Electrochemical synthesis of highly ordered Ni nanowire arrays through AAO templates

2015-12-22LIMeijingLIXiaoruSONGGuojunZHAOQingpei

LI Mei-jing LI Xiao-ru SONG Guo-jun ZHAO Qing-pei

(Institute of Polymer Materials,Qingdao University,No.308 Ningxia Road,Qingdao Shandong 266071,China)

0 Introduction

Carbon nanotubes were researched by a Japanese named IIJIMA in the 1990s.Since then all kinds of structure and shape of one-dimensional nanomaterials have received the widespread attention,such as nanowires,nanotubes and nanoparticles.As a result of Fe,Co,Ni,magnetic metal nanoarrays has attractive application prospect of the high -density perpendicular magnetic recording areas.So the scholars both at home and abroad have the great interest in the magnetic metal nanoarrays.At present,more and more techniques have been developed to synthesis metal nanoarray structure,and template-assisted synthesis is one of the most representative preparation technology.The porous anode Aluminum oxide(AAO) is used as the template to synthesis metal nanoarrays.The method has many advantages,such as high density,good verticality,high porosity,large length to diameter ratio and so on.In this paper,the highly ordered magnetic metal Ni nanowires were prepared.The Ni nanowires are hoped to provide the conditions for the field of magnetism.

1 Experimental

1.1 Preparation of the working electrode

The AAO templates used in the experiment are fabricated by Whatman Company.The diameter of the AAO template pore is about 200 nm,and the depth of template is about 60μm.First of all,AAO template was put into the ethanol for ultrasonic treatment for 3s.The AAO template was fixed on a glass slide.Then the side of the AAO template was sprayed a layer of gold on in the ion sputtering apparatus as working electrode.

1.2 Preparation of nanowires

Ni nanowires were synthesized by CHI730E electrochemical workstation.The reference electrode was used as saturated calomel electrode.A platinum film was used as opposing auxiliary electrode.The working electrode was AAO template with gold layer.Ni nanowires were produced in the template pores from a solution of a certain concentration for 20 min at room temperature.

1.3 Morphology Characterization

Scanning electron microscopy(SEM;JEOL JSM-6390LV),transmission electron microscopy(TEM;CM200-FEG equipped with a GIF)were used to characterize the morphology and microstructure of Ni nanowires.X-ray diffraction(XRD)wasusedtocharacterizethecrystallizationofNinanowires.

2 Results and discussion

2.1 The morphology of Ni nanowire arrays

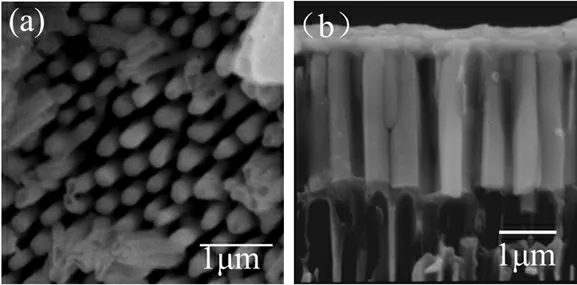

Deposition was carried out at the room temperature with an AC voltage of -2.5V for 20 minutes and the concentration of Ni2+was 0.6mol/L.Figure 1(a),(b) is SEM images of Ni nanowires.From the figure 1(a),it can be clearly seen that Ni nanowire arrays have closed end and a large area of Ni nanowire arrays structure can be prepared by the AC sedimentary system.Then Ni nanowire arrays have the neat rows,with the highly consisten arrays.It can be seen from Figure 1(b),the length of the Ni nanowire is about 2 μm.It also can be seen the nanowire structure.

Fig.1 SEM images of Ni nanowire(a) Top view SEM;(b) Side view SEM

2.2 The microstructure of Ni nanowire arrays

Figure 2 is the TEM image of the Ni nanowires.More independent nanowires we can be seen from the picture.Nanowire structure is obvious and has the perfect solid structure.The diameter of the Ni nanowire is uniform,about 300nm,It also can be seen that the length of the nanowires is about 2μm.The nanowires has certain mechanical properties.This is because the nanomaterials have large specific surface area.Surface atomic arrangement is confusion.So the surface atom of nanowire moves easily under the condition of external force,and the metal nanostructure materials exhibit excellent mechanical properties.

Fig.2 TEM images of Ni nanowire

2.3 The crystal structure of Ni nanowire arrays

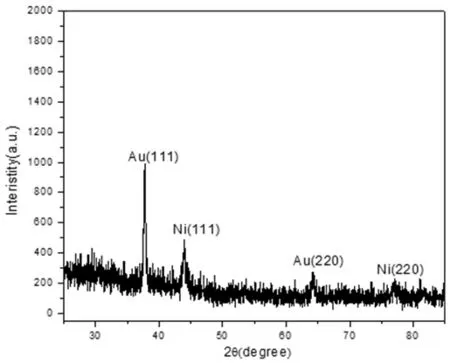

Fig.3 XRD spectrum of Ni nanowire array

XRD was used to test the crystal structure of Ni nanowire arrays.Figure 3 is the XRD spectrum of Ni nanowire arrays which were prepared with the direct current deposition method.From the figure 3,four obvious diffraction peak are detected,and their corresponding values respectively are 37.74,44.08,64.28,76.96.Referencing standard XRD spectra obtained that those diffraction peaks are respectively for Au and Ni diffraction peak,and their diffraction index were noted down on the drawing.It shows that Ni nanowire is facecentered cubic structure.In addition,diagram 3 shows:Ni nanowires have certain preferred orientation in growth Process.

3 Conclusion

Ni nanowires arrays were successfully fabricated in AAO template by the method of electrochemical deposition,and the diameter of nanowires is consistent with that of the template.And the Ni nanowire arrays have neat rows.The length of Ni nanowires is about 2 μm,and the diameter of Ni nanowire is about 300 nm.In addition,the experiment also showed that the crystallization of the nanowire is face-centered cubic,and they have certain mechanical properties.

[1]LIJIMA S.Helical microtubules of graphitic carbon[J].Nature,1991,354(6348):56-58.

[2]HU J T,ODOM T W,LIEBER C M.Chemistry and physics in one dimension:Synthesis and properties of nanowires and nanotubes[J].Acc Chem Res,1999,32:435-445.

[3]PAN Z W,DAI Z R,WANG Z L.Nanobelts of semiconducting oxides[J].Science,2001,291:1947-1949.

[4]LIANG H W,LIU S,YU S H.Controlled synthesis of one-dimensional inorganic nanostructures using pre-existing one-dimensional nanostructures as templates [J].Advanced Materials,2010,22:3925-3937.

[5]KHAN H R,PETRIKOWSKI K.Synthesis and properties of the arrays of magnetic nanowires of Co and Fe[J].Mater Sci Eng,2002,19(1/2):345-348.

[6]QIN D H,LU M,LI H L.Magnetic force microscopy of magnetic domain structure in highly ordered Co nanowire arrays[J].Chem Phys Lett,2001,350(1/2):51-56

[7]NAPOLSKII K S,ELISEEV A A,YESIN N V.Ordered arrays of Ni magnetic nanowires:synthesis and investigation[J].Physica E,2007,37(1/2):178-183