kg, the humidity effectiveness was increased by 2%~10% and the isenthalpic effectiveness was increased by about 0.3.The higher inlet temperature of airflow yields the lower humidity effectiveness, and when the liquid-gas ratio is low, the effect of air's inlet temperature on humidity effectiveness is high.The effect of air's inlet temperature on isenthalpic effectiveness is similar to solution's inlet temperature, which shows when the inlet temperature of air is higher than that of solution, the isenthalpic effectiveness is negative and otherwise it is positive.As the product of area per unit volume and length of air flow channel increased from 110 to 180, the humidity effectiveness was increased by about 0.1, however, the isenthalpic effectiveness was basically unchanged.Therefore, the humidity effectiveness increases with the increasing of the inlet temperature, the concentration of solution, the area per unit volume as well as the length of air flow channel, and decreases with the increase in humidity ratio and air temperature at the inlet.The isenthalpic effectiveness is affected dramatically by inlet temperatures of air and solution.Structure parameters of packing have little effect on the isenthalpic effectiveness.Moreover, with the increasing of the liquid-gas ratio, the humidity effectiveness increases and the isenthalpic effectiveness decreases.Finally, 2 equations about humidity effectiveness and isenthalpic effectiveness were obtained by applying a nonlinear regression to rearrange numerical simulation results, which provide the theoretical basis for the modeling of solar air-pretreatment solution grading collector/regenerator.

Keywords:models; solar; liquid desiccant dehumidification; humidity effectiveness; isenthalpic effectiveness; ratio of flowrate of solution to air

作者简介:彭冬根(1975-),男,博士,副教授,主要从事太阳能制冷空调研究,南昌南昌大学建筑工程学院,330031。Email: ncu_hvac2013@163.com

基金项目:国家自然科学基金项目(51266010);江西省科技支撑计划项目(20123BBG70195)

收稿日期:2015-08-07

修订日期:2015-11-16

中图分类号:TK511.3

文献标志码:A

文章编号:1002-6819(2016)-01-0206-06

doi:10.11975/j.issn.1002-6819.2016.01.029